Decoform® technology Back Injection and Compression Moulding

Decoform® technology Back Injection and Compression Moulding

Decoform® technology Back Injection and Compression Moulding

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

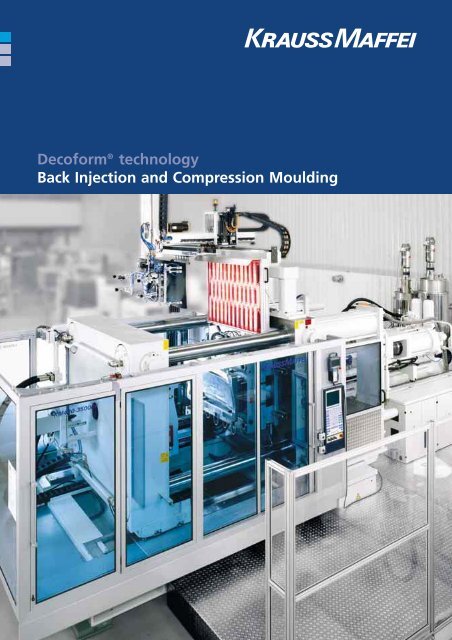

Decoform ® <strong>technology</strong><br />

<strong>Back</strong> <strong>Injection</strong> <strong>and</strong> <strong>Compression</strong> <strong>Moulding</strong>

Compact Decoform ® manufacturing cell with<br />

KM 420-3500 DF for boot trim panels

04<br />

06<br />

08<br />

10<br />

Decoform ®<br />

<strong>Back</strong> injection <strong>and</strong> compression moulding<br />

Machine features for Decoform ® <strong>technology</strong><br />

Systematically engineered for premium quality<br />

The pace of change <strong>and</strong> innovation<br />

in the automotive sector is speeding<br />

up, with the development time for<br />

new models shortening year by<br />

year. At the same time, fittings <strong>and</strong><br />

comfort features are becoming a<br />

powerful factor in model <strong>and</strong><br />

marque differentiation. This means<br />

that the design <strong>and</strong> quality of car<br />

interiors play an important role in<br />

many purchase decisions. Decoform ®<br />

<strong>technology</strong> offers processors an<br />

attractive method for producing<br />

ready-decorated parts on injection<br />

moulding machines. Precision,<br />

repeatability <strong>and</strong> cost-effectiveness<br />

are part of the package deal.<br />

3

Innovative production <strong>technology</strong> for<br />

top quality decor elements: Decoform ®<br />

A pillar trim, DaimlerChrysler B pillar trim, DaimlerChrysler<br />

NCV2 door trim, DaimlerChrysler<br />

Operating in a highly competitive market,<br />

automotive companies strive to achieve<br />

maximum differentiation under intense<br />

cost pressure. This situation challenges<br />

components suppliers to find innovative,<br />

cost-cutting production methods for<br />

high-quality moulded parts. It drives the<br />

rapid advances in production technologies<br />

for each new generation of cars. The<br />

automotive industry leads the way, but<br />

other sectors are quick to follow. The<br />

same techniques deliver quality <strong>and</strong> cost<br />

advantages in aircraft <strong>and</strong> train interiors<br />

<strong>and</strong> seating, <strong>and</strong> for the furniture industry.<br />

With Krauss-Maffei’s Decoform ® systems,<br />

the proven quality of our engineering <strong>and</strong><br />

our underst<strong>and</strong>ing of these applications<br />

make a big difference. Our high-performance<br />

machines can deliver high quality<br />

<strong>and</strong> low unit cost. Modular <strong>and</strong> upgradeable,<br />

they are also ready for the future.<br />

4<br />

Decoform ® – <strong>technology</strong> with quality<br />

<strong>and</strong> cost benefits<br />

■ Flexibility<br />

■ High process integration cuts the<br />

number of process steps<br />

■ High productivity, small footprint<br />

■ Integration of functional elements<br />

■ Environmentally-friendly<br />

(no solvents or adhesives)<br />

■ Recycling-friendly products (all PP)<br />

■ High repeatability, stable process<br />

■ Good for the bottom line (15-30%<br />

lower costs than conventional<br />

laminating processes)<br />

Manufacturing cell for door trim<br />

with KM 250-1900 DF

C/D pillar trim, Volvo S80<br />

KM 420-2700 DF manufacturing cell<br />

for pillar trim (Collins & Aikman)<br />

5

Decoform ®<br />

<strong>Back</strong> injection <strong>and</strong> back compression moulding – the differences<br />

