You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

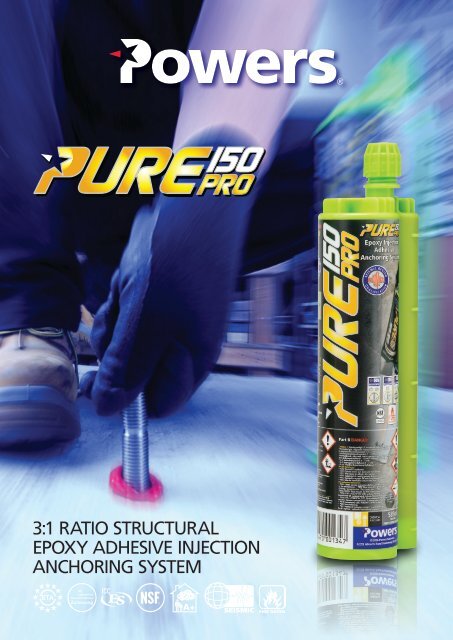

3:1 RATIO STRUCTURAL<br />

EPOXY ADHESIVE INJECTION<br />

ANCHORING SYSTEM

The Powers Plus range includes many mechanical and chemical anchoring systems the have<br />

ETA reports and can be used with confidence to meet the new NCC requirements.<br />

Approval Listing<br />

Anchor products holding a European <strong>Technical</strong> Approval/Assessment (ETA) are qualified according to one of the<br />

following technical guidelines (ETAG):<br />

• ETAG 001 for metal anchors installed in concrete.<br />

(Option 1 for cracked concrete, Option 7 for uncracked concrete, Part 6 for multiple use for non-structural applications)<br />

• ETAG 029 for metal injection anchors installed in masonry.<br />

• EOTA TR 023 for post-installed reinforcement bars.<br />

Products complying with European standards or approvals are marked with the CE Marking.<br />

The German <strong>Technical</strong> Approval of post installed reinforcement bars certifies that the product meets the<br />

requirements to be installed by trained personnel. The German <strong>Technical</strong> Approvals are next to the European<br />

<strong>Technical</strong> Approvals the most renowned qualifications of anchor products.<br />

The Evaluation Service of the International Code Council (ICC ES) provides test guidelines for anchor qualification<br />

in the US. The technical reports issued on the basis of these guidelines are internationally recognized and provide a<br />

high degree of safety.<br />

NSF International is an independent organization that provides standards for e.g. product certification for public<br />

health and the environment.<br />

VOC CLASSIFICATION<br />

Products tested for the emission of volatile substances in indoor air, with a risk of inhalation toxicity, on a scale<br />

ranging from class A + (very low emissions) to C (high emissions) level.<br />

Loads evolving from earthquakes are termed seismic loads and are characterised by cyclic loading. The suitability of<br />

the seismic load is classified as:<br />

• Seismic Category C1<br />

• Seismic Category C2<br />

FIRE RATED<br />

A fire resistance rating provides the duration of fire exposure for which the anchor product is qualified based<br />

on the ETA (EOTA TR 020) or other relevant evaluation reports. Ratings within the context of the European<br />

Organization of <strong>Technical</strong> Assessment (EOTA) are based on the following <strong>Technical</strong> Report (TR):<br />

• EOTA TR 020 “Evaluation of anchorages in concrete concerning resistance to fire”. In general, the design<br />

strength is reduced if exposure to fire is taken into account. Maximum duration for fire resistance is given in the<br />

specific product section and generally ranges from 120 to 240 min, depending on whether the anchor product is<br />

qualified for concrete anchoring or post-installed rebar connections.<br />

POWERS is one of the founding members of AEFAC (Australian Engineered Fasteners and Anchor Council).<br />

AEFAC is a consortium made of leading industry partners / suppliers of quality anchors to the construction industry<br />

and Swinburne University of Technology.<br />

AEFAC is a new industry-focused initiative which aims to set the standard for the specification, selection, design,<br />

applications and installation of structural anchors and fasteners in the Australian construction industry. AEFAC aims<br />

to enhance safety and efficiency associated with the use of structural anchors and fasteners. AEFAC is based at<br />

Swinburne University of Technology with access to state-of-the-art testing and research capabilities.<br />

The guidelines and resources being developed by AEFAC are intended to become the codes of practice in Australia.<br />

As well as being a founding member, POWERS is also on the Board and <strong>Technical</strong> Committee of AEFAC. POWERS<br />

also retains membership in several international organisations including Concrete Anchoring Manufacturers.<br />

2<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

PURE<strong>150</strong>-PRO<br />

Pure Epoxy 3:1 Adhesive Injection System<br />

The Pure<strong>150</strong>-Pro is a two-component 3:1 ratio structural epoxy adhesive<br />

injection system. High strength adhesive designed for bonding threaded rod,<br />

internal threaded sleeve or reinforcement bars into cracked and<br />

un-cracked concrete and other solid base materials. Consistent performance<br />

in un-cracked and cracked concrete of variable strength. Pure<strong>150</strong>-Pro is also<br />

qualified for core-drilled holes (diamond coring). †<br />

† Please refer to relevant Powers ETA documentation for load capacities in diamond core drilled holes.<br />

The design of the Pure<strong>150</strong>-Pro cartridge eliminates the leakage and dispensing problems often<br />

found with other systems. Each cartridge is configured with two parallel chambers containing<br />

the Component-A base resin and the Component-B hardener. During dispensing the epoxy is<br />

pressurised as it passes through a unique tapered nozzle containing a series of static mixing<br />

elements. As the epoxy components are pumped through the nozzle, they are progressively<br />

divided and recombined by the mixing elements to provide an easy, smooth flow, with a<br />

perfect mix ratio.<br />

Features<br />

• Long 24 month shelf life*<br />

• Low odour level (Low VOC)<br />

• Highly visible red colouration for easy on-site inspection<br />

• Long gel/working time<br />

• Non-sag ideal for overhead application<br />

• Excellent performance in hammer and diamond core drilled holes<br />

*from date of manufacture<br />

Approvals<br />

The following ETA assessment reports can be used to design anchors in accordance with SA TS 101:2015<br />

which is referenced in the National Construction Code (NCC) 2016:<br />

• ETA-08/0376 ETAG 001-5 Option 1 - Threaded rod (M8-M30), internal threaded sleeve (M8-M20) &<br />

reinforcing bar (Ø8-Ø32) - cracked & uncracked concrete<br />

• ETA-11/0352 ETAG 001-5 Option 7 - Diamond core holes (Uncracked concrete)<br />

• ETA-12/0541 ETAG 001-5 TR023 - Post installed rebar connection<br />

• ESR-2583 ICC-ES - Threaded rod (Cracked & uncracked concrete)<br />

• F120 Fire Resistance report<br />

• F240 Fire Resistance report (Rebar Connections)<br />

• Seismic Loading approval (C1: M12-M30 & rebar Ø12-Ø32. C2: M12-M16)<br />

• AS/NZS 4020:2005 Drinking water applications<br />

• NSF/ANSI 61 Potable drinking water certification<br />

• LEED report<br />

VOC CLASSIFICATION<br />

FIRE RATED<br />

APPROVED BASE MATERIAL LOADING CONDITIONS HOLE CONDITIONS<br />

Uncracked<br />

Concrete<br />

Cracked Concrete Solid Brick Hollow Brick Static Load Quasi-Static Load Seismic Moderate Wind High Wind<br />

