MANmagazine Truck edition 1/2017 Great Britain

In this issue of MANmagazine, we introduce the many different areas in which our family of trucks can be used to meet a wide range of customer requirements. We accompany a TGM on a fire-fighting exercise in Izmir, take fuel to filling stations in Indonesia in a TGS, deliver "white goods" in a TGL and transport valuable sports cars to race tracks in a TGX. We also visit the high-tech Polish plant in Września on your behalf where MAN TGE vans are made. You can also read about how the RIO platform can open up new opportunities for the transport industry and why you can get way ahead with a long truck.

In this issue of MANmagazine, we introduce the many different areas in which our family of trucks can be used to meet a wide range of customer requirements. We accompany a TGM on a fire-fighting exercise in Izmir, take fuel to filling stations in Indonesia in a TGS, deliver "white goods" in a TGL and transport valuable sports cars to race tracks in a TGX. We also visit the high-tech Polish plant in Września on your behalf where MAN TGE vans are made. You can also read about how the RIO platform can open up new opportunities for the transport industry and why you can get way ahead with a long truck.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

01 / <strong>2017</strong><br />

<strong>Great</strong> <strong>Britain</strong><br />

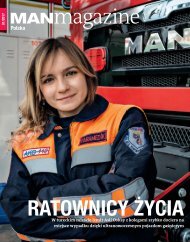

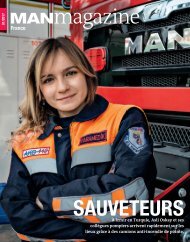

LIFESAVERS<br />

In Turkey’s city of Izmir, Asli Oskay and her firefighter colleagues<br />

ride modern engines to arrive at crisis points just in time

01 / <strong>2017</strong><br />

PERFORMANCE UP.<br />

CONSUMPTION DOWN.<br />

GREAT BRITAIN<br />

CONTENT<br />

06<br />

04 Extreme athlete<br />

Off to bungee jumping with the all-road truck<br />

06 Custom vehicles<br />

A look into the image archives illustrates<br />

the diversity of MAN.<br />

04<br />

08<br />

All-rounder:<br />

MAN covers an impressive range of operations<br />

with its truck portfolio: singular portraits of the<br />

TGX, TGS, TGM, TGL and TGE models.<br />

08 Picture-book family<br />

An overview of the five MAN truck models<br />

12 Pole position<br />

The TGX carries DTM cars to their races.<br />

16 Lifesavers<br />

In Turkey’s Izmir, TGM engines ensure that<br />

firefighters save valuable time.<br />

20 On location<br />

News from the British MAN market<br />

28 Carry on with caution<br />

A Munich-based forwarder delivers sensitive white<br />

goods with its TGL fleet.<br />

32 From tiny to tall<br />

On site at the highly modern TGE plant in Poland<br />

36 Timber tech<br />

MAN ProfiDrive training for the logging industry<br />

20<br />

The new MAN TGX<br />

We present you with our best tool against cost pressure on the road: the new MAN TGX.<br />

With drive tuned ideally for efficiency and performance, you can gain even more from every<br />

single drop of fuel: more distance, more torque and power, more reserves. Because we have<br />

invested no end of expertise in it and incorporated a whole range of improvements such<br />

as MAN EfficientCruise® and MAN EfficientRoll, LED daytime driving lights, light and rain<br />

sensors and also a new infotainment system. Find out more about the best MAN TGX of all<br />

time at www.truck.man<br />

MASTHEAD<br />

<strong>MANmagazine</strong> is published twice a year in 16 languages. PUBLISHED BY MAN <strong>Truck</strong> & Bus, Stefan Klatt (resp.), Dachauer Straße 667, 80995 Munich, Germany EDITOR IN CHIEF & PROJECT MANAGER Joachim Kelz,<br />

Tel.: +49. 89. 1580-1175, magazin@man.eu, www.man.eu EDITORIAL GREAT BRITAIN Verity Cullum PUBLISHER C3 Creative Code and Content GmbH, Heiligegeistkirchplatz 1, 10178 Berlin, www.c3.co. Shareholders of C3 Creative<br />

Code and Content GmbH are the Burda Gesellschaft mit beschränkter Haftung (limited liability company), Offenburg (85%), and the KB Holding GmbH, Berlin (15%). Sole shareholder of the Burda Gesellschaft mit beschränkter Haftung is<br />

the Hubert Burda Media Holding Kommanditgesellschaft (limited partnership), Offenburg. Shareholders of the KB Holding GmbH are Lukas Kircher (managing director, Berlin) and Rainer Burkhardt (managing director) to 50% each.<br />

CONTENT DIRECTOR Klaus-Peter Hilger EDITORS & AUTHORS Yasmine Sailer (resp.), Uli John-Ertle, Jutta Schreiner; freelance authors: Diana Gäntzle, Richard Kienberger, Philipp Mattheis, Marcus Schick<br />

EDITORS, INTERNATIONAL EDITION Patricia Preston (freelance, resp.), Asa C. Tomash PROJECT MANAGEMENT Sara Austen-Schrick GRAPHICS Igor Clukas, Michael Helble, Christian Kühn, Micheline Pollach IMAGE EDITORS<br />

Elke Maria Latinovic, Samantha Taruvinga COVER IMAGE Monique Jaques PRODUCTION C3 Creative Code and Content GmbH PRINTING Gotteswinter und Aumaier GmbH, Joseph-Dollinger-Bogen 22, 80807 Munich, Germany<br />

REPRODUCTION permitted with reference. Any changes must be coordinated with the editors. ADVERTISING SALES Zeitzeichen Vertriebs GmbH, Radka Neumann, Tel.: +49. 8323. 9984630, radkaneumann@zeitzeichen.de<br />

COPYRIGHT ©<strong>2017</strong> MAN and C3 Creative Code and Content GmbH<br />

03

01 / <strong>2017</strong><br />

”My passengers are<br />

adventure-seekers from<br />

around the world.”<br />

John Hughes, bus driver at AJ Hackett<br />

Bus and truck driver in one: The 57-year-old<br />

John Hughes has been driving trucks since<br />

1996.These days, he’s not moving goods, but<br />

rather conveying tourists in his MAN.<br />

Working for the New Zealand-based<br />

adventure company AJ Hackett, John Hughes<br />

drives tourists from Queenstown to bungee<br />

jumping hot spots in the vicinity. As these sites<br />

are unreachable by bus due to extreme road<br />

conditions, including steep inclines and gravel<br />

tracks, Hughes operates an MAN all-wheeler<br />

with a 44-seat omnibus superstructure. In<br />

four years, his truck has chalked up about<br />

350,000 kilometres.<br />

Mr Hughes, how did you become a truck<br />

driver? That’s a funny story, actually. For<br />

quite a while, I worked as the co-driver for a<br />

municipal truck. One day, the driver broke his<br />

ankle somewhere in the outback. Since there<br />

wasn’t any phone service, I simply plopped<br />

myself behind the steering wheel and drove<br />

my injured colleague back. When we arrived<br />

at the depot, my boss spotted us and simply<br />

said, “You can drive? Well, you’re a driver<br />

now.” Naturally, I also went and got my truck<br />

licence after that.<br />

Where do the customers whom you<br />

transport in your MAN come from? Our<br />

customers are mainly young and adventurous<br />

people. Backpackers are definitely the<br />

majority. Lots of them come from Germany,<br />

but also from Asia – especially from Japan.<br />

During the journey back after bungee<br />

jumping, can you still see the spark in your<br />

passengers’ eyes? Oh, no. Most of them are<br />

completely worn out by the adrenaline kick.<br />

Many call home to talk with their mums and<br />

dads. “Guess what I just did!” That’s the phone<br />

phrase I usually hear.<br />

Have you already experienced a special<br />

moment with your MAN? Yes, just a short<br />

while ago. Since the adventure activities here<br />

around Queenstown are so very unique, our<br />

locations are repeatedly booked for shooting<br />

commercials. The last TV spot that my truck<br />

and I got the chance to appear in was viewed<br />

by four million people. Just my mum has not<br />

seen it yet, for she doesn’t have a computer.<br />

Extreme<br />

athlete<br />

All-wheel bus: The converted truck<br />

offers seating for 44 passengers.<br />

Robust and rugged: The MAN 15.290 4x4 easily<br />

handles steep inclines and gravelled off-road<br />

tracks on the South Island of New Zealand.<br />

MY MAN<br />

© Richard Kienberger<br />

04<br />

05

01 / <strong>2017</strong><br />

Custom vehicles<br />

From construction and municipal vehicles to lumber trucks,<br />

city buses and intercity coaches to fire trucks: MAN has always<br />

appealed to every sector with the right solutions.<br />

CITY BUSES AND INTERCITY COACHES<br />

Intercity coaches (below) were widely known, as<br />

they transported both passengers and mail. The<br />

early 1920s then witnessed the first open-topped<br />

coaches (right), which became very popular for<br />

undertaking regional excursions.<br />

BACK IN 1915, MAN began building<br />

commercial vehicles. The first trucks and<br />

buses were built in southern Germany’s<br />

Lindau in cooperation with the Swiss<br />

manufacturer Saurer, until production<br />

was moved to Nuremberg in 1916. During<br />

the early years, MAN and Saurer still<br />

followed a strongly regulated production<br />

agreement. MAN was not permitted to<br />

make any autonomous construction<br />

changes and therefore focused primarily<br />

on making vehicle bodies. This resulted<br />

in MAN developing a high level of<br />

industry expertise early on, which is still<br />

being reflected by the company’s wide<br />

range of vehicles.<br />

1951: F8 tipper for reconstruction<br />

© MAN archives<br />

1921: Post coach 1922: Open-topped coach<br />

LUMBER TRUCKS<br />

The Munich-based building company Stöhr became one of MAN’s very first customers.<br />

