Mueller® Meter Xchanger™ System - Mueller Gas Products Division

Mueller® Meter Xchanger™ System - Mueller Gas Products Division

Mueller® Meter Xchanger™ System - Mueller Gas Products Division

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

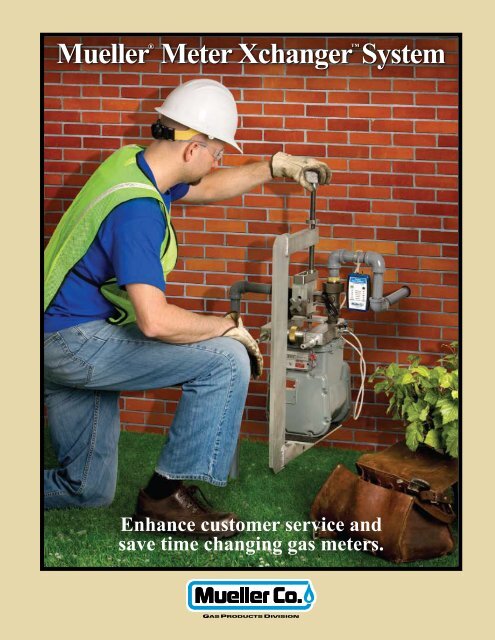

<strong>Mueller</strong> ®<br />

<strong>Meter</strong> Xchanger <br />

<strong>System</strong><br />

Enhance customer service and<br />

save time changing gas meters.

Change-out gas meters when you want…<br />

without interrupting service.<br />

Even though most gas<br />

meters can operate reliably<br />

for decades, at some point<br />

meter replacement becomes<br />

necessary. And to date, the<br />

only way to successfully<br />

change a meter has been<br />

to first shut off the gas. Of<br />

course, that can cause a<br />

host of other problems that<br />

can complicate the process.<br />

There’s no doubt that meter replacement is a hassle… that is,<br />

until now.<br />

The intelligent solution<br />

Shutting off the gas is a thing of the past! The <strong>Mueller</strong> ®<br />

<strong>Meter</strong> Xchanger <br />

<strong>System</strong> now lets you work on your own schedule without affecting<br />

the customer’s service. The property owner will probably not even<br />

realize that your crews have been on the scene. And since gas<br />

service is maintained and pilots remain lit, there is no reason for the<br />

customer to be present… and no need for crews to enter buildings.<br />

No more missed appointments or rescheduling problems either–<br />

setting appointments is now a matter of courtesy, not necessity. This<br />

new system truly changes the ground rules!<br />

How the system works<br />

The <strong>Mueller</strong> <strong>Meter</strong> Xchanger <strong>System</strong> is a portable gas meter changeout<br />

system. Within the <strong>Mueller</strong> <strong>Meter</strong> Xchanger <strong>System</strong> are two<br />

nearly identical tools that fit around the meter connections at the<br />

swivels. These tools are easily adjustable to fit 20LT meter bars with<br />

straight or offset swivels. A lightweight aluminum platform, which<br />

clamps to the meter bar, is an integral part of the unit, providing<br />

support for the meter during disconnection– and as a new meter is<br />

positioned and installed. As the tools are attached to the swivels, a<br />

uniquely designed bypass component connects the two tools and<br />

allows safe, uninterrupted gas flow through the service line, until the<br />

replacement meter is installed.<br />

Once the tools are secured, the old connection is mechanically<br />

opened, by manipulating the knobs, levers and slides of the tools.<br />

<strong>Gas</strong> flow is automatically activated and maintained during the<br />

change-out. The old meter is then dropped down and removed, as<br />

the swivel ends are automatically sealed to prevent gas leakage.<br />

To install a new meter and<br />

gaskets, the whole process<br />

is essentially reversed. After<br />

the new meter is in place, the<br />

tools can purge excess natural<br />

gas through bleed-off valves.<br />

A battery-powered electronic<br />

monitor is also part of the<br />

system. It monitors high/<br />

low pressure to the property<br />

owner’s service. In the event<br />

service pressure fluctuates outside operator set limits, patterns of<br />

LEDs are illuminated to indicate what occurred and remain lighted to<br />

alert the service technician.<br />

Designed for long service<br />

<strong>Mueller</strong> has designed the tools for durability and easy access to<br />

