GCN_WN_BRO_Roller_Brochure_1608486

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

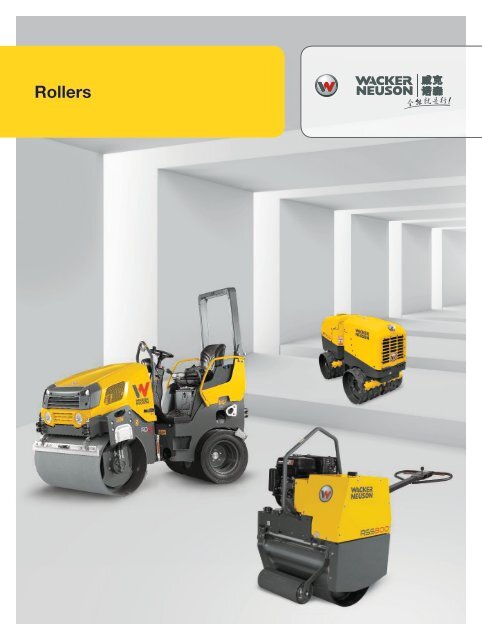

<strong>Roller</strong>s

These reasons speak for rollers from Wacker Neuson.<br />

1. Your needs in focus! With the complete selection of<br />

compaction equipment.<br />

The range of rollers is not only matched to your different<br />

application areas, but is also ease of maintenance. We are happy<br />

to advise you about which product is the right one for your<br />

project.<br />

3. Perfect results –<br />

with the specialists in soil compaction.<br />

In terms of soil compaction, we at offer a comprehensive<br />

product range of compaction equipment, we offer the best<br />

solutions for a variety of challenges. We are now rounding<br />

off our portfolio with our variety of rollers – so you have many<br />

choices of compaction projects.<br />

2. First-class quality products –<br />

with a long service life.<br />

You want to complete your projects perfectly – there is no<br />

question that you do not make any compromises when it comes<br />

to the quality of your equipment. As with all products and solutions<br />

from Wacker Neuson, you also receive high quality products with<br />

our rollers, which will satisfy you in every aspect.<br />

Wacker Neuson-all it takes!<br />

We offer products and services rendered that meet<br />

your high requirements and diverse applications.<br />

Wacker Neuson stands for reliability. This also applies to all of<br />

our rollers. We do our best every day to ensure your success.<br />

We do our job with passion.<br />

All rollers at a glance.<br />

Trench<br />

roller<br />

Single drum<br />

walk-behind<br />

rollers<br />

RTx<br />

RS600<br />

RSS800<br />

Operating weight<br />

1,467 kg<br />

> Page 04<br />

276 kg<br />

> Page 06<br />

450 kg<br />

Tandem<br />

rollers<br />

RD27-120<br />

RD27-120c<br />

RD40-130<br />

RD40-130c<br />

Operating weight<br />

2,695 kg<br />

> Page 10<br />

2,595 kg<br />

3,965 kg<br />

> Page 12<br />

3,825 kg<br />

02

<strong>Roller</strong> expertise down to the last detail.<br />

Professional service nationwide<br />

We are always there for you: Thanks to<br />

our trained service staff we make a point<br />

of training our sales partners so that you<br />

can always rely on a quick support.<br />

First-class compaction performance<br />

Regardless of which of our models<br />

you choose – one thing is certain: The<br />

compaction performance of our<br />

rollers will excite you. Guaranteed!<br />

Finely tiered model selection<br />

Different tonnages and a varied selection<br />

of single drum walk-behind rollers,<br />

trench rollers and tandem rollers:<br />

Choose exactly the model that you need<br />

for your project.<br />

Remote-controlled operation<br />

The trench roller can be operated<br />

comfortably and safely by infrared<br />

remote control.<br />

Read more on page 04 and 05<br />

Tandem<br />

rollers<br />

RD12<br />

1,220 kg<br />

RD45-140<br />

4,345 kg<br />

> Page 08<br />

> Page 12<br />

RD16<br />

1,485 kg<br />

RD45-140c<br />

3,995 kg<br />

Since the year 1848, Wacker<br />

Neuson has always put a<br />

strong emphasis on the<br />

German standards and<br />

focusing on the engineering,<br />

development and production<br />

in its factories worldwide.<br />

03

Compaction - complete without compromise.<br />

Everything for perfect compaction results for maintenance work and in road and highway construction and<br />