In order to navigate tight curves, the driver’s assistant also had to muster all available power<br />

to help turn the steering wheel. Occasionally, another passenger rode along on the vehicle’s<br />

rear end – the trailer – to support the braking process.<br />

1916: Lumber truck<br />

1922: Semi-trailer truck<br />

TRACTOR-TRAILERS<br />

MAN manufactured the first tractor-trailers<br />

as early as 1921/22.<br />

1921: Rotating tipper 2016: TGS<br />

MUNICIPAL VEHICLES<br />

As early as 1915, MAN supplied a sewage truck<br />

to the city of Nuremberg – namely a 4-tonner with<br />

30 hp. Numerous repeat orders followed, primarily<br />

for refuse collection trucks and road sprinklers<br />

(below), the predecessors of today’s sweepers.<br />

FIRE ENGINES<br />

MAN already supplied fire trucks back in 1916.<br />

Among other orders, eight fire engines went to<br />

Munich’s professional fire brigade, while six were<br />

delivered to the city’s volunteer firefighters.<br />

1915: Brewery truck<br />

CONSTRUCTION VEHICLES<br />

MAN’s truck plants introduced their first rotating<br />

tipper as early as 1921 (above). Drivers could<br />

operate the tipper without leaving their seat – a true<br />

innovation. Today, MAN offers a complete range of<br />

construction truck series, including the TGE, TGL,<br />

TGM, TGS (right) and TGX.<br />

1918: Road sprinkler<br />

1921: Fire engine<br />

BEER TRANSPORTERS<br />

Breweries were some of the first enterprises to<br />

transition from horse-drawn carriages to trucks,<br />

which allowed them to commence with transregional<br />

delivery. Renowned companies, such as Munich’s<br />

breweries Augustiner (above), Paulaner and<br />

Löwenbräu, were among the first customers of MAN.<br />

06<br />

07

01 / <strong>2017</strong><br />

Picture-book<br />

family<br />

41<br />

tonnes<br />

total weight is how much the MAN TGX<br />

and the MAN TGS are permitted to carry.<br />

They hereby cover the heaviest transport<br />

segment.<br />

Commercial vehicles by<br />

MAN are deployed in<br />

almost every business<br />

area. Be it construction,<br />

technology or equipment:<br />

The truck family is flexible<br />

enough to cover a vast<br />

range of customer needs.<br />

An overview.<br />

Find the entire MAN truck family<br />

at a glance under<br />

> www.truck.man/series-overview<br />

Upon introducing the MAN TGE at<br />

the 2016 IAA Commercial<br />

Vehicles trade show, MAN<br />

expanded its product portfolio,<br />

thus becoming a full-range<br />

provider of commercial vehicles<br />

and covering all weight classes. It begins with<br />

light commercial vehicles with 3.0 tonnes of<br />

permissible total weight and ranges up to<br />

41-tonners for use in the heavy-duty transport<br />

segment. Depending on configuration and deployment,<br />

this allows for an overall gross combination<br />

weight of up to 250 tonnes. Thus, MAN<br />

trucks are suitable for a most diverse range of<br />

applications – whether in long-distance<br />

transport, in construction or in distribution<br />

traffic, and wherever special trucks are needed.<br />

The performance<br />

artist: MAN TGX<br />

With its powertrain trimmed for efficiency<br />

and performance, the TGX delivers heavyduty<br />

performance every day. This transport<br />

professional is especially competent in longdistance<br />

transport, easily handles ascents and<br />

reaches high transport speeds even on tough<br />

routes. Its proficiency is ensured by the supplemental<br />

range of six-cylinder rail engines,<br />

optional with a range of 360 hp to 640 hp. In<br />

addition to lightweight components and aerodynamic<br />

solutions, assistance systems simultaneously<br />

minimise fuel consumption. In<br />

2016, the TGX EfficientLine 3 proved this yet<br />

again: In the latest model generation, the<br />

anticipatory GPS-controlled EfficientCruise<br />

speed control also manages the EfficientRoll<br />

freewheel mode, thereby saving even more<br />

fuel. The new MAN TGX thus sets the<br />

benchmark for the greatest transport efficiency,<br />

reliability and economy. Furthermore, the<br />

new TG series from MAN offer the best ergonomics<br />

for drivers. The driver’s cabs for longdistance<br />

transport, for example, stand out<br />

with perfect comfort for living and sleeping.<br />

A broad range of configurations with<br />

various wheelbases, and different coupling<br />

heights for variable Eurotrailers and volume<br />

trailers, allows this performance artist to<br />

handle every transport task flexibly. Read<br />

about how TGX trucks transport DTM race<br />

cars – along with their entire workshops – to<br />

their race track venues, on page 12.<br />

© Ben Poser<br />

The top achiever: MAN TGS<br />

The MAN TGS shoulders quite a load: It serves tinuous damping control for roll stabilisation<br />

