Machinery Update September \ October 2017

Machinery Update September \ October 2017 - PPMA Show Preview

Machinery Update September \ October 2017 - PPMA Show Preview

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

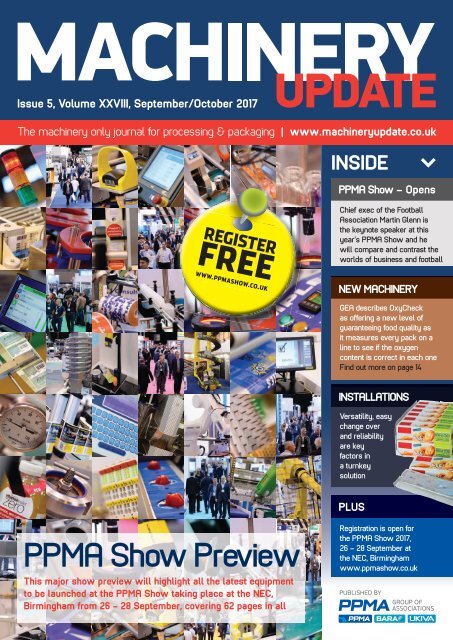

Issue 5, Volume XXVIII, <strong>September</strong>/<strong>October</strong> <strong>2017</strong><br />

The machinery only journal for processing & packaging | www.machineryupdate.co.uk<br />

INSIDE<br />

NEWS PPMA Show – Opens<br />

REGISTER<br />

FREE<br />

Lorem Chief exec ipsum of the dolor Football sit<br />

amet, Association consectetuer Martin Glenn adipiscing<br />

the keynote elit, sed speaker diam nonum-<br />

at this<br />

is<br />

my year’s nibh PPMA euismod Show tincidunt and he<br />

ut will laoreet compare dolore and magna contrast the<br />

worlds of business and football<br />

WWW.PPMASHOW.CO.UK<br />

NEW MACHINERY<br />

GEA describes OxyCheck<br />

as offering a new level of<br />

guaranteeing food quality as<br />

it measures every pack on a<br />

line to see if the oxygen<br />

content is correct in each one<br />

Find out more on page 14<br />

INSTALLATIONS<br />

Versatility, easy<br />

change over<br />

and reliability<br />

are key<br />

factors in<br />

a turnkey<br />

solution<br />

PLUS<br />

PPMA Show Preview<br />

This major show preview will highlight all the latest equipment<br />

to be launched at the PPMA Show taking place at the NEC,<br />

Birmingham from 26 - 28 <strong>September</strong>, covering 62 pages in all<br />

Registration is open for<br />

the PPMA Show <strong>2017</strong>,<br />

26 – 28 <strong>September</strong> at<br />

the NEC, Birmingham<br />

www.ppmashow.co.uk

Cama Group is a leading supplier of advanced technology secondary<br />

packaging systems, continuously investing in innovative solutions.<br />

www.camagroup.com - cama3@camagroup.com<br />

BIRMINGHAM - UK<br />

26 - 28 SEPTEMBER<br />

HALL 5 - STAND A90

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 3<br />

<strong>September</strong>/<strong>October</strong><br />

Sollas MU S-O <strong>2017</strong>.qxp_HR 21/07/<strong>2017</strong> 08:42 Page<br />

Contents<br />

7 NEWS<br />

14 NEW MACHINERY<br />

24 INSTALLATIONS<br />

40 SPECIAL FEATURE<br />

PPMA SHOW PREVIEW<br />

This 62 page preview details<br />

many of the new product<br />

launches from the 350 or so<br />

exhibitors that will feature at<br />

the PPMA Show at the NEC,<br />

Birmingham. Over 1,500<br />

companies will be represented<br />

102 SPECIAL FEATURE<br />

SUSTAINABILITY<br />

The ‘circular economy’ is the<br />

buzz word in sustainability and<br />

here, we discuss the new BSI<br />

standard that this has led to as<br />

well as covering new technology<br />

102<br />

REGULAR FEATURES<br />

110 VISION<br />

A range of systems for industrial<br />

3D vision operation is launched<br />

112 LABELLING,<br />

CODING & MARKING<br />

Feeder/overprinter is meeting<br />

new legislation and sales needs<br />

114 COMPONENTS<br />

Four pages of the latest options<br />

to deliver machine builder benefits<br />

35<br />

120 REGULATIONS<br />

The entire machinery supply<br />

chain including manufacturers,<br />

importers and integrators now<br />

have to comply with the EU’s<br />

new Radio Equipment Directive<br />

122 WHO WHAT WHERE<br />

People, events and diary dates<br />

123 BUYERS’ GUIDES<br />

<strong>Machinery</strong> and services<br />

EDITOR:<br />

Gail Hunt<br />

PUBLISHING MANAGER:<br />

Bill Lake<br />

BUYERS GUIDE CO-ORDINATOR:<br />

Chris Valdes<br />

ARTWORK CONTRIBUTOR:<br />

Barry Heath<br />

HEAD OF PUBLISHING:<br />

David Chadd<br />

A PPMA PUBLICATION<br />

PPMA Ltd<br />

New Progress House,<br />

34 Stafford Road,<br />

Wallington,<br />

Surrey<br />

SM6 9AA<br />

TEL: +44 (0) 20 8773 8111<br />

FAX: +44 (0) 20 8773 0022<br />

E-MAIL ADDRESSES:<br />

publishing@ppma.co.uk<br />

show@ppma.co.uk<br />

technical@ppma.co.uk<br />

WEBSITE:<br />

www.machineryupdate.co.uk<br />

APPLICATIONS FOR FREE COPIES<br />

of <strong>Machinery</strong> <strong>Update</strong> are<br />

considered from specifiers,<br />

managers and purchasers of<br />

processing and packaging<br />

machinery in the UK.<br />

ANNUAL SUBSCRIPTION:<br />

£35 (UK), £50 (Continental<br />

Europe), £65 (rest of world).<br />

ISSN 0969-4145<br />

PRINTED BY:<br />

Brown Knight and Truscott<br />

North Farm Road, Tunbridge Wells<br />

Kent TN2 3BW<br />

Tel: 01892 511678<br />

The Processing and Packaging <strong>Machinery</strong><br />

Association assumes no responsibility for the<br />

statements or opinions, whether attributed<br />

or otherwise, in <strong>Machinery</strong> <strong>Update</strong>.<br />

This publication is copyright under the Berne<br />

convention and the International copyright<br />

convention. Apart from any fair dealing for<br />

the purposes of research or private study, as<br />

permitted under the Copyright, Designs and<br />

Patents Act 1988, no part of this publication<br />

may be reproduced, stored in a retrieval<br />

system or transmitted in any form or by any<br />

means in any form without prior written<br />

permission of the publishers.<br />

Publishers: PPMA Ltd

<strong>2017</strong><br />

21 st <strong>September</strong> <strong>2017</strong><br />

JLR Castle Bromwich Experience<br />

Centre (B35 7RA)<br />

Next GeNeratioN iNdustrial<br />

traNsport techNoloGy<br />

www.br-automation.com/transport-technology<br />

Integrates into any process<br />

< Synchronizes perfectly with CNC and robotics<br />

Field proven<br />

< Best-in-class reliability<br />

Easy maintenance<br />

< Industrial-grade quality, service-friendly design<br />

B&R UK & Ireland HQ:<br />

B&R Industrial Automation Ltd. | office.uk@br-automation.com | Southgate Park PE2 6YS Peterborough UK | +44 / 1733 392862

www.machineryupdate.co.uk MACHINERY UPDATE 5<br />

PPMA matters<br />

Show visit is<br />

THE smarter<br />

way to learn<br />

Rulmeca half page (270x87) <strong>Machinery</strong> <strong>Update</strong> PPMA_Layout 1 08/06/<strong>2017</strong> 11:<br />

Rulmeca<br />

WE’VE BEEN AROUND FOR OVER 50 YEARS<br />

Conveyor<br />

rollers<br />

Andrew Mint<br />

CEO PPMA GROUP OF ASSOCIATIONS<br />

(INCORPORATING PPMA, BARA AND UKIVA)<br />

Welcome to the latest issue of <strong>Machinery</strong> <strong>Update</strong>.<br />

