Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

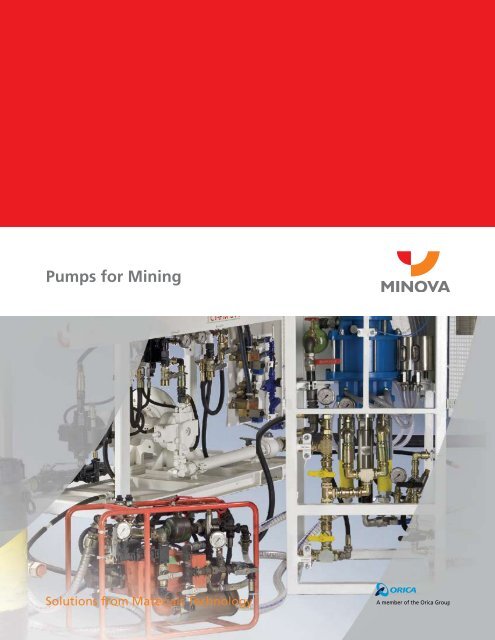

<strong>Pumps</strong> <strong>for</strong> <strong>Mining</strong><br />

Solutions from Materials Technology

Overview of <strong>Mining</strong> <strong>Pumps</strong><br />

Efficient and, above all, reliable pump technology is indispensable, in addition<br />

to the tried and trusted injection systems from <strong>Minova</strong>. The company has both<br />

pneumatically- and electrically-driven pumps <strong>for</strong> mining, constructed in the most up-to-date<br />

way, in its program.<br />

Efficiency, a long serviceable life of the components and good handling were in the<br />

<strong>for</strong>eground during the development of the pumps. Mature technology, specially modified<br />

<strong>for</strong> the processing of <strong>Minova</strong> injection media, has been used.<br />

The range stretches from simple dual operating reciprocating pumps to radial piston and<br />

piston membrane technology.<br />

All pumps comply with the European Code (Atex, CE) <strong>for</strong> the use of machines in areas<br />

endangered by explosion. All pumps are particularly maintenance-friendly because of easily<br />

replaceable wearing parts.

CT-PM Remote Dredging Pump<br />

Benefits of the CT-PM<br />

Rock-conserving<br />

injection<br />

Remote data<br />

transmission<br />

Long conveyer<br />

distances<br />

High measuring<br />

precision<br />

Large collector tanks<br />

The CT-PM is a modular remote dredging pump, consisting of a pump unit and separate<br />

collecting tanks. Collecting tanks with a useful volume from approximately 500 to 2,000 liters<br />

per container are available as standard. The connection to large packing drums, such as<br />

returnable tanks from <strong>Minova</strong>, always ensures an adequate container.<br />

Electrically-driven radial piston pumps ensure an almost constant conveyer stream across<br />

the whole pressure range. The continuously adjustable volume stream, the limitation of the<br />

conveyer pressure and the pulsation-free conveyer stream ensure an injection conserving<br />

the rock at all times. Polyurethane and silicate resin can there<strong>for</strong>e be conveyed manless and<br />

in an operationally safe way across distances up to 5,000 m (pipeline operation). Setting<br />

up at a distance from the injection pump will guarantee high operational safety and the<br />

optimized logistics <strong>for</strong> using the <strong>Minova</strong> returnable container system.<br />

The CT-PM can be equipped with measuring equipment <strong>for</strong> checking the filled status of the<br />

collector tanks and remote data transmission as required.

DP 40 Injection Pump<br />

The DP 0 injection pump is a pneumatically-driven, simple-to-operate reciprocating pump<br />

that operates in accordance with the principle of pressure transmission. The surface ratio of<br />

drive pistons to pressure pistons give the operating transmission ratio, which is 0:1 in the<br />

case of this injection pump.<br />

The pump consists of the pneumatically-operated drive component and the high pressure<br />

component. The drive component and the high pressure component are connected by a<br />

piston rod. The two parallel lying high pressure pistons (plungers) are located, connected by<br />

means of a yoke, at the end of this piston rod. It is not possible that conveyer medium can<br />

reach the air drive components in the case of leaks at the injection pump, because of the<br />

separation of drive and high pressure components by mechanical technology.<br />

The plungers are made of stainless steel and are characterized by a long serviceable life.<br />