in continuous operations for heavy distribution,<br />

municipal and construction deploy-<br />

centre of gravity, such as swap body trucks or<br />

is also available for vehicles with a high<br />

ment as well as national and near-border timber transporters.<br />

long-distance transport. The transport sector<br />

relies on the MAN TGS when heavy-duty<br />

loads such as timber, bricks and much more<br />

must be reliably hauled to their destinations.<br />

In Indonesia, for example, the national<br />

mineral oil company Pertamina deploys TGS<br />

rigs to supply fuel to petrol stations. The<br />

efficient powertrain with the new six-cylinder<br />

common-rail diesel engines delivers up<br />

to 500 hp and makes it possible to save the<br />

maximum amount of fuel. Transport safety<br />

also plays an important role in the MAN TGS:<br />

It is available with an Electronic Stability<br />

Programme (ESP), Adaptive Cruise Control<br />

(ACC), Lane Guard System (LGS) and<br />

Emergency Brake Assist (EBA). An active con-<br />

08<br />

09

01 / <strong>2017</strong><br />

The powerhouse:<br />

MAN TGM<br />

Thanks to its first-class load capacity,<br />

economy and reliability, the MAN TGM is an<br />

established player in medium-duty traction<br />

and distribution transport. The common-rail<br />

D08 engine with high output density<br />

installed in the trucks of this class is available<br />

with 250 hp to 340 hp, depending on the<br />

vehicle’s weight class. Wherever special crosscountry<br />

mobility is needed, the TGM<br />

two-axle vehicles, which come in 13-tonne<br />

and 18-tonne total weight versions, can<br />

clearly show off their attributes: Due to their<br />

all-wheel drive, they can handle nearly any<br />

surface. Deployed on construction sites – for<br />

example, as a three-way tipper or skip loader,<br />

equipped with a loading crane, or as a<br />

concrete mixer truck – its frame with its<br />

maximum lightweight construction is<br />

extremely stable and weight-bearing. It<br />

comes as no surprise that TGM trucks are<br />

also used by many fire brigades – including<br />

in the Turkish port city of Izmir, where firefighting<br />

crews head out with two TGM trucks<br />

that are outfitted with state-of-the-art<br />

equipment (starting on page 16).<br />

The athlete: MAN TGE<br />

Transporters for the light-duty segment were<br />

still missing from MAN’s portfolio – until the<br />

autumn of 2016, that is. At last year’s IAA<br />

Commercial Vehicles trade show in Hanover,<br />

the TGE was introduced for the weight<br />

category from 3.0 to 5.5 tonnes, thus closing<br />

the gap and rendering MAN a full-range<br />

provider. The newcomer is produced in<br />

Września, Poland, in a recently built, ultramodern<br />

plant (report starting on page 32),<br />

which was designed for a wide range of<br />

variants. The TGE comes with a choice of four<br />

diesel engines with an output of 102, 122, 140<br />

and 177 hp and, depending on the total permissible<br />

weight, three different types of<br />

drive: front-wheel, all-wheel and rear-wheel<br />

drive. In addition, there are also two wheelbases,<br />

three roof heights, three vehicle<br />

lengths and various body designs. Depending<br />

on the combination, the delivery van offers a<br />

maximum cargo volume of 18.3 cubic metres.<br />

This very generous storage room is accompanied<br />

by high load reserves. Consequently, the<br />

transporter is not only suitable for use in distribution<br />

transport and building craft, but<br />

also useful for trade and passenger transport.<br />

3.0<br />

tonnes<br />

total weight is how much the light MAN<br />

TGE covers. It is the smallest member of<br />

the truck family.<br />

The agile one:<br />

MAN TGL<br />

Because of their short wheelbases, the trucks<br />

in the TGL series are extraordinarily flexible<br />

and can handle even the tightest turns in<br />

inner cities. The 7.5- to 12-tonners can also<br />

handle transport tasks in densely built-up<br />

areas, and have therefore become popular allrounders<br />

for use in municipalities, in trade<br />

and business, in construction, and especially<br />

in classic distribution transport. They can be<br />

configured precisely for each area of deployment,<br />

be it as a road salt vehicle, refrigerated<br />

transporter or beverage truck with a low<br />

loading edge. They combine maximum<br />

payload with high loading capacity, low fuel<br />

consumption and simple handling. This is<br />

ensured by the powerful D08 engines with<br />

150 hp to 250 hp. The four- and six-cylinder<br />

trucks can also be optionally equipped with<br />

the comfortable, automated TipMatic gearbox<br />

with integrated EasyStart. How the TGL<br />

performs reliably in regional distribution<br />

transport, is explained as of page 28.<br />

© Ben Poser<br />

10<br />

11

12<br />

POLE<br />

01 / <strong>2017</strong><br />

How do DTM cars journey to the race track?<br />

With trucks made by MAN. At least the racers<br />

competing for the racing team Audi Sport<br />

Team ABT Sportsline, based in southern<br />

Germany, do. We went along for the ride, from<br />

the workshop in Kempten to Hockenheim.<br />

Right off, it will become quite a<br />

squeeze again. The man behind<br />

the wheel of the Audi race car is<br />

completely focused – as this<br />

spot is about mere centimetres.<br />

Speed is not what matters today,<br />

however, but rather the most finely honed of<br />

skills. The DTM season finale on Germany’s<br />

famous Hockenheimring is coming up shortly<br />

and preparations are in full swing in the<br />

enormous hall of the Audi Sport Team ABT<br />

Sportsline racing team. The cars must be<br />

moved from the workshop in Kempten,<br />

located in the Allgäu region in southern<br />

Germany, to the race track. As Mattias Ekström,<br />

an Audi legend in the DTM and an all-rounder<br />

in motor racing, is absent due to competing in<br />

the rallycross championships, only four cars<br />

polished to a glossy shine are being loaded this<br />

time around – namely those driven by teammates<br />

Miguel Molina, Edoardo Mortara, Nico<br />

Müller and Mike Rockenfeller. With open tailboards,<br />

four equally buffed silver TGX 18.480<br />

trailers stand waiting for their precious cargo.<br />

CLEANLINESS IS AN IMPORTANT FACTOR in<br />

the DTM universe. “No team would ever<br />

dream of showing up with a dirty car or an<br />

unwashed truck,” says Johannes Riedmüller,<br />

Head of Fleet and Logistics for Audi Sport<br />

Team ABT Sportsline. Riedmüller makes sure<br />

that materials from the workshop in Kempten<br />

aren’t just clean but also complete when they<br />

arrive at the race course – ranging from the<br />

screwdrivers to spare parts and tires up to the<br />

cars themselves. “We require fully equipped<br />

workshops in the pit lane,” he explains. In<br />

handling this mammoth logistical task, he<br />

© Guenther Bayerl<br />

POLE POSITION<br />

13

„<br />

floor”<br />

01 / <strong>2017</strong><br />

We transport entire workshops,<br />

and it’s a herculean task.”<br />

Johannes Riedmüller, Head of Fleet and Logistics for Audi Sport Team ABT Sportsline<br />