I hope you had an enjoyable summer even though<br />

the unpredictable British weather has hit us all again.<br />

There is some ‘sunshine’ on the horizon, however in the form<br />

of the PPMA Show that is now only a matter of weeks away.<br />

The <strong>2017</strong> PPMA Show promises to be a cracker; the biggest in<br />

12 years in fact. We have over 350 exhibitors across packaging and<br />

processing machinery, automation, robotics and machine vision.<br />

These exhibitors represent equipment and services from over<br />

1,500 companies, so a visit to the NEC Birmingham from<br />

26 – 28 <strong>September</strong> is a no brainer in terms of time well spent.<br />

Numerous working displays of the very latest innovations<br />

will greet visitors, which, let’s be honest, it is hard to beat the<br />

live experience of seeing new equipment in action. This, I would<br />

argue, is one of the key strengths of the PPMA Show and why<br />

deciding to visit the free-to-attend exhibition is one of the easiest<br />

business decisions you will probably make today.<br />

The PPMA Show <strong>2017</strong><br />

will bring sunshine not showers<br />

to the business end of the year<br />

The PPMA Show always likes to provide a fascinating headline<br />

speaker and this year, we are honoured to have Martin Glenn,<br />

CEO at the Football Association (FA), and former food industry<br />

marketer taking centre stage on the first morning. Glenn was<br />

CEO of United Biscuits, as well as being key in transforming the<br />

Walkers and Bird’s Eye brands before going to the FA.<br />

He will share his experiences by comparing food<br />

manufacturing businesses and football as well as talking<br />

about the common issues facing both going forward. He is also<br />

happy to take questions after his presentation, so if you want<br />

to know when England (men) will next win the World Cup,<br />

here’s your chance!<br />

Glenn will speak in the Learning Hub, which will also play host<br />

to a raft of speakers from organisations like the Food Standards<br />

Agency, the Food & Drink Federation and the CE Marking<br />

Association. Take a look at the insert between pages 82 and 83 of<br />

this issue to see the full programme which is designed to enhance<br />

your visit. And to find out more about some of the new equipment<br />

on show, our 62 page PPMA Show Preview starts on page 40.<br />

I look forward to welcoming you to the PPMA Show at the<br />

end of <strong>September</strong> in Birmingham where there will be some<br />

incredible products and services being showcased.<br />

n<br />

Rulmeca offers a comprehensive range of high<br />

quality rollers and components for conveyors,<br />

constructed from aluminium, mild steel, stainless<br />

steel and high resistance technopolymers.<br />

Rulmeca drum motors provide the ideal drive<br />

solution for belt conveyors and associated material<br />

handling equipment. They are versatile, energy<br />

efficient and hermetically sealed for hygienic<br />

operations and wash-down applications<br />

(IP66/IP69) in food processing, packing operations<br />

and logistics.<br />

Contact our experienced Rulmeca team to discuss<br />

the most suitable product for your application.<br />

Call Rulmeca UK on 01536 748525<br />

www.rulmeca.com<br />

Rulmeca UK LTD<br />

Brunel Road,<br />

Earlstrees Road,<br />

Earlstrees Ind. Estate,<br />

Corby, NN17 4JW<br />

E. uk@rulmeca.com<br />

Moving ahead.<br />

DrUM MoTors<br />

See us on stand G26

Find the smallest objects<br />

before they cause the<br />

biggest problems<br />

Our quality control systems leave no stone unturned.<br />

Or shard of plastic or glass. Or piece of metal or rubber.<br />

If there’s a foreign body in your product, our machines will<br />

find it. Reducing product recalls and protecting your brand.<br />

Work in harmony with Ishida.<br />

ishidaeurope.com

News<br />

www.machineryupdate.co.uk september/october <strong>2017</strong> MACHINERY UPDATE 7<br />

