DGLR-MTR-2000.PDF

DGLR-MTR-2000.PDF

DGLR-MTR-2000.PDF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

It demonstrated particularly good tolerance to FOD<br />

during the development and qualification tests (sand,<br />

ice, water, …).<br />

Both stages can be easily inspected with boroscopes<br />

in order to monitor the mechanical<br />

condition.<br />

6.2 Combustor<br />

A reverse-flow annular combustor was chosen for its<br />

advantages regarding the whole engine architecture.<br />

Best adapted to the centrifugal compressor design, it<br />

minimises engine length, provides good accessibility<br />

to fuel nozzles and allows a short and rigid generator<br />

rotor.<br />

The combustor [1] can be shortened only provided<br />

rapid fuel conversion is achieved in its primary combustion<br />

zone. Primary zone conversion is controlled<br />

by the fuel mixing and vaporisation subprocesses.<br />

These processes can be precipitated by achieving a<br />

preferably small size of fuel droplet, a high relative<br />

velocity between the drops and the gas, a preferably<br />

homogeneous fuel distribution in the primary zone,<br />

and a high turbulence level conducive to efficient mixing.<br />

Therefore, the fuel conditioning system proved to<br />

be a key criterion.<br />

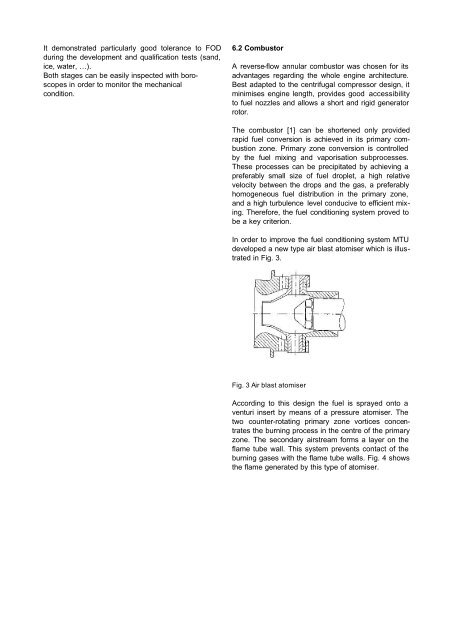

In order to improve the fuel conditioning system MTU<br />

developed a new type air blast atomiser which is illustrated<br />

in Fig. 3.<br />

Fig. 3 Air blast atomiser<br />

According to this design the fuel is sprayed onto a<br />

venturi insert by means of a pressure atomiser. The<br />

two counter-rotating primary zone vortices concentrates<br />

the burning process in the centre of the primary<br />

zone. The secondary airstream forms a layer on the<br />

flame tube wall. This system prevents contact of the<br />

burning gases with the flame tube walls. Fig. 4 shows<br />

the flame generated by this type of atomiser.