Precision work: The trailer<br />

on the MAN TGX is barely<br />

wider than the Audi race car.<br />

relies on his team members, his decade of<br />

expertise – and on trucks made by MAN.<br />

During Germany’s Deutsche Tourenwagen<br />

Masters (DTM) tournament, the three car<br />

manufacturers Audi, BMW and Mercedes are<br />

competing for the title with a total of 10 teams<br />

and 24 drivers. Over the course of the season’s<br />

nine racing weekends, the vehicles are<br />

serviced and repaired if necessary in the<br />

teams’ workshops. Each team has its own<br />

“Official <strong>Truck</strong> Supplier” for transport. The<br />

managers of Audi Sport Team ABT Sportsline<br />

collaborate with MAN. On this late morning in<br />

mid-October, Riedmüller’s 12-member team<br />

has already pushed powerful flight cases and<br />

metal boxes the size of refrigerators into the<br />

TGX trailer. These are followed by stacks of<br />

tires, the motor scooter and e-bikes for the<br />

drivers, spare parts, rims, tools, ladders, cable<br />

spools, brooms. Altogether, 70 cubic metres of<br />

materials have vanished into each truck.<br />

Now the great moment has arrived and it<br />

is time to load the race car: Four men finesse<br />

an Audi racer onto the powerful hydraulic lift<br />

behind the trailer. The mechanic behind the<br />

wheel steers and brakes while the others<br />

manoeuvre it forwards and backwards. How<br />

the RS 5 is raised upwards by the strong<br />

hydraulic lift into what is basically the “upper<br />

Final sprint: The TGX carries<br />

its precious cargo into the pit<br />

lane at the Hockenheimring.<br />

Piece by piece:<br />

Within just a short<br />

while, a complete<br />

workshop emerges<br />

from the trailer.<br />

© Guenther Bayerl<br />

Best outlook: The driver’s<br />

cab of the TGX truck is<br />

equipped with every amenity.<br />

Successful trio:<br />

Ekström, ABT and MAN<br />

THE SWEDISH RACE CAR DRIVER Mattias<br />

Ekström has been racing for the Audi Sport<br />

Team ABT Sportsline in the Deutschen<br />

Tourenwagen Masters (DTM) tournament<br />

since 2001. With his two DTM titles from<br />

2004 and 2007, he is viewed as one of the<br />

world’s best touring car racers and also is<br />

the most senior and successful Audi driver<br />

in the DTM. For more than 20 years, the<br />

Audi Sport Team ABT Sportsline outfit has<br />

depended on the reliable MAN trucks to<br />

transport its valuable race cars.<br />

of the trailer looks awfully risky. Such<br />

an undertaking requires millimetre precision.<br />

As the trailer is not wide enough, the driver’s<br />

side door of the race car has been removed.<br />

Once having arrived on top, the car is pushed<br />

into the narrow cargo space and lashed into<br />

place with tension belts. This action is<br />

repeated three more times until all Audi cars<br />

are stored in the trucks and readied for their<br />

journey to the race track.<br />

Logistics expert Riedmüller – who is also<br />

one of the truck drivers – climbs into his TGX<br />

vehicle and starts the engine. Astonishingly,<br />

the 480-hp motor is barely audible in the<br />

driver’s cab. In fact, it is surprisingly comfortable,<br />

if not even cosy inside the cab. Installed<br />

behind the driver’s seat is a comfortable<br />

sleeping cot along with adequate storage space<br />

and reading lights for the driver and assistant.<br />

“There are certainly worse places to work,”<br />

Riedmüller says with a laugh, before setting<br />

off in his truck. About 300 kilometres lie<br />

between ABT headquarters in Kempten and<br />

his destination, the race track in Hockenheim,<br />

located in the state of Baden-Württemberg.<br />

THICK LAYERS OF FOG are rolling over the<br />

Hockenheimring this morning. The trucks of<br />

every team stand assembled on a large field<br />

next to the switchback, including the four<br />

silver-grey MAN trucks servicing the ABT<br />

Sportsline stable. Work begins at 10:00 a.m.<br />

sharp. The first trucks head across the home<br />

straight to the sponsored Ravenol curve, then<br />

turning into the pit lane. The loading crew<br />

members are still in a relaxed mood, sharing<br />

wisecracks with colleagues on the other<br />

teams. Then things get started. Riedmüller<br />

stands in front of one of the two ABT pits and<br />

waits for the first truck. The tailboards open,<br />

and in no time the men are carrying the hard<br />

boxes, stacks of tires, rims, tools and spare<br />

parts to their designated places. The cars are<br />

covered by fabric tarps. As soon as they have<br />

rolled off the truck ramp, they’re pushed into<br />

the pit. “We try to limit any opportunity for<br />

other teams to discover what might be new or<br />

different about the vehicle as much as<br />

possible,” explains Riedmüller. After all, the<br />

Audi Sport Team ABT Sportsline still has<br />

every chance on the last DTM racing day. In<br />

less than three hours, the trucks are emptied<br />

and the workshop has been readied in the<br />

Audi pit. Johannes Riedmüller can take a deep<br />

breath. He and his crew have created the<br />

perfect setting for a successful racing<br />

weekend. “Now it is up to the others to win,”<br />

he says with a smile.<br />

Pit stop: Speed and<br />

precision are also critical<br />

when unloading the race<br />

cars and equipment.<br />

14<br />

15

01/<strong>2017</strong><br />

Inspection: Kansu<br />

Ozurtürk checks<br />

his equipment<br />

before climbing<br />

one of the ladders.<br />

Close and personal: The<br />

fire brigade even advances<br />

to the historic clock tower<br />

in the heart of the city.<br />

Strong presence: Whenever needed,<br />

the two fire trucks will be on the scene<br />

anywhere in the port city.<br />

The fire brigade serving Izmir in Turkey is experiencing a push for modernisation.<br />

This includes Rosenbauer fire trucks based on MAN chassis and equipped with the latest<br />

technology. They offer firefighters the sometimes decisively critical factor: time.<br />