Dry Hole/ Wet<br />

Concrete<br />

Flooded Holes Core Drillled<br />

Description Box Qty Carton Qty Part No.<br />

385ml Cartridge + 2 Mixing Nozzles 2 10 PURE<strong>150</strong>PRO-385-PWR<br />

585ml Cartridge + 2 Mixing Nozzles 2 10 PURE<strong>150</strong>PRO-585-PWR<br />

Please refer to the relevant ETA / ICC-ES report for complete information before selection, design and use to check suitability of the product.<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last Modified September, 2017 3

Ultimate Limit State Design<br />

Concrete Temperature Range: 40 0 C/24 0 C (Maximum long term 24 0 C and Maximum short term 40 0 C).<br />

Concrete Thickness = 1xh min<br />

where h min<br />

as per ETA. Hole condition: Dry/wet, non-flooded hole.<br />

Drilling method: HAMMER DRILLED HOLES ONLY (Refer to PDA software for core drilled or flooded holes).<br />

Edge Distance: No concrete edge distance effect considered.(i.e. edge distance > maximum (10 X h eff<br />

& 60 X d) in all directions).<br />

Spacing between anchors: The values are for single anchors installed well away from concrete edges and other anchors. No spacing effects considered.<br />

UNCRACKED CONCRETE<br />

Single Anchor Load Capacities (kN) for Threaded Rod (static or quasi-static loads)<br />

Anchor<br />

Size<br />

(mm)<br />

Hole<br />

Size<br />

(mm)<br />

8 10<br />

10 12<br />

12 14<br />

16 18<br />

20 24<br />

24 28<br />

30 35<br />

Depth<br />

h eff<br />

(mm)<br />

Concrete<br />

Thickness<br />

h min<br />

(mm)<br />

Class 5.8 Threaded Rod Class 8.8 Threaded Rod A4-50 Stainless Steel<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa<br />

60 100<br />

12.6 13.2 13.6 13.8<br />

80 110 12.2 7.3 16.8 17.6 18.1 18.4 11.7 6.4 3.8<br />

120 <strong>150</strong> 19.5<br />

60 100 13.0 16.5 17.0 17.3<br />

13.0 16.5 17.0 17.3<br />

90 120<br />

11.6 23.6 24.7 25.4 25.9 18.6 10.2 6.1<br />

19.3<br />

120 <strong>150</strong> 30.9<br />

70 100 16.4 20.8 23.2 24.2<br />

16.4 20.8 23.2 24.2<br />

110 140<br />

16.9 32.4 36.2 37.3 38.0 27.0 14.8 8.9<br />

28.1<br />

155 185 45.0<br />

80 116 20.1 25.4 28.4 31.1<br />

20.1 25.4 28.4 31.1 C-Pryout 20.1 25.4 27.4<br />

125 161 39.2 49.6 52.2 31.3 39.2 49.6 52.8 53.8<br />

16.5<br />

50.1 27.4<br />

215 251 52.2 83.6<br />

90 138 20.5 26.0 29.0 31.8<br />

20.5 26.0 29.0 31.8 C-Pryout 20.5 26.0 29.0 31.8<br />

170 218 53.3 67.4 71.4 72.7 53.3 67.4 71.4 72.7<br />

49.0<br />

25.7<br />

230 278<br />

83.9 93.8 96.6 98.4 78.3 42.8<br />

81.6<br />

320 368 124.5 130.4 130.6<br />

100 156 24.0 30.4 34.0 37.3 C-Pryout 24.0 30.4 34.0 37.3 C-Pryout 24.0 30.4 34.0 37.3<br />

210 266 73.2 92.6 97.7 99.5<br />

73.2 92.6 97.7 99.5<br />

250 306 95.1 112.9 116.3 117.5 70.5 95.1 112.9 116.3 118.5 112.8 61.7<br />

37.0<br />

400 456 117.5 172.3 180.6 186.1 188.0<br />

120 190 31.6 40.0 44.7 49.0 C-Pryout 31.6 40.0 44.7 49.0 C-Pryout 31.6 40.0 44.7 49.0 58.9<br />

270 340 106.7 135.0 <strong>150</strong>.9 160.0<br />

106.7 135.0 <strong>150</strong>.9 160.0<br />

300 370 125.0 158.1 174.5 177.7 125.0 158.1 174.5 177.7<br />

112.1<br />

179.4 98.1 58.9<br />

450 520<br />

229.6 254.0 261.7 266.6<br />

186.9<br />

550 620 296.2 299.0<br />

Capacity is limited by steel strength. C-Pryout: Capacity is limited by the shear concrete pry-out<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Ultimate Limit State Design<br />

CRACKED CONCRETE<br />

Cracked concrete does not mean concrete having existing / physical cracks.<br />

The condition of concrete (cracked or uncracked) needs to be determined via<br />

stress analysis by the design engineer.<br />

Single Anchor Load Capacities (kN) for Threaded Rod (static or quasi-static loads)<br />

Anchor<br />

Size<br />

(mm)<br />

Hole<br />

Size<br />

(mm)<br />

12 14<br />

16 18<br />

20 24<br />

24 28<br />

30 35<br />

Depth<br />

h eff<br />

(mm)<br />

Concrete<br />

Thickness<br />

h min<br />

(mm)<br />

Class 5.8 Threaded Rod Class 8.8 Threaded Rod A4-50 Stainless Steel<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa<br />

70 100 11.0 11.5 11.9 12.1<br />

110 140 17.3 18.1 18.7 19.0 17.3 18.1 18.7 19.0<br />

16.9<br />

<strong>150</strong> 180 22.0 23.0 23.8 24.2 22.0 23.0 23.8 24.2<br />

240 270 28.1 35.2 36.9 38.0 38.7<br />

80 116 14.3 15.2 15.7 16.0<br />

125 161 22.7 23.8 24.5 25.0 22.7 23.8 24.5 25.0<br />

31.3<br />

250 286 45.4 47.6 49.0 49.9 45.4 47.6 49.0 49.9<br />

300 336 52.2 54.5 57.1 58.8 59.9<br />

11.0 11.5 11.9 12.1 C-Pryout 11.0 11.5 11.9 12.1<br />

27.0 14.8<br />

14.3 15.2 15.7 16.0 C-Pryout 14.3 15.2 15.7 16.0<br />

50.1<br />

22.7 23.8 24.5 25.0<br />

90 138 14.6 16.9 17.4 17.8 C-Pryout 14.6 16.9 17.4 17.8 C-Pryout 14.6 16.9 17.4 17.8<br />

170 218 30.5 32.0 33.0 33.6<br />

30.5 32.0 33.0 33.6<br />

300 348 53.9 56.4 58.2 59.2 49.0 53.9 56.4 58.2 59.2<br />

350 398 62.8 65.8 67.9 69.1 62.8 65.8 67.9 69.1<br />

78.3<br />

27.4<br />

30.5 32.0 33.0 33.6<br />

100 156 17.1 20.7 21.3 21.7 C-Pryout 17.1 20.7 21.3 21.7 C-Pryout 17.1 20.7 21.3 21.7<br />