C pillar, VW Golf<br />

Decoform ® back injection moulding<br />

Decoform ® back injection is recommended<br />

especially for narrow, elongated parts,<br />

like pillar or door trim. A film or fabric<br />

insert is placed in the mould. The mould<br />

is closed <strong>and</strong> the polymer injected onto<br />

the insert using cascade <strong>technology</strong>.<br />

The flow front shifts from one cascade<br />

to the next as cascade blocks are rapidly<br />

opened <strong>and</strong> shut under the control of<br />

the MC5 software. Each needle shut-off<br />

nozzle is independently controlled.<br />

Precisely regulating their activation<br />

6<br />

Door trim panel, Peugeot 307 Door trim panel, VW Golf<br />

eliminates the problem of folds forming<br />

in the décor material. Pressure <strong>and</strong> temperature<br />

damage to sensitive material<br />

can be minimized by the right number<br />

of cascades. With the Decoform ® module,<br />

clamp-force build-up during injection can<br />

be gradual, following a preset profile<br />

which allows the mould to breathe<br />

(depends on mould design). After the<br />

holding pressure phase, the clamp force<br />

can also be released in stages. This<br />

eliminates the risk of cavity pressure<br />

damaging the décor insert.

Chrysler Crossfire instrument panel,<br />

DaimlerChrysler<br />

Decoform ® back compression<br />

moulding<br />

<strong>Back</strong> compression moulding is especially<br />

suitable for very large area parts with<br />

pressure- <strong>and</strong> temperature-sensitive<br />

décor material. Typical products are door<br />

trim panels, instrument panel elements,<br />

seatback shells, boot trim sections <strong>and</strong><br />

floormats. To keep cavity pressure as low<br />

as possible, the clamp moves during the<br />

injection phase.<br />

NCV2 door trim panel, DaimlerChrysler<br />

Field trials have shown that compression<br />

gaps as big as 60 mm are sometimes<br />

necessary. Gap width is closely related<br />

to the type of décor, the thermoplastic<br />

substrate <strong>and</strong> the gating pattern. Conventional<br />

injection compression moulding<br />

cannot fill the mould with repeatable<br />

precision, because, under the influence<br />

of gravity, the melt flows downwards<br />

as it is injected. To achieve a repeatable<br />

filling profile, Krauss-Maffei developed<br />

a special compression process.<br />

Door trim panel, Seat Ibiza<br />

Complex design of a boot trim panel for<br />

a new car generation<br />

7

Manufacturing cell for door trim with KM 350-1900 DF,<br />

Johnson Controls<br />

8<br />

Décor preheating unit integrated in the<br />

robotic systems

Decoform ® machine features<br />

Decoform ® clamp unit<br />

Cavity pressures in the Decoform ® process<br />

are far lower than in normal injection<br />

moulding. This makes it possible to<br />

produce large parts with relatively low<br />

clamp force. Typical of the applicationspecific<br />

Decoform ® clamps are the<br />

extremely large platens <strong>and</strong> generous<br />

opening widths.<br />

The fully hydraulic clamp unit allows<br />

pressure build-up in all four cylinders to<br />

be precisely synchronized. This guarantees<br />

that the moving platen is always exactly<br />

parallel to the fixed platen. Pressure<br />

<strong>and</strong> speed profiles can be programmed<br />

with a high degree of precision <strong>and</strong><br />

synchronized with the injection phase.<br />

Design <strong>and</strong> operation of the 2-platen clamp Decoform ® machines are engineered to<br />