FA chief exec will ‘put in<br />

a shift’ for PPMA Show<br />

CEO of the Football<br />

Association and former<br />

senior food marketer<br />

Martin Glenn is delivering the<br />

keynote speech at the PPMA<br />

Show in <strong>September</strong>.<br />

Taking centre stage at<br />

11.30am on the first morning<br />

– <strong>September</strong> 26, at the NEC,<br />

Birmingham – Glenn will<br />

compare and contrast the<br />

worlds of business and<br />

football. He will also discuss<br />

the role that technology plays<br />

in the FMCG marketing mix<br />

and how this was harnessed<br />

during his time in various<br />

food industry roles.<br />

Glenn was responsible<br />

for doubling profitability at<br />

PepsiCo and rejuvenating<br />

the Walkers brand as well as<br />

sanctioning huge investments<br />

in United Biscuits factories<br />

in his time as chief executive.<br />

He will explain how passion,<br />

innovation and a thorough<br />

understanding of the<br />

consumer and technology<br />

HONORARY DEGREE AWARDED TO PPMA DIRECTOR<br />

University link is rewarded<br />

MD of Jenton International Richard Little has been awarded an<br />

honorary degree of Doctor of Engineering from Southampton Solent<br />

University. “I feel very honoured as I have been involved with the<br />

University for many years now from sponsorship, right through to<br />

employing a couple of students who used to study here, so this is a<br />

real bonus,” he said. His love of innovation led him to co-found<br />

the Wessex Round Table of Inventors at Solent some years ago.<br />

Martin Glenn will take centre stage at the PPMA Show on the first morning<br />

guarantees FMCG growth, even<br />

in mature markets.<br />

“Salty snacks is obviously<br />

a packaging intensive business<br />

and so I oversaw many<br />

packaging and technology<br />

innovations during my time at<br />

Walkers,” says Glenn. “What<br />

I understood from the food<br />

business was that consumers<br />

would not pay for gimmicky<br />

packaging innovation but they<br />

would pay for convenience.<br />

“I also learnt that we could<br />

use packaging as a competitive<br />

advantage, if we got it right,”<br />

he told <strong>Machinery</strong> <strong>Update</strong>.<br />

He says that there are many<br />

similarities between his former<br />

roles in manufacturing and his<br />

current job at the FA, politics<br />

aside, and he will share his<br />

thoughts on this during his<br />

opening day speech.<br />

He will also welcome<br />

questions from the audience<br />

about either, on the day.<br />

W www.ppmashow.co.uk<br />

Seminar programme<br />

includes a must-see<br />

CE marking update<br />

Editor of <strong>Machinery</strong> <strong>Update</strong><br />

Gail Hunt will be hosting<br />

a seminar at 10.30pm on<br />

Tuesday 27th <strong>September</strong> at<br />

the PPMA Show which will<br />

see managing director of<br />

the CE Marking Association<br />

Mike Foster answer the<br />

question: CE marking<br />

machines – whose<br />

responsibility is it anyway?<br />

This session will show<br />

how the CE mark is more<br />

than just a compliance mark<br />

and how it can be an effective<br />

tool for designing new<br />

machines and assembly lines.<br />

Foster will also explain<br />

how the regulatory changes<br />

of last year can be met.<br />

PPMA Show<br />

is a sell-out<br />

event again<br />

Over 1,500 companies will be<br />

represented at the PPMA Show<br />

in <strong>September</strong>, making this year’s<br />

event the UK’s unmissable<br />

processing and packaging<br />

machinery exhibition.<br />

Taking place in hall 5 of the<br />

NEC, Birmingham from<br />

26-28 <strong>September</strong>, over 350<br />

exhibitors will be filling<br />

10,000sq m of space with<br />

the very latest machinery,<br />

technologies and services that<br />

manufacturing industry requires.<br />

Registration for this free-toattend<br />

show is now open and takes<br />

less than three minutes to secure.<br />

Organised by the Processing<br />

and Packaging <strong>Machinery</strong><br />

Association (PPMA), the show<br />

offers visitors the chance to see<br />

a plethora of equipment in action.<br />

It also presents the opportunity<br />

to talk face-to-face with the<br />

industry’s leading technical<br />

experts across all sectors.<br />

Also featured is a three day<br />

seminar programme in the<br />

Learning Hub that will cover a<br />

wide range of topics in short, half<br />

hour sessions. This gives visitors a<br />

chance to mix attending seminars<br />

with visiting stands, very easily.<br />

In this issue of <strong>Machinery</strong><br />

<strong>Update</strong>, you will find a 62 page<br />

PPMA Show Preview to help you<br />

plan your visit and to determine<br />

which new equipment you would<br />

like to investigate further.<br />

Turn to page 40 to find out more.<br />

T 020 8773 8111<br />

W www.ppmashow.co.uk<br />

Last year’s event was a total success

8 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

News<br />

Business chiefs are concerned<br />

about UK’s digitalisation pace<br />

The proof of our equipment is in the eating<br />

X-ray and vision inspection systems<br />

to ensure products are:<br />

• Safe to consume<br />

• Free of contaminants<br />

• Correct weight<br />

• Legally compliant<br />

Protecting you and your customers for over 40 years<br />

Providing world-class systems and pinpoint accuracy to the bakery,<br />

protein and produce sectors for over 40 years.<br />

SPARC-SYSTEMS.COM<br />

Business leaders from<br />

across industry have<br />

called for the rapid<br />

acceleration of digitalisation<br />

to counter uncertainty in the<br />

economy as well as provide<br />

a much needed boost to<br />

productivity and skills.<br />

Siemens polled 30 CEOs<br />

and board level executives of<br />

the UK’s leading small and<br />

large businesses at a summit<br />

that discussed the challenges<br />

facing the UK economy over<br />

the next two years. Themed<br />

around digitalisation and the<br />

fourth industrial revolution,<br />

the grouping discussed how<br />

the UK could best embrace<br />

new digital technologies.<br />

THE UK IS NOT AMBITIOUS<br />

IN THIS AREA, BELIEVES<br />

82%<br />

of business leaders when asked<br />

about creating new technologies<br />

The Industrial Digitalisation<br />

Review, led by Siemens CEO<br />

Juergen Maier on behalf of<br />

business for Government, was<br />

used as the foundation of the<br />

discussion, and the input will<br />

be factored into its conclusions<br />

which are due later this year.<br />

When asked how good the<br />

UK is at providing the skills for<br />

the next generation and also in<br />

up-skilling existing workforces<br />

required for the fast adoption<br />

of new digital technologies,<br />

the picture was stark. Indeed,<br />

85% of those polled said the<br />

lack of advanced digital skills<br />

in the workforce was holding<br />

back the UK in the global<br />

technology race.<br />

Only 15% said the UK was<br />

among the most skilled.<br />

Attendees agreed<br />

that a defined national<br />

skills standard for digital<br />

engineering should inform<br />

teaching and learning in<br />

schools and colleges.

News<br />

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 9<br />

First career open days<br />

generate applications<br />

PP Control & Automation,<br />

which has seen sales<br />

rise to £20m this year,<br />

hosted its first ever Career<br />

Open Days to give individuals<br />

considering a career in<br />

industry the chance to see<br />

what opportunities there are<br />

to progress in the sector.<br />

School leavers, people<br />

looking to change professions<br />

or those wanting to get back into<br />

manufacturing attended one of<br />

the two hour slots that included<br />

a guided tour of the firm’s<br />

40,000sq ft facility in Cheslyn<br />

Hay, the chance to speak with<br />

current employees and an<br />

overview of current vacancies.<br />

“The last twelve months<br />

have been very good for our<br />

business and we have won<br />

a lot of new outsourcing<br />

contracts both at home<br />

and abroad,” explains<br />

Philip Newell, training and<br />

continuous improvement<br />

manager at PP Control<br />

& Automation. “To cope with<br />

this increase in demand, we<br />

need to boost the workforce<br />

and are looking to create up<br />

to 30 new jobs.<br />

“These range from<br />

apprentices and shop floor<br />

technicians, to logistics<br />

specialists and project<br />

managers,” he says.<br />

“Getting the right skills<br />

is important so we want to<br />

make sure everyone knows<br />

what type of company we are<br />

building here at PP, a company<br />

that currently supplies twelve<br />

of the world’s largest machine<br />

builders,” he continues.<br />

“Opening our doors and letting<br />

Astec Ad 182 x 80 +QR Mar 17_Layout 1 27/04/<strong>2017</strong> 17:54 Page 1<br />

The Open Days included a tour of the firm’s facilities with current employees<br />

them see the technology we<br />

use and the processes we<br />

employ was a great way of<br />

getting people to consider<br />

a career with us.”<br />

On the day, attendees were<br />

introduced to the company<br />

by local training providers,<br />

colleges and schools,<br />

with all of those attending<br />

subsequently applying for one<br />

of the firm’s traineeship or<br />

apprenticeship roles.<br />

New format revealed<br />

for Vision Technology<br />

Forum this November<br />

Stemmer Imaging’s Machine<br />

Vision Technology Forum has a<br />

new 2-day format for <strong>2017</strong>.<br />

Taking place on 15 and 16<br />

November at the Silverstone<br />

Wing Exhibition and Conference<br />

Centre, the event now features<br />

a complete day dedicated to<br />

hands-on training (see website<br />

for fees). Day two includes a<br />

technical seminar programme,<br />

live product demonstrations and<br />

a new ‘Integrator Zone’ with real<br />

application examples and is free<br />

of charge to attend.<br />

The first day is limited<br />

to 50 people and allows<br />

attendees to choose between<br />

six European Imaging Academy<br />

training courses, book in depth<br />

manufacturer meetings and<br />

product master class sessions.<br />

T 01252 780000<br />

W www.stemmer-imaging.co.uk<br />

CONVEYOR SYSTEMS<br />

Astec Conveyors manufacture a range of stainless steel conveyor systems for the food and<br />

beverage industries. We also supply conveyor systems for e-commerce, logistics and<br />