210 266 41.5 43.5 44.8 45.6<br />

41.5 43.5 44.8 45.6<br />

300 356 59.2 62.1 64.0 65.2 70.5 59.2 62.1 64.0 65.2 112.8 59.2 61.7<br />

42.8<br />

41.5 43.5 44.8 45.6<br />

450 506 88.9 93.1 96.0 97.7 88.9 93.1 96.0 97.7 61.7<br />

120 190 22.5 28.5 31.9 32.6 C-Pryout 22.5 28.5 31.9 32.6 C-Pryout 22.5 28.5 31.9 32.6<br />

270 340 66.6 69.8 72.0 73.3<br />

66.6 69.8 72.0 73.3<br />

66.6 69.8 72.0 73.3<br />

350 420 86.4 90.5 93.3 95.0 112.1 86.4 90.5 93.3 95.0 179.4 86.4 90.5 93.3 95.0<br />

600 670 148.1 155.2 160.0 162.9 148.1 155.2 160.0 162.9 98.1<br />

8.9<br />

16.5<br />

25.7<br />

37.0<br />

58.9<br />

Capacity is limited by steel strength. C-Pryout: Capacity is limited by the shear concrete pry-out<br />

Notes:<br />

• The above tension load capacities are the minimum values from concrete cone, concrete bond/pullout and steel capacities.<br />

• The above shear load capacities are the minimum values from concrete cone pryout, concrete pullout pryout, concrete<br />

edge and steel capacities.<br />

• C-Pryout: Where indicated capacity is limited by the shear concrete pry-out failure mode. Please use PDA software to<br />

calculate capacities.<br />

• Please refer to SATS101 : 2015 for sustained load conditions requirement. The published data may be used when the ratio<br />

of sustained load to total load acting on the anchor at ultimate limit state is ≤ 0.6.<br />

• Interpolation is not permitted. Please use PDA software to calculate capacities for the configurations outside the published<br />

information.<br />

• Use of PDA software is recommended to calculate the capacities for multiple anchor configurations and single anchor<br />

installed close to edge/s of concrete, and / or other anchors.<br />

Combined Loading: Anchors loaded<br />

in both tension and shear must satisfy<br />

the relevant combined load equation.<br />

Incorporated Strength Reduction Factors for Ultimate Limit State Design Capacities:<br />

The following strength reduction factors are derived using the information given in SA TS 101:2015 and the<br />

partial safety factors in the issued ETA (Assessment Report) for static and quasi-static loads.<br />

Concrete Steel<br />

≤ M16 > M16 Cl 5.8 Cl 8.8 A4-50<br />

Tension (Strength Reduction Factor “ ”) 0.56 0.48 0.67 0.67 0.35<br />

Shear (Strength Reduction Factor “ ”) 0.67 0.67 0.80 0.80 0.42<br />

PARTIAL SAFETY FACTORS GIVEN FOR DESIGN CAPACITIES IN ETA-08/0376<br />

M<br />

Tension (ETA Partial Safety Factor “ ”) 1.80 2.10 1.50 1.50 2.86<br />

Shear (ETA Partial Safety Factor “ M<br />

”) 1.50 1.50 1.25 1.25 2.38<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Working Stress Design<br />

Concrete Temperature Range: 40 0 C/24 0 C (Maximum long term 24 0 C and Maximum short term 40 0 C).<br />

Concrete Thickness = 1xh min<br />

where h min<br />

as per ETA.<br />

Hole condition: Dry/wet, non-flooded hole.<br />

Drilling method: HAMMER DRILLED HOLES ONLY (Refer to PDA software for core drilled or flooded holes).<br />

Edge Distance: No concrete edge distance effect considered.(i.e. edge distance > maximum (10 X h eff<br />

& 60 X d) in all directions).<br />

Spacing between anchors: The values are for single anchors installed well away from concrete edges and other anchors. No spacing effects considered.<br />

UNCRACKED CONCRETE<br />

Single Anchor Load Capacities (kN) for Threaded Rod (static or quasi-static loads)<br />

Anchor<br />

Size<br />

(mm)<br />

Hole<br />

Size<br />

(mm)<br />

8 10<br />

10 12<br />

12 14<br />

16 18<br />

20 24<br />

24 28<br />

30 35<br />

Depth<br />

h eff<br />

(mm)<br />

Concrete<br />

Thickness<br />

h min<br />

(mm)<br />

Class 5.8 Threaded Rod Class 8.8 Threaded Rod A4-50 Stainless Steel<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa<br />

60 100<br />

7.5 7.9 8.1 8.3<br />

80 110 7.3 3.7 10.1 10.5 10.9 11.1 5.9 5.2 2.6<br />

120 <strong>150</strong> 11.7<br />

60 100 7.8 9.9 10.2 10.4<br />

7.8 9.9 10.2 10.4<br />

7.8 8.3<br />

90 120<br />

5.8 14.1 14.8 15.3 15.6 9.3<br />

4.1<br />

11.6<br />

8.3<br />

120 <strong>150</strong> 18.6<br />

70 100 9.9 12.5 13.9 14.5<br />

9.9 12.5 13.9 14.5<br />

9.9 12.0<br />

110 140<br />

8.4 19.4 21.7 22.4 22.8 13.5<br />

6.0<br />

16.9<br />

12.0<br />

155 185 27.0<br />

80 116 12.0 15.2 17.0 18.7<br />

12.0 15.2 17.0 18.7 C-Pryout 12.0 15.2 17.0 18.7<br />

125 161 23.5 29.8 31.3 15.7 23.5 29.8 31.7 32.3<br />

11.2<br />

25.1 22.4<br />

215 251 31.3 50.1<br />

90 138 14.4 18.2 20.3 22.3<br />

14.4 18.2 20.3 22.3 C-Pryout 14.4 18.2 20.3 22.3<br />

170 230 320 218 37.3 47.2 49.0 37.3 47.2 50.0 50.9<br />

24.5<br />

17.5<br />

278<br />

58.7 65.6 67.6 68.9 39.2 35.0<br />

49.0<br />

368 78.3<br />

100 156 16.8 21.3 23.8 26.1 C-Pryout 16.8 21.3 23.8 26.1 C-Pryout 16.8 21.3 23.8 26.1<br />

210 266 51.2 64.8 68.4 69.7<br />

51.2 64.8 68.4 69.7<br />

250 306 66.5 70.5 35.3 66.5 79.0 81.4 82.9 56.4 50.4<br />

25.2<br />

400 456 70.5 112.8<br />

120 190 22.1 28.0 31.3 34.3 C-Pryout 22.1 28.0 31.3 34.3 C-Pryout 22.1 28.0 31.3 34.3<br />

270 340 74.7 94.5 105.6 112.0<br />

74.7 94.5 105.6 112.0<br />

74.7 80.1<br />

40.0<br />

300 370 87.5 110.6 112.1 56.1 87.5 110.6 122.1 124.4 89.7<br />

80.1<br />

450 520 112.1 160.7 177.8 179.4<br />

Capacity is limited by steel strength. C-Pryout: Capacity is limited by the shear concrete pry-out<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Working Stress Design<br />

CRACKED CONCRETE<br />

Cracked concrete does not mean concrete having existing / physical cracks.<br />

The condition of concrete (cracked or uncracked) needs to be determined via<br />

stress analysis by the design engineer.<br />

Single Anchor Load Capacities (kN) for Threaded Rod (static or quasi-static loads)<br />

