Australian Blade Ed 2 Sep 2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

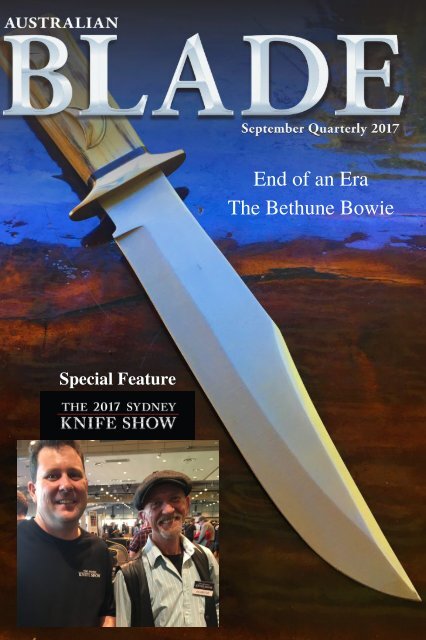

End of an Era<br />

The Bethune Bowie<br />

Special Feature

to the second edition of <strong>Australian</strong> <strong>Blade</strong>. The response to the first edition<br />

was overwhelmingly positive and its success was due to the folks who<br />

Welcome<br />

contributed. One of the many congratulations came from Joan Renton-<br />

Spencer, wife of <strong>Australian</strong>’s most prolific knife writer, the late Keith<br />

Spencer. Joan wrote:<br />

“Well done Chris. I must admit to have been very surprised to read your article<br />

that included our George Lee Sye book - and chuffed over your reaction to<br />

actually seeing the knives we featured in the book from our collection. Keith<br />

would have smiled about that too. He would have also been extremely pleased to<br />

see an <strong>Australian</strong> writing about knives. So, just wanted to wish you the very best<br />

with your publication… keep the pen sharp.”<br />

Thank you Joan. This edition is even better, again due to the input from a number of people. So<br />

thank you very much to Dylan Jones of Cape York <strong>Blade</strong>s, Michael Masion of <strong>Australian</strong> Knife,<br />

Andrew Smith, Kirk Powell, Gillian and Graham Wilson of Queensland Metal Artisans Collective<br />

(QMAC), Corin Urquhart of Gameco, James Johnson, Steve Filicietti, Bruce Barnett of Barnett<br />

Custom Knives, Dan Comeau of D. Comeau Custom Knives, Canada, Tiago De Matos of Wild<br />

<strong>Ed</strong>ge, United Kingdom and Captain Barry Cross. Ultimately though, the gauge of success for any<br />

publication is whether folks take it up and have a read. So thank you for taking an interest in<br />

<strong>Australian</strong> <strong>Blade</strong>!<br />

This edition covers the <strong>2017</strong> Sydney Knife Show, which just gets bigger and better each year. And<br />

just like magazines it is the people who contribute to the Show that ensures its success. Corin<br />

Urquhart of Gameco advises that key folks included Andrew Smith who managed all the logistics,<br />

Keith Fludder, the Master of Ceremonies and the Knife Competition judges (all chefs), who<br />

donated their time in exchange for a donation to charity, Ben Shewry, Mike Eggert and Jemma<br />

Whiteman. Well done to them and the unnamed multitude of others behind the scenes who lifted<br />

and shifted into the long wee hours. Well done all the <strong>Australian</strong> knifemakers who burnt the<br />

midnight oil to put that final loving touch to their blades and then travel from near and far across<br />

the width and breadth of this big island. Well done the international attendees Noriyuki Tshida of<br />

Rockstead Knifes and Kansei Matsuno who both travelled from Japan to attend the Show and<br />

exhibit. Michael Morris of Morris Knives came from Yale, Michigan in the USA to exhibit. But<br />

most of all – the folks who attended!<br />

Jack O’Brien.<br />

Vale,<br />

Renton-Spencer has advised that long established bladesmith from Perth, Jack O’Brien passed<br />

Joan<br />

away in August. In Joan's words:<br />

“Jack was working on his final blade, another commemorative knife, before he<br />

became too tired to continue. We covered Jack a fair bit in the old Knife Annuals…<br />

he was best known for his beautifully mirror polished special blades for service unit<br />

commemoratives. He was a good bladesmith too and had mastered the art of mixing<br />

bronze with steel, something others said couldn't be done!”<br />

Our sincere condolences to Jack’s family and friends.

Contents<br />

Welcome.........................................................................2<br />

Contents..........................................................................3<br />

The <strong>2017</strong> Sydney Knife Show - THE Place to be! ...... 4<br />

Cape York <strong>Blade</strong>s - Northern Frontier..........................9<br />

Four Questions – Dylan Jones of Cape York <strong>Blade</strong>s...12<br />

Damascus Magic!.........................................................13<br />

<strong>Australian</strong> Knife Magazine...........................................14<br />

Queensland Metal Artisans Collective.........................16<br />

Maker profile - James Johnson.....................................19<br />

Versions of Perfection...................................................21<br />

Bethune Bowie..............................................................23<br />

International Make - Dan Comeau...............................26<br />

Book Review - Beowulf...............................................27<br />

Software review - Procreate.........................................29<br />

Forged SUP9, copper guard, filed space and stag handle by Cape York <strong>Blade</strong>s.