The high pressure seals have been specially adjusted to the conveyer media of <strong>Minova</strong>.<br />

Benefits of the DP 40<br />

Conveyer distances up<br />

to 500 m<br />

High measuring<br />

precision<br />

High reliability<br />

5

PHP Injection Pump<br />

Benefits of the PHP<br />

High conveyer<br />

per<strong>for</strong>mance<br />

High measuring<br />

precision<br />

High reliability<br />

Good handling<br />

The PHP phenolic resin pump is a pneumatically driven, dual operating reciprocating pump<br />

that works in accordance with the principle of pressure transmission. The 2:1 area ratio of the<br />

drive piston to the pressure piston gives the operating transmission ratio.<br />

The pump consists of the pneumatically-operated drive component and the high pressure<br />

component, consisting of three cylinders.<br />

The drive and the high pressure components are connected with piston rods. The three A and<br />

B cylinders arranged under the air motor are located at the end of the piston rod.<br />

The pressure pistons are manufactured from stainless steel (the B piston has an additional<br />

special coating) and are characterized by a long serviceable life. The high pressure seals have<br />

been specially adjusted to the phenolic resins of <strong>Minova</strong>.<br />

Collection tanks containing approx. 75 l provide clean charging, where the A side is<br />

additionally equipped with a static mechanism.

SK 90 1:1 and 4:1 Injection Pump<br />

The SK 90 is a pneumatically-driven gear pump. The modular structure allows the<br />

installation of gear pump stages <strong>for</strong> the processing of polyurethane, silicate and phenolic<br />

resin. The volumetric conveyer ratio can be changed from 1:1 to :1 with little ef<strong>for</strong>t.<br />

Plastic collection tanks provide clean charging. The collection tank of the A components is<br />

additionally equipped with a static mechanism <strong>for</strong> use with phenolic resin. The injection<br />

substance is sucked out of the collection tanks (scope of the delivery) and pumped through<br />

tube or piping to the place of use by the gear pumps.<br />

The SK 90 is controlled by a pneumatic pressure switch and integrated pressure control<br />

valves. The pressure switch enables the pump to be operated remotely, where the pump<br />

switches off when the set pressure <strong>for</strong> switching off has been reached, and switches the<br />

pump on again when the pressure <strong>for</strong> switching on has been reached, during the fall of the<br />

pressure in the conveyer conduit. Surplus injection substance is taken back to the collection<br />

tank by a pressure control valve if the maximum permissible pressure is exceeded.<br />

Benefits of the SK 90<br />

Good handling<br />

High conveyer<br />

per<strong>for</strong>mance<br />

Low weight<br />

Can be used in varied<br />

ways<br />

Operated remotely<br />

7

WF 100 Potassium Silicate Conveyer Pump<br />

Benefits of the WF 100<br />

Long serviceable life<br />

Pulsation-free<br />

conveyer stream<br />

Compact construction<br />

Can be operated<br />

remotely<br />

High volume stream<br />

The WF 100 potassium silicate conveyer pump is an electrically-driven pump <strong>for</strong> conveying<br />

accelerating admixtures.<br />

The piston membrane pump is the core of the WF 100. The piston membrane technology<br />

has proved its worth <strong>for</strong> conveying media containing solid matter, as a combination of the<br />

piston and the membrane pump.<br />

The lifting sequence of the pistons in an offset arrangement is managed by the<br />

swash plate in such a way that an almost pulsation-free conveyer stream of up to<br />

2 l/min is possible.<br />

The necessary monitoring and operating elements run together in a central control block.<br />

All components are clearly arranged in a square tubular frame suitable <strong>for</strong> mining.