production sectors.<br />

www.astecconveyors.com<br />

+44 (0)1283 210333 • sales@astecconveyors.com

10 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

News<br />

Video use is<br />

increasing in<br />

getting data<br />

A recent survey conducted by<br />

test and measurement company<br />

HBM found that video use<br />

is accelerating in data collection.<br />

The study shows that almost<br />

half of the respondents (47%)<br />

already use video in data<br />

recording today, while 54%<br />

of the respondents expect video<br />

use within their organisation to<br />

increase in the next year.<br />

TACTILE SENSORS<br />

Video cameras are already used<br />

in many test and measurement<br />

applications throughout the<br />

industry in addition to data<br />

collection with traditional tactile<br />

sensors. But until now, there has<br />

been very little information on the<br />

level and nature of this use.<br />

“There is no longer any question<br />

that recording video data in parallel<br />

to tactile sensors or digital bus<br />

signals is becoming more and<br />

more attractive to users,” says<br />

Christof Salcher, product manager<br />

instrumentation at HBM.<br />

“Video supports traditional sensor<br />

data and is becoming a valuable<br />

source of additional information,<br />

making the room for interpretation<br />

even narrower in testing.”<br />

ADDITIONAL INPUT<br />

The survey showed that the most<br />

common reason for using video in<br />

data collection is to gain additional<br />

input analysing unexpected<br />

deviations (73%). Other common<br />

reasons are decision finding (50%)<br />

and visualisation of results to<br />

management (41%).<br />

Regular video (such as<br />

webcams) is by far the most<br />

common equipment for video in<br />

data collection. In the survey, 80%<br />

of respondents use this type.<br />

“As the tactile and non-tactile<br />

worlds of data collection come<br />

together, there is not a question<br />

of using either video or traditional<br />

sensor data - but both,” says<br />

Salcher. “HBM is well positioned<br />

to face a growing demand in this<br />

area, already integrating video in<br />

a range of our applications.”<br />

New Industry 4.0 course<br />

will equip future leaders<br />

Festo Training & Consulting<br />

has launched its first<br />

Industry 4.0 course.<br />

It is designed to equip<br />

business leaders with the<br />

strategic skills and insights<br />

to make the most of the<br />

opportunities presented by<br />

the fourth industrial<br />

revolution where the ready<br />

availability of data and the<br />

standardisation of machine<br />

communication will enable<br />

new and disruptive business<br />

models to emerge.<br />

Over two days, Festo’s<br />

course will assist leaders to<br />

identify opportunities for<br />

change within their own<br />

workplaces and help them<br />

recognise how and where<br />

to apply the principles of<br />

Industry 4.0.<br />

Whether participants are<br />

considering a new factory or<br />

plant and want to understand<br />

the principles behind<br />

Industry 4.0 or whether<br />

they are looking to apply<br />

certain aspects within the<br />

current limitations of existing<br />

processes, this course will<br />

help them take a big step<br />

forward, says Festo.<br />

The course runs either as an<br />

Pharmaceutical packaging<br />

machine company Uhlmann<br />

Packaging Systems<br />

has acquired Cremer<br />

Speciaalmachines, the Dutch<br />

manufacturer of counting and<br />

packaging systems. The two<br />

family-owned companies will<br />

combine their technological,<br />

research and market<br />

development expertise.<br />

By acquiring Cremer,<br />

Uhlmann strengthens its<br />

market position in bottle<br />

packaging systems.<br />

Festo’s two day 4.0 course helps leaders identify opportunities for change<br />

open course for participants<br />

from different companies<br />

or as an in-company course<br />

across an organisation or from<br />

within a department.<br />

Dates of the open courses<br />

this year are:<br />

• 12/13 <strong>September</strong> <strong>2017</strong><br />

• 24/25 <strong>October</strong> <strong>2017</strong><br />

• 14/15 November <strong>2017</strong>.<br />

All open courses will be held<br />

at Festo in Northampton, while<br />

Acquisition brings together two specialists<br />

in the pharmaceutical machinery business<br />

Talents of two pharma firms combine<br />

Tobias Uhlmann, owner<br />

and chairman of the Uhlmann<br />

supervisory board said:<br />

“The respective expertise of<br />

Festo can also run in-company<br />

courses in any location.<br />

“Working in small groups<br />

and teams, the course is<br />

for leaders who want to<br />

make better investment<br />

decisions that will equip their<br />

organisations for the future,”<br />

says Neil Lewin from Festo<br />

Training & Consulting.<br />

W www.festo-didactic.co.uk/<br />

TCM261<br />

our company’s complements<br />

each other perfectly, and by<br />

bundling up our talents, we<br />

will drive the goals of both<br />

companies forward.”<br />

“It was important for me<br />

to hand my company over to<br />

a highly competent partner<br />

with a long-term interest<br />

in its health and continued<br />

development,” says<br />

Fred Cremer, owner of<br />

Cremer Speciaalmachines.<br />

“In this sense, we have found<br />

our new home at Uhlmann.”