civil engineering: With our rollers, you create a durable foundation for your successful project. From our<br />

comprehensive assortment, choose exactly the unit that meets your needs perfectly—we have the right<br />

solution for every challenge!<br />

The infrared remote control<br />

guarantees save operation.<br />

Ideally for compaction in trenches.<br />

04

Ideally for maintenance work:<br />

The rollers from Wacker Neuson<br />

Perfect view of the working area.<br />

Comprehensive product portfolio.<br />

05

Remote controlled vibratory trench rollers.<br />

Maneuver easily, work safely: Thanks to the articulated joint<br />

and the operation via remote control, you will achieve your<br />

compaction objective more quickly with the trench roller in<br />

many ground conditions.<br />

Ideal for earthwork in trench<br />

applications, e.g. for supply lines<br />

• Easy to maneuver, thanks to the articulated joint technology<br />

• Adjustable compaction performance (from 34 kN to 68 kN)<br />

• Very high compaction performance through exciters,<br />

which are below the axle<br />

• Diagnostic LED display to monitor various engine functions<br />

• RTx is a 2 in 1 machine - drum width: 82cm or 56cm<br />

Compatec – compaction control:<br />

Compatec indicates the relative compaction level of the soil. Maximum<br />

compaction has been reached once the number of lights stops increasing.<br />

Specifically placed:<br />

Due to the low position below the axle in the drums, the<br />

centrifugal forces are transferred directly into the ground:<br />

for a high compaction performance.<br />

Articulated joint technology:<br />

for easy maneuvering.<br />

06

RT82-SC3 RT82-SC3 RTX-SC3 RTX-SC3<br />

Kubota Motor Kohler Motor Kubota Motor Kohler Motor<br />

Performance 34,2–68,4 kN 34,2–68,4 kN 34,2–68,4 kN 34,2–68,4 kN<br />

Weight 1.422 kg 1.450 kg 1.467 kg 1.495 kg<br />

Engine type<br />

Diesel engine<br />

Far-reaching control:<br />

A transmission field of up to 20 meters at an angle of<br />

45 degrees guarantees a high level of working comfort.<br />

Intelligent proximity recognition sensor:<br />

The machine stops automatically at a minimum safety distance<br />

between the operator and machine of less than two meters.<br />

Reach in m<br />

High safety levels:<br />

It stops moving if there is no clear line of sight between the operator and the compaction equipment.<br />