LIFE-<br />

SAVERS<br />

© Monique Jaques<br />

N<br />

ever losing faith is the most important<br />

thing. “Firefighters will<br />

maintain hope until the end,”<br />

says Serdar Yücel, Captain of the<br />

Izmir Fire Brigade. There are 130<br />

people working here, with 80 of<br />

them on active service and the others engaged<br />

in administrative duties.<br />

Sirens wail. Volkan Salgut, Kansu Ozurtürk,<br />

Asli Oskay and four other emergency personnel<br />

sprint across the courtyard to the fire<br />

truck. The MAN TGM 18.290 is among the most<br />

advanced of its kind, a 290-hp 18-tonner designed<br />

for six firefighters. Their duties are<br />

clearly defined: Salgut is the driver and, once<br />

on site, operates the pumps to fill the hoses<br />

with water or foam. Team leader Ozurtürk coordinates<br />

the individual tasks. The staff of four<br />

in the crew compartment are the firefighters.<br />

As respirators and breathing air bottles are installed<br />

in their back rests, they can be easily<br />

donned during the journey just like a backpack<br />

– and the firefighters are able to walk through<br />

fire with breathing equipment. The truck rear<br />

holds reservoirs of water and foam, a power<br />

generator, and a multitude of tools, including<br />

chainsaws, jet pipes and hoses. A second vehicle<br />

transports four more firefighters and carries<br />

a ladder on the roof that can extend up to<br />

32 metres. This makes even higher-up flats ac-<br />

„<br />

cessible for the firefighting crew. Together, the<br />

two vehicles make the perfect combination<br />

for deployment. Salgut takes off, with the second<br />

vehicle in his wake.<br />

IZMIR IS INDEED NOT AN EASY PLACE for a fire<br />

brigade. With four million residents, Turkey’s<br />

third-largest city is built around a bay. Residential<br />

buildings rise steeply from the sea to<br />

the slopes, and the streets are narrow and<br />

winding. Since the economic boom in the<br />

2000s, the number of cars has multiplied exponentially.<br />

The result is heavy traffic, often<br />

making it hard for the fire brigade to get<br />

through. Due to modern technology, however,<br />

the crew makes it to the deployment site faster<br />

than before – much faster, actually. “We<br />

once needed about 15 minutes to get from the<br />

station to the call site,” says Yücel. “Nowadays<br />

it takes between six and eight minutes.” Min-<br />

Izmir<br />

Izmir<br />

Turkey<br />

With more than four million residents,<br />

Izmir is the third-largest city in Turkey<br />

and the capital of Izmir Province. The<br />

metropolis on the Aegean coast in the<br />

Gulf of Izmir is also home to the nation’s<br />

second-largest harbour, behind Istanbul.<br />

We reach the<br />

call site in six to<br />

eight minutes.”<br />

Serdar Yücel, Captain of Izmir’s fire brigade<br />

16<br />

17

01/<strong>2017</strong><br />

Urban traffic: The vehicles don’t always<br />

find such clear roads, but must often fight<br />

their way through traffic instead.<br />

Female pioneer: Emergency technician<br />

Asli Oskay is still the only woman on Izmir’s<br />

fire brigade. For now, as modernisation<br />

efforts are also underway here.<br />

ternet presence, and virtual visitors to the<br />

website are now greeted by a group of women<br />

in uniform. That doesn’t quite match reality:<br />

Asli Oskay is the only female staff member not<br />

working in administration. “Yet the numbers<br />

are growing,” says the 22-year-old emergency<br />

medical technician.<br />

SERDAR YÜCEL IS ALSO INVESTING in new<br />

equipment, including two MAN TGM-series<br />

trucks equipped with state-of-the-art technology.<br />

“At the same time, these vehicles offer the<br />

best price-to-performance ratio,” says Bülent<br />

Tosun, chief of fire operations. Important features<br />

include the 290 hp and the automatic<br />

Just one button: The built-in pump<br />

is easy to operate and delivers<br />

3,500 litres of water per minute.<br />

utes can mean lives. The goal is to get to an<br />

emergency in no more than five minutes.<br />

Yücel, formerly department chief in charge<br />

of maritime affairs at the municipality, assumed<br />

his position at the fire brigade four<br />

years ago. At that time, the mayor was seeking<br />

an individual with a strong vision, someone he<br />

could trust to modernise Izmir’s fire brigade.<br />

Yücel first travelled to Austria, Germany and<br />

then Finland to learn from colleagues there.<br />

“One problem is that Turkey has hardly any<br />

voluntary fire brigades,” says the 53-year-old.<br />

“In addition, many young people shy away<br />

from the hard work hours and the relatively<br />

low pay earned by professional firefighters.” In<br />

Izmir, the team works in 24-hour shifts with<br />

48 hours in between. The long-term plan is to<br />

allow a 72-hour break, as is customary practice<br />

in other countries. Employees earn a monthly<br />

salary of around €1,000. To promote his profession,<br />

Yücel modernised the fire brigade’s In-<br />

© Monique Jaques<br />

drive. “This accelerates the journey, and I can<br />

focus on other things,” says Salgut. While one<br />

electronic control panel next to the dashboard<br />

indicates the filling levels of extinguishing fluids,<br />

another connects the vehicle to the communication<br />

system. The manufacturer Rosenbauer<br />

provides both the structure and the<br />

entire firefighting technology. Yücel is also<br />

proud of the risk management system. An interactive<br />

map shows call probabilities based on<br />

empirical data. On it, he can also see the two<br />

vehicles that have reached the motorway<br />

headed towards the coast and are now stuck in<br />

traffic. “Unfortunately, Turkish drivers are still<br />

not taught how to form an emergency lane,”<br />

says Salgut. That eats up time. With the help of<br />

blaring sirens, the vehicles can advance only<br />

slowly. Kansu Ozurtürk, the senior firefighter<br />

in the group with 16 years of experience, emphasises<br />

that while traffic used to be better, today<br />

the vehicles are much improved: “Because<br />

of modern technology, we can use the pumps<br />

more quickly, so we save precious minutes at<br />

the call site.”<br />

The team heads out about five times each<br />

day. Half of the calls relate to putting out fires.<br />

“Buildings in Izmir are often more than 40<br />

years old and outdated,” says Yücel. “That<br />

makes houses susceptible to fires.” The rest of<br />

the calls are traffic accidents, suicide attempts<br />

and stray pets.<br />

After just over seven minutes, the two vehicles<br />

reach the destination of their training<br />

call, Izmir’s famous clock tower. Children immediately<br />

surround the team while their parents<br />

take photos. “The nicest part of this job is<br />

that you get so much back,” says Yücel, before<br />

he tells us the story of two brothers, who one<br />

day came up with the questionable idea of<br />

searching for treasure in an old well. Once the<br />

two men in their mid thirties had dug down to<br />

about 10 metres, the walls of the well suddenly<br />

collapsed. Hundreds of rocks buried one of the<br />

brothers. For two days, the fire brigade removed<br />

them, one by one. The man’s family<br />

stood at the accident site, crying, hoping,<br />

doubting. After 48 hours, they heard the brittle<br />

voice of the buried man. Two days later, he<br />

was freed. “That was an indescribable feeling,”<br />

says Yücel.<br />

Obviously, daily routine isn’t always that<br />

dramatic. “We’re also often called to rescue<br />

cats that climbed up too tall a tree and are<br />

afraid to come back down,” says Kansu. Even<br />

here, a firefighter must never give up hope.<br />

„We save precious<br />

minutes thanks to<br />

modern equipment.”<br />

Kansu Ozurtürk, firefighter in Izmir<br />

MAN fire trucks are deployed around the<br />

world – such as at Munich’s airport:<br />

> www.truck.man/airport-fire-brigade<br />

18<br />

19

01 / <strong>2017</strong><br />

On the road with<br />

the green<br />

business hauler<br />

the side of the cabs and an intense green<br />

overall paint job.<br />

The company was established back in 1961<br />

and still proudly remains a family-run firm<br />

today. As Parry & Evans has enjoyed continuous<br />

expansion, each new management generation<br />

contributed to innovations that have<br />

resulted in steady growth.<br />

“These new vehicles will be put to work<br />

across the country, and with MAN we know<br />

our drivers will be happy – essential in daily<br />

operations,” observed Lee Evans, Operations<br />

Director at Parry & Evans. “The cabs are<br />

spacious and comfortable, and from a<br />

business perspective they are both economical<br />

and reliable.” The recycling company took<br />

out the full repair and maintenance contracts<br />

on all vehicles and found the A. N. Richards<br />

dealership to be very helpful throughout the<br />

process. The choice fell on interim rental<br />

vehicles using the spot-hire package.<br />

MAN sales executive Chris Clee said: “It is<br />

indeed a credit to MAN that customers like<br />

Parry & Evans show such loyalty to the MAN<br />

brand. The trucks will look fantastic on the<br />

road, as the design is truly eye-catching.”<br />

Vehicle information<br />

MODEL<br />

TGS 26.400 6x2-2 BL<br />

With rear steering axle<br />

CAB<br />

M day<br />

ENGINE<br />

D2676LF 6-cylinder<br />

12.4-litre<br />

POWER<br />

400 hp at 1,800 rpm<br />

TORQUE 1,900 Nm at 930–1,400 rpm<br />

“TopTorque”<br />

GEARBOX MAN Tipmatic 12 Speed<br />

SUSPENSION<br />

Steel/air<br />

WHEELBASE 4,200 mm + 1,350 mm<br />

Rear bogie spread<br />

PLATED WEIGHT<br />

44,000 kg GTW<br />

Premier recycling company Parry & Evans expands<br />

its service fleet with MAN <strong>Truck</strong> & Bus UK vehicles.<br />

Becoming colours: The striking<br />

company colours and logo<br />

emphasise identity and image.<br />

Seeking to meet rising demand in<br />

services due to growing environmental<br />

awareness, recycling<br />

specialist Parry & Evans ordered<br />

seven MAN vehicles of different<br />

series from MAN <strong>Truck</strong> & Bus<br />

UK. Based in Welshpool, eastern Wales, the<br />

paper and cardboard recycling company has<br />

been in business for more than 50 years and<br />

has grown into one of the leading recycling<br />