26 – 28 <strong>September</strong> <strong>2017</strong><br />

NEC, Birmingham<br />

THE UK’S UNMISSABLE TRADE<br />

EVENT FOR PROCESSING AND<br />

PACKAGING MACHINERY<br />

Including materials, robots and<br />

industrial vision<br />

FREE<br />

TO ATTEND<br />

REGISTER<br />

NOW!<br />

See the latest<br />

machinery in action<br />

Network with<br />

industry peers<br />

Gain valuable insights<br />

at seminars<br />

“A day at the show gives you a year of vision”<br />

PPMA Show 2016 Visitor<br />

ppmashow.co.uk<br />

Organised by

12 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

News<br />

Fuji stalwart has died<br />

Powtech takes place in Germany<br />

Powder and bulk<br />

solids processing<br />

fair in <strong>September</strong><br />

One of the<br />

founding<br />

directors<br />

of Paramount<br />

Packaging John<br />

Roberts has sadly<br />

passed away at the<br />

age of 59 after a<br />

long battle against<br />

a brain tumour.<br />

Roberts had been<br />

in the packaging<br />

machinery business<br />

for over 40 years,<br />

having started<br />

his career at 18, at<br />

Avery Berkel. He<br />

formed Paramount,<br />

along with its<br />

current technical<br />

director Charles Ingham,<br />

25 years ago and was its sales<br />

director. The business has<br />

expanded over the years<br />

and has supplied over<br />

Powtech, the trade fair for<br />

the processing, analysis and<br />

handling of powder and bulk<br />

solids takes place in Nuremberg,<br />

Germany from 26 – 28<br />

<strong>September</strong>, <strong>2017</strong>. The event is<br />

billed as offering a complete<br />

overview of all processes for the<br />

manufacture of quality products<br />

from powder, granules and bulk<br />

solids, and covers almost all<br />

industries including chemicals,<br />

pharmaceuticals, food,<br />

environmental and recycling.<br />

W<br />

TM Robotics MU www.powtech.de/en<br />

S-O <strong>2017</strong>.qxp_MU 22/08/<strong>2017</strong> 16:26 Page 1<br />

700 machines to companies<br />

Paramount Packaging sales director John Roberts is seen here<br />

with his wife Julie. He will be sadly missed by everyone<br />

all over the UK and Ireland.<br />

The company continues<br />

to maintain a very special<br />

relationship with the Fuji<br />

Packaging <strong>Machinery</strong><br />

Company of Japan, for which<br />

it is exclusive UK & Ireland<br />

distributor. John<br />

loved this special<br />

relationship that<br />

has been built<br />

with Fuji and took<br />

great pleasure<br />

from visiting<br />

Japan for product<br />

launches and sales<br />

seminars as well<br />

as introducing<br />

customers to the<br />

Fuji family.<br />

“He was an<br />

excellent salesman<br />

and businessman,<br />

coupled with a<br />

good sense of<br />

humour that kept<br />

us all down to earth,” says<br />

Charles Ingham.<br />

“He will be sadly missed.”<br />

Roberts is survived by<br />

his wife Julie, his two sons<br />

Andrew and Christopher and<br />

two grandchildren.<br />

NEW TVM 6-AXIS ROBOTS FROM<br />

T: 01707 290 370 E: sales@tmrobotics.co.uk www.tmrobotics.co.uk

I can see something<br />

you cannot see.<br />

SmartReflect ® Transparent – detects any transparent object.<br />

SmartReflect ® , the light barrier without a<br />

reflector, sets new benchmarks by detecting<br />

transparent objects within 1 m distance – at a mere<br />

0.25 ms response time. Available in compact<br />

plastic and stainless steel designs.<br />

Learn more at<br />

www.baumer.com/smartreflect

14 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

Labelling, New <strong>Machinery</strong> Coding & Marking<br />

Oxygen content is measured<br />

in-line to guarantee quality<br />

GEA describes OxyCheck<br />

as offering a new level<br />

of ensuring food quality<br />

as it measures every pack<br />

on a line to see if the oxygen<br />

content is correct.<br />

The non-invasive, in-line<br />

quality control system<br />

for modified atmosphere<br />

packaging (MAP) is designed<br />

to benefit consumers, retailers<br />

and food producers alike.<br />

This technology checks and<br />

analyses the oxygen content<br />

in every MAP pack produced.<br />

It is not just checking for leaks<br />

where oxygen is escaping.<br />

“The correct oxygen content<br />

is absolutely critical when it<br />

comes to reach the promised<br />

shelf life and product quality<br />

like taste and colour,” explains<br />

Volker Sassmannshausen,<br />

senior product manager at GEA.<br />

“The fact that we are able<br />

to introduce this non-invasive<br />

system fully integrated into a<br />

thermoforming machine on<br />

an industrial scale without<br />

slowing down or stopping<br />

the process really sets our<br />

technology apart,” he says.<br />

Many invasive oxygen<br />

Invasive oxygen measuring only inspects samples but OxyCheck tests 100%<br />

measuring techniques only<br />

inspect sample packs but<br />

the GEA OxyCheck inspects<br />

100% of all packages<br />

produced without damaging<br />

the film or breaking the<br />

seal. This, according to<br />

Sassmannshausen, means<br />

only packages that don’t<br />

meet the residual oxygen<br />

specifications are discarded<br />

and no material or contents<br />

are wasted.<br />

Previously, a single package<br />

with deteriorated content<br />

could often lead to the<br />

rejection of an entire batch<br />

to prevent unsafe foods from<br />

reaching consumers. And the<br />

potential costs of a recall can<br />

be very substantial.<br />

“The GEA OxyCheck<br />

effectively minimises the risk<br />

to recall entire food batches<br />

and thus increases food safety<br />

and limits food waste, while<br />

saving our customers money,”<br />

says Sassmannshausen.<br />

In operation, a sensor spot<br />

is used to measure the oxygen<br />

level in the MAP packs,<br />

and these are preprinted at<br />

the film supplier as opposed<br />

to being printed in-line. Going<br />

forward, the company will<br />

license film suppliers to print<br />

this sensor spot.<br />

Currently, this technology<br />

can be included on the<br />

GEA PowerPak horizontal<br />

thermoformer as an option<br />

on new machines with<br />

MAP capability. In the<br />

future, however, the range<br />

of applications may grow<br />

to include other packaging<br />

machines, free-standing<br />

or hand-held scanners at<br />

distribution centres or pointof-sale<br />

monitoring for retailers.<br />

Readers visiting the PPMA<br />

Show at the NEC in <strong>September</strong><br />

(26-28) have two opportunities<br />

to learn more about this<br />

technology: at 1pm on Tuesday<br />

and 1pm on Wednesday in<br />

the Learning Hub at the event.<br />

T 01908 513500<br />

W www.gea.com<br />

New dual gripper not only increases productivity, but it<br />

also makes life easier for workers tending any machines<br />

RARUK Automation believes<br />

its links with Universal<br />

Robots and Robotiq grippers<br />

& sensors provides the perfect<br />

combination for off-the-shelf,<br />

customised automation<br />

solutions. To widen the<br />

scope of this partnership,<br />

the company has announced<br />

the availability of the new<br />

Robotiq dual gripper.<br />

It is designed specifically for<br />

machine tending applications<br />

where the robot is required to<br />

remove a completed part from<br />

the machine and replace it<br />

with a new one for processing.<br />

The clear benefit of the<br />

Robotiq dual gripper is<br />

productivity. By having<br />

two grippers on the same<br />

Universal Robot arm shortens<br />

cycle times, creates a more<br />

efficient production line and<br />

increases output. Indeed,<br />

it’s even possible to have two,<br />

dual grippers on the same<br />

robot to boost productivity<br />

even further.<br />

One early user of this new<br />

combination has reduced<br />

changeover times by 50%<br />

The Robotiq dual gripper is available<br />

– from 40 minutes to<br />

20 minutes – when compared<br />

to loading its PCB products<br />

manually. Importantly, this<br />

technology also relieves<br />

employees of repetitive<br />

tasks that can cause<br />

physical and mental<br />

tiredness, allowing<br />

them to move on to<br />

more fulfilling roles<br />

within the business.<br />

The new gripper is suitable<br />

for all manufacturers seeking<br />

greater productivity and<br />

flexibility, whatever their<br />

size or level of experience<br />

in automation.<br />

T 01462 670044<br />

W www.rarukautomation.com

Components<br />

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 15<br />

New tipper discharges bulk<br />

materials from mobile bins<br />

Changing requirements are met<br />

Mobile conveyors<br />

offer flexibility for<br />

e-commerce packing<br />

To meet the complex challenges<br />

that ever-changing customer<br />

purchasing behaviour presents<br />

for e-commerce packaging<br />

requirements, Astec Conveyors<br />

is offering a range of mobile<br />

modular conveyors. These<br />

include gravity or powered roller<br />

conveyors, belt conveyors or<br />

modular belt conveyors.<br />

“There is a greater need from<br />

these customers to be able to<br />

change and configure conveyor<br />

positions easily and quickly,<br />

ready for the next sorting or<br />

packing operation and in food<br />

environments mobile conveyors<br />

can be easily moved to assist with<br />

cleaning operations,” says Astec<br />

sales manager Paul Fox.<br />

These conveyors can be made<br />

from stainless steel or powder<br />

coated mild steel.<br />

T 01283 210333<br />

W www.astecconveyors.com<br />

Anew<br />

hydraulic<br />

tipper<br />

from Flexicon<br />

discharges<br />

bulk solid<br />

materials from<br />

mobile bins<br />

at controlled<br />

rates into<br />

downstream<br />

process<br />

equipment or<br />

storage vessels<br />

free of dust.<br />

With lid<br />

open, the bin<br />

is rolled into<br />

a receiving<br />

frame, which<br />

positions it over<br />

a lifting tongue<br />

centred inboard<br />

of the castors. Side bracing<br />

prevents lateral movement<br />

of the bin during tipping.<br />

After securing the bin in<br />

place with a safety-interlocked<br />

door, a pair of hydraulic<br />

cylinders raises the bin<br />

vertically, seating its rim<br />

against the underside of a<br />

rectangular discharge hood.<br />

A second pair of hydraulic<br />

The new tipper for mobile bins transfers bulk material dust-free<br />

cylinders then elevates<br />

and tips the assembly, causing<br />

the discharge spout on the<br />

hood to mate with a gasketed<br />

inlet ring fitted to the lid<br />

of receiving hoppers,<br />

storage vessels or process<br />

equipment for total dust<br />

containment.<br />

Opening a pneumaticallyactuated<br />

slide gate valve at the<br />

spout outlet allows<br />

dust-free discharge<br />

at controlled rates.<br />

Closing the valve<br />

allows empty or<br />

partially empty bins<br />

to be returned to the<br />

plant floor with no<br />

dust emission.<br />

The unit<br />

can be sized to<br />

accommodate bins<br />

with rim dimensions<br />

up to 1220mm on<br />

a side, and up to<br />

1117mm in height.<br />

It is constructed<br />

as standard of carbon<br />

steel with stainless<br />

steel material<br />

contact surfaces, or<br />

in all stainless steel<br />

finished to food,<br />

dairy, pharmaceuticals or<br />

industrial standards.<br />

Optional receiving hoppers<br />

are available integrated<br />

with the company’s<br />

mechanical or pneumatic<br />

conveyors to transport<br />

discharged material to any<br />

plant location.<br />

T 01227 374710<br />

W www.flexicon.co.uk

16 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Pilot fermenter for APIs offers<br />

a broad range of process choice<br />

ubbles, <strong>Machinery</strong> <strong>Update</strong>, 149 x 225 mm, CC-en46-AZ356 07/17<br />