Anchor<br />

Size<br />

(mm)<br />

Hole<br />

Size<br />

(mm)<br />

12 14<br />

16 18<br />

20 24<br />

24 28<br />

30 35<br />

Depth<br />

h eff<br />

(mm)<br />

Concrete<br />

Thickness<br />

h min<br />

(mm)<br />

Class 5.8 Threaded Rod Class 8.8 Threaded Rod A4-50 Stainless Steel<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

Tension Load (Concrete) Shear<br />

Load<br />

(Steel)<br />

20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa 20MPa 32MPa 40MPa 50MPa<br />

70 100 6.6 6.9 7.1 7.3<br />

6.6 6.9 7.1 7.3 C-Pryout 6.6 6.9 7.1 7.3<br />

110 140 10.4 10.9 11.2 11.4 10.4 10.9 11.2 11.4<br />

10.4 10.9 11.2 11.4<br />

8.4<br />

6.0<br />

<strong>150</strong> 180 13.2 13.8 14.3 14.5 13.2 13.8 14.3 14.5 13.5<br />

12.0<br />

240 270 16.9 21.1 22.1 22.8 23.2<br />

80 116 8.6 9.1 9.4 9.6<br />

8.6 9.1 9.4 9.6 C-Pryout 8.6 9.1 9.4 9.6<br />

125 161 13.6 14.3 14.7 15.0 13.6 14.3 14.7 15.0<br />

13.6 14.3 14.7 15.0<br />

15.7<br />

11.2<br />

250 286 27.2 28.5 29.4 29.9 27.2 28.5 29.4 29.9 25.1<br />

22.4<br />

300 336 31.3 32.7 34.2 35.3 35.9<br />

90 138 10.2 11.9 12.2 12.4 C-Pryout 10.2 11.9 12.2 12.4 C-Pryout 10.2 11.9 12.2 12.4<br />

170 218 21.4 22.4 23.1 23.5<br />

21.4 22.4 23.1 23.5<br />

21.4 22.4 23.1 23.5<br />

17.5<br />

300 348 37.7 39.5 40.7 41.5 24.5 37.7 39.5 40.7 41.5 39.2<br />

35.0<br />

350 398 44.0 46.1 47.5 48.4 44.0 46.1 47.5 48.4<br />

100 156 12.0 14.5 14.9 15.2 C-Pryout 12.0 14.5 14.9 15.2 C-Pryout 12.0 14.5 14.9 15.2 C-Pryout<br />

210 266 29.0 30.4 31.4 31.9<br />

29.0 30.4 31.4 31.9<br />

29.0 30.4 31.4 31.9<br />

300 356 41.5 43.5 44.8 45.6 35.3 41.5 43.5 44.8 45.6 56.4 41.5 43.5 44.8 45.6 25.2<br />

450 506 62.2 65.2 67.2 68.4 62.2 65.2 67.2 68.4 50.4<br />

120 190 15.8 20.0 22.3 22.8 C-Pryout 15.8 20.0 22.3 22.8 C-Pryout 15.8 20.0 22.3 22.8 C-Pryout<br />

270 340 46.7 48.9 50.4 51.3<br />

46.7 48.9 50.4 51.3<br />

46.7 48.9 50.4 51.3<br />

350 420 60.5 63.4 65.3 66.5 56.1 60.5 63.4 65.3 66.5 89.7 60.5 63.4 65.3 66.5 40.0<br />

600 670 103.7 108.6 112.0 112.1 103.7 108.6 112.0 114.0 80.1<br />

Capacity is limited by steel strength. C-Pryout: Capacity is limited by the shear concrete pry-out<br />

Notes:<br />

• The above tension load capacities are the minimum values from concrete cone, concrete bond/pullout and steel capacities.<br />

• The above shear load capacities are the minimum values from concrete cone pryout, concrete pullout pryout, concrete edge and steel capacities.<br />

• C-Pryout: Where indicated capacity is limited by the shear concrete pry-out failure mode. Please use PDA software to calculate capacities.<br />

• Please refer to SATS101 : 2015 for sustained load conditions requirement. The published data may be used when the ratio of sustained load to total load<br />

acting on the anchor at ultimate limit state is ≤ 0.6.<br />

• Interpolation is not permitted. Please use PDA software to calculate capacities for the configurations outside the published information.<br />

• Use of PDA software is recommended to calculate the capacities for multiple anchor configurations and single anchor installed close to edge/s of concrete,<br />

and / or other anchors.<br />

• To determine working load capacities a further suitable safety factor (minimum 1.4 or higher) shall be applied to the limit state design capacities derived<br />

from the PDA software.<br />

Combined Loading: Anchors loaded<br />

in both tension and shear must satisfy<br />

the relevant combined load equation.<br />

Incorporated Safety Factors for Working Stress Design Load Capacities:<br />

The following safety factors are used to derive values in the above table for the working<br />

stress design capacities for static load conditions<br />

Steel<br />

Concrete<br />

Cl 5.8 Cl 8.8 A4-50<br />

Tension 3.00 2.50 2.50 3.50<br />

Shear 3.00 2.50 2.50 3.50<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Material Properties<br />

The PURE<strong>150</strong>-PRO Epoxy is a two component reaction resin mortar based on Pure Epoxy. It has better resistance to moisture and better<br />

chemical resistance. The properties listed below apply to the PURE<strong>150</strong>-PRO Epoxy Injection Adhesive.<br />

Property Test Method Value<br />

Mixed Colour<br />

Red<br />

Mixing Ratio 3:1<br />

Viscosity (A-component) ASTM D 2556 16600 mPas<br />

Viscosity (B-component) ASTM D 2556 16400mPas<br />

Consistency<br />

Smooth, Non-Sag Paste<br />

Shelf life<br />

24 Months<br />

Working Time @ 20°C<br />

30 min<br />

Loading Time @ 20°C in dry concrete<br />

10 hours<br />

Minimum Substrate Temperature 5°C<br />

Temperature Stability 72°C<br />

UV Resistance Pass<br />

Watertightness DIN EN 12390-8 Pass<br />

pH-value >12<br />

Shore D Hardness ISO 7619 85<br />

Compressive Strength EN 196 Teil1 120 N / mm 2<br />

Flexural Strength EN 196 Teil1 42 N / mm 2<br />

Electrical Resistance IEC 93 1.2 X 1012 Ωm<br />

Thermal Conductivity IEC 60093 0.47 W / m.K<br />

Density 1.41 kg / dm 3<br />

E modulus EN 196 Teil1 10800 N / mm 2<br />

Shrinkage < 0.02%<br />

Storage Cold & dark place +5° to 25°C<br />

PURE<strong>150</strong>-PRO guns out red for<br />

easy on-site inspection<br />

Setting Time<br />

The setting times listed for the PURE<strong>150</strong>-PRO epoxy vary according to the volume of epoxy used and the base material temperature.<br />

The working time is the maximum time during which the epoxy can be dispensed before it begins to set. The minimum curing time<br />

is the time required for the epoxy to reach its published physical properties.<br />

Base Material Temp (°C) Max Working Time (minutes) Minimum Curing Time (hours)*<br />

≥ + 5°C 120 50<br />

≥ + 10°C 90 30<br />

≥ + 20°C 30 10<br />

≥ + 30°C 20 6<br />

≥ + 40°C 12 4<br />

*NOTE: Curing time is for dry concrete. Curing time must be doubled for wet concrete.<br />