THE Place to Be!<br />

Article by Andrew Smith<br />

Photos by Kirk Powell<br />

The first weekend in August has made Rosehill THE place to be for those interested in all things knife<br />

and knife related. Australia’s top knifemakers, sellers and industry suppliers once again setup for the<br />

second Sydney Knife Show at the racecourse, now encompassing the entire second level of the Grand<br />

Pavilion with outdoor demonstrations from the NSW Artisan Blacksmith Association and Norton<br />

abrasives. Even at the start of the bump in on Friday night, the 3000 square metre exhibition space<br />

was almost overwhelmed. By 9:00 AM on Saturday morning, we had 99 exhibitors setup on over 170<br />

tables and booths waiting for the doors to open to the public.<br />

Before the doors opened on Saturday, the Knife Art Association Show Committee conducted the<br />

knife awards judging, assessing the submitted knives for their aesthetics, construction, and fit and<br />

finish. It’s difficult to quantify how much the quality of the knives has increased since the first show<br />

in 2014 (then known as the International Cutlers Exhibition), but it makes our job harder and harder<br />

every year. In saying that, this year Steve Filicietti dominated the competition with his incredibly<br />

detailed forged pattern welded steels and the immaculate fit and finish of his knives.

Australia” Best Chef’s Knife Competition, sponsored by<br />

Steve took home the awards for “Best Damascus Knife”, “Best Forged Knife”, “Best Art Knife”<br />

and “Best in Show”, a feat which will be very hard to equal in years to come. Other winners<br />

include Brett Selley of BSG Knife Co. for “Best Hunting Knife”, Ali Bastian of Bastian Knives for<br />

“Best Folder”, Ian Stewart for “Best New Exhibitor” and Kevin Slattery of Kev's Forge for “Best<br />

Utility Knife”.<br />

Ali Bastian Ian Stewart Kevin Slattery Mike Dicketts Brett Selley Steve Filicietti<br />

The show awards this year also included the “Made in<br />

Damasteel and Artisan Supplied, with prized steel<br />

awarded to the top three placed makers. Ben Shewry of<br />

Melbourne’s Attica Restaurant and Mike Eggert and<br />

Jemma Whiteman of Pinbone in Sydney judged this<br />

year’s competition. The best fourteen knives were put<br />

through a series of practical cutting tests with each<br />

judge scoring the blades on their technical difficulty, fit<br />

and finish, ergonomics, and practical tests cutting<br />

tomatoes, carrots, potatoes and sweet potatoes. After<br />

much testing, re-tests, discussion and deliberation, the<br />

judges had come to their decision. Third place for the<br />

Chef’s Knife Competition went to Kevin Room of<br />

Room Custom Knives and second place went to Tobias<br />

Bockholt of Metal Monkey Knives. The winner for the<br />

“Made In Australia” competition and deemed best<br />

Chef’s Knife was Mert Tansu of Tansu Knives entry.<br />

Mert, a skilled knifemaker and chef from the NSW<br />

Hunter Valley, took home over $1500 worth of<br />

Damasteel’s Vinland patterned stainless steel which will<br />

no doubt be put to good use in the near future.

After the Chef’s Knife Competition, the patrons of the Sydney Knife Show were privileged to see<br />

a very dynamic demonstration from the Sydney School for Japanese Swordsmanship. Ben Chow<br />

and Hans Fricke, along with other members of their Sei Do Kan Dojo gave an action packed<br />

display showing different sword techniques including sword vs sword, sword vs spear and<br />

technical cutting displays of tamashigiri (bamboo matting), close paper cutting and even a held<br />

banana, showing the true skill, and trust needed to accurately use a Japanese sword. Judging by<br />

the five deep crowd gathered around the display area, both exhibitors and public enjoyed the<br />

demonstration and we’ve already booked the school to put on another demonstration next year.<br />

Sunday is always geared a little more towards families<br />

especially as kids under twelve get in for free. This<br />

year we arranged Barry Armstead to come to the show.<br />

For those unaware, Barry is part of the knife making<br />

community in Canberra and though selling his knives,<br />

had funded a fully wearable and working Iron Man suit<br />

made of steel. Barry, as Iron Man, visits children’s<br />

hospitals and has public displays raising money for the<br />

Starlight Children’s Foundation. Barry suited up a few<br />

times during Sunday, walking the exhibition area and<br />

posing for photos for a gold coin donation. On Sunday,<br />

Barry raised over $800 for the Starlight Children’s<br />

Foundation, taking photographs with children,<br />

exhibitors (and organisers) alike.

The show has gone from strength to strength, since the first show at the Australia Technology Park<br />

in 2014, the number of exhibitors has tripled and the number or patrons has nearly doubled. We<br />

spent more money on advertising this year than the previous two shows combined, investing in<br />

social media ads, radio, print media, billboards and more.

Of course we’d like to get more people through the doors and supporting the industry, but at the<br />

same time to get 2800 people through the door is still no mean feat, up about 20% from last year.<br />

The biggest indicator of the show’s success came with the amount of custom knives sold. At nearly<br />

500 up almost 60% from 2016 and confirms the ethos behind the show and the Knife Art Association<br />

in promoting the art of knifemaking is working. We are already looking forward towards a bigger<br />

and better show in 2018.

Frontier<br />

According author of “Wilderness: Earth’s last wild places”, Cape York<br />

Northern<br />

Peninsula (Cape York) is the largest unspoiled wilderness in northern Australia<br />

and one of the last remaining wilderness areas on Earth. “To qualify as<br />

"wilderness," an area must have 70 percent or more of its original vegetation,<br />

cover at least 10,000 square kilometres, and have fewer than five people per<br />

square kilometre.” Cape York is 137,000 square kilometres and Thursday Island is<br />

some 39 kilometres north of the Tip, nestled in the Torres Strait archipelago. As<br />

the crow flies, Thursday Island is 2,745 kilometres north of Sydney and 143<br />