drinktec <strong>2017</strong><br />

Munich, 11 – 15 <strong>September</strong><br />

Hall B6<br />

B<br />

osch has introduced<br />

a new pilot fermenter<br />

for the cultivation<br />

of active pharmaceutical<br />

ingredients (APIs) on<br />

laboratory and pilot scale.<br />

“With the new pilot<br />

fermenter, Bosch has rolled<br />

out a modular, fully automatic<br />

system that is suitable for<br />

R&D applications, clinical<br />

studies in the lab and industrial<br />

production of small batches,”<br />

explains Dr John Medina,<br />

sales director at the Bosch<br />

subsidiary Pharmatec.<br />

“Whether the desired<br />

substance is an insulin<br />

preparation or a medication<br />

for targeted cancer therapy,<br />

our bioprocessing systems<br />

deliver optimum product<br />

quality and excellent process<br />

results,” he says.<br />

BATCH SIZES THAT CAN BE<br />

PROCESSED RANGE FROM<br />

8litres<br />

or 13 litres, up to 50 litres<br />

subject to mixer selection<br />

The factory of the future<br />

starts now<br />

We do more.<br />

Thanks to its modular<br />

design, the bioreactor is well<br />

suited to various cultivation<br />

processes and cell cultures.<br />

Interchangeable mixing and<br />

dosing technologies ensure<br />

that the optimal fermentation<br />

process can be found to match<br />

customer needs.<br />

The system can be<br />

equipped with one of<br />

several interchangeable<br />

mixing elements designed<br />

for different cell types and<br />

process controls, depending<br />

on customer requirements.<br />

The mixer regulates the inflow<br />

of liquids or gases needed for<br />

cell cultivation.<br />

Process media is fed fully<br />

automatically.<br />

T 01332 626262<br />

W www.boschpackaging.com

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 17<br />

Unwrapper/Unbagger is<br />

a flexible robotic option<br />

The BW Container<br />

Systems robotic<br />

Unwrapper/Unbagger<br />

is designed to remove<br />

stretch and/or shrink<br />

wrap from pallet loads<br />

prior to de-palletising.<br />

The machine has the<br />

capability to unwrap<br />

virtually any type of load<br />

utilising either form of<br />

wrapping.<br />

These loads include bulk<br />

glass or plastic bottles,<br />

aluminium or steel cans<br />

and pallets of cases or<br />

stretch wrapped bundles.<br />

The Unbagging option<br />

allows for removal of<br />

shrink wrap from bulk glass loads.<br />

As not all wrap types can be handled<br />

in the same way, the company offers<br />

three applications depending on specific<br />

requirements for wrap removal. These are<br />

the standard stretch wrap Unwrapper;<br />

the shrink wrap Unbagger and the fully<br />

featured Unwrapper/Unbagger which<br />

will remove both stretch or shrink wrap<br />

from pallet loads.<br />

In operation, the Unwrapper utilises a<br />

focused hot air gun (or heat gun) to apply<br />

a stream of hot air to the wrap. The hot<br />

air weakens the strength of the alreadystretched<br />

plastic, causing it to break apart<br />

In operation, the Unwrapper utilises a focused hot air gun to apply steam<br />

and therefore separating the wrap.<br />

The robot then places the wrap into a pinch<br />

roller assembly that pulls it through and<br />

into one of a variety of post unwrapping<br />

removal options.<br />

These start out as simple as a bin or it can<br />

be as integrated as a vacuum pipe system<br />

to a bailer. Multiple Unwrappers can feed a<br />

common bailer for multi-line applications.<br />

The Unbagger option utilises a knife<br />

to cut the shrink wrap but otherwise,<br />

the procedure is similar to the unwrapping<br />

process, says the company.<br />

T 01302 711056<br />

W www.bwcontainersystems.com<br />

FLEXIBLE<br />

FRIEND<br />

We offer unique flexible <br />

drive solutions, providing <br />

cost effective, multi-functional<br />

and bespoke<br />

<br />

designs which can be a<br />

perfect solution where <br />

rotational flexibility is <br />

required for critical<br />

applications.<br />

<br />

Thermal transfer overprinters improve<br />

production line efficiency and cut costs<br />

Videojet has launched its next generation<br />

of thermal transfer overprinters (TTO) to<br />

meet manufacturer’s demands for high<br />

code accuracy and legibility.<br />

The Videojet 6530 and 6330 come with<br />

iAssure technology which Videojet says is<br />

an industry-first, integrated code quality<br />

assurance system that automatically<br />

detects common print defects. Used to<br />

complement existing quality control<br />

processes, as it does not read barcodes,<br />

operators can now decide to stop the line<br />

when multiple common print defects are<br />

detected, reducing the need to scrap or<br />

rework product.<br />

“Videojet iAssure technology will help<br />

our customers consistently deliver high<br />

quality images by detecting print defects<br />

caused by things like dirty printheads,<br />

uneven print surfaces or ribbon wrinkles,”<br />

says Heidi Wright, business unit manager<br />

for Videojet Technologies. “iAssure<br />

technology complements existing quality<br />

control processes and no other TTO printer<br />

on the market can do this,” she claims.<br />

The 6530 and 6330 printers can also print<br />

on zipper packs or pouches of varying<br />

thickness with no special set up.<br />

T 0800 500 3023<br />

W www.videojet.co.uk<br />

E1A Enterprise Centre<br />

Enterprise Way<br />

Evesham<br />

Worcestershire WR11 1GS<br />

01386 421005<br />

sales@abssac.co.uk<br />

www.abssac.co.uk

18 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

drinktec preview<br />

Latest product handling<br />

meets today’s demands<br />

Visitors queuing to attend the<br />

2013 event at Messe München<br />

The world of drinks<br />

will meet once again<br />

in Munich this Sept<br />

The World’s leading trade fair<br />

for the beverage and liquid food<br />

industry is taking place again<br />

at Messe München from<br />

<strong>September</strong> 11 to 15, <strong>2017</strong>, where<br />

70,000 visitors are expected<br />

from 180 countries.<br />

Producers from all over the<br />

world will be attending to meet<br />

with suppliers and customers.<br />

Organisers say that once again,<br />

drinktec will be the platform for<br />

an array of world premieres from<br />

nearly 1,600 exhibitors from more<br />

than 75 countries. They will be<br />

housed in 15 halls with more than<br />

150,000sq m of exhibition space.<br />

Visitors can save 50% on<br />

ticket prices (full price day ticket<br />

is 59 euros) by buying online.<br />

W www.drinktec.com<br />

With Sidel and<br />

Gebo Cermex<br />

exhibiting<br />

together at drinktec<br />

<strong>2017</strong>, the Sidel Group<br />

companies will be<br />

showcasing their<br />

Agility 4.0 programme.<br />

The initiative is helping<br />

manufacturers and<br />

brand owners shift from<br />

mass production to mass<br />

customisation, and gain<br />

the many benefits of Industry<br />

4.0, while boosting Overall<br />

Equipment Effectiveness<br />

and sustainability while<br />

minimising Total Cost of<br />

Ownership.<br />

At the same time, Gebo<br />

Cermex will demonstrate<br />

AQFlex which it describes<br />

as breakthrough product<br />

handling technology.<br />

Thanks to its radically new<br />

approach of conveying and<br />

accumulation, AQFlex delivers<br />

unprecedented packaging<br />

line performance, says the<br />

company. It offers this,<br />

together with agility and<br />

smooth contactless product<br />

conveying and accumulation,<br />

Gebo Cermex describes AQFlex as the intelligent product handling solution<br />

in a very compact space.<br />

“After spending 50 years<br />

in pioneering conveying<br />

solutions and line regulation<br />

systems, we believe this<br />

introduction to be the<br />

culmination of our innovation<br />

processes,” says Ludovic<br />

Tanchou, vice president<br />

strategy, products and<br />

innovation at Gebo Cermex.<br />

“AQFlex is the new IQ<br />

in product handling,<br />

encompassing all the<br />

advantages given by the<br />

existing conveying machines<br />

in a much smarter way,”<br />

he tells <strong>Machinery</strong> <strong>Update</strong>.<br />

Freeing product innovation<br />

thanks to total flexibility<br />

AQFlex is designed by Gebo<br />

Cermex as a packaging<br />

solution that accommodates<br />

any product, whatever the<br />

application, whatever the<br />

market, in all container<br />

materials, formats and shapes,<br />

full or empty, while also<br />

enabling automatic changeovers<br />

via an intuitive HMI.<br />

Care of product integrity<br />

is completely ensured by<br />

the single-lane, contactfree<br />

product handling and<br />

accumulation system that<br />

is able to process even<br />

fragile, unstable or premium<br />

containers.<br />

STAND Hall A6 Stand 330<br />

W www.gebocermex.com<br />

Filling and packing systems<br />

under technology 4.0 banner<br />

Board chairman Matthias Niemeyer<br />

The KHS Group will be<br />

exhibiting the future of filling<br />

and packaging systems under<br />

the motto Technology 4.0 at<br />

the show. The effective and<br />

sustainable processes to be<br />

demonstrated are suitable for<br />

all sectors, from small craft<br />

brewers to large water bottlers.<br />

“Technology 4.0 means<br />

that innovative strength and<br />

future viability continue to<br />

characterise our systems<br />

and services,” says Matthias<br />

Niemeyer, KHS chairman.<br />

“Our focus of attention is<br />

on the innovative use of<br />

digitisation.”<br />

STAND Hall B4 Stand 328<br />

W www.khs.com<br />

Schubert’s key areas of expertise are erecting, filling and also sealing boxes<br />