Change drum width:<br />

done in a few simple steps<br />

with the RTx.<br />

Third infrared receiving eye:<br />

It ensures that the remote control contact is maintained<br />

permanently, even in the trench shoring.<br />

07

Single Drum Walk-behind rollers<br />

Maintenance and repair of asphalt concrete pavement<br />

and narrow areas is no longer an obstacle: The lightweight<br />

and highly maneuverable walk-behind rollers have<br />

infinitely variable hydrostatic drive for smooth, even<br />

acceleration. High curb clearance and close side clearance<br />

accommodates work adjacent to curbs and walls.<br />

• Beveled edge steel drum with adjustable and reversible<br />

polyurethane self-cleaning scrapers to prevent soil and<br />

asphalt buildup<br />

• Operator safety in focus: Automatic breaking system in<br />

forward and reverse<br />

• Adjustable, enclosed handle improves operator comfort<br />

and folds vertically for convenient transportation and<br />

storage<br />

Large water tank reduces refill stops for<br />

continued operation and higher productivity.<br />

Adjustable and foldable handle for easy<br />

transportation and comfortable working.<br />

08

RS600 RSS800<br />

Operating weight 2,475 kg 2,385 kg<br />

Drum diameter 450 mm 560 mm<br />

Engine output 4.5 kW 7.1. kW<br />

Excellent choice for the compaction of<br />

sand, gravel, soil and asphalt on roadways,<br />

walkways, bridges and parking lots.<br />

Transport in no time: Sophisticated details<br />

make transporting convenient and easy<br />

09

<strong>Roller</strong>s of the 1 and 1.5 ton class<br />

Dual drum drive for maximum traction and articulated steering<br />

for extremely accurate control: These models have proven<br />

themselves for many years in the market.<br />

• Outstanding overall roller performance and a high exciter<br />

frequency allows compaction at faster speeds while delivering<br />

even coverage and excellent results<br />

• No overhangs in the front and rear make the machine easily<br />

maneuverable<br />

• The articulated steering leads to a small turning radius<br />

• Vibration-damped operator platform helps to reduce both<br />

hand/arm vibration (HAV) as well as whole body vibration<br />

Switch easily from vibration in one or both drums:<br />

Front drum vibration with static rear drum leaves a<br />

quality asphalt finish.<br />

Engine hood tilts forward: Easy<br />

access to all engine components<br />

Free choice of vibration:<br />

Change to a static roller<br />

when needed<br />

10

RD12A-90 RD16-90<br />

Operating weight 1,220 kg 1,485 kg<br />

Drum width 900 mm 900 mm<br />

Engine output 15.1 kW 16.8 kW<br />

Outstanding overall roller performance and a high<br />

exciter frequency allow compaction at faster<br />

speeds while delivering even coverage and<br />

excellent results.<br />

Vibration controls integrated into<br />

operating lever.<br />

Ideally suited for compaction of a<br />

variety of soils.<br />

11

<strong>Roller</strong>s of the 2.5 ton class<br />

First-class performance, sophisticated technology: With the<br />

rollers in this weight class, you can move safely everywhere<br />

– even in confined areas.<br />

• Maneuverable, compact roller models for first-class<br />

compaction in road and highway construction<br />

• Two vibration levels<br />

• First-class compaction quality due to the large drum<br />

diameter combined with a low machine center of gravity<br />

• High level of tipping safety thanks to the low work platform<br />

and the articulated pendulum joint<br />

• Intuitive instrument panel<br />

• Highly maneuverable, thanks to the special 3-point<br />

pendulum articulation<br />

Specialists for asphalt<br />

compaction, but can<br />

also be used for soil<br />

compaction.<br />

12

RD27-120 RD27-120c<br />

Operating weight with roll-over 2,695 kg 2,595 kg<br />

protective structure (CECE)<br />

Drum width 120 cm 120 cm<br />

Engine output 22.9 kW 22.9 kW<br />

Two model versions: Tandem-axle roller<br />

with 2 vibrating drums or as combination roller.<br />

Easy understandable<br />

operators display.<br />

All rollers are easy to service, good access<br />

to all relevant parts is guaranteed.<br />

13

<strong>Roller</strong>s of the 4.0 ton class<br />

The full compaction force for your project: The rollers with one of the highest<br />

centrifugal force on the market will meet any demand.<br />

• Optionally available as a traditional tandem roller or a combination roller<br />

• The three-point articulated pendulum joint provides for a sturdy<br />

driving position and high level of maneuverability<br />

• The vibration can be adjusted in two levels<br />

• Outfitted with fold-down roll-over protective structure (ROPS) as a standard<br />