Quality Control Procedures<br />

PURE<strong>150</strong>-PRO Epoxy Injection Adhesive is packaged individually. Each cartridge contains an expiry date which provides traceability<br />

of the components back to the original manufacturing batch. Every batch of material is subjected to extensive physical and chemical<br />

property testing during manufacture. Each combination of base resin and hardener material batches is tested as an installed anchor<br />

to ensure that the proper bond strength is developed. These procedures ensure consistent, top-quality performance to the specifier<br />

and the installer of the PURE<strong>150</strong>-PRO Epoxy Injection Adhesive.<br />

OH&S<br />

Safety <strong>Data</strong> <strong>Sheet</strong>s are available on request (Ref. Chemwatch 18-3723 and 18-3724) or can be downloaded from<br />

www.powers.com.au<br />

8<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Resistance to Chemicals<br />

Chemical Agent Concentration Resistant Not Resistant<br />

Acetic acid 40 X<br />

Laitance<br />

<br />

Acetone 10 X<br />

Ammonia, aqueous solution 5 <br />

Aniline 100 X<br />

Beer 100<br />

Chlorine All<br />

<br />

<br />

Benzol 100 X<br />

Boric Acid, aqueous solution<br />

<br />

Calcium carbonate, suspended in water All <br />

Calcium chloride, suspended in water<br />

<br />

Calcium hydroxide, suspended in water<br />

<br />

Carbon tetrachloride 100 <br />

Caustic soda solution 40 <br />

Citric acid All <br />

Chlorine water, swimming pool All <br />

Diesel oil 100 <br />

Ethyl alcohol, aqueous solution 50 X<br />

Formic acid 100 X<br />

Formaldehyde, aqueous solution 30 <br />

Freon<br />

<br />

Fuel Oil<br />

<br />

Gasoline (premium grade) 100 <br />

Glycol (Ethylene glycol)<br />

<br />

Hydrochloric acid (Muriatic Acid) Conc. X<br />

Hydrogen peroxide 30 X<br />

Isopropyi alcohol 100 X<br />

Lactic acid All X<br />

Linseed oil 100 <br />

Lubricating oil 100 <br />

Magnesium chloride, aqueous solution All <br />

Methanol 100 <br />

Motor oil (SAE 20 W-50) 100 <br />

Nitric acid 10 X<br />

Oleic acid 100 <br />

Perchloroethylene 100 <br />

Petroleum 100 <br />

Phenol, aqueous solution 8 X<br />

Phosphoric acid 85 <br />

Phosphoric acid 10 <br />

Potash lye (Potassium hydroxide, 10% and 40% solution)<br />

<br />

Potassium carbonate, aqueous solution All <br />

Potassium chlorite, aqueous solution All <br />

Potassium nitrate, aqueous solution All <br />

Sea water, salty All <br />

Sodium carbonate All <br />

Sodium Chloride, aqueous solution All <br />

Sodium phosphate, aqueous solution All <br />

Sodium silicate All <br />

Sulfuric acid 30 X<br />

Tartaric acid All <br />

Tetrachloroethylene 100 <br />

Toluene<br />

Trichloroethylene 100 X<br />

Turpentine 100 <br />

NOTE: Results shown on this table are applicable to brief periods of chemical contact with fully cured adhesive (e.g. temporary contact with adhesive during a spill).<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last Modified September, 2017 9<br />

X

Installation information<br />

Installation data - threaded rod<br />

T max<br />

Notation<br />

Unit<br />

Pure<strong>150</strong>-PRO - Threaded rod<br />

M8 M10 M12 M16 M20 M24 M27 M30<br />

S w<br />

Anchor diameter d [mm] 8 10 12 16 20 24 27 30<br />

d f<br />

Nominal drill bit diameter d 0<br />

= [mm] 10 12 14 18 24 28 32 35<br />

Diameter of hole clearance in fixture d f<br />

≤ [mm] 9 12 14 18 22 26 30 33<br />

Diameter of steel brush d b<br />

≥ [mm] 12 14 16 20 26 30 34 37<br />

h min<br />

h 1<br />

h ef<br />

Min embedment & drill hole depth h ef,min<br />

[mm] 60 60 70 80 90 96 108 120<br />

Max embedment & drill hole depth h ef,max<br />

[mm] 160 200 240 320 400 480 540 600<br />

Minimum member thickness h min<br />

[mm] h ef<br />

+ 30mm ≥ 100mm h ef<br />

+ 2 x d 0<br />

Minimum spacing s min<br />

[mm] 40 50 60 80 100 120 135 <strong>150</strong><br />

d 0<br />

Minimum edge distance c min<br />

[mm] 40 50 60 80 100 120 135 <strong>150</strong><br />

Thickness of fixture t fix<br />

[mm] 0 mm ≤ t fix<br />

≤ <strong>150</strong>0mm<br />

Maximum torque T max<br />

[Nm] 10 20 40 80 120 160 180 200<br />

Torque wrench socket size S w<br />

[mm] 13 17 19 24 30 36 41 46<br />

Installation data - internal threaded sleeve<br />

T max<br />

Notation<br />

Unit<br />

Pure<strong>150</strong>-PRO - Internal threaded sleeve<br />

M8 M10 M12 M16 M20<br />

S w<br />

External diameter of sleeve d [mm] 12 16 20 24 30<br />

t fix<br />

d f<br />

Nominal drill bit diameter d 0<br />

= [mm] 14 18 24 28 35<br />

Diameter of hole clearance in fixture d f<br />

≤ [mm] 9 12 14 18 22<br />

Diameter of steel brush d b<br />

≥ [mm] 16 20 26 30 37<br />

t fix<br />

h 1<br />

h ef<br />

h min<br />

h 1<br />

h ef<br />

Embedment and drill hole depth h ef<br />

[mm] 80 90 110 <strong>150</strong> 200<br />

Minimum member thickness h min<br />

[mm] 110 130 160 210 270<br />

Minimum edge distance c min<br />

[mm] 60 80 100 120 <strong>150</strong><br />

Minimum spacing s min<br />

[mm] 60 80 100 120 <strong>150</strong><br />

d 0<br />

Screw diameter d 1<br />

[mm] 8 10 12 16 20<br />

Minimum length of screw l 1,min<br />

[mm] 8 10 12 16 20<br />

Maximum length of screw l 1,max<br />

[mm] 35 45 55 75 85<br />

Maximum torque T max<br />

[Nm] 10 20 40 80 120<br />

Recommended Torque wrench socket size S w<br />

[mm] 13 17 19 24 30<br />

Installation data – reinforcement bar<br />

Notation Unit<br />

Ø8<br />

Pure<strong>150</strong>-PRO - Reinforcement bar<br />

Ø10 Ø12 Ø14 Ø16 Ø20 Ø24 Ø28 Ø32<br />

Nominal diameter of rebar d [mm] 8 10 12 14 16 20 24 28 32<br />

Nominal drill bit diameter d 0<br />

= [mm] 12 14 16 18 20 24 28 35 37<br />

Diameter of steel brush d b<br />

≥ [mm] 14 16 18 20 22 27 34 37 40<br />

Min embedment and drill hole depth h ef,min<br />

[mm] 60 60 70 75 80 90 96 112 128<br />

Max embedment and drill hole depth h ef,max<br />

[mm] 160 200 240 280 320 400 480 560 640<br />

Minimum member thickness h min<br />

[mm]<br />

h ef<br />

+ 30 mm<br />

≥ 100mm<br />

h ef<br />

+ 2 x d 0<br />

d 0<br />

Minimum edge distance c min<br />

[mm] 40 50 60 70 80 100 120 140 160<br />

Minimum spacing s min<br />

[mm] 40 50 60 70 80 100 120 140 160<br />

10<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Installation Instructions<br />