kilometres south of Papua New Guinea. Truly the Northern Frontier!<br />

Dylan Jones of Cape York <strong>Blade</strong>s is based on Thursday<br />

Island and as such, can legitimately claim the title of<br />

“Australia’s most northern knife maker”. Given the<br />

remoteness on Australia’s northern border, it was rather apt<br />

that Dylan presented his “Frontier” range of knives at the<br />

<strong>2017</strong> Sydney Knife Show. Here's Dylan’s own account.<br />

“When I got back from the American <strong>Blade</strong> Smith<br />

course in Sydney and started to plan for the Sydney<br />

Knife Show, I thought to myself “I have heaps of time!<br />

I’ll use some of the blades forged over the last couple<br />

of weeks.” I already had a good idea about some<br />

others that I wanted to make. Then “Boom!” all of a<br />

sudden I was six weeks out from the show and only had<br />

four knives ready! This was partly my fault as I kept<br />

selling knives as I made them thinking I had heaps of<br />

time before the show. The next six weeks were chaos."<br />

"Every weekend in the shed away from the<br />

family (thankfully I have an understanding<br />

wife) every night after I sorted out the kids I<br />

would be burning the midnight oil trying to get<br />

everything done in time."<br />

"On top of all that I had two split Damascus<br />

guards, warped blades and split scales just to<br />

keep things interesting. Originally I wanted 20<br />

knives for the show and ended up with 13.<br />

Considering the lead up I was pretty happy<br />

with the outcome and the quality of the builds.<br />

The last week involved sheath making with the<br />

wife hand stitching at night after the kids were<br />

in bed."

"Living on Thursday Island is great till you have to travel, I left home a 7AM on the<br />

Friday and 1 ferry, 2 buses and 2 plane flights later I arrived in Sydney at 9 PM that<br />

night. Straight to the in laws to get some shut eye before getting back up at 4:30 AM to<br />

get ready for the show. I recruited my father-in-law Digby to help me at the table over<br />

the weekend. We arrived at the Show around 6 AM on the Saturday, found our table and<br />

began to set up. To be honest I was a little nervous - it was only the second show I have<br />

been to, the first being the Canberra show the previous year. As we got there a little early<br />

I had a chance to catch up with some of the other makers that I knew and meet some new<br />

ones. I also submitted two knives in the competition but fell short of winning a prize."<br />

"The show started at 9 AM along with the butterflies in my stomach! The first hour rolled by as people made their way<br />

around checking out all the amazing work that was on display. I had made a batch of frontier style knives for the show and a<br />

lot of people were showing interest in them. I was busy answering lots of questions then after a bit I sold a knife then another<br />

and I was on a roll. At the end of day one I had sold 6 knives which I was very happy with. It’s fun trying to figure out the<br />

people who are going to buy a knife, they come and look and touch then come again than after maybe three or four visits<br />

they come back and buy it, with the occasional person coming back to find it had been sold in the meantime."

"Day two started at a more respectable hour which was nice. Sunday in general<br />

for me was a bit slower than Saturday but still a good day overall and I sold 3<br />

more knives. Got a chance to meet a heap of new people and help get my name out<br />

there which was the point of the trip. Being a little quieter allowed me to get<br />

around and talk to some of the other makers out there which was great - so many<br />

talented makers with amazing ideas and skill. Overall I had a great show, I<br />

covered my costs, promoted Cape York <strong>Blade</strong>s and caught up with some mates and<br />

made some new ones. The Sydney show is a great event run by all the hard<br />

working volunteers from the Knife Art Association. Even if you’re not a knife<br />

enthusiast it’s worth the trip to see what these great <strong>Australian</strong> makers are<br />

producing.”<br />

By his own account Dylan had a successful show and left Sydney richer for the experience. But that positive<br />

experience was by no means one sided. Bruce Barnett was moved to remark :<br />

“I've been following Dylan's progress … since he did the ABS course in Sydney and he's coming out with<br />

some interesting stuff. I really like where Dylan is going with the frontier style because no one else has really<br />

gone for it in Australia."<br />

The future looks bright for Cape York <strong>Blade</strong>s with Dylan Jones at the edge of the frontier.

Four Questions – Dylan Jones of<br />

Cape York <strong>Blade</strong>s<br />

What got you into knife making?<br />

Being a hunter and outdoorsman I have always had a connection with quality knives. In 2009 I was in New<br />

Zealand hunting and was staying with family on the west coast and noticed a sign for Barry town knifemaking.<br />

They were running a one day knifemaking workshop so I gave them a call and made my first knife. Form there<br />

I made a few crude knives without any real direction. And decided to go to Canberra to Tharwa Valley Forge<br />

and do a two day knifemaking course. This changed everything for me and I haven't looked back<br />

What's your favourite knife steel and why?<br />

This is a hard one as the steel has to match the application. So I'll do this it two parts the first being carbons<br />

steels. I love to forge though I don't do as much as I would like. It opens up so many possibilities that stock<br />

removal doesn't provide. I've have used a few different carbon steels but 1075 and 52100 are my favourite.<br />

1075 is forgiving easy to heat treat and very affordable, heat treated right it performs very well. After some<br />

heat treating tips from Bill Burke I've had a lot of success with 52100. While heat treating 52100 is a little<br />

more complex than 1075, it's still pretty straight forward and makes for a great knife. I've only used two types<br />

of stainless 12C27 and RWL-34. The RWL-34 would be my pick. I sent some 12C27 Skinners to be field<br />

tested in New Zealand during the <strong>2017</strong> Red Deer Roar and got excellent feedback from a full time guide over<br />

there but I still prefer the RWL-34 for its ease of use and being able to get a very keen edge that's holds up to a<br />

lot of abuse.<br />

Which maker has influenced you the most?<br />

Another hard one as many makers have influenced me. First of it would be Karim from Tharwa Valley Forge<br />

and Kev from Kev’s Forge. These guys ran the first course I did and Karim continues to mentor me and answer<br />

my stupid questions. After that it would be Bruce Barnett and Shawn McIntyre who both make the best San<br />

Mai I have ever seen and both also continue to offer advice on various aspects of my knife making. Lately I<br />

have been trying something different with my Frontier collection of knives and have taken inspiration from<br />

John Cohea from the US<br />

If you could only have one knife, what would it be?<br />

Probably one of my Cape York <strong>Blade</strong>s Small hunters in 52100 or RWL34 with rams horn scales. It’s just a<br />

good size, general purpose blade and easily the one I've sold the most of. Otherwise I would love one of Shawn<br />

McIntyre's San Mai hunters with a stag handle.