• Central drainage: The water can be drained in one simple step<br />

Long application<br />

times without<br />

refueling: Large tanks<br />

for fuel and water<br />

RD40-130 RD40-130c<br />

Operating weight with roll-over 3,965 kg 3,825 kg<br />

protective structure (CECE)<br />

Drum width 130 cm 130 cm<br />

Engine output 34.6 kW 34.6 kW<br />

14

Convenient work:<br />

Ergonomic seats with<br />

plenty of legroom allow for<br />

a very good view of the<br />

working area<br />

RD45-140 RD45-140c<br />

Operating weight with roll-over 4,345 kg 3,995 kg<br />

protective structure (CECE)<br />

Drum width 138 cm 138 cm<br />

Engine output 34.6 kW 34.6 kW<br />

15

The function of vibration<br />

drums<br />

The vibration drum optimally brings the material<br />

to be compacted into oscillation with quick<br />

successive vertical forces. The built-in eccentric<br />

weight provides for a fast rotation and an excellent<br />

compaction performance.<br />

Drum offset<br />

The drum offset allows for easy maneuvering when<br />

compacting along walls. In addition to a reduction<br />

in vut marks, drum offset increases productivity,<br />

with less asphalt pushing and shoving.<br />

In-line<br />

Offset<br />

Ideal for all traditional compaction work.<br />

All Wacker Neuson rollers have adjustable<br />

drum offset.<br />

16<br />

Edge pressing and<br />

cutting equipment<br />

Entirely as needed, the edge pressing and cutting<br />

equipment can be attached on the right, left or<br />

on both sides of the roller and with its integrated<br />

track indicator ensures a clean edge of the paths.<br />

Edge pressure and cutting equipment is available as an<br />

option for all rollers of the 2.5 and 4-ton class.