Hammer Drilled Hole in Solid Concrete<br />

1 Using the proper drill bit size, drill a hole into the base material to the required depth.<br />

2 Blow the hole clean using a hand pump (suitable for maximum 20mm dia. hole) or compressed<br />

air 2 - 2 times minimum.<br />

3 Brush the hole with the proper wire brush - 2 times minimum.<br />

4 Blow the hole clean using a hand pump (suitable for maximum 20mm dia. hole) or compressed<br />

air 2 - 2 times minimum 3 .<br />

5 Squeeze out separately and discard a minimum of 10cm until the mortar is uniformly mixed and<br />

shows consistent colour. Starting from the rear of the hole, fill the hole up to approximately 2/3<br />

with uniformly mixed adhesive.<br />

6 Push the threaded rod / rebar into the hole while turning slightly to ensure positive distribution<br />

of the adhesive. Be sure that the rod / rebar is seated at the bottom of the hole and that some<br />

adhesive has flowed from the top of the hole.<br />

7 Allow the adhesive to cure for the time specified for the actual concrete temperature. Do not<br />

disturb or load the anchor until the adhesive has fully cured. Follow the longer curing time for<br />

wet concrete.<br />

1 2 3 4 5 6 7<br />

e.g.<br />

20˚C<br />

Deep Embedment<br />

Installation (Ground /<br />

Overhead / Horizontal)<br />

i Use a compressed air<br />

extension gun to blow<br />

debris from the hole. 4<br />

2X<br />

2X<br />

2X<br />

10 hr<br />

Core-Drilled Hole in Solid Concrete<br />

1 Using the proper core bit size, drill a hole into the base material to the required depth.<br />

2 Rinse the hole until water runs clear.<br />

3 Brush the hole with the proper wire brush - 2 times minimum.<br />

4 Rinse the hole until water runs clear.<br />

5 Blow the hole clean using a hand pump (suitable for maximum 20mm dia. hole) or compressed<br />

air 2 - 2 times minimum.<br />

6 Brush the hole with the proper wire brush - 2 times minimum.<br />

7 Blow the hole clean using a hand pump (suitable for maximum 20mm dia. hole) or compressed<br />

air 2 - 2 times minimum 3 .<br />

8 Squeeze out separately and discard a minimum of 10cm until the mortar is uniformly mixed and<br />

shows consistent colour. Starting from the rear of the hole, fill the hole up to approximately 2/3<br />

with uniformly mixed adhesive.<br />

9 Push the threaded rod / rebar into the hole while turning slightly to ensure positive distribution<br />

of the adhesive. Be sure that the rod / rebar is seated at the bottom of the hole and that some<br />

adhesive has flowed from the top of the hole.<br />

10 Allow the adhesive to cure for the time specified for the actual concrete temperature (in dry<br />

concrete). Do not disturb or load the anchor until the adhesive has fully cured. Follow the longer<br />

curing time for wet concrete.<br />

1 2 3 4 5<br />

SDS Plus<br />

Brush<br />

Adaptor<br />

ii Extend the reach of<br />

the brush by using a<br />

Powers 300mm SDS<br />

brush adaptor.<br />

Nozzle<br />

6 7 8 9 10<br />

2X<br />

2X<br />

2X<br />

e.g.<br />

20˚C<br />

10 hr<br />

2X<br />

Extension<br />

Piston<br />

Plug<br />

iii Attach the plastic<br />

extension tube and<br />

correct size piston<br />

plug to the mixing<br />

nozzle. The Powers<br />

Battery Dispensing<br />

Tool is recommended<br />

for deep embedment<br />

applications.<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last Modified September, 2017 11

Overhead Installation - Hammer Drilled Hole in Solid Concrete<br />

1 Using the proper drill bit size, drill a hole into the base material to the required depth.<br />

2 Blow the hole clean using a hand pump or compressed air 2 - 2 times minimum.<br />

3 Brush the hole with the proper wire brush - 2 times minimum.<br />

4 Blow the hole clean using a hand pump or compressed air 2 - 2 times minimum 3 .<br />

5 (a) Small Holes: Squeeze out separately and discard a minimum of 10cm until the mortar is uniformly mixed and shows consistent<br />

colour. Starting from the rear of the hole, fill the hole up to approximately 2/3 with uniformly mixed adhesive. or<br />

(b) Overhead/Horizontal Holes: Attach the plastic extension tube and correct size piston plug to the mixing nozzle. Squeeze<br />

out separately and discard a minimum of 10cm until the mortar is uniformly mixed and shows consistent colour. Starting from<br />

the rear of the hole, fill the hole up to approximately 2/3 with uniformly mixed adhesive.<br />

6 Assemble the correct size retaining cap onto threaded rod at desired position, ensuring accurate embedment depth is achieved.<br />

7 Push the threaded rod into the hole while turning slightly to ensure positive distribution of the adhesive. Be sure that the rod<br />

is seated at the bottom of the hole and that some adhesive has flowed from the top of the hole. Ensure the retaining cap<br />

is wedged in the hole to support the threaded rod during curing time. If additional support is required, or the retaining cap<br />

does not fit, commercially available plastic wedges should be used as a secondary support system to provide further stability.<br />

A wedge should be positioned on either side of the threaded rod / rebar to ensure it is stable and centered in the hole. There<br />

should be no movement or slippage during curing time. Extra measures should be used to support heavier / longer lengths<br />

of reinforcing bar / rod to avoid any movement during curing time. Ensure the rebar/threaded rod is free of dirt, grease, oil or<br />

other foreign material.<br />

8 Allow the adhesive to cure for the time specified for the actual concrete temperature (in dry concrete). Do not disturb or load<br />

the anchor until the adhesive has fully cured. Follow the longer curing time for wet concrete.<br />

1 2 3 4 5 (a) 5 (b)<br />

2X<br />

2X<br />

2X<br />

Piston<br />

Plug<br />

Extension<br />

Tube<br />

6 7 8<br />

Nozzle<br />

Retaining<br />

Cap<br />

Retaining<br />

Cap<br />

Wedges<br />

e.g.<br />

20˚C<br />

10 hr<br />

Notes:<br />

1. Always refer to the product assessment reports and approvals (e.g. ETA) for detailed information including the design criteria<br />

2. Always use appropriate filters to prevent oil from the compressed air unit contaminating the drilled hole. The compressed air<br />

shall be free from oil.<br />

3. Holes may be dry or damp, but should be free of standing water or frost.<br />

4. An industrial wet/dry vacuum shall be used in combination with compressed air to extract debris and water from deeper holes<br />

in step 5 and 7 for core-drilled holes. For deeper depths an industrial vacuum shall be used to help clean the dust/debris from<br />

the holes in steps 2 and 4 for hammer-drilled holes. A proper size hose of vacuum shall be inserted to the bottom of the hole<br />

for removal of debris/water.<br />

5. When a longer extension tube is attached to the cartridge for injecting into deeper holes, the cartridge and its contents are required<br />

to be pre-warmed / conditioned to higher temperatures (e.g. 25-30ºC) just before injecting especially in cold conditions.<br />