companies in the UK.<br />

With the addition of three new MAN TGS<br />

26.400 6X2-2 BL trucks, an MAN TGX 26.480<br />

6X2-2 BLS, as well as three MAN TopUsed<br />

vehicles, including two MAN TGX 26.440 XLX<br />

tractor units, Parry & Evans now operates<br />

more than 25 vehicles in their fleet.<br />

All trucks will be decked out in the rather<br />

striking company design of Parry & Evans,<br />

which features a large red Welsh dragon on<br />

Vehicle information<br />

MODEL<br />

TGX 26.480 6x2/2 BLS<br />

CAB<br />

XLX sleeper<br />

Air-management kit<br />

ENGINE<br />

D2676LF 6-cylinder<br />

12.4-litre<br />

POWER<br />

480 hp at 1,800 rpm<br />

TORQUE 2,300 Nm at 930–1,400 rpm<br />

“TopTorque”<br />

GEARBOX MAN Tipmatic 12-speed<br />

SUSPENSION<br />

Steel/air<br />

WHEELBASE<br />

2,600 mm<br />

Rear bogie spread<br />

PLATED WEIGHT<br />

44,000 kg GTW<br />

With MAN, we know that our<br />

drivers are happy. That is essential<br />

in daily operations.”<br />

Lee Evans, Operations Director, Parry & Evans<br />

© Xxxxxxx name Xxxxx<br />

20<br />

21

01 / <strong>2017</strong><br />

Concrete order boost for<br />

MAN in Northern Ireland<br />

Based in Enniskillen, Northern<br />

Ireland, and one of the largest<br />

precast concrete manufacturers<br />

in the UK as well as Ireland,<br />

Tracey Concrete received three<br />

new MAN TGS 35.440 8x4 vehicles<br />

fitted with Liebherr mixers from MAN<br />

<strong>Truck</strong> & Bus UK to join its ready-mix fleet.<br />

The company required particularly sturdy,<br />

enduring and reliable vehicles, and MAN‘s<br />

portfolio provided just the right product.<br />

“We operate a fleet of approximately<br />

30 trucks, and half of our more recent additions<br />

are manufactured by MAN,” said company<br />

manager Anton Tracey. “We specifically<br />

opted for the MAN TGS and the 8x4 spec<br />

because we were looking for a vehicle with a<br />

strong chassis. They will be delivering<br />

ready-mix concrete and flow screed to local<br />

sites with rough, hilly terrain, and the 440<br />

engine is ideally suited for this.”<br />

The specialised vehicles were purchased<br />

due to a company expansion, and also in order<br />

to rejuvenate the fleet of Tracey Concrete.<br />

The cab trucks are powered by<br />

Off to rough terrain:<br />

The MAN TGS 8x4s can<br />

tackle the hard jobs.<br />

D2676LF 6-cylinder 12.4-litre engines with<br />

an output of 440 hp, and feature manual<br />

transmissions and steel suspensions.<br />

Brian Beattie, MAN area sales manager,<br />

added: “Tracey Concrete is a well-known<br />

company, and we are glad to deliver vehicles<br />

that can meet their exacting requirements.<br />

While the trucks will certainly be put to the<br />

test out there, we are very confident that<br />

they will stand up to the tough challenges<br />

ahead and deliver on the efficiency as well<br />

as quality that MAN is known for.”<br />

Vehicle information<br />

MODEL:<br />

TGS 35.440 8x4 BB<br />

CAB:<br />

M day cab<br />

ENGINE:<br />

D2676LF 6-cylinder<br />

12.4-litre<br />

POWER:<br />

440 hp at 1,800 rpm<br />

TORQUE: 2,100 Nm at 930–1,400 rpm<br />

GEARBOX:<br />

16S223 Manual OD<br />

SUSPENSION:<br />

Steel/steel<br />

WHEELBASE:<br />

3,205 mm<br />

PLATED WEIGHT: 32,000 kg GVW<br />

Spotlight of recognition<br />

on MAN aftersales<br />

THE MAN TRUCK & BUS UK dealership located in<br />

Preston once again assisted the HPH Group, a<br />

Lancashire-based warehousing and distribution<br />

company, in meeting vehicle fleet needs.<br />

The haulage expert placed an order for a total<br />

of ten MAN TopUsed TGX 26.440s with XLX<br />

cabs with the MAN specialist in Preston and<br />

began <strong>2017</strong> with an order for yet another one.<br />

Specialising in warehousing and distribution,<br />

the HPH Group currently operates 97 vehicles,<br />

with 95% of its fleet being composed of<br />

MAN. They are a mixture of newly owned,<br />

MAN TopUsed and rental vehicles and range<br />

from 7.5-tonners to 44-tonners.<br />

Steve Sugden, General Manager of the HPH<br />

Group, explains: “We have gone with MAN for<br />

a long time and we know they are competitive<br />

and offer a good product, but for us it is the<br />

aftersales service that makes us return. The<br />

service is truly second to none, and we have<br />

never had a problem. We have the new vehicles<br />

on a repair and maintenance contract,<br />

and the MAN TopUsed are maintained by our<br />

own workshop facility, which is only about<br />

three miles from MAN Preston. Everything<br />

from the supply of parts through to the support<br />

we receive is excellent.”<br />

Matt Neal, MAN sales executive, added: “MAN<br />

has a very strong relationship with the HPH<br />

Group, and that is primarily due to the products<br />

and services MAN <strong>Truck</strong> & Bus UK can<br />

offer. The fact that they repeatedly return to<br />

MAN highlights our apparent capability to<br />

meet their requirements, whether they are<br />

looking for MAN TopUsed or new trucks.”<br />

MAN moves<br />

logistics expert<br />

New TGX Euro 6c models join vehicle fleet of<br />

supply chain service provider in central UK.<br />

Located in Northamptonshire, in<br />

the so-called Golden Triangle for<br />

rapid distribution throughout the<br />

UK, the transport specialist Route<br />

Logistics adds six new MAN TGX<br />

26.500 Euro 6c trucks to its fleet.<br />

The family-run company placed an order for<br />

the tractor units after experiencing a demo<br />

vehicle at its Rockingham base.<br />

Route Logistics Ltd is a family-owned<br />

business established in 2005 by its current<br />

Managing Director Paul Clifton. It operates a<br />

fleet of 25 units and 15 trailers, which are based<br />

at Rockingham Motor Speedway near Corby.<br />

Route Logistics has grown significantly over<br />

just the past 12 to 18 months, and needs to<br />

meet the growing demand, says Amanda<br />

Wells, Financial Director at Route Logistics:<br />

“Due to our diversifying into different market<br />

sectors, growth within the general haulage<br />

and tramping activities of our business<br />

resulted in considering the option for a<br />

greater specification vehicle, and the MAN<br />

TGX 26.500XXL seemed the ideal fit. We<br />

initially agreed on taking three units, but<br />

positive results from the demonstrator soon<br />

led to us increasing that order to six.”<br />

Chris Robinson, Transport Operations<br />

Director at Route Logistics, added: “The<br />

miles-per-gallon figures of a vehicle this size<br />

were indeed very impressive, with one driver<br />

even managing a return of 11.77 mpg during<br />

his shift. The drivers were very impressed<br />

with the comfort of the ride, spacious interior<br />

and the general performance of the TGX.”<br />

Including the Microlise telematics system<br />

and forward-facing/near-side look-down<br />

cameras assist in supporting driver training<br />

Vehicle details<br />

MODEL<br />

TGX 26.500 6x2/2 BLS<br />

CAB<br />

XXL Slp cab<br />

ENGINE<br />

D2676LF 6-cylinder<br />

12.4-litre<br />

POWER<br />

500 hp at 1,800 rpm<br />

TORQUE 2,500 Nm at 930–1,350 rpm<br />

GEARBOX<br />

Tipmatic 12-speed<br />

SUSPENSION<br />

Steel/air<br />

WHEELBASE<br />

2,600 mm<br />

PLATED WEIGHT<br />

44,000 kg GTW<br />

and proper implementation of SAFED policies.<br />

Route Logistics was particularly impressed by<br />

the back-office support of MAN, as it was<br />

clearly dedicated to creating an even more<br />

efficient and compliant fleet to further<br />

strengthen the capabilities of the logisticssupply-chain<br />

expert.<br />

Scott Munton, MAN Sales Executive, said:<br />

“Route Logistics is a new customer for MAN,<br />

but they have already been impressed with<br />

the quality of our product and our offered<br />

services. We were able to put together a highly<br />

competitive package in terms of rental and<br />

running costs, and they were happy to take a<br />

two-year contract on the vehicles even before<br />

they had operated the demo. Obviously, we<br />

are delighted to have won Route Logistics<br />

business and look forward to providing them<br />

with unbeatable service in to the future.”<br />

22<br />

On the track to success: The supply chain company<br />

Route Logistics is perfectly positioned for growth.<br />

23

01 / <strong>2017</strong><br />

MAN Bus & Coach hands<br />

over the 400th NEOPLAN<br />

Tourliner model to be<br />

sold in the UK.<br />

Small and spirited: Travel<br />

operator Buckleys Tours was<br />

happy to accept the<br />

commemorative miniature.<br />

Once again showcasing its<br />

strong focus on customer<br />

relations, the team at MAN<br />

Bus & Coach UK made it a<br />

memorable moment when<br />

Buckleys Tours took delivery of<br />

the 400th NEOPLAN Tourliner sold in the UK.<br />

Wayne Ulph, General Manager of MAN Bus &<br />

Coach UK, had arranged for a commemorative<br />

miniature model, which was presented<br />

on the occasion of holiday operator Buckleys<br />

Tours receiving its NEOPLAN Tourliner Select<br />

P21 model, the 400th NEOPLAN Tourliner<br />

vehicle to be purchased in the UK market.<br />

THE LANDMARK agreement had been made<br />

at the Euro Bus Expo 2016 in Birmingham,<br />

which MAN Bus & Coach registered as their<br />

most successful exhibition to date. The<br />

company secured 14 new sales as well as<br />

signing a contract worth millions with the international<br />

transport company Arriva.<br />

Buckleys Tours, a family-run business<br />

based in Doncaster, now has six NEOPLAN<br />

Tourliners in its fleet. The holiday company<br />

offers trips to both UK and European destinations,<br />

as well as day trips, weekend and minitours.<br />

Its latest addition to the fleet is a<br />

Neoplan Tourliner Select P21 featuring 53 seats<br />

and a DVD system with twin monitors, which<br />

will be operating on a school contract. It is<br />

fitted with emergency brake assist and lane<br />

guard systems and powered by an MAN-made<br />

D20 10.5l Euro 6 engine with 400 hp.<br />

“We are honoured to be the customer who<br />

purchased MAN’s 400th NEOPLAN Tourliner.<br />

Slated for journeys across the UK and Europe,<br />

it will go into service straight away,” observed<br />

company manager Richard Buckley. He also<br />

noted that the aftersales and support offered<br />

by MAN was quite unparalleled and perfect for<br />