Damascus Magic!<br />

Steve Filicietti is a man of few words. He doesn’t need to say much, because his knives speak volumes for him.<br />

Artistic, integral, forged, masterpiece and art are all words that spring to mind, yet fall just short of doing justice<br />

to the blades that leave Steve’s workshop.<br />

Steve scooped the awards at the <strong>2017</strong> Sydney<br />

Knife Show and walked away with Best<br />

Damascus Knife, Best Forged Knife, Best Art<br />

Knife and Best in Show. That’s an outstanding<br />

effort and is testament to the number of years<br />

and effort Steve has devoted to knife<br />

making. Steve's a humble bloke who regularly<br />

donates his time to drive from his home in<br />

northern New South Wales up to Ipswich in<br />

Queensland to conduct forging workshops,<br />

such is his generosity. His willingness to share<br />

and teach is greatly appreciated.<br />

Bill Burke, American <strong>Blade</strong> Society Master<br />

Smith was recently moved to comment:<br />

"Of the Aussie knifemakers who's (sic) work I<br />

have seen, only Steve Filicietti's is consistently<br />

good enough to be of "master smith" quality.”<br />

Bill went on to contextualise his comments<br />

with: “This is not to say that others work is not<br />

(as good) just that I haven't seen any others<br />

who are. I am sure there are others."<br />

13'' sanmai blade and black palm handle

13'' blade, desert ironwood handle and blued steel fittings<br />

Perhaps the man himself has the best advice<br />

for the aspiring knifemakers out there.<br />

“…just keep working and learning. If you can<br />

continually improve and push the standard of<br />

the performance and workmanship in your<br />

knives you are a master. Mastering one little<br />

thing at a time.”<br />

Words of wisdom indeed.

Knife Magazine<br />

Tricks” and a rarity in this PC day and age – a “Sexy Naked Centrefold”! A number of people<br />

<strong>Australian</strong><br />

<strong>Australian</strong> Knife – the highly<br />

anticipated, new quarterly<br />

magazine was launched at the<br />

<strong>2017</strong> Sydney Knife Show. The<br />

driving force behind it, Michael<br />

Masion confessed to a few<br />

sleepless nights in the lead up to<br />

the launch but needn’t have<br />

worried. This new Aussie<br />

publication has been well<br />

received and Mike is to be<br />

congratulated for a professional<br />

and informative read.<br />

“Bloody hell” ventured one<br />

show exhibitor (who shall<br />

remain nameless as he sat<br />

behind his awards for Best<br />

Beard, Best Flannie and Best<br />

Bloody-Big-Buggar-Off <strong>Blade</strong>)<br />

“You can’t even get a New Idea<br />

for five bucks! I dunno how the<br />

hell he does it!”<br />

<strong>Australian</strong> Knife has a little bit for everyone including “Focus on Makers”, “Shop Talk”, “Tips N<br />

contributed articles to the first edition including Matt Preece, Adam and Terri Parker, Glenn Waters,<br />

John Kroezen and Christian Mathieson.<br />

Gillian Wilson provides a rundown on QMAC – Queensland Metal Artisans Collective, Tom<br />

Germain reviews a hunter and Paul-Emmanuel Arestan details an acid etching tutorial.<br />

Michael Masion who describes himself as “a collector, curator and supporter” also authored a<br />

number of articles. So “well done!” to all who contributed. We look forward to many more issues.<br />

Subscriptions and further information can be found at www.australianknife.com.au

Queensland Metal<br />

Artisans Collective<br />

Gillian Wilson<br />

The Queensland Metal Artisans Collective (QMAC) is a recently formed, very active not for profit association based in<br />

the South East corner of Queensland. As you can tell from the name, the club supports a range of metal arts and counts<br />

among its members knife and sword makers, blacksmiths, jewellers, and a whole bunch of blokes who just want to bash<br />

hot metal. About half of our membership are beginners.<br />

QMAC was generously donated a table at the Sydney Knife Show this year by the Knife Art Association. We have<br />

received immense support from Corin and the team. Conditions of the table were for the promotion of the club only.<br />

Not really sure what we were going to do to “promote the club”, we thought we may tap the Sydney market for raffle<br />

tickets. Fly the flag, raise the banner, hand out business cards and flyers. Pretty clueless, really. We had booked Air<br />

B&B accommodation a few kilometers away from the venue, and with Uber, we were pretty much set.<br />

We were astounded at the warm welcome received from knifemakers, many of whom seemed to know exactly who we<br />

were. Started to feel like legends in our own minds (about 15 mins) until the public started streaming in at 9am.<br />

We had a quick peek at our fellow QMAC members’ tables, Paul-Emmanuel Arestan, Kevin Room, Tim Kingsford,<br />

Brad White, Adam Grosskopf, and of course, Steve Filicietti, and they were looking good, and full. Except for Steve’s.<br />

You wouldn’t really call it full. But ooooohhhh, the knives….<br />

By then, we had all our beginner knives (and a few not-so beginners) proudly displayed, the QMAC banner strung<br />

across the front of the table, business cards and flyers ready, Josh Day’s knife proudly displayed to ensure the public<br />

that at least some of our members had a clue, and with the thumbs-up from Kevin Room across the aisle, we were<br />

ready to start “promoting” the club.