The cartridges shall be stored within the storage conditions but only conditioned to higher temperatures just before injecting.<br />

12<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Dispensers<br />

Manual Dispensing Tools<br />

CG PRO-4 Manual Injection Tool is ideal for those who use the entire POWERS<br />

adhesive range. Designed with a pump style drive mechanism which has a high pump<br />

ratio to provide fast dispensing. The base unit is a unique design which allows for the<br />

dispensing of different cartridge and component ratios. The CG PRO-4 will dispense<br />

the 385 & 585ml (3:1) cartridge, as well as 300, 380 & 420ml (10:1) cartridges.<br />

CG PRO Manual Injection Tool like the CG PRO-4, is designed for use with all Powers<br />

adhesives, however is suitable for low to medium volume users. Designed with a<br />

high-ratio pump style drive mechanism to provide fast dispensing. The base unit and<br />

handle assembly are manufactured from precision steel casting for long life. A specially<br />

designed wear compensation mechanism ensures consistent pumping over the life of<br />

the tool.<br />

CG585 Manual Injection Tool is designed with a pump style drive mechanism which<br />

has a high pump ratio to provide fast dispensing. The base unit and handle assembly<br />

are manufactured from a precision steel casting for long life. A specially designed<br />

wear compensation mechanism ensures consistent pumping over the life of the tool.<br />

Suitable for use with both 385 & 585ml (3:1) coaxial cartridge.<br />

Pneumatic Dispensing Tool<br />

CGPN Pneumatic Injection Tool is designed for large jobs. The main cylinder is formed<br />

using top quality aluminum to provide a lightweight, durable tool. The dispensing<br />

trigger is designed to provide instant pressure relief from the cartridge to reduce<br />

waste. Suitable for use with both 385 & 585ml (3:1) coaxial cartridge.<br />

Maximum Operating Pressure: 110 psi<br />

Normal Operating Range: 80 to 100 psi<br />

Maximum Free Air Required: 1 CFM based on average use<br />

Battery Dispensing Tool<br />

CGB Battery Injection Tool works on<br />

Lithium-Ion technology providing longlasting<br />

consistent performance. It features<br />

a reinforced steel sheet cradle and a trigger<br />

system which provides instant pressure relief<br />

for the cartridge to reduce waste. Suitable<br />

for use with both 385 & 585ml (3:1) coaxial<br />

cartridge.<br />

Charge Time: 60 minutes<br />

Drive System: 5000N (500kg)<br />

Extrusion Rate: 120 to 240 ml/m<br />

Description Cartridge Box Qty Carton Qty Part No.<br />

Manual Dispensing Tool 385 & 585ml 1 10 CG585-PWR<br />

Manual Dispensing Tool all POWERS Adhesives 1 10 CGPRO-PWR<br />

Manual Dispensing Tool all POWERS Adhesives 1 10 CGPRO-4-PWR<br />

Pneumatic Dispensing Tool 385ml 1 10 CGPN385-PWR<br />

Pneumatic Dispensing Tool 585ml 1 10 CGPN585-PWR<br />

Battery Dispensing Tool ( 2 x Batteries) 385 & 585ml 1 10 CGB-585-PWR<br />

Replacement Battery Li-Ion 10.8V 1.5Ah 1 N/A CGB-10.8V-PWR<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last Modified September, 2017 13

Threaded Rod<br />

POWERS supplies a range of adhesive anchor studs for use based on standard embedment depth applications. For alternate<br />

embedment depths, studs should be cut to specified size as per application requirements. Studs are available in stainless steel,<br />

galvanised steel and zinc plated steel complete with nut and washer. Environmental factors and application factors should be<br />

considered carefully prior to selecting the correct stud.<br />

Flat Cut Stud<br />

• Suitable for use with any adhesive injection system.<br />

• Depth set mark for standard embedment depth<br />

ZINC<br />

GAL<br />

Size Drill Dia Embed Depth Fixture Thickness Box Qty Carton Qty Part No. Part No.<br />

8 x 110mm 10 80 17 10 200 FCS8110-PWR FCSG8110-PWR<br />

10 x 130mm 12 90 28 10 200 FCS10130-PWR FCSG10130-PWR<br />

12 x 160mm 14 110 36 10 100 FCS12160-PWR FCSG12160-PWR<br />

16 x 190mm 18 125 42 10 50 FCS16190-PWR FCSG16190-PWR<br />

20 x 260mm 24 170 72 5 25 FCS20260-PWR FCSG20260-PWR<br />

24 x 300mm 28 210 66 5 20 FCS24300-PWR FCSG24300-PWR<br />

Chisel Point Stud<br />

• Suitable for use with Powers SC-PRO capsules or any adhesive<br />

injection system.<br />

• Depth set mark for accurate embedment depth.<br />

• External hex for stability when driving the stud in glass<br />

Size Drill Dia Embed<br />

Depth<br />

Fixture<br />

Thickness<br />

Box<br />

Qty<br />

ZINC<br />

GAL<br />

STAINLESS<br />

Carton Qty Part No. Part No. Part No.<br />

8 x 110mm 10 80 15 10 200 STM8110-PWR STM8110G-PWR STM8110SS-PWR<br />

10 x 130mm 12 90 21 10 200 STM10130-PWR STM10130G-PWR STM10130SS-PWR<br />

12 x 160mm 14 110 27 10 100 STM12160-PWR STM12160G-PWR STM12160SS-PWR<br />

16 x 190mm 18 125 40 10 50 STM16190-PWR STM16190G-PWR STM16190SS-PWR<br />

20 x 260mm 24 170 60 5 25 STM20260-PWR STM20260G-PWR STM20260SS-PWR<br />

24 x 300mm 28 210 56 5 20 STM24300-PWR STM24300G-PWR STM24300SS-PWR<br />

Internally Threaded Sleeve<br />

Internally threaded sleeves for use in cracked and un-cracked concrete to provide a<br />

female anchorage allowing the use of standard metric fasteners. ETA Approvals apply<br />

when used with Powers PURE<strong>150</strong>PRO in concrete.<br />

ZINC CLEAR<br />

STAINLESS<br />

Size Drill Dia Embed Depth Thread Dia Thread Depth Box Qty Carton Qty Part No. Part No.<br />

M8 14 80 M8 35 10 100 ITS-M8-PWR ITS-SS-M8-PWR<br />

M10 18 90 M10 45 10 100 ITS-M10-PWR ITS-SS-M10-PWR<br />

M12 24 110 M12 55 5 50 ITS-M12-PWR ITS-SS-M12-PWR<br />

M16 28 <strong>150</strong> M16 75 5 20 ITS-M16-PWR ITS-SS-M16-PWR<br />

M20 35 200 M20 85 5 20 ITS-M20-PWR ITS-SS-M20-PWR<br />

14<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last modified September, 2017

Accessories<br />

Mixing Nozzle<br />

To ensure complete and proper mixing of the epoxy components, the PURE<strong>150</strong>-PRO system uses a static mixing nozzle. This reduces<br />

the possibility of mixing errors which are common with hand mixed pourable grout materials.<br />

Each nozzle contains a series of static mixing elements. As the epoxy components are pumped through the nozzle, they are<br />

progressively divided and recombined by the mixing elements to ensure precise automatic mixing.<br />

