Clean Everyday CLEAN Show Edition

Spindle connects and integrates data from all of your existing equipment and previously untracked metrics of your labor force. By collecting this data, analyzing it and providing a single and simple stream of actionable information, we save your organization precious time in achieving its performance goals.

Spindle connects and integrates data from all of your existing equipment and previously untracked metrics of your labor force. By collecting this data, analyzing it and providing a single and simple stream of actionable information, we save your organization precious time in achieving its performance goals.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Improve Dryer Safety<br />

Wash floor dashboards are an integral part of commercial<br />

laundries. This visual feedback display has proven effectiveness<br />

in improving productivity from the washers.<br />

But what about the dryers,<br />

an equally critical role in the process?<br />

Dryers are often one of the highest consumers of natural gas,<br />

bottleneck flow from wash floor to finishing and are often to<br />

blame for fires.<br />

and Efficiency<br />

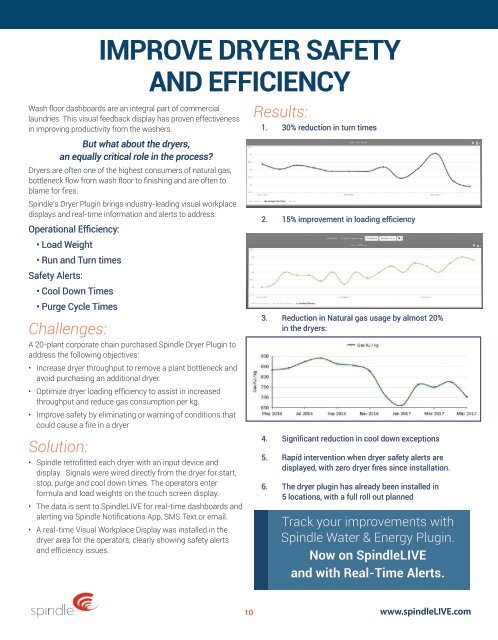

Results:<br />

1. 30% reduction in turn times<br />

Spindle’s Dryer Plugin brings industry-leading visual workplace<br />

displays and real-time information and alerts to address:<br />

Operational Efficiency:<br />

• Load Weight<br />

• Run and Turn times<br />

Safety Alerts:<br />

• Cool Down Times<br />

• Purge Cycle Times<br />

Challenges:<br />

A 20-plant corporate chain purchased Spindle Dryer Plugin to<br />

address the following objectives:<br />

• Increase dryer throughput to remove a plant bottleneck and<br />

avoid purchasing an additional dryer.<br />

• Optimize dryer loading efficiency to assist in increased<br />

throughput and reduce gas consumption per kg.<br />

• Improve safety by eliminating or warning of conditions that<br />

could cause a fire in a dryer<br />

Solution:<br />

• Spindle retrofitted each dryer with an input device and<br />

display. Signals were wired directly from the dryer for start,<br />

stop, purge and cool down times. The operators enter<br />

formula and load weights on the touch screen display.<br />

• The data is sent to SpindleLIVE for real-time dashboards and<br />

alerting via Spindle Notifications App, SMS Text or email.<br />

• A real-time Visual Workplace Display was installed in the<br />

dryer area for the operators, clearly showing safety alerts<br />

and efficiency issues.<br />

2. 15% improvement in loading efficiency<br />

3. Reduction in Natural gas usage by almost 20%<br />

in the dryers:<br />

4. Significant reduction in cool down exceptions<br />

5. Rapid intervention when dryer safety alerts are<br />

displayed, with zero dryer fires since installation.<br />

6. The dryer plugin has already been installed in<br />

5 locations, with a full roll out planned<br />

Track your improvements with<br />

Spindle Water & Energy Plugin.<br />

Now on SpindleLIVE<br />

and with Real-Time Alerts.<br />

10 www.spindleLIVE.com