WINNERS ANNOUNCEMENT<br />

Then came the announcement just before the show opened that<br />

the winners were being announced. I held my breath when I<br />

saw Steve standing with a group of guys, obviously waiting.<br />

Sure enough, his name was called, again, and again, and again.<br />

Just when I thought it couldn’t get better, Steve won Best in<br />

Show. A magical, heart-stopping moment. We were so<br />

delighted for the man who gives up so much time and effort for<br />

our club. So very well done, and well-deserved Steve.<br />

“PROMOTING”<br />

My heart sunk into my shoes when the first visitors came calling<br />

at our table. My closely held theory was that if we displayed our<br />

beginner knives, the public would notice the difference, pause,<br />

look puzzled, which would allow us to then explain that these<br />

were beginner knives, many of them first knives ever.<br />

Then, while getting over their shock, we would explain what the<br />

club does and then beg them to purchase a raffle ticket. QMAC<br />

members Kevin Room and Luke Cole donated a beautifully<br />

made knife black and a set of Mokume Rings to help us raise<br />

funds for our desperately needed new workshop.<br />

CHEF’S KNIFE CHALLENGE<br />

While we were busy “promoting” the club, we heard an announcement that the Chef’s Knife competition was taking<br />

place. To my immense shame and deep regret, I gave the comp a miss in favour of relieving someone of their hard-<br />

earned cash. I had no idea that our quietly spoken and modest Kevin Room had entered the competition with a truly<br />

gorgeous knife. Kevin’s impeccable work and attention to detail brought him third place in the competition, sailing past<br />

seasoned and experienced knifemakers. We are so proud of Kevin – rack up another award for a QMAC member.

knifemakers’ tables.<br />

To my great surprise and relief, the shock tactic of displaying beginner knives worked like magic. It’s possible that<br />

people were so glazed over from seeing beautiful things on all the other tables, it was a relief to look at something<br />

that was perhaps not so beautiful. I have never been prouder of our members.<br />

We had shouts of “What?!! First knife ever?” which drew attention to our table from other members of the public,<br />

and we advised them the they too had the capacity to make beautiful things, and the beginning point was right here<br />

(dramatically pointing at our wares). We then immediately setting about relieving them of their cash.<br />

Drew and Luke were QMAC stalwarts at the show, taking over the table at a moment’s notice for all QMAC<br />

members when they needed a breather, or the voice started taking strain.<br />

After a very successful first day, we had a quick drink at the hotel, and Uber’ed back to the apartment. Early night<br />

after a stiff Irish coffee (Graham style), and prepared to do it all over again.<br />

The pace was not as frenetic the next<br />

morning – we knew what we were in<br />

for, and had an opportunity to walk<br />

around and have a look at other<br />

The atmosphere was like a reunion of<br />

likeminded people, and it seemed<br />

almost as though the public were a<br />

necessary evil, but an imposition on<br />

people just wanting to catch up with<br />

one another.<br />

We received a number of comments about why the other States did not have a QMAC, how great it was that<br />

Queensland was taking the lead on this fantastic idea, and what brilliant work our beginners were doing. The real need<br />

for knifemakers (and all artisans) to be able to together and bounce around ideas, collectively work out problems seems<br />

to have put our members on a steeper learning curve than most – this was evident from the comments we received. Go<br />

QMAC! All our members did really well, and much interest was shown in Josh Day’s work. We believe Josh will be a<br />

real contender for next year’s show. Get ready for 2018 Josh! All in all, it was a great experience, and inspiring to look<br />

at the fantastic work that is being done. Corin and the Knife Art Association put on something really special – well<br />

organised, with a great atmosphere. We hope to attend again in 2018 and show everyone how far our guys have come in<br />

another 12 months.

Profile<br />

Maker<br />

Johnson<br />

James<br />

A little bit about me and my knifemaking<br />

journey. Over the years I have spent a large<br />

amount of my life travelling around Australia<br />

and the world working an array of different<br />

jobs from body guarding to coal mining. I have<br />

always had a passion for knives as I have been<br />

and still am an avid fisherman and hunter. In<br />

2003 while working on pearling boats in<br />

Broome Western Australia I met my partner<br />

and we now have 3 children together. In 2010<br />

we moved to Mackay Queensland where I<br />

worked in the underground coal mines,<br />

conducting maintenance and installing<br />

conveyor systems. After a string of accidents<br />

underground it was decided I’d hand in my<br />

notice, which unknowingly, was perfect timing<br />

as my wife had just been offered a job in<br />

nursing. From that moment on I would be a<br />

stay at home dad and get into knife making,<br />

which had been something I'd wanted to do for<br />

some time. I started with very basic hand tools,<br />

a file, rasp and hacksaw etc. which worked<br />

well, but the knife making bug had bitten me<br />

and I needed more!

As my skills developed and I was able<br />

to save the dollars I purchased an<br />

<strong>Australian</strong> made Radius Master Belt<br />

Grinder which was a real game<br />

changer for me. It was perfect for<br />

profiling blades using the smaller<br />

wheels and general grinding, bevels<br />

etc. a great piece of kit! My next<br />

purchase and I believe the most<br />

important was a Paragon Heat<br />

Treating Furnace/Kiln an absolute<br />

must for custom knifemaking. Being<br />

able to get the exact hardness for a<br />

specific blade type or a customer’s<br />

preferences is essential. In the<br />

beginning I found a lot of<br />

misinformation on heat treating recipes on the internet and found its best to keep it simple, follow<br />

the steel manufacturer’s heat treating guidelines and there shouldn't be too many issues. I also found<br />

websites like "Cashenblades" in the US a good source for heat treating recipes for carbon steels.<br />

Moving forward to August <strong>2017</strong>, I recently had the privilege of having a table at the Sydney Knife<br />

Show. This being my first show it was a great experience and a little nerve wrecking in the<br />

beginning but the nerves soon left and I really enjoyed myself meeting and speaking to other<br />

knifemakers and customers. Being able to see in person some of the work from so many talented<br />

<strong>Australian</strong> knifemakers was an inspiration and has pushed and driven me in a positive direction to<br />

improve my skills and continue my journey in knifemaking.

