You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MMC<br />

Product News<br />

Armstrong takes installers to new<br />

heights<br />

A new, highly engineered<br />

suspension system that is<br />

up to 20% quicker to install<br />

has been launched by<br />

Armstrong Ceiling<br />

Solutions. The new TLS<br />

metal hook cross tees<br />

manufactured from solid<br />

steel and engineered with<br />

total precision now delivers<br />

the three Ss - Simplicity, Stability and Solidity.<br />

The superior functionality of TLS is characterised by three key<br />

elements. It is simple and safe to install due to a secure hook design.<br />

It aligns and sets into position with an audible click, guaranteeing<br />

ceiling stability and self-squaring, and it features a solid clip<br />

manufactured from pre-shaped steel, for stronger and more secure<br />

connections that lock into place.<br />

For specifiers, it also lies flush to the main runner, providing a<br />

streamlined aesthetic to the fully finished ceiling, while for<br />

installers, pre-shaped embossments on the clip increase rigidity and<br />

also control rotation.<br />

In addition, the new Prelude 24mm TLS cross tees enable Armstrong<br />

to deliver a fire resistant and fully Cradle To Cradle® certified<br />

system when installed with Cradle To Cradle certified ceilings such<br />

as Ultima+, Perla and Dune Supreme.<br />

www.armstrongceilings.co.uk<br />

Clean up with demountable bathroom<br />

pods<br />

Offsite Solutions, the UK’s leading bathroom pod manufacturer, has<br />

developed an innovative demountable pod solution for refurbishment<br />

and new build projects where there is insufficient a<strong>cc</strong>ess for fully<br />

assembled pods. Demountable pods radically reduce work on site, and<br />

offer the superior and consistent quality of factory-built bathrooms.<br />

The demountable solution uses a unique sectional design where the<br />

shower tray forms part of the floor and the wall panels create the<br />

shower enclosure. Holes for<br />

sanitaryware are pre-drilled and<br />

only the shower door is then<br />

installed on site. The pod walls<br />

are completely vertical with 90°<br />

corners – unlike pods created<br />

from complete GRP moulds<br />

which have tapered walls – so<br />

integration is very simple.<br />

Offsite Solutions’ demountable<br />

pods are manufactured from<br />

GRP which is very robust and<br />

offers ease of maintenance and<br />

longevity. A wide variety of wall<br />

finishes are available for the<br />

sectional pods, including tile<br />

effect, matt or gloss and with<br />

feature recesses if required.<br />

www.offsitesolutions.com/demountables<br />

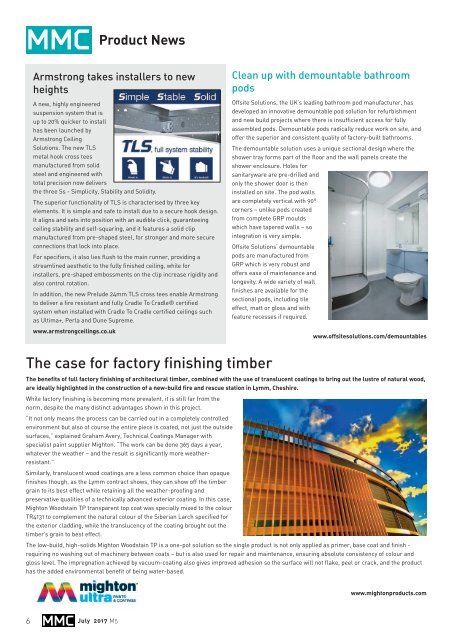

The case for factory finishing timber<br />

The benefits of full factory finishing of architectural timber, combined with the use of translucent coatings to bring out the lustre of natural wood,<br />

are ideally highlighted in the construction of a new-build fire and rescue station in Lymm, Cheshire.<br />

While factory finishing is becoming more prevalent, it is still far from the<br />

norm, despite the many distinct advantages shown in this project.<br />

“It not only means the process can be carried out in a completely controlled<br />

environment but also of course the entire piece is coated, not just the outside<br />

surfaces,” explained Graham Avery, Technical Coatings Manager with<br />

specialist paint supplier Mighton. “The work can be done 365 days a year,<br />

whatever the weather – and the result is significantly more weatherresistant.”<br />

Similarly, translucent wood coatings are a less common choice than opaque<br />

finishes though, as the Lymm contract shows, they can show off the timber<br />

grain to its best effect while retaining all the weather-proofing and<br />

preservative qualities of a technically advanced exterior coating. In this case,<br />

Mighton Woodstain TP transparent top coat was specially mixed to the colour<br />

TR4131 to complement the natural colour of the Siberian Larch specified for<br />

the exterior cladding, while the translucency of the coating brought out the<br />

timber’s grain to best effect.<br />

The low-build, high-solids Mighton Woodstain TP is a one-pot solution so the single product is not only applied as primer, base coat and finish -<br />

requiring no washing out of machinery between coats – but is also used for repair and maintenance, ensuring absolute consistency of colour and<br />

gloss level. The impregnation achieved by vacuum-coating also gives improved adhesion so the surface will not flake, peel or crack, and the product<br />

has the added environmental benefit of being water-based.<br />

www.mightonproducts.com<br />

6 MMC<br />

July 2017 <strong>M5</strong>