WD74W2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 The Dixie Wing built a rotisserie to facilitate easy<br />

access to the fuselage during the restoration. The<br />

workshop was abuzz with activity on most days as<br />

the core team of volunteers reconstructed the airplane.<br />

Photo: Charles Burcher Collection<br />

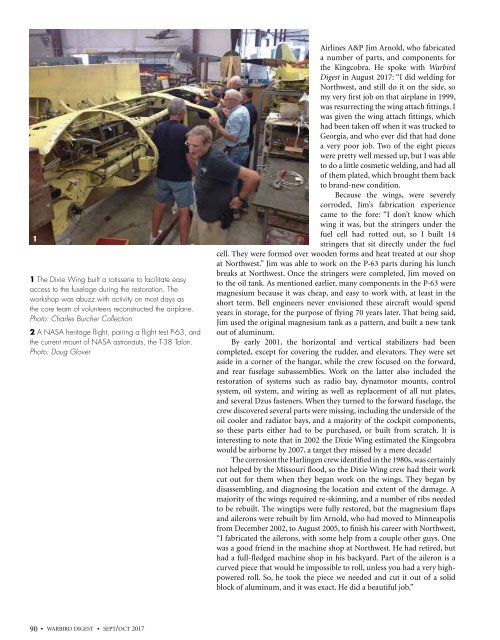

2 A NASA heritage flight, pairing a flight test P-63, and<br />

the current mount of NASA astronauts, the T-38 Talon.<br />

Photo: Doug Glover<br />

Airlines A&P Jim Arnold, who fabricated<br />

a number of parts, and components for<br />

the Kingcobra. He spoke with Warbird<br />

Digest in August 2017: “I did welding for<br />

Northwest, and still do it on the side, so<br />

my very first job on that airplane in 1999,<br />

was resurrecting the wing attach fittings. I<br />

was given the wing attach fittings, which<br />

had been taken off when it was trucked to<br />

Georgia, and who ever did that had done<br />

a very poor job. Two of the eight pieces<br />

were pretty well messed up, but I was able<br />

to do a little cosmetic welding, and had all<br />

of them plated, which brought them back<br />

to brand-new condition.<br />

Because the wings, were severely<br />

corroded, Jim’s fabrication experience<br />

came to the fore: “I don’t know which<br />

wing it was, but the stringers under the<br />

fuel cell had rotted out, so I built 14<br />

stringers that sit directly under the fuel<br />

cell. They were formed over wooden forms and heat treated at our shop<br />

at Northwest.” Jim was able to work on the P-63 parts during his lunch<br />

breaks at Northwest. Once the stringers were completed, Jim moved on<br />

to the oil tank. As mentioned earlier, many components in the P-63 were<br />

magnesium because it was cheap, and easy to work with, at least in the<br />

short term. Bell engineers never envisioned these aircraft would spend<br />

years in storage, for the purpose of flying 70 years later. That being said,<br />

Jim used the original magnesium tank as a pattern, and built a new tank<br />

out of aluminum.<br />

By early 2001, the horizontal and vertical stabilizers had been<br />

completed, except for covering the rudder, and elevators. They were set<br />

aside in a corner of the hangar, while the crew focused on the forward,<br />

and rear fuselage subassemblies. Work on the latter also included the<br />

restoration of systems such as radio bay, dynamotor mounts, control<br />

system, oil system, and wiring as well as replacement of all nut plates,<br />

and several Dzus fasteners. When they turned to the forward fuselage, the<br />

crew discovered several parts were missing, including the underside of the<br />

oil cooler and radiator bays, and a majority of the cockpit components,<br />

so these parts either had to be purchased, or built from scratch. It is<br />

interesting to note that in 2002 the Dixie Wing estimated the Kingcobra<br />

would be airborne by 2007, a target they missed by a mere decade!<br />

The corrosion the Harlingen crew identified in the 1980s, was certainly<br />

not helped by the Missouri flood, so the Dixie Wing crew had their work<br />

cut out for them when they began work on the wings. They began by<br />

disassembling, and diagnosing the location and extent of the damage. A<br />

majority of the wings required re-skinning, and a number of ribs needed<br />

to be rebuilt. The wingtips were fully restored, but the magnesium flaps<br />

and ailerons were rebuilt by Jim Arnold, who had moved to Minneapolis<br />

from December 2002, to August 2005, to finish his career with Northwest,<br />

“I fabricated the ailerons, with some help from a couple other guys. One<br />

was a good friend in the machine shop at Northwest. He had retired, but<br />

had a full-fledged machine shop in his backyard. Part of the aileron is a<br />

curved piece that would be impossible to roll, unless you had a very highpowered<br />

roll. So, he took the piece we needed and cut it out of a solid<br />

block of aluminum, and it was exact. He did a beautiful job.”<br />

90 • warbird digest • sept/oct 2017