Versions of Perfection<br />

Drew Weeks - Member - Queensland Metal Artisans Collective<br />

As a member of Queensland<br />

Metal Artisans Collective<br />

(QMAC) I originally joined up<br />

in the hope of furthering my<br />

blacksmith ambitions, with<br />

little interest in knifemaking<br />

beyond something simple and<br />

functional. Then I met Steve<br />

Filicietti. From afar Steve’s<br />

work appeared solid at first,<br />

the closer I got the more I<br />

quickly realised the skill,<br />

talent and attention to detail<br />

that had been put into every<br />

piece he produced. He spoke<br />

in a humble and matter-of-fact<br />

way that can only come from<br />

the confidence of having been-<br />

there and done-that.<br />

Nearly 8 months after seeing Steve's first demo on making Damascus at his home workshop in Ballina, I sat in amazement<br />

behind the QMAC table at the <strong>2017</strong> Sydney Knife Show as I heard his name being called out over the loud speaker for the<br />

third time. Steve had just won Best Damascus Knife, Best Forged Knife and Best Art Knife, after accepting his Best Art<br />

Knife Award I heard the announcer over the PA System warn Steve "don't go too far..." Before calling his name again for<br />

The Best in Show, bringing his total to 4 awards for 3 knives, winning every category he entered.<br />

After the ceremony the show quickly kicked off, I stopped by Steve’s table to check out the goods and congratulate him as<br />

Graham and Gill took over the QMAC table showing off our beginners work and selling raffle tickets for Kevin Room's<br />

beautiful steak knife set and Luke Cole's stunning mokume ring set. I quickly moved up to where Dar Lu had his table and<br />

greedily collected my SWF Rams Head touchmark. Then began the adventure that would turn an interest into an obsession<br />

as I moved from table to table, inspecting the wares and asking the questions. Most were happy to oblige but all beamed<br />

with pride when complemented.<br />

The common theme throughout the<br />

custom knifemaking tables was<br />

undoubtedly quality. With different<br />

makers all emphasizing different<br />

aspects, some of the most noteworthy<br />

were DPC Knives and the hamons they<br />

produce which in contrast to the clean<br />

smooth lines of the various kitchen<br />

knives gave them a dramatic and artistic<br />

flair turning a simple kitchen tool in to a<br />

literal art piece any self-respecting cook<br />

would display with joy. Something that<br />

could perhaps persuade even the biggest<br />

takeaway advocate to take up the<br />

vocation and have them julienning a<br />

bushel of carrots in next to no time.

Another favourite of mine was Fromholtz Forge based out<br />

of Canberra, not only was his work of high quality but he<br />

was more than happy to share the story behind his work<br />

which made me and the other people at his table feel a real<br />

connection.<br />

The highlight of the show for me was the testing of the Chef<br />

Knives. I was lucky enough to be present when they were<br />

testing Kevin Room's entry and was delighted to see the look<br />

of satisfaction on Chef Mike Eggert as he motioned to his<br />

fellow judges and appeared to comment on the feel of the<br />

knife in his hands.<br />

After the show it was good to talk to<br />

the various vendors and introduce<br />

myself. It was promising to hear<br />

many of them talk about how<br />

educated the crowd appeared to be<br />

compared to previous years and<br />

other shows. Whilst looking after the<br />

QMAC stand I was pleasantly<br />

surprised to see the interest in the<br />

beginner knives that we had on<br />

display and was more than happy to<br />

pass on the public’s compliments to<br />

the various makers within our club.<br />

All in all a huge congratulations are due to the organisers, the<br />

exhibitors and even the crowd for creating and maintaining such<br />

an amazing atmosphere, but in my book it all swings back around<br />

to Steve and his 3 knives that won the 4 awards. I believe what<br />

Steve has created embodies everything that is special about the<br />

custom knife scene. Not everyone forges, not everyone makes<br />

their own Damascus billets or stabilises their own handle materials<br />

(and the list goes on), but all the makers strive for their own<br />

version of perfection in their own styles and it was more than<br />

evident by the pride shown by everyone I spoke to.<br />

I’m not sure on the exact number of people through the door or the<br />

number of knives sold, but from every angle I approached it, from<br />

wandering through the aisles filming some of the tables, to<br />

interacting with the crowd when sitting behind the QMAC table or<br />

relieving Steve Fillicieti for the odd break, to the after show drinks<br />

on Sunday evening, this show was undoubtedly a massive success.<br />

I personally walked away with more knowledge, drive and<br />

ambition then I ever thought possible.

Bowie<br />

with Captain Barry Cross<br />

Bethune<br />

In his book “George Lee Sye: Pioneer of <strong>Australian</strong><br />

Custom Knifemaking” Keith Spencer detailed how<br />

Joseph Bethune was first introduced to custom knife<br />

making by George Lee Sye. Captain Barry Cross<br />

relates how this huge 40 centimeter Bowie - the last<br />

knife by Joeseph Bethune - came into existence.<br />

"Well, when I was chasing Lee Sye<br />

knives I got Joseph's name as<br />

someone that may have one. So I<br />

chased him up, went to see him …,<br />

yes, I got hold of him ...and went to<br />

his house up in Atherton and ...<br />

workshop immaculate and a lot of<br />

the equipment ... made by him. Just<br />

a very, very talented, meticulous<br />

fellow."<br />

"Seen six or eight of his knives that he<br />

still had there that he considered not<br />

worthy of letting anyone see them, and<br />

I then discussed with him, would he<br />

consider making a custom knife for<br />

me? And the original idea was to make<br />

a big filleter. That was the original<br />

idea, and then use some marlin bill for<br />

a handle."