seals during routine maintenance. The primary parts of the tools<br />

are also constructed of lightweight aluminum. Critical moving parts<br />

on the unit are made of either stainless steel or bronze for superior<br />

durability, low maintenance and long life. All system components<br />

including monitor are nested into a form-fitted, padded, heavy-duty<br />

carrying case that is both compact and lightweight for easy transport<br />

from location to location.<br />

<strong>Mueller</strong> <strong>Meter</strong> Xchanger <strong>System</strong><br />

Features & Benefits<br />

• Change meters without interrupting gas service<br />

• No need to enter property owners’ buildings to inspect and<br />

relight pilots<br />

• Complete meter change-out quickly and safely<br />

• Do the work on your schedule– no appointments or<br />

scheduling with customers necessary– because service<br />

work can be done at any time<br />

• <strong>System</strong> establishes its own bypass, with no need for an<br />

auxiliary gas supply<br />

• Allows service technicians to make better use of their time–<br />

reduces change-out time by as much as 40%*<br />

• Drastic reduction of time needed for customer interaction<br />

and travel– an estimated 54% for this type of work*<br />

• Most frame and body components constructed of<br />

lightweight aluminum for easy handling and transport; key<br />

moving parts constructed of stainless steel and bronze for<br />

durability and low maintenance<br />

• Battery-powered electronic monitor tracks pressure<br />

throughout the replacement process<br />

* GTI <strong>Gas</strong> Operations NEWS, November 2007, Volume 4, No. 2

<strong><strong>Mueller</strong>®</strong><br />

<strong>Meter</strong> Xchanger<br />

<strong>System</strong><br />

<strong>Meter</strong> Removal<br />

Procedure<br />

Clamp supports old meter during<br />

drop-down and easy installation<br />

of new one<br />

Multi-function tools automatically<br />

initiate bypass, keeping pilots lit<br />

Tools perform each step with<br />

controlled gas flow start to finish<br />

Electronic monitor helps<br />

assure uninterrupted gas<br />

flow to customer<br />

Bypasses meter as<br />

replacement operation takes<br />

place, providing uninterrupted<br />

gas service to the customer<br />

Electronic monitor tracks pressure<br />

downstream of work to alert<br />

personnel to pressure fluctuations<br />

Built-in valves allow air<br />

to be purged, once work<br />

is completed

Parts Description & Specifications<br />

Parts Description:<br />

Standard Kit Includes:<br />

• Inlet & Outlet Xchanger Units<br />

• <strong>Meter</strong> Support Clamp<br />

• <strong>Meter</strong> Removal and<br />

Installation Collars<br />

• Center Support Clamp<br />

• Hold Down Plate<br />

• Leverage Plate<br />

• Replacement <strong>Gas</strong>kets<br />

• Replacement O-rings<br />

• Pressure Monitor/Hose<br />

Specification Requirements:<br />

• 20 LT Swivel Size<br />

• Cast <strong>Meter</strong> Bar<br />

• Straight or Offset Swivels with <strong>Gas</strong>ket Seals to meter<br />

• 1 PSI MAOP<br />

• O-ring Splitting Tool<br />

• Sealing Grease<br />

• Adjustable Wrench for<br />

Collar Installation Procedure<br />

• Tape<br />

Patent Pending<br />

Technology developed by or in conjunction with Operations Technology Development, NFP<br />

All products must be installed and maintained in accordance with applicable instructions and/or standards. All <strong>Mueller</strong> Co. brochures and/or products are subject to<br />

change without notice.<br />

Main Office – Chattanooga, TN<br />

<strong>Gas</strong> <strong>Division</strong>: 1-800-798-3131<br />

Canada – <strong>Mueller</strong> Canada Inc., Barrie, Ontario 1-705-719-9965<br />

www.muellercompany.com<br />

Form No. 12718-05/11-5M-1 © 2011 <strong>Mueller</strong> Co. Printed in USA