Articulated pendulum joint<br />

Uniform compaction, optimal driving stability: The<br />

three-point articulated pendulum joint ensures<br />

uniform weight distribution on the front and rear drums<br />

at all times. This also improves the maneuverability and<br />

provides for maximum tipping safety and stability when<br />

turning curves.<br />

All rollers from Wacker Neuson have<br />

an articulated pendulum joint.<br />

Optimal visibility<br />

Everything is perfectly within view: With the specially<br />

designed, tapered design of the roller, you always<br />

have an excellent view of the drum edges, the<br />

machine environment and the job site.<br />

ROPS bar<br />

Guaranteed safety: The standard ROPS (Roll Over<br />

Protective Structure) can conveniently be folded<br />

back for transport.<br />

All rollers from Wacker Neuson<br />

have a ROPS bar.<br />

17

Technical data for <strong>Roller</strong>s<br />

RT82-SC2 RTX-SC3 RTX-SC3<br />

TANDEM ROLLERS 1,0 - 1,5 TONS SINGLE DRUM WALK-BEHIND ROLLERS<br />

TRENCH ROLLERS<br />

UNIT<br />

Engine / Motor manufacturer Kohler Kubota D902 Kohler KDW 1,003<br />

Operating performance (DIN ISO 3046) kW 15.5 15.5 14.8<br />

Operating weight kg 1,497 1,467 1,495<br />

Centrifugal force (min.) kN 34.2 34.2 34.2<br />

L x W x H mm 1,855 x 820 x 1,230 1,853 x 820 x 1,270 1,853 x 820 x 1,270<br />

Drum diameter mm 520 520 520<br />

Drum width (max.) mm 820 820 820<br />

Frequency Hz 41.7 21.7 21.7<br />

Turning radius (inside) mm 1,600 1,600 1,600<br />

UNIT<br />

UNIT<br />

RS600<br />

RD12A-90<br />

RSS800A<br />

Operating weight kg 276 450<br />

Drum diameter mm 450 560<br />

Centrifugal force kN 12 15,2<br />

Frequency Hz 70<br />

Advance travel m/min 62<br />

Reverse travel m/min 46<br />

Gradeability % 20 30<br />

Drive Robin Honda<br />

Gasoline engine<br />

Operating performance Max.<br />

Rated at 3600 rpm<br />

kW 7,1<br />

Tank capacity Fuel l 7<br />

Tank capacity Water l 18 30<br />

RD16-90<br />

Operating weight with ballast kg 1,220 1,485<br />

L x W x H mm 1825 x 1035 x 2300 1,950 x 1,002 x 2,547<br />

Drum width mm 900 900<br />

Drum diameter mm 560 560<br />

Turning radius Outside mm 2,451 2,921<br />

Travel speed Forward km/h 8.7 9.3<br />

Travel Speed Reverse km/h 8.7 9.3<br />

Drive Honda GX 630 Gasoline engine Kohler Diesel engine<br />

Operating performance kW 15,1 13,8<br />

Fuel tank volume l 23 23<br />

Displacement m³ 688 1,028<br />

Gradeability max. % 30 30<br />

Centrifugal force Dynamic (Front) kN 16,8 15<br />

Water tank volume l 100 100<br />

18

Vibration-reduced<br />

comfortable driver's cabin<br />

Central lifting<br />

point<br />

With the completely vibrationinsolated<br />

driver's cabin,<br />

operating the roller is extremely<br />

comfortable. The large amount<br />

of legroom and a seat that moves<br />

forward as well as laterally to<br />

the left and right also ensure a<br />

pleasant working situation.<br />

The central lifting point that<br />

is practically placed in the<br />

center ensures easy lifting<br />

and quick transport of the<br />

roller.<br />

All rollers from Wacker Neuson have a laterally<br />

moving seat *Not RD12.<br />

Central lifting point for RD12, RD16 and RD27.<br />

RD27-120 RD27-120c RD40-130 RD40-130c RD45-140 RD45-140c<br />

TANDEM ROLLERS<br />

UNIT<br />

Max. operating weight kg 3,410 3,320 4,920 4,790 5,300 4,960<br />

Operating weight with roll-over<br />

protective structure (CECE)<br />

kg 2,695 2,595 3,965 3,825 4,345 3,995<br />

Max. operating width mm 1,250 1,220 1,350 1,338 1,430 1,380<br />

Lateral overhang mm 55/55 55/55 63/63 63/63 63/63 63/63<br />

Turning radius (inside) mm 2,370 2,370 2,690 2,690 2,650 2,650<br />

Drum type in front – smooth / undivided smooth / undivided smooth / undivided smooth / undivided smooth / undivided smooth / undivided<br />

Drum type in rear – smooth / undivided – smooth / undivided – smooth / undivided –<br />

Tire size in rear – – 9.5/65-15 – – – 10.5/80-16<br />

Drive –<br />

Kubota<br />

Diesel engine<br />

D1503<br />

Kubota<br />

Diesel engine<br />

D1503<br />

Kubota<br />

Diesel engine<br />

V2203<br />

Kubota<br />

Diesel engine<br />

V2203<br />

Kubota<br />

Diesel engine<br />

V2203<br />

Kubota<br />

Diesel engine<br />

V2203<br />

Power output (ISO 14396) kW 22.9 22.9 34.6 34.6 34.6 34.6<br />

Fuel tank volume l 42 42 73 73 73 73<br />

Infinitely variable speed km/h 0-12.0 0-12.0 0–11.0 0–11.0 0–11.0 0–11.0<br />

Gradeability with/without vibration % 30/40 30/40 30/40 30/40 30/40 30/40<br />

Centrifugal force in front I/II kN 52/32 52/32 64/39 – 64/39 64/39<br />

Centrifugal force in rear I/II kN 52/32 – – – 64/39 –<br />

Water tank volume l 180 180 285 285 285 285<br />

19

Your everyday work day is full of challenges. We have the right<br />

solutions and help you to be ahead of the competition. We offer<br />

you everything you need for this purpose:<br />

Wacker Neuson-all it takes!<br />

Products<br />

Concrete technology<br />

Compaction<br />

Demolition technology<br />

Excavators<br />

(Telescopic) wheel loaders<br />

Lighting<br />

Pumps<br />

Generators<br />

Services<br />

Spare parts<br />

Repair &<br />

maintenance<br />

Trainings<br />

Finance<br />

www.wackerneuson.cn<br />

扫 一 扫 , 更 多 惊 喜 !