"But by the time he'd done his mathematics and worked it all out,<br />

the filleter turned into a Bowie because the handle accepted the<br />

measurements better than a filleter did, the Bowie handle with the<br />

black marlin bill suited it better, so we talked about it and Joseph<br />

said, "Well, look, I haven't made a knife for 20-odd years and this<br />

would certainly be the last one I ever make."<br />

"And we struck up an agreement. I<br />

wanted the black marlin bill handle<br />

with the bull whaler shark and the<br />

tiger shark tooth inlaid into each side<br />

of the handle. This was because they<br />

were the two sharks that ate our big<br />

black marlin when we were fishing for<br />

them. And so Joseph worked with that<br />

and came up with the Bowie and the<br />

end result came out pretty (good) ...<br />

I'm happy with the end result, yeah."

"So (it's) ... the last of the Mohicans, a knife made by Joseph. And even Joseph, when he finished the<br />

knife he said it was a real challenge for him making it. (Joseph) hadn't made anything quite like that<br />

before, ... hadn't worked with marlin bill or shark's teeth before and hadn't really done a knife as big<br />

before. So he said it was quite challenging to make it. ....We had an agreed value that I wanted to<br />

spend up to and as with most custom things, things change and we renegotiated at the end there and<br />

I ended up with something that I'm pretty happy with."

Maker<br />

International<br />

Comeau<br />

Dan<br />

Dan is a respected and prolific knife designer and maker living in Canada. Dan is passionate about sharing knowledge and<br />

willingly assists others along the way. In his own words Dan is a "Modern day Renaissance Guy, D.I.Y. and re-purposing<br />

Jedi, crafting knives and tools and finding new uses for old junk along the way." In this article Dan describes how how his<br />

knife interest really fired for him.<br />

"Back in the early 1990's I attended a survival course in the foothills of the Canadian Rocky Mountains.<br />

The instructor was an amazing individual named Mors who guided us through a stellar weekend of<br />

shelter craft, fire craft and of course axe and knife craft. (Mors has published several books and videos<br />

on these subjects-- Google 'karamat')<br />

I'd always had an interest in knives, but never had much of an understanding what a knife could do in<br />

the hands of a skilled operator. During the course we learned some knife dos and do nots and how to<br />

maintain and sharpen it. Up until then, my idea of a "bush knife" was something that John Rambo would<br />

be wielding in the movies. You know the massive blade with the hollowed out handle with matches inside<br />

and compass on the butt? Reality was, not many of those features are terribly useful in survival<br />

situations if one knows what they are doing.<br />

Mors' idea of a perfect bush craft knife had a small blade, approximately the width of your palm, say<br />

100 mm (4"), a Scandi grind that was easy to field sharpen and a comfortable, roundish handle that<br />

could be held in various ways without creating hot spots or blisters on your hand. The steel needed to be<br />

quality so we could create and hold a sharp edge. We were using Mora (Swedish) knives. A truly useful<br />

knife was used for scraping roots and bark, carving a bowl or a spoon or a snare hook, splitting wood<br />

with a baton and having a morning shave. What did I say? Shave?<br />

We learned a very basic technique to sharpen and strop the blade to a razor edge. This involved a single<br />

water stone and a leather belt. The stone was whetted with water and the blade was pushed edge first<br />

across the stone. A slurry formed after gliding the knife across the stone a few times. Repeating left and<br />

right until a slight but uniform burr could be felt along the edge. This burr was barely visible, but could<br />

be detected by feel as it dragged slightly on the fingernail. Next came a discount-store leather belt and<br />

fifty alternating strokes. A moment later, and much to our surprise the instructor began shaving his<br />

beard with this primitively sharpened instrument. Mouths agape we watched in horror. Something<br />

intrigued me enough at that moment to spark a fascination in sharpening things from chisels to chef's<br />

knives. The take away was that it doesn't require sophisticated machinery or expensive tools to make a<br />

razor edge, rather a knowledge of materials and some basic technique and a steady hand. I have since<br />

sharpened and honed knives with terra cotta plant pots, saucers, sand paper, glass, cotton t-shirts,<br />

newspaper, jeans and just about anything that offers even the mildest of abrasive properties. Experiment<br />

with what you have around you. You just may be pleasantly surprised.<br />

Stay sharp.<br />

Dan Comeau"<br />

Chief Custodian at D. Comeau Custom Knives<br />

Dan's Blog

Review - Beowulf<br />

Book<br />

Harriss<br />

Chris<br />

Now I don’t pretend to be anything I’m not. Except sober. I’ve pretended to be<br />

sober a few times! So in writing this article I’m not pretending to be an authority<br />

on classical literature, which Beowulf is. Neither am I pretending to be an<br />

authority on Wootz and Damascus. And what the heck has classical literature got<br />

to do with knives anyway? Well it all started at Brisbane airport when I decided I<br />

needed something to read on the plane home. There was nothing in the trendy<br />

coffee-shop-come-bookstore that interested me. I’d either read it, it didn’t interest<br />

me, it was too pooncey or too expensive. Now I’ve never been accused of being a<br />

poonce but I have been accused of being a tight arse! Anyway the tight arse in me<br />

settled on the Penguin Classics - Beowulf. It was $12.99, my flight was being<br />

called and I thought “How bad could it be? It’s a classic!” So I grabbed it.<br />

Beowulf is sometimes described as the oldest surviving poem in Old English. The story is thought to have been<br />

first committed to writing between 700 to 1000 AD, but the actual tale is apparently much older. After sailing from<br />

Geatland (an area in southern Sweden) in the sixth century, Beowulf leads a band of warriors to assist Hrothgar,<br />

King of the Danes who is being monstered in his mead-hall (boozer) by a troll. Grendel-the-troll keeps sneaking<br />

into the boozer at night and eating the drunks that have crashed there. Every time he does it, he leaves a mess!<br />