his business, also when considering the outstanding<br />

vehicle quality: “Our drivers are<br />

proud to be behind the wheel of an MAN coach,<br />

and our customers receive the quality travelling<br />

experience they expect and deserve.”<br />

“Selling our 400th Neoplan Tourliner<br />

certainly presents a landmark in our sales<br />

book. It is a marvellous testament to the MAN<br />

brand that our customers have shown such<br />

loyalty through the years, Buckleys being<br />

among them,” said Wayne Ulph. “We look<br />

forward to more success stories with NEOPLAN<br />

down the road, as well as to the future launch<br />

of the MAN TGE with so much potential for the<br />

small-commercial-vehicles market.”<br />

VIP treatment for<br />

valued customer<br />

Lined up for business: With its<br />

groundbreaking pick-up<br />

service, Buckleys has attracted<br />

a very loyal customer base.<br />

24<br />

25

01 / <strong>2017</strong><br />

Sweet new delivery<br />

for distribution<br />

Major transport player chooses MAN after securing<br />

large, long-term contract for consignment.<br />

Commercial vehicle manufacturer<br />

MAN <strong>Truck</strong> & Bus UK recently<br />

delivered 17 truck units to Bibby<br />

Distribution as part of an order for<br />

70 new vehicles commissioned<br />

by the customer after securing a<br />

new contract with Tangerine, the UK’s leading<br />

independent sugar-confectionery supplier.<br />

A subsidiary of the internationally active<br />

Bibby Line Group, long-time MAN customer<br />

Bibby Distribution purchased the MAN TGX<br />

26.460 Euro 6c commercial vehicles as part of<br />

the company’s fleet expansion and renewal<br />

programme, which resulted in an order of<br />

70 MAN trucks being handed over to Bibby<br />

Distribution from February to April, <strong>2017</strong>.<br />

The company has more than 2,000<br />

employees and over three decades of experience<br />

in industrials, paper and packaging,<br />

consumer, and food and drink distribution;<br />

warehousing; and other value-added support<br />

services. It operates in more than 90 locations<br />

across the UK, with its fleet of 650 vehicles<br />

and 1,500 trailers travelling tens of millions of<br />

miles every year to meet customer demands.<br />

Remaining a family-owned business, the<br />

corporate Bibby Line Group looks back on a<br />

200-year heritage and is active in a wide range<br />

of industries, including financial and offshore<br />

services, as well as retail and logistics.<br />

Emphasising the long-standing relationship<br />

with MAN, Adam Purshall, who oversees<br />

the Bibby Distribution fleet, said: “Obviously,<br />

we have been supporters of MAN vehicles for<br />

quite some time, with 450 units currently<br />

utilised in our fleet. We have found that time<br />

and time again, MAN has not just met, but<br />

rather exceeded, our requirements and<br />

delivered the most in terms of reliability,<br />

uptime and fuel economy. We enjoy an<br />

excellent relationship with MAN and adopted<br />

a flexible, true-partnership approach.”<br />

Bibby Distribution especially appreciates<br />

the seamless interaction with both the MAN<br />

dealer network as well as after-sales support,<br />

which strives to deliver very competitive<br />

value to MAN’s customers throughout the<br />

operational cycle of any vehicle. The TGX Euro<br />

6 in question has already been well-proven<br />

and established in Bibby’s fleet, with a high<br />

specification in line with the company’s operational<br />

demands. This meant that a flexible<br />

contract through MAN Rental with excellent<br />

reliability, improved fuel efficiency and<br />

excellent driver acceptance made it a natural<br />

choice for the distribution expert.<br />

“We not only always take a full repair and<br />

maintenance package from MAN, but also use<br />

the entire dealer network across the UK. With<br />

such widespread operations, it is key that<br />

dealers are located in the right places and our<br />

vehicles maintain the very best safety and<br />

maintenance standards with a focus on maximising<br />

uptime and technology,” said Purshall.<br />

MAN key account manager Neil Waters,<br />

who spearheaded the agreement, said: “Bibby<br />

Distribution is a long-time MAN customer,<br />

and we consider it a credit to our brand that<br />

they have remained so loyal. The price and<br />

package have obviously measured up, and we<br />

are confident that the performance of the<br />

TGX will continue to speak for itself in future.”<br />

Vehicle information<br />

MODEL<br />

TGX 26.460 6x2/2 BLS<br />

CAB<br />

XLX Slp cab<br />

ENGINE<br />

D2676LF 6-cylinder<br />

12.4-litre<br />

POWER<br />

460 hp at 1,800 rpm<br />

TORQUE 2,300 Nm at 930–1,350 rpm<br />

GEARBOX MAN Tipmatic 12-speed<br />

SUSPENSION<br />

Steel/air<br />

WHEELBASE<br />

2,600 mm<br />

PLATED WEIGHT<br />

44,000 kg GTW<br />

Ready to roll: A key company in<br />

terms of consignment and goods<br />

transport, Bibby Distribution<br />

relies on MAN trucks.<br />

Sweet dreams are made of<br />

this: MAN trucks distribute the<br />

goodies throughout the UK.<br />

26<br />

27

01 / <strong>2017</strong><br />

The man for fragile things:<br />

Peter Unertl and his forwarding<br />

company carry white goods<br />

safely to the customer.<br />

Passionate driver: Calm and<br />

collected, Stefan Hauf enjoys being<br />

on the road with his TGL truck.<br />

Carry on with<br />

caution<br />

The haulage company Unertl, based in Munich, specialises<br />

in the delivery of delicate household appliances.<br />

Managing the family business in its third generation,<br />

the owner still rides the forklift every day.<br />

© Stefan Hobmaier<br />

Early in the morning, the trucks are<br />

lined up along the loading ramps<br />

installed in the courtyard of the<br />

Unertl forwarding firm. Oversized<br />

images of dishwashers displayed<br />

on the side panels of the MAN<br />

trucks reveal which kind of cargo is being loaded<br />

here. While many trucks carry the greencoloured<br />

lettering of Siemens, the main customer,<br />

there’s no sign of a specific Unertl logo<br />

anywhere. “We don’t need any advertising,<br />

everyone knows us,” shrugs laid-back owner<br />

Peter Unertl. Throughout its nearly 60-year<br />

history, his family-owned company has earned<br />

a reputation for delivering electrical appliances.<br />

Customers like Bosch Siemens Hausgeräte<br />

know that their sensitive merchandise will<br />

not only arrive quickly and reliably, but also –<br />

most importantly – in undamaged condition.<br />

While Unertl himself is already on site before<br />

five in the morning, manoeuvring the<br />

forklift to unload deliveries, the workday for<br />

his drivers begins just before six. Stefan Hauf,<br />

wiry and wearing grey glasses, is the first to<br />

sort through the bills of delivery that have<br />

been allocated to him. “First I count all the appliances,”<br />

he says. Today, he’s assigned to take<br />

over the Fürstenfeldbruck route again. “The<br />

drivers run their routes every day,” explains<br />

Unertl. Thus, they know the access routes, possible<br />

places to stop and opening times from<br />

the inside out.<br />

NEXT DOOR IN THE WAREHOUSE, music from<br />

the radio provides the right mood. Bustling<br />

and focused, the drivers walk past the rows of<br />

appliances stacked high and gather their<br />

goods. Recording every loaded unit, a scanner<br />

beeps if somebody has mistakenly picked the<br />

wrong refrigerator model. “This certainly is a<br />

challenging job,” emphasises Unertl, “with lots<br />

of lifting and being on your feet. The loading<br />

„I’m certainly<br />

satisfied with my<br />

MAN truck, and<br />

I’ll stick with it.”<br />

Stefan Hauf, driver<br />

2828<br />

29

01 / <strong>2017</strong><br />

process is the most strenuous bit.” Dressed in<br />

neon-yellow fleece jackets, the men heave<br />

washing machines of up to 100 kilograms, or<br />

push three ovens stacked atop each other into<br />

the truck via a hand barrow. Now begins what<br />

Unertl refers to as “Tetris”, based on the video<br />

game, where different shapes must be stacked<br />

side by side or one above the other with as few<br />

gaps as possible. “We can fit 54 appliances on a<br />

truck,” works out the boss. Which means that<br />

Stefan Hauf is short by one dishwasher. He unsuccessfully<br />

walks up and down the rows several<br />

times and checks with the dispatcher<br />

once more. Finally, he’s relieved: the missing<br />

item was found. Hauf loads it up and sets off<br />

from the premises shortly after eight a.m.,<br />

heading for the A99 motorway and his first<br />

customer in Neuaubing.<br />

BEHIND THE WHEEL OF HIS MAN TGL, the<br />

37-year-old feels at home. “I really like sitting<br />

behind the wheel,” acknowledges the family<br />

man. “Even back when I was still a driving<br />

novice, I practised every minute with the car.“<br />

During the summer months, Hauf commutes<br />

to work on his motorcycle. In his truck, he enjoys<br />

the automatic drive, the GPS system and<br />

his rear-view backup camera. “I’m certainly<br />

satisfied, and I’ll stick with MAN,” he says.<br />

Most of the 13 company trucks came from the<br />

Munich-based manufacturer, and nearly all<br />

comply with the Euro 6 standard. The preheating<br />

system is also a welcome feature and<br />

much appreciated on a morning with temperatures<br />

of –14°C, when Hauf discovered a flat<br />

tire just as he was trying to head out with a<br />

fully loaded vehicle. “I spent an hour with a<br />

colleague changing the tire,” he remembers.<br />

He then relished leaving the icy cold and<br />

climbing into his preheated cab.<br />

Although he can already dispense with<br />

half of his cargo when he arrives at the first<br />

customer today, he has to wait. The unloading<br />

ramp is occupied. Hauf remains unperturbed.<br />

“Waiting is normal. It’s the opening hours that<br />

create a bit of pressure,” he admits. Some receiving<br />

departments close at lunchtime. The<br />

wait is easily bridged with a little chat. “I have<br />

a good relationship with our customers, and<br />

we do enjoy sharing some jokes and laughter,”<br />

relates Hauf. A trusting interaction with contractors<br />

and customers is part of the company’s<br />

philosophy. Some clients even leave their<br />

keys with the forwarder to allow drivers to<br />

