The Journal of Australian Ceramics Vol 53 No 1 April 2014

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

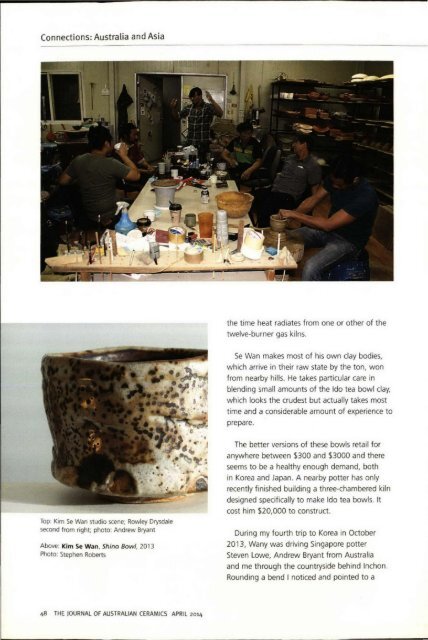

Con nections: Australia and Asia<br />

the time heat radiates from one or other <strong>of</strong> the<br />

twelve-burner gas kilns.<br />

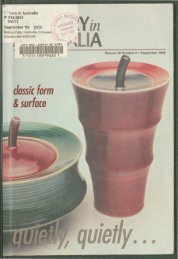

Se Wan makes most <strong>of</strong> his own clay bodies,<br />

which arrive in their raw state by the ton, won<br />

from nearby hills. He takes particular care in<br />

blending small amounts <strong>of</strong> the Ido tea bowl clay,<br />

which looks the crudest but actually takes most<br />

time and a considerable amount <strong>of</strong> experience to<br />

prepare.<br />

Top: Kim Se Wan studio scene; Rowley Orysdale<br />

second from right; photo: Andrew Bryant<br />

Above: Kim Se Wan, Shino Bowl, 2013<br />

Photo: Stephen Roberts<br />

<strong>The</strong> better versions <strong>of</strong> these bowls retail for<br />

anywhere between $300 and $3000 and there<br />

seems to be a healthy enough demand, both<br />

in Korea and Japan. A nearby potter has only<br />

recently finished building a three-chambered kiln<br />

designed specifically to make Ido tea bowls. It<br />

cost him $20,000 to construct.<br />

During my fourth trip to Korea in October<br />

2013, Wany was driving Singapore potter<br />

Steven Lowe, Andrew Bryant from Australia<br />

and me through the countryside behind Inchon.<br />

Rounding a bend I noticed and pointed to a<br />

48 THE JOURNAL OF AUSTRALIAN CERAMICS APRIL <strong>2014</strong>