Technical data of the pump unit<br />

CT-PM DP 0 PHP<br />

Dimensions (L x W x H mm) 1 950 x 7 0 x 955 9 0 x 70 x 90 20 x 20 x 1 0<br />

Weight (kg) 510 120 1 5<br />

Max. Operating Pressure (bar) 2 0 250 250<br />

Compressed-Air Supply -- - max.<br />

Max. Flow Rate 2 x 2 l/min. 0,2 l / Hub / stroke 0,1 l / Hub / stroke<br />

Max. Delivery Distance (m) < 5000 < 500 < 00<br />

Power Unit<br />

Technical data of the container<br />

Dimensions (L x W x H mm)<br />

Net Weight (kg)<br />

E-Motor B /B5,<br />

500 o. 1 000 Volt,<br />

7,5 – 11 kW,<br />

1 500 min-1 *<br />

1 950 x 7 0 x 955 ( 00 l)<br />

120 x 7 0 x 9 0<br />

(2 000 l)<br />

550 ( 00 l)<br />

50 (2 000 l)<br />

pneumatisch<br />

pneumatical<br />

pneumatisch<br />

pneumatical<br />

-- Ø 20 x H 700<br />

--<br />

12 (A mit Rührwerk /<br />

with agitator)<br />

,7 (B)<br />

* The electronic motor is not included in delivery, as all of the electronic installation is provided and operated by the<br />

operating company.<br />

9

10<br />

Technical data of the pump unit<br />

SK 90 1:1 SK 90 :1 WF 100<br />

Dimensions (L x W x H mm) 720 x 720 x 500 720 x 720 x 500 1 1 0 x 00 x 0<br />

Weight (kg) 100 100<br />

Max. Operating Pressure (bar) 120 120 5<br />

Compressed-Air Supply 5 5 --<br />

Max. Flow Rate (l/min.) 0 0 ca. 2<br />

Max. Delivery Distance (m)<br />

Power Unit<br />

Technical data of the container<br />

abhängig von<br />

Volumenstrom u.<br />

Leitung<br />

depends on flow rate<br />

and pipe length<br />

Luftmotor/air motor<br />

LS 10,<br />

,0 KW,<br />

max. 1 000 U/min<br />

abhängig von<br />

Volumenstrom u.<br />

Leitung<br />

depends on flow rate<br />

and pipe length<br />

Luftmotor/air motor<br />

LS 10,<br />

,0 KW,<br />

max. 1 000 U/min<br />

Dimensions (L x W x H mm) Ø 20 x H 700 Ø 20 x H 700 --<br />

Net Weight (kg)<br />

je ,7 kg<br />

,7 kg each<br />

12 (A mit Rührwerk/<br />

with agitator)<br />

,7 (B)<br />

ca. 150 kg ohne E-Motor/<br />

without motor<br />

abhängig von<br />

Volumenstrom u.<br />

Leitung<br />

depends on flow rate<br />

and pipe length<br />

E-Motor B ,<br />

,0 - ,0 KW<br />

1 000 o. 500 Volt,<br />

max. 1 500 min-1 *<br />

* The electronic motor is not included in delivery, as all of the electronic installation is provided and operated by the<br />

operating company.<br />

--

<strong>Minova</strong> USA Inc.<br />

150 Carley Court<br />

Georgetown KY 0 2 USA<br />

Phone 502 00<br />

Fax 502 1 7<br />

Email sales.info@minovaint.com<br />

Website www.minovausa.com<br />

Important Note: Warranty<br />

<strong>Minova</strong> USA Inc. warrants that its products, at the time of shipment, con<strong>for</strong>m to the applicable descriptions set <strong>for</strong>th in the invoice and are free from defects<br />

in material and workmanship. NO OTHER WARRANTY, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABI-<br />

LITY, OR FITNESS FOR A PARTICULAR PURPOSE, SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF ANY MINOVA USA INC. PRODUCT, AND ALL SUCH<br />

WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED AND EXCLUDED.<br />

All claims under this warranty must be made in writing to <strong>Minova</strong> USA Inc. within 15 days after discovery of the defect, and within 90 days of the date of<br />

shipment by <strong>Minova</strong> USA Inc. of the product claimed defective. Upon timely receipt of a claim, <strong>Minova</strong> USA Inc. shall have the option either to inspect the<br />

product while in Buyer’s possession or to request Buyer to return the product to <strong>Minova</strong> USA Inc. <strong>for</strong> inspection. Claims not made as provided above and<br />

within the applicable time period will be barred. All warranties shall be null and void if the products have not been stored and used in accordance with<br />

procedures recommended by <strong>Minova</strong> USA Inc.<br />

<strong>Minova</strong> USA Inc. shall, at its option, either replace the noncon<strong>for</strong>ming or defective product or refund to Buyer its purchase price. The <strong>for</strong>egoing constitutes<br />

Buyer’s sole and exclusive remedy <strong>for</strong> any breach or warranty.