take larger moulds than st<strong>and</strong>ard injection<br />

moulding machines<br />

Fully hydraulic clamp guarantees<br />

premium quality<br />

The ideal machine for back injection<br />

<strong>and</strong> back compression moulding has a<br />

completely hydraulic clamp unit. This is<br />

the only system capable of guaranteeing<br />

precisely repeatable processes through<br />

very tight control of position <strong>and</strong> pressure<br />

throughout the mould closing <strong>and</strong> compression<br />

sequences.<br />

Decoform ® <strong>technology</strong> for st<strong>and</strong>ard<br />

KM machines<br />

Krauss-Maffei’s Decoform ® module is the<br />

ideal hardware upgrade for st<strong>and</strong>ard C<br />

<strong>and</strong> MX Series machines. It’s an option<br />

that gives you more flexibility <strong>and</strong> better<br />

capacity utilization for a better return on<br />

your investment.<br />

One keystroke calls up the Decoform ®<br />

software module for full access to all<br />

functions.<br />

Optional add-ons for st<strong>and</strong>ard<br />

injection moulding machines<br />

■ Decoform ® module for all KM<br />

injection moulding machines<br />

■ Decoform ® clamp frame module<br />

■ Decoform ® gripper control<br />

9

Systematically engineered for uncompromising quality<br />

Floormats, Volvo<br />

Displaying selected process parameters<br />

KM 650-5700 DF for pillar trim, Montaplast<br />

10<br />

Door trim panel, Volvo V40<br />

Decoform ® module – a dedicated<br />

system for perfect results<br />

The superior <strong>technology</strong> of the Decoform ®<br />

system sets quality benchmarks. The<br />

most important features:<br />

■ High-precision mould positioning<br />

during closing, compression <strong>and</strong><br />

opening<br />

■ Independent setting of compression<br />

profile<br />

■ Freely selectable compression force<br />

■ Multi-stage profiles for clamp force<br />

<strong>and</strong> closing, compression <strong>and</strong> opening<br />

movements<br />

■ Freely selectable clamp force build-up<br />

<strong>and</strong> clamp speed profiles in synchrony<br />

with injection phase<br />

■ Graphical display shows all main<br />

processing parameters with tolerance<br />

range monitoring, for example:<br />

– compression force<br />

– screw stroke<br />

– mould breathing<br />

– cavity pressure<br />

Seat component, Jaguar<br />

More design flexibility with the<br />

Decoform ® clamp frame module<br />

A hydraulically controlled clamp frame is<br />

precisely positioned in the mould. It holds<br />

the décor in position as the mould closes<br />

preventing slippage <strong>and</strong> folds forming.<br />

In combination with the Decoform ®<br />

module, the clamp frame module opens<br />

the way to very wide freedom <strong>and</strong><br />

flexibility in part design.<br />

More quality for your money<br />

Decoform ® delivers outst<strong>and</strong>ing quality<br />

at a competitive cost with:<br />

■ In-mould shaping of decor material<br />

■ High repeatability<br />

■ Successful with sensitive décor<br />

materials (TPO/PP foambacked film<br />

<strong>and</strong> carpets)<br />

■ Simplified logistics<br />

■ High productivity <strong>and</strong> a small footprint

Simultaneous insertion of decor material (left) <strong>and</strong> removal of a finished part<br />

Manufacturing cell for pillar trim with<br />

KM 350-1900 DF, Johnson Controls<br />

Transfer to laser trimming unit<br />

Laser edge trimming for pillar elements<br />

11

Creative people around the world work for Krauss-Maffei.<br />

And for you.<br />

Krauss-Maffei Kunststofftechnik GmbH · Krauss-Maffei-Strasse 2 · D-80997 Munich · Germany<br />