Format diversity is combined<br />

with a small footprint at show<br />

Schubert will present the<br />

Innopack-TLM block packaging<br />

system which was developed<br />

with KHS to pack several<br />

different bottle and secondary<br />

packaging formats efficiently,<br />

and also in tight spaces for<br />

a range of beverages.<br />

STAND Hall B4 Stand 328<br />

W www.schubert-uk.co.uk

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 19<br />

Digitalisation is the<br />

unifying stand offer<br />

At this year’s drinktec Krones<br />

will, as in all the previous<br />

years, be showcasing its<br />

corporate capabilities in Hall B6.<br />

The principal focus this time is on<br />

innovations primarily designed<br />

to improve line performance still<br />

further, to ensure even higher<br />

individualisation and flexibility,<br />

and to impart additional<br />

sustainability to the production<br />

operation.<br />

Digitalisation plays a key role<br />

in this context, and constitutes a<br />

unifying theme for the entire Krones<br />

stand. Because marrying iron and<br />

steel to clouds and data makes<br />

for an even closer intermeshing<br />

of all processes along the entire<br />

value added chain, and will in the end<br />

significantly upgrade performance levels<br />

in the production environment as well.<br />

When it comes to filling beverages<br />

and liquid foods, the speed of the filling<br />

process plays a crucial role. For this<br />

reason, Krones is continuing to prioritise<br />

high speeds for its lines. Therefore, at<br />

drinktec <strong>2017</strong>, a high-speed line for filling<br />

bottles with beer will be on show, with a<br />

rating unequalled at present by any rival<br />

on the market, says the company.<br />

Also on show will be a pilot line that<br />

combines a filler, direct printing machine<br />

and intelligent conveyors, to demonstrate<br />

Krones will be intermeshing iron and steel with clouds and data<br />

that even small batch sizes can be<br />

efficiently produced while nonetheless<br />

retaining maximised flexibility.<br />

Krones is also driving forward the<br />

issue of eco-efficiency – and the vision<br />

of an energy-autonomous, sustainable<br />

production operation is already taking<br />

tangible shape in the ‘Brewery of the<br />

Future’, the company says.<br />

In addition, the demand for space-saving<br />

layouts is steadily increasing, which is<br />

why Krones is developing the block concept<br />

for complete lines.<br />

STAND Hall 6 Stand 100<br />

W www.krones.com<br />

HAVE YOU<br />

HEARD<br />

Ground and rolled ball<br />

screws for miniature high<br />

accuracy to heavy duty<br />

industrial applications, <br />

Abssac provides fast<br />

delivery, keen prices and<br />

knowledgeable sales staff.<br />

<br />

<br />

High speed transport technology is a<br />

slosh-free and easy to change option<br />

At drinktec, B&R Automation is offering<br />

beverage and liquid food producers a<br />

new generation of high-speed, slosh-free<br />

transport with the versatility for fast<br />

format changeovers.<br />

The company says this industrial-grade;<br />

service-friendly SuperTrak is the only longstator<br />

linear motor based system on the<br />

market to feature anti-sloshing technology.<br />

This prevents spills during transport and<br />

positioning and allows filling lines to be<br />

operated at higher speeds.<br />

Also, the independent SuperTrak shuttles<br />

allow mass customisation with minimal<br />

time lost on stoppages and changeover.<br />

The anti-sloshing technology prevents spillages<br />

STAND Hall A3 Stand 328<br />

W www.br-automation.com<br />

E1A Enterprise Centre<br />

Enterprise Way<br />

Evesham<br />

Worcestershire WR11 1GS<br />

01386 421005<br />

sales@abssac.co.uk<br />

www.abssac.co.uk

20 MACHINERY UPDATE SEPTEMBER/OCTOBER <strong>2017</strong> www.machineryupdate.co.uk<br />

New <strong>Machinery</strong><br />

Mid-range multihead weighers<br />

are designed for food suppliers<br />

ord MU S-O <strong>2017</strong>.qxp_MU 11/08/<strong>2017</strong> 11:02 Page 1<br />

I<br />

shida is launching a<br />

new series of mid-range<br />

multihead weighers for the<br />

high performance weighing of<br />

free-flowing and semi-sticky<br />

products for a large number<br />

of dry, fresh and frozen food<br />

applications.<br />

The new Ishida RVE range<br />

is available in a wide choice of<br />

models – including 10, 14, 16<br />

and 20 head units – together<br />

with a broad selection of radial<br />

troughs, hoppers (from 3 to 7<br />

litres) and discharge chutes.<br />

This enables the weighers<br />

to be tailored to individual<br />

product requirements with<br />

models available for mono-,<br />

mixed product (handling<br />

up to four different products<br />

simultaneously) and multipleoutlet<br />

weighing, and from<br />

small to large target weights.<br />

SPEEDS CAN REACH UP TO<br />

120<br />

weighments a minute depending<br />

on the model and application<br />

Key to the performance<br />

of the new RVE weighers is<br />

the introduction of several<br />

advanced technology features<br />

from Ishida’s top-of-the-range<br />

RV multihead weighers,<br />

including programmable<br />

digital filtering and advanced<br />

automatic feeder adjustment.<br />

An important benefit of the<br />

RVE range is that all models<br />

are pre-configured for the new<br />

generation of ‘smart’ factories<br />

and are available with a choice<br />

of packages incorporating<br />

Ishida’s Sentinel remote<br />

customer care software.<br />

“The speed, accuracy and<br />

reliability of every model<br />

will ensure they deliver a fast<br />

return on investment,”<br />

says Ian Atkinson of Ishida.<br />

T 0121 607 7700<br />

W www.ishidaeurope.com

www.machineryupdate.co.uk SEPTEMBER/OCTOBER <strong>2017</strong> MACHINERY UPDATE 21<br />

EASY<br />

PEASY<br />

TM Robotics has now launched Toshiba Machine’s latest range of six-axis robots in Europe and also in the US<br />

u<br />

u<br />

ETP’s Precision hydraulic<br />

bushes allow quick, easy<br />

and precise shaft<br />

P<br />

mounting for a multitude<br />

of applications. Utilising a<br />

single screw operation, for<br />

mounting and<br />

dismounting of the hub,<br />

makes life easy.<br />

Six-axis robot range is<br />

long arm length choice<br />

TM Robotics, Toshiba Machine’s<br />

EMEA and US partner, has launched<br />

its latest range of six-axis robots<br />

that can be used in a variety of industrial<br />

applications including manufacturing for<br />

automotive components, plastics, medical,<br />

packaging and the pharmaceutical sector.<br />

This vertically articulated robot series<br />

is available in three models, each with<br />

varying reach and payload specifications.<br />

Compared to previous ranges, the<br />

improved TVM six-axis robot series also<br />

provides a longer arm length in each of<br />

its three models.<br />

The largest model, the TVM1500,<br />

provides a maximum reach of 1715mm,<br />

the TVM1200 can reach up to 1418mm<br />

and the smallest model, the TVM900,<br />

provides a maximum reach of up to<br />

1124mm. In addition to three distinctive<br />

arm lengths, the operating range of each<br />

model can be expanded by mounting the<br />

robot on an optional linear actuator.<br />

Even though the robot body has been<br />

reduced in weight, the six-axis TVM range<br />

can still manage payloads of up to 20kg,<br />

with the TVM900 model. The smaller<br />

models, the TVM1200 and TVM1500 can<br />

each manage 15kg and 10kg respectively.<br />

These robots also provide complete<br />

hardware compatibility with other<br />

Toshiba Machine equipment, including<br />

the company’s robot vision recognition<br />

package TSVision3D. What’s more, all<br />

three models are compatible with the same<br />

robot controller, the TSL3200.<br />

As with all Toshiba Machine industrial<br />

robots, the controllers are programmed<br />

in SCOL, a programming language similar<br />

to BASIC.<br />

CELL BASED ROBOTS ON OFFER<br />

“Everyone is talking about the potential<br />

of collaborative robotics in manufacturing,<br />

however investing in this technology is<br />

not always feasible, or even necessary,”<br />

says Nigel Smith, founder and CEO of<br />

TM Robotics. “By trusting in our expertise,<br />

manufacturers can discover whether<br />

they really need to invest in collaborative<br />

robotics, or whether cell based robots<br />

could provide them with a more cost<br />

effective solution.<br />

“Toshiba Machine’s new six-axis TVM<br />

range will expand our robotics offering,<br />

allowing us to provide cost effective<br />

six-axis automation to manufacturers and<br />

industrial applications around the globe,”<br />

he continues. “Alongside our Toshiba<br />

Machine SCARA and Cartesian robots<br />

and the new six-axis TVM range,<br />

TM Robotics also delivers training<br />

and support services for industrial<br />

and commercial applications.”<br />

T 01707 290370<br />

W www.tmrobotics.co.uk<br />

E1A Enterprise Centre<br />

Enterprise Way<br />

Evesham<br />

Worcestershire WR11 1GS<br />

01386 421005<br />

sales@abssac.co.uk<br />

www.abssac.co.uk

Domino Ax-Series: Coding<br />

Without Compromise<br />

Rewriting the Rules of Ink Jet<br />

Rewriting<br />

Print Quality<br />

• Perfect drops every time<br />

• Higher resolution text<br />

and 2D Codes<br />

• Inks for the toughest<br />

substrates<br />

Rewriting<br />

Value<br />

• Service free operation<br />

• Optimised fluid<br />

management systems,<br />

reducing waste<br />

• Minimum operator<br />

intervention<br />

Rewriting<br />

Performance<br />

• 29% Faster<br />

• Ideal for High Speed<br />

serialisation<br />

• Designed for the<br />

factory of the future<br />

Designed by Customers,<br />

Engineered by Domino<br />

The way we think about it, if you want to improve your products,<br />

listen to your customers. So we did. We learned from your coding<br />

experiences and studied the regulatory, environmental and supply<br />

chain pressures you face.<br />

And then we deconstructed Continuous Ink Jet as we’ve known it<br />

for the past four decades – before rebuilding it as a better, faster,<br />

more responsive and cost effective technology.<br />

Experience the Domino Ax-Series and rethink Continuous Ink Jet.<br />

To fi nd out more or to book a demo visit<br />

www.ax-series.com<br />

THE RULES

www.machineryupdate.co.uk september/october <strong>2017</strong> MACHINERY UPDATE 23<br />