There’s blood all over the place and it’s not real good for business.<br />

So Beowulf and his boys land in Denmark, there’s some introductions and a good old Viking booze up in the mead-<br />

hall, which the Danes call Heorot. After everyone’s smashed and the speeches are over, the drunks all crash for the<br />

night. Meanwhile old Grendel’s been watching from afar and when everything’s quiet thinks “You bewdy! Time for<br />

a feed!” and scarpers on down. But Beowulf was just playing possum, so when Grendel rocks up, Beowulf jumps up,<br />

grabs him and just like Aunty Jack (Google her if you’re too young!) rips his bloody arm off! Grendel cracks the<br />

sads and feeling pretty armless, racks off and dies. Next day everyone reckons Beowulf is a bloody good bloke.<br />

They all have another big booze up and crash in the mead-hall again with Grendel’s honking big arm hanging as a<br />

trophy above the door.<br />

When Grendel’s mum finds out what befell her boy, she goes absolutely spak and surprise, surprise attacks the<br />

boozer. She kills the King’s favourite thane (nobleman) “…clutched him to herself” and flees into the night.<br />

Beowulf then has to track this “water hag” to a pool tinged with blood, the entrance to her lair. So wearing armour<br />

Beowulf decides he’s going to dive in and sort the witch out. In one translation, the sword Hrunting was loaned to<br />

Beowulf before he dives in and was described thus.<br />

"And another item lent by Unferth<br />

at that moment of need was of no small importance:<br />

the brehon handed him a hilted weapon,<br />

a rare and ancient sword named Hrunting.<br />

The iron blade with its ill-boding patterns<br />

had been tempered in blood. It had never failed<br />

the hand of anyone who hefted it in battle,<br />

anyone who had fought and faced the worst<br />

in the gap of danger. This was not the first time<br />

it had been called to perform heroic feats”<br />

1. Seamus Heaney, (trans., 2002). Beowulf: A Verse Translation (Norton Critical <strong>Ed</strong>ition, NY, W.W. Norton, 2002) page 39.

life” (carks it).<br />

Alexander, Michael, Beowulf: a verse translation Penguin Books, 2001, page 54<br />

2<br />

Ian G. Peirce, Ewart Oakeshott. Swords of the Viking Age. p. 145.<br />

3<br />

In another translation, before diving into the pool, Beowulf provides instructions should he “be sundered from<br />

"Let Unferth have the blade that I inherited - he is a<br />

widely known man - this wave-patterned sword of rare<br />

hardness. With Hrunting shall I achieve this deed – or<br />

death shall take me.”2<br />

So at this point we have a story written between 1017 to 1317 years ago (but much older) that describes a<br />

sword that in 500 AD was variously:<br />

“rare and ancient sword… with … ill-boding<br />

patterns… tempered in blood” and<br />

“…wave-patterned … of rare hardness”<br />

This sounds exactly like the knives that won Best in Show, Best Damascus and Best Everything Else at<br />

Sydney in August! No seriously – how cool is that! We have an ancient description of what could be either<br />

Wootz steel or Damascus, but which type? Wootz, also known as the “True Damascus” was an ancient way of<br />

producing patterned steel, the technique of which is long forgotten. Wootz is distinct from the pattern<br />

welded/laminated steel we call “Damascus” today. Both steels however were known in ancient times and were<br />

around at the time the story was set in the 6th century. Denmark, the setting for Beowulf has been described as<br />

the spiritual and historical home of the Vikings. As intrepid traders, they established the Volga trade route<br />

from the 5th century which stretched from Sweden to Iran and beyond. Wootz steel is acknowledged to have<br />

been worked by smiths from China to Scandinavia, spread via the trade routes. The Vikings were also fond of<br />

laminated or pattern welded steel 3 which:<br />

“…is known to have existed as early as 500 BCE as it is found in some Celtic swords from that era.”4<br />

So which steel is described in Beowulf? I’m not going to venture an opinion. In my view, it’s impossible to<br />

know and in any event it hardly matters. So there you have it! That’s how classical literature fits with knives.<br />

Anyway Beowulf wasn’t able to kill Grendel’s mother with Hrunting, but not through any flaw in that sword.<br />

He did defeat the water witch with a sword or part thereof but you’ll need to buy the book and read about it<br />

yourself. Beo later goes on to slay a dragon with another “excellent ancient sword”, Næġling.<br />

Anyway Beowulf is a rollicking good read, if somewhat a little heavily at times due to the archaic language.<br />

As the oldest surviving poem in Old English and given the subject matter, in my view, it’s the original story<br />

that inspired the multitude of sword and sorcery tales ever since. Finally it provides a handy tip on how to<br />

temper a blade if you want to take out the Sydney Knife Show – blood!<br />

4 David J. Atkinson. Atkinson Collection: Swords and Knives, Pattern Welding.

Review - Procreate<br />

Software<br />

Harriss<br />

Chris<br />

Procreate is a natty little app for your ipad that will enable you to<br />

have some fun designing your next blade and help you to sketch<br />

out your latest and greatest etching and engraving ideas.<br />

"How's it work?" - Well here's a little video I did soon after I got the app.<br />

The layer feature really appeals to me. I have taken a photo of an antler in my shed, inserted<br />

that image onto my canvas and then proceeded to sketch the knife blade to suit.<br />

Save you design as a PDF or an image, print and you're ready to go back to the shed and use<br />

it to cut out your knife blank. You can do all sorts of other things, the only limitations - your<br />

time and imagination. I can see a whole new range of Damascus patterns emerging - maybe.<br />

Anyway for about thirteen bucks, the cheaper side of me approves!

We'd love to hear from the maker of this knife,<br />

Phil <strong>Ed</strong>wards. There's a story there somewhere.<br />

If you'd like to contribute to <strong>Australian</strong> <strong>Blade</strong><br />

drop us a line at qldfossicker@bigpond.com or<br />

catch us on Facebook.<br />

Apologies for any errors or omissions and<br />

thanks for reading!