Description Box Qty Carton Qty Part No.<br />

Pure Epoxy Mixing Nozzle & Extension 1 N/A PFPN-PWR<br />

Mixing Nozzle Extensions (200mm) 10 N/A MNEXT-PWR<br />

Mixing Nozzle Extensions (1000mm) 10 N/A AEXTN-PWR<br />

Hole Cleaning<br />

Blow Pump<br />

For dust extraction (up to 20mm hole sizes)<br />

SDS Plus Wire Brush<br />

For machine cleaning<br />

Description<br />

Drilled<br />

Hole Ø<br />

Brush<br />

Size<br />

Thread<br />

Width<br />

Box Qty Carton Qty Part No.<br />

Standard Steel Brush 18 20 M6 1 N/A AWBM16-PWR<br />

Standard Steel Brush 20 22 M6 1 N/A AWBR16-PWR<br />

Standard Steel Brush 24 26 M6 1 N/A AWBM20M24-PWR<br />

Standard Steel Brush 32 34 M6 1 N/A AWBM30-PWR<br />

Standard Steel Brush 37 40 M6 1 N/A AWBM36-PWR<br />

Standard Steel Brush - SDS Plus Extension 300mm M6 1 N/A AWBEXT-PWR<br />

Standard Steel Brush - SDS Plus Adaptor M6 1 N/A AWBSDSPLUS-PWR<br />

Blow Pump - Industrial 1 N/A BLOWPUMP-PWR<br />

Piston Plugs – For Deep Hole Anchoring<br />

Description Box Qty Carton Qty Part No.<br />

Adhesive Piston Plug - 18mm Hole 10 N/A APP18-PWR<br />

Adhesive Piston Plug - 20mm Hole 10 N/A APP20-PWR<br />

Adhesive Piston Plug - 24mm Hole 10 N/A APP24-PWR<br />

Adhesive Piston Plug - 28mm Hole 10 N/A APP28-PWR<br />

Adhesive Piston Plug - 35mm Hole 10 N/A APP35-PWR<br />

Adhesive Piston Plug - 40mm Hole 10 N/A APP40-PWR<br />

Threaded Rod Retaining Cap<br />

(For overhead and horizontal installation)<br />

Size Drill Dia Stud Dia Box Qty Carton Qty Part No.<br />

8 10 8 10 N/A RC8-PWR<br />

10 12 10 10 N/A RC10-PWR<br />

12 14 12 10 N/A RC12-PWR<br />

16 18 16 10 N/A RC16-PWR<br />

20 24 20 10 N/A RC20-PWR<br />

PURE<strong>150</strong>-PRO <strong>Technical</strong> <strong>Data</strong> <strong>Sheet</strong>. Last Modified September, 2017 15

Powers Design Assist<br />

Real-Time Anchor Design Software.<br />

This pioneering software has become the industry standard. It contains data on Powers anchoring systems and makes anchor design<br />

to both ETAG and ACI requirements effortless. Its easy-to-use tab structure, real-time 3D graphics and dynamic results make anchor<br />

design simple, safe and economical.<br />

• Fully featured and easy to use interface<br />

• Easy 5 step anchor design with 3D modelling of fastening<br />

• Professional specification of Powers fastenings to ETA guidelines<br />

• Customised anchor design facility<br />

KEEP PACE WITH CHANGING CONSTRUCTION ENVIRONMENTS<br />

WITH POWERS DESIGN ASSIST.<br />

www.powersdesignassist.com<br />

Locations<br />

Australia<br />

VIC (Head Office)<br />

Level 2, 810 Whitehorse Road,<br />

Box Hill, Victoria, 3128<br />

Tel: (03) 8669 5200<br />

Fax: (03) 8401 3501<br />

Email: info@powers.com.au<br />

NSW<br />

11 Smeaton Grange Road<br />

Smeaton Grange NSW 2567<br />

T: (02) 4634 7600<br />

F: (02) 4648 3139<br />

E: info@powers.com.au<br />

QLD<br />

58 Link Drive<br />

Yatala QLD 4207<br />

T: (07) 3441 9300<br />

F: (07) 3441 9399<br />

E: info@powers.com.au<br />

New Zealand<br />

39 Business Parade North, Highbrook,<br />

East Tamaki Heights, Auckland, 2013<br />

PO Box 12-135, Penrose, Auckland, 1642<br />

T: 0800 3392 58<br />

F: 0800 2782 6539<br />

E: nzsales@sbdinc.com<br />

SA<br />

5 Stirling Street<br />

Thebarton SA 5031<br />

T: (08) 8161 3000<br />

F: (08) 8443 6565<br />

E: info@powers.com.au<br />

WA<br />

49A Mercantile Way<br />

Malaga WA 6090<br />

T: (08) 6102 1610<br />

F: (08) 9303 4477<br />

E: info@powers.com.au<br />

NT<br />

1/14 Menmuir Street<br />

Winnellie NT 0820<br />

T: (08) 8947 5097<br />

F: (08) 8947 5124<br />

E: info@powers.com.au<br />

DISCLAIMER FOR RECOMMENDATIONS, INFORMATION AND USE OF DATA:<br />

The recommendations, information and data contained in this manual are put together with the greatest care and accuracy possible. It is based on principles, equations and safety factors set out in the technical documentation of Stanley<br />

Black & Decker that are believed to be correct and current as of 11/09/17. The information and data is subject to change after such date as Stanley Black & Decker reserves the right to change the designs, materials and specifications of the<br />

products in this manual without notice. It is the responsibility of the design professional to ensure that a suitable product is selected, properly designed and used in the intended application. This includes that the selected product and its<br />

use is compliant with the applicable building codes and other legal requirements and will satisfy durability and performance criteria and margins of safety which they determine are applicable. The products must be used, handled, applied<br />

and installed strictly in accordance with all current instructions for use published by Stanley Black & Decker. The performance data given in this manual are the result of the evaluation of tests conducted under laboratory conditions. It is<br />

the responsibility of the designer and installer in charge to consider the conditions on site and to ensure the performance data given in the manual is applicable to the actual conditions. In particular the base material and environmental<br />

conditions have to be checked prior to installation. In case of doubt, contact the technical support of Stanley Black & Decker.<br />

LIMITATION OF LIABILITY<br />

Stanley Black & Decker offers a limited product warranty to customers or end users that the product meets its applicable specifications. Except for the express warranty in the immediately preceding sentence, Stanley Black & Decker grants<br />

no other warranties, express or implied, regarding the products, their fitness for any purpose, their quality, their merchantability or otherwise. Further, Stanley Black & Decker shall have no liability with respect to changes in the design,<br />

materials and specifications in the products presented in this manual, nor with respect to any product which has been modified or installed improperly, regardless of any specific instructions to the installer. The responsible designer and<br />

installer shall indemnify, defend, and hold harmless Stanley Black & Decker for any and all claimed loss or damage occasioned, in a whole or in part, by the modified products or deviation in product installation procedures.<br />

LIMITATION OF DAMAGES<br />

Stanley Black & Decker or its affiliates or their respective officers, members, managers, directors, representatives, agents or employees are not obligated for direct, indirect, incidental or consequential damages, losses or expenses in<br />

connection with, or by reason of, the use of, or inability to use the products for any purpose. Implied warranties of merchantability or fitness for a particular purpose are specifically excluded. Last Modified September, 2017<br />

www.powers.com.au