Components PACK EXPO Las Vegas Preview<br />

Complete wrapping and<br />

cartoning line on display<br />

Seen for the first time<br />

in the US on the<br />

Bradman Lake stand<br />

is the latest integrated<br />

packaging technology in a<br />

packaging line comprising<br />

flow wrapping and end<br />

load cartoning.<br />

The line includes an<br />

FT120 flow wrapper<br />

and the IMSL end load<br />

cartoner. In operation,<br />

once the products have<br />

been flow wrapped, they<br />

enter the IMSL end load<br />

cartoner – Bradman<br />

Lake’s latest machine.<br />

This compact-footprint<br />

IMSL incorporates a<br />

Rockwell Automation<br />

iTRAK unit to create a fully<br />

integrated product infeed<br />

system that uses minimal<br />

product transfers.<br />

To further enhance the IMSL’s<br />

compact footprint, products<br />

are side loaded into the cartons<br />

via a linear motion loader.<br />

The system is set-up with<br />

a single point of access<br />

with remote connectivity<br />

for online fault diagnostics<br />

and ‘Factory Talk Analytics’<br />

The new end load cartoner from Bradman Lake<br />

incorporates a Rockwell Automation iTRAK unit<br />

for system data collection.<br />

The system incorporates the<br />

latest integrated connectivity<br />

Industry 4.0 technology to<br />

communicate seamlessly<br />

over a common network<br />

and protocol.<br />

This enables the installation<br />

of customised systems that<br />

deliver enhanced productivity,<br />

security and operational<br />

intelligence with live data<br />

output to drive smarter<br />

management decisions.<br />

This flexible, intelligent<br />

system allows for<br />

an exhaustive range<br />

of possible system<br />

configurations to meet<br />

every conceivable<br />

packaging need, says<br />

the company.<br />

Factory Talk View<br />

Point is utilised for<br />

local connectivity to<br />

link each machine,<br />

providing system control<br />

and performance data<br />

locally at each of the<br />

machines HMIs.<br />

“Our technologies<br />

are influenced by our<br />

ability to serve a variety<br />

of markets with tailor made<br />

solutions, and at the same time<br />

developing new and innovative<br />

packaging technologies to suit<br />

current day market demands,”<br />

says John Marlee, managing<br />

director at the Bradman Lake<br />

Group. “Our investment to<br />

achieve this, demonstrates<br />

our commitment to our<br />

global customers.”<br />

STAND C-4027<br />

W www.bradmanlake.com<br />

PACK EXPO<br />

Las Vegas takes<br />

place in <strong>September</strong><br />

Sustainability, efficiency and<br />

product safety are among the<br />

top issues to be addressed with<br />

the latest packaging technology<br />

at PACK EXPO Las Vegas<br />

(Las Vegas Convention Centre,<br />

<strong>September</strong> 25–27), produced<br />

by PMMI, The Association<br />

of Packaging and Processing<br />

Technologies.<br />

Co-located with the Healthcare<br />

Packaging EXPO, the event<br />

is expected to host 30,000<br />

attendees, including 5,000<br />

international visitors from more<br />

than 125 countries, and 2,000-<br />

plus exhibiting companies that<br />

will span nearly 900,000<br />

net-square-feet of an almost<br />

sold-out exhibition floor.<br />

In addition to the technology<br />

to be demonstrated on the show<br />

floor, PACK EXPO Las Vegas will<br />

offer a host of educational and<br />

networking opportunities, as well<br />

as industry specific events.<br />

W www.packexpolasvegas.com<br />

New turbo-emulsifiers mix<br />

cosmetics more efficiently<br />

The Marchesini Group will<br />

show the vacuum turboemulsifier<br />

TURBO-MEK 150<br />

by Dumek and its own new<br />

continuous motion horizontal<br />

cartoner MA 400.<br />

Dumek is a specialised<br />

manufacturer of processing<br />

machines such as turboemulsifiers<br />

for mixing<br />

make-up, cleansers, hair dyes,<br />

and toothpaste as well as<br />

shaving products and is a new<br />

brand offered by the Group.<br />

The Dumek unit is<br />

designed to process liquid<br />

and creamy products for<br />

the cosmetics industry, in<br />

particular emulsions (cream/<br />

milk products), serums, oils<br />

and balms, gels and lotions.<br />

Special versions of these<br />

machines are able to process<br />

other products such as make<br />

up, suppositories, hair dyes,<br />

toothpastes, mud products<br />

and shaving creams.<br />

All the essential functions<br />

are commanded from the<br />

Dumek designed control panel.<br />

STAND N-215<br />

W www.marchesini.com<br />

This machine shows cosmetics is of growing importance to the Group

24 MACHINERY UPDATE september/october <strong>2017</strong> www.machineryupdate.co.uk<br />

Installation News<br />

A fresh approach to robot type<br />

has delivered line efficiencies<br />

Fox’s, one of the UK’s<br />

leading biscuit brands,<br />

has replaced hard<br />

working SCARA type<br />

robots with conventional<br />

six axis robots to overcome<br />

efficiency issues relating to<br />

obsolescence.<br />

The move away from SCARA<br />

configuration to conventional<br />

six axis arms illustrates the<br />

affordability and efficiency<br />

gains offered by today’s<br />

advanced robotic designs,<br />

says supplier Kawasaki.<br />

The biscuit maker’s Uttoxeter<br />

facility first implemented<br />

robotic handling of wrapped<br />

biscuits, using SCARA<br />

configuration robots in 1998.<br />

This move reduced operators<br />

from 34 to just 14, at the time.<br />

OPERATOR EFFICIENCY<br />

Designed originally for<br />

high-speed handling and<br />

assembly, the arms operated<br />

at their upper efficiency<br />

range for 80,000 hours before<br />

a complete rebuild and a<br />

further ten years of operation<br />

rendered them obsolete as<br />

they were operating at just<br />

70% efficiency.<br />

Out of three replacement<br />

options proposed to Fox’s,<br />

only Kawasaki Robotics UK<br />

suggested a move back to<br />

conventional six axis arms.<br />

Through simulations, the<br />

company was able to illustrate<br />

that its RS-20N robots would<br />

cost effectively match, and<br />

exceed if required, the output<br />

of the existing SCARA robots.<br />

“The SCARA arms had<br />

worked well but operating<br />

Out of three replacement options, only Kawasaki suggested six axis robots<br />

The Kawasaki RS-20N robot arms have met the specification cost effectively<br />

consistently at such high<br />

speeds, and obsolescence<br />

of parts, took its toll on<br />

operational efficiency,”<br />

explains David Bill, Fox’s<br />

maintenance manager and<br />

project manager for the<br />

update. “Our replacement<br />

criteria was straight-forward;<br />

to meet existing production<br />

levels and to fit within the<br />

existing work envelope,”<br />

he continues.<br />

“Kawasaki proved to us<br />

that its RS-20N robot arms<br />

could meet the specification<br />

cost effectively and operate<br />

well within their scope of<br />

performance,” explains Bill.<br />

Integration of the<br />

replacement robots and<br />

the updating of control and<br />

peripheral equipment was<br />

carried out by food and<br />

beverage automation specialists<br />

Visppro Limited. As an existing<br />

supplier to Fox’s and familiar<br />

with the production line,<br />

Visppro was ideally suited to<br />

ensure a smooth transition over<br />

a two week period.<br />

The production area<br />

produces variety packs, each<br />

pack comprising 4 separate<br />

packs of biscuits, typically<br />

Nice, Bourbon, Malted Milk<br />

and Custard Creams.<br />

Each robot’s job is to load<br />

an input conveyor with packs<br />

of one type of biscuit from a<br />