make deliveries at any time. After a good half<br />

an hour, Hauf once again leaves the customer’s<br />

premises. The next two stops proceed quickly.<br />

Two appliances are dropped off at a small electronics<br />

store, another unit goes to a kitchen<br />

studio in Freiham. There, Hauf must stop on<br />

the road to do his unloading. A female motorist<br />

rails at the blocked lane. Hauf is used to that<br />

and not phased by it. “I like doing this job; otherwise<br />

I wouldn’t have stuck with it for eight<br />

years already,” he says. He particularly likes the<br />

family atmosphere in the company. “We’re all<br />

on a first-name basis and do share the occasional<br />

merriment.” The boss, Peter Unertl, can<br />

rely on many long-time colleagues, some of<br />

whom have been with his company for decades.<br />

“This actually goes beyond a mere employment<br />

relationship and resembles more of<br />

a friendship – through thick and thin,” says the<br />

owner, who took over business operations<br />

from his parents 11 years ago. The 52-year-old<br />

still pitches in every day and knows exactly<br />

how much work his people do. “I’m no pencilpusher,”<br />

explains Unertl. He’s been on the road<br />

himself since he was 18 and spent six of those<br />

years handling private customer deliveries.<br />

He’s witnessed quite a few scenes, such as the<br />

customer whose refrigerator wouldn’t fit<br />

through the kitchen door after all. “One would<br />

assume that a tape measure isn’t that difficult<br />

to handle,” remarks a slightly bemused Unertl.<br />

He will certainly never forget one homeowner<br />

who absolutely insisted on installing a deep<br />

freezer in his cellar, even though it would not<br />

fit through the stairwell. Ultimately, the man<br />

grabbed hammer and chisel and energetically<br />

worked on the staircase until the hauler crew<br />

could carry the freezer downstairs.<br />

It has become late morning during the<br />

route of Stefan Hauf. After a large electronics<br />

store in Germering, he’s now heading into the<br />

countryside. At a tiny driveway to a carpenter’s<br />

workshop in Gilching, the truck must manoeuvre<br />

on the main road. Hauf uses a hand<br />

truck to haul a refrigerator into the workshop<br />

and then heads off to his last customer. It’s<br />

still not yet noon when he turns back onto the<br />

company premises and starts loading up for<br />

„Our damage ratio<br />

can be considered<br />

practically zero.”<br />

Peter Unertl, owner of the Unertl forwarding firm<br />

© Stefan Hobmaier<br />

First one to show up for work:<br />

Company boss Peter Unertl<br />

starts unloading deliveries in<br />

the wee hours of the morning.<br />

Diligent preparation:<br />

The drivers take great<br />

care in arranging the<br />

goods for their routes.<br />

his second route. He will still be en route for<br />

half of the afternoon. Each day, the 28 employees<br />

of Unertl deliver up to 1,600 electrical appliances.<br />

A second, smaller business leg is salt,<br />

– ranging from road and pickling salt to pretzel<br />

salt for the Hofpfisterei baking company.<br />

Business is good and “we keep growing,”<br />

reports Unertl. Electrical appliance manufacturers<br />

increasingly rely on specialist forwarders.<br />

“Our damage ratio can be considered practically<br />

zero,” says Unertl. He then adds, “We<br />

handle very delicate merchandise. An electric<br />

oven can cost about €1,000 and if set down a<br />

little too hard, the glass pane is damaged.” So<br />

such heavy appliances need to be handled not<br />

just with power but also with great dexterity.<br />

No problem for Hauf. In his former job he also<br />

drove trucks, making customer deliveries for a<br />

supermarket chain. Many people ordered beverages<br />

and had them hauled upstairs. He<br />

knows how to tackle a tough task. And how to<br />

put on velvet gloves first.<br />

Nonstop road trips: Every day, the forwarder delivers up to<br />

1,600 electrical appliances, both in Munich and in its surroundings.<br />

30<br />

31

01 / <strong>2017</strong><br />

In production: A floor<br />

assembly and two side<br />

walls – this “triple” will<br />

become a TGE truck.<br />

© MAN <strong>Truck</strong> & Bus<br />

A<br />

TGE is made up of roughly<br />

3,000 parts,” observes Cezary<br />

Tadej, who maintains such an<br />

overview as Head of Assembly.<br />

“Yet you can’t say how<br />

many exactly, for it also depends<br />

on precisely which model and how detailed<br />

you count, down to the very last screw.”<br />

Ultimately, however, it does not matter. For in<br />

the end, every piece must be in its place. Yet<br />

Cezary offers a jovial smile upon this comment,<br />

as he knows about the quality that defines<br />

“his” TGE. During the production process,<br />

it passes through a veritable odyssey of<br />

human and technical quality checks. Both the<br />

gentle hands of women and the snappy timing<br />

of robots assure the high quality standards of<br />

this “small” MAN, which begins at the permitted<br />

total weight of 3.0 tonnes. However, that is<br />

just the beginning, for the 3.5-tonne version of<br />

the vehicle offers for example a cargo capacity<br />

of 1.5 tonnes. That creates a range of entirely<br />

new options in daily work operations.<br />

AT THE PLANT SITE, the production process<br />

of the floor assembly already requires accuracy<br />

to the decimillimetre and is checked repeatedly<br />

by various “geometry stations”,<br />

where automated lasers and digital cameras<br />

measure exact alignments and positions, including<br />

those of axle fixtures. “Even while the<br />

floor assembly is constructed, it goes through<br />

three of these so-called geo-stations, as we<br />

call them here at the plant,” explains Frank<br />

Schemmel, as the foundation of a new TGE is<br />

being checked in the background.<br />

Accompanied by the typical whirring<br />

sound of industrial robots, lasers and cameras<br />

are scanning every component dimension,<br />

every angle, every radius – calibrating themselves<br />

at regular intervals by means of globes<br />

that are affixed next to the assembly line.<br />

“While the side walls are being built, each<br />

geo-station gets an additional two geo-stations,<br />

for a total of nine,” explains Schemmel,<br />

Head of Bodyshell Production. Meanwhile,<br />

the welding robots are back at work in the<br />

background: lifting, checking, welding.<br />

Women are also found working in the<br />

bodyshell construction area, something that<br />

is completely normal in Września – even<br />

From<br />

tiny<br />

to tall<br />

By necessity, the first parts of an MAN TGE<br />

are made of metal: stamped, formed and punched.<br />

These metal sheets form the basis for building<br />

the latest member of the MAN family.<br />

As the TGE leaves the assembly line in Poland’s<br />

Września, a visit offers some fascinating insights.<br />

MAN’s future<br />

talent: The<br />

19-year-old<br />

Piotr installs<br />

instrument<br />

panels into<br />

the TGE.<br />

32<br />

33

01/<strong>2017</strong><br />

asked whether she feels at home here, she answers<br />

with a widely smiled “Tak!” Her expression<br />

certainly goes beyond a simple “yeah”.<br />

It isn’t just the “spring chickens” who feel<br />

fine in this TGE production plant. True MAN<br />

veterans such as Robert Michalak and Marcin<br />

Roszyk, who have been employed at MAN<br />

since 2001 and 1998 respectively, also enjoy<br />

working on an entirely new vehicle with the<br />

characteristic lion on the front. “It’s really nice<br />

to see our old and familiar logo,” admits<br />

Marcin. “We used to build buses, and now we<br />

build the TGE. They’re all part of the same<br />

family, aren’t they?” The two were part of<br />

Września from the get-go and, like many others,<br />

lent their wealth of experience to the<br />

plant. A good example of this is “horizontal assembly”,<br />

where the new TGEs are lined up in a<br />

row like cartridges in a belt, which facilitates<br />

the assembly of bulky parts such as the roof<br />

liner and the inner panelling. “If the vehicles<br />

Jump start for Września: The two seasoned<br />

MAN employees Robert Michalak (left) and<br />

Marcin Roszyk shared their wealth of experience.<br />

Glossy product of many industrious hands:<br />

The Września plant creates about 3,000 jobs.<br />

came one after another along the assembly<br />

line, there would hardly be enough space to<br />

manoeuvre these components into the loading<br />

space. This way, however, it’s not a problem,”<br />

explains Marcin. Once again, experience,<br />

and the capacity to think outside the<br />

box, proves tremendously useful.<br />

„I have prospects here.<br />

And responsibility!”<br />

Ewelina Gèodek, Final Check for Body Construction at MAN’s Września plant<br />

though it is a rather unusual phenomenon in<br />

Poland. This might be due to the fact that<br />

“KaRoBau”, the German term for body construction,<br />

is known under the Polish name<br />

“Spawalnia”, or “welding shop”. That sounds<br />

like heavy industry, reminiscent of smelting<br />

furnaces, dirt and noise – yet this gritty vision<br />

is far removed from the TGE in its unfinished<br />

state, where machinery handles the<br />

hardest work.<br />

Soon thereafter, the two side walls are attached<br />

to the flooring assembly to create the<br />

“triple” form. “In that moment, we’re defining<br />

the body shape,” explains Frank Schemmel.<br />

“Wheelbase, window, vehicle length – that’s<br />

been determined here. All the other welding<br />

work simply completes the structure.” A step<br />

that now actually allows for the reference to a<br />

“commercial vehicle”: Deliverable in three<br />

lengths and three heights, the TGE already assumed<br />

its identity at the very beginning,<br />

without even the very first welding points.<br />

© MAN <strong>Truck</strong> & Bus<br />

3,000<br />

individual<br />

components<br />

are installed in the MAN TGE. Each part<br />

must meet the high quality standards of<br />

the Września plant.<br />

Quite a while later, when the body glides<br />

toward completion, Ewelina Gèodek uses her<br />

eyes and hands to check whether all of the<br />

welding points are positioned correctly. She<br />

has been working at the plant since 2016 and<br />

was drawn there mainly because of the advancement<br />