Phone +49/89/88 99-0 · Fax +49/89/88 99-22 06 · www.krauss-maffei.com<br />

Krauss-Maffei<br />

Kunststofftechnik<br />

Vertrieb und Service<br />

Nord-Deutschl<strong>and</strong> GmbH<br />

Oesternweg 12<br />

D-33415 Verl<br />

Germany<br />

Phone +49/52 46/70 0010<br />

Fax +49/52 46/70 00 70<br />

Krauss-Maffei<br />

Kunststofftechnik (Benelux)<br />

Minervum 74 08<br />

NL-4817 ZG Breda<br />

Netherl<strong>and</strong>s<br />

Phone +31/765 72 25 22<br />

Fax +31/765 8756 86<br />

Krauss-Maffei<br />

Asia Pacific Pte. Ltd.<br />

23 Tagore Lane, 04-15<br />

Singapore 787601<br />

Phone +65/65/53-58 28<br />

Fax +65/64/55-0419<br />

Krauss-Maffei<br />

Kunststofftechnik<br />

Vertrieb und Service<br />

Süd-Westdeutschl<strong>and</strong> GmbH<br />

Weilheimer Strasse 34<br />

D-73119 Zell<br />

Germany<br />

Phone +49/71 64/94 41-900<br />

Fax +49/71 64/94 41-999<br />

Krauss-Maffei<br />

Italiana S.r.l.<br />

Via Giovanni XXIII, 77/b<br />

I-25086 Rezzato (BS)<br />

Italy<br />

Phone +39/030/259-07 07<br />

Fax +39/030/259-23 69<br />

Krauss-Maffei Plastics Machinery<br />

(Shanghai) Co. Ltd.<br />

Grd. Fl., Part D1, No. 44 Bldg.<br />

D12 Plot, No. 207 Tai Gu Rd.<br />

Wai Gao Qiao, Pudong New Area<br />

Shanghai 200131, P. R. China<br />

Phone +86/21-58 68 04 60<br />

Fax +86/21-58 6804 63<br />

Krauss-Maffei<br />

Kunststofftechnik<br />

Vertrieb und Service<br />

Süd-Ostdeutschl<strong>and</strong> GmbH<br />

Krauss-Maffei-Strasse 2<br />

D-80997 Munich<br />

Germany<br />

Phone +49/89/88 99-25 38<br />

Fax +49/89/88 99-40 98<br />

Krauss-Maffei U.K. Ltd.<br />

Europa Boulevard<br />

Gemini Business Park<br />

GB-Warrington WA5 7TR<br />

United Kingdom<br />

Phone +44/1/9 25/64 41 00<br />

Fax +44/1/9 25/23 42 84<br />

Krauss-Maffei Corporation<br />

7095 Industrial Road<br />

P.O. Box 6270<br />

Florence, KY 41042-6270<br />

USA<br />

Phone +1/859/28 30-200<br />

Fax +1/859/28 30-2910<br />

Krauss-Maffei Kunststofftechnik<br />

(Schweiz) AG<br />

Grundstrasse 3<br />

CH-6343 Rotkreuz<br />

Switzerl<strong>and</strong><br />

Phone +41/41/799 71-80<br />

Fax +41/41/799 71-81<br />

Krauss-Maffei<br />

Plastics Machinery Sweden<br />

Herkulesvägen 4<br />

S-55303 Jönköping<br />

Sweden<br />

Phone +46/36/3418-30<br />

Fax +46/36 /3418-39<br />

Krauss-Maffei Corporation<br />

Av. Jorge Jiménez Cantú 11-8<br />

Col. Rancho Viejo<br />

Atizapán de Zaragoza, 52937<br />

Mexico<br />

Phone +52/55/53 08-23 83<br />

Fax +52/55/53 08-17 27<br />

Krauss-Maffei<br />

Kunststofftechnik<br />

Austria Ges.m.b.H.<br />

Ricoweg 30 B1<br />

A-2351 Wiener Neudorf<br />

Austria<br />

Phone +43/22 36/628 88-0<br />

Fax +43/22 36/628 88-77<br />

Krauss-Maffei<br />

Kunststofftechnik GmbH<br />

Filial Finl<strong>and</strong>, Tietäjäntie 10<br />

FIN-02130 Espoo<br />

Finl<strong>and</strong><br />

Phone +358/9/412-32 66<br />

Fax +358/9/412-21 97<br />

<strong>Injection</strong> <strong>Moulding</strong> Technology<br />

Reaction Process Machinery<br />

Extrusion Technology<br />

Krauss-Maffei<br />

France SAS<br />

5, Allée des Barbanniers<br />

F-92632 Gennevilliers Cedex<br />

France<br />

Phone +33/1/46 85 25-25<br />

Fax +33/1/46 85 25-49<br />

Krauss-Maffei<br />

do Brasil Ltda.<br />

Rua Canto e Melo, 210<br />

04756-100 São Paulo-SP<br />

Brazil<br />

Phone +55/11/56 41-22 73<br />

Fax +55/11/56 41-93 37<br />

1.0 We · 1st edition 10/04 · Printed in Germany · Printed on 100% chlorine-free bleached paper · SGM 032 A PRO 10/2004 GB