You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

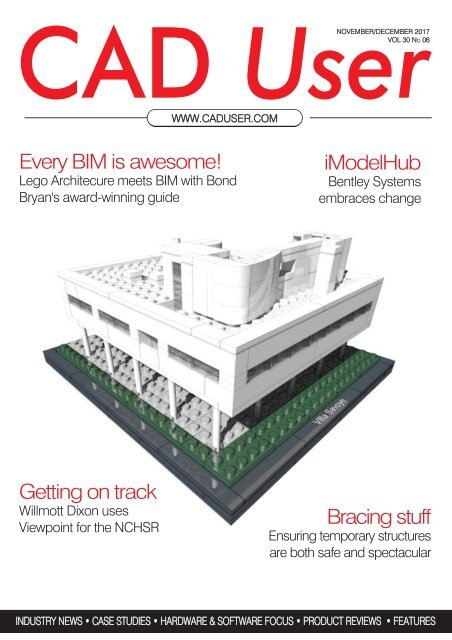

CAD User<br />

NOVEMBER/DECEMBER 2017<br />

VOL 30 NO 06<br />

WWW.CADUSER.COM<br />

Every BIM is awesome!<br />

Lego Architecure meets BIM with Bond<br />

Bryan's award-winning guide<br />

iModelHub<br />

Bentley Systems<br />

embraces change<br />

Getting on track<br />

Willmott Dixon uses<br />

Viewpoint for the NCHSR<br />

Bracing stuff<br />

Ensuring temporary structures<br />

are both safe and spectacular<br />

INDUSTRY NEWS • CASE STUDIES • HARDWARE & SOFTWARE FOCUS • PRODUCT REVIEWS • FEATURES

City of Coatesville Brownfield<br />

Redevelopment Project<br />

Site revitalization project leveraged<br />

reality modeling to prepare plans for future<br />

commercial development and to quantify<br />

22,400 cubic yard of available clean fill.<br />

High Fidelity, Engineering<br />

Ready Reality Context<br />

ContextCapture Saved the City of Coatesville $300,000<br />

With ContextCapture, you can quickly and automatically generate a high fidelity<br />

geo-referenced 3D model from ordinary digital photography captured from<br />

UAVs, vehicles, or handheld smartphones. The resulting 3D mesh is precise<br />

and extremely accurate, available the day you take the photos for the most<br />

demanding projects. The model is engineering ready and does not require<br />

any further processing, translation, or manipulation.<br />

» 750 aerial photos in 20 minutes<br />

» 3D engineering-ready model<br />

in 8 hours<br />

» Final engineered plan in 3 days<br />

“ContextCapture has changed the way<br />

we work. It helped us reduce risk, ensure<br />

safety, and deliver a superior project<br />

result. And, we accomplished it all with<br />

a dramatically compressed timeline and<br />

with significant cost savings.”<br />

April M. Barkasi, PE, Coatesville’s<br />

City Engineer, CEO/President,<br />

CEDARVILLE Engineering<br />

To learn more and try it out yourself visit www.bentley.com/CoatesvilleFidelity<br />

© 2017 Bentley Systems, Incorporated. Bentley, the “B” Bentley logo, and ContextCapture are either registered or unregistered trademarks or service marks of Bentley Systems, Incorporated or one of its direct<br />

or indirect wholly-owned subsidiaries. Other brands and product names are trademarks of their respective owners.

CONTENTS<br />

NOVEMBER/DECEMBER 2017<br />

CONTENTS<br />

BRACING STUFF 8<br />

The Braceworks add-on for Vectorworks helps<br />

designers ensure that temporary structures are<br />

both spectacular and safe<br />

TAKING CONTROL 18<br />

David Chadwick reports back from November's<br />

Construction Computing Seminar on<br />

Information Management, held in association<br />

with Newforma at the Institute of Civil Engineers<br />

LEGO ARCHITECTURE MEETS BIM 20<br />

Bond Bryan Architects, early proponents of BIM<br />

through their use of ARCHICAD, have<br />

produced the 'LEGO Architecture meets BIM'<br />

guide, taking LEGO's popular building blocks<br />

as its focus<br />

CONSTRUCTIVE PRAISE! 26<br />

The 2017 Construction Computing Awards<br />

were held in London this November. Discover<br />

more about this year's winners in our extended<br />

round-up this issue<br />

I NEWS................................................INDUSTRY NEWS....................................................................................................6<br />

• EASYPARK UNVEILS ITS SMART CITIES INDEX 2017 • FARO SETS THE SCENE WITH VR<br />

CASE STUDY....................................GRANDFATHER’S BRIDGE...............................................................................12<br />

• A RECENT TEKLA BASED PROJECT TESTED BIM FULLY, FROM CONCEPTION TO COMPLETION<br />

SOFTWARE FOCUS.........................WARBOARD STRATEGIES.................................................................................14<br />

• WARBOARD ENABLES USERS TO MARSHALL THE INFORMATION IN MODEL ANALYTICAL TOOLS<br />

TECHNOLOGY FOCUS....................iMODELHUB......................................................................................................16<br />

• BENTLEY’S iMODELHUB HAS BEEN CONCEIVED TO LEVERAGE CHANGE RATHER THAN FIGHT IT<br />

CASE STUDY...................................GETTING ON TRACK...........................................................................................24<br />

• WIMOTT DIXON UTILISES VIEWPOINT SOLUTIONS FOR THE NATIIONAL COLLEGE FOR HIGH SPEED RAIL PROJECT<br />

TRAINING MAP................................AUTODESK TRAINING........................................................................................32<br />

• YOUR GUIDE TO AUTODESK TRAINING<br />

TECHNOLOGY FOCUS...................FORGING AHEAD...............................................................................................34<br />

• AUTODESK USED THEIR LATEST AUTODESK UNIVERSITY EVENT TO OUTLINE THE ROAD AHEAD FOR FORGE<br />

November/December 2017 3

COMMENT<br />

Editor:<br />

David Chadwick<br />

(cad.user@btc.co.uk)<br />

News Editor:<br />

Mark Lyward<br />

(mark.lyward@btc.co.uk)<br />

Advertising Sales:<br />

Josh Boulton<br />

(josh.boulton@btc.co.uk)<br />

Production Manager:<br />

Abby Penn<br />

(abby.penn@btc.co.uk)<br />

Design/Layout:<br />

Ian Collis<br />

ian.collis@btc.co.uk<br />

Circulation/Subscriptions:<br />

Christina Willis<br />

(christina.willis@btc.co.uk)<br />

Publisher:<br />

John Jageurs<br />

john.jageurs@btc.co.uk<br />

Published by Barrow &<br />

Thompkins Connexion Ltd.<br />

35 Station Square, Petts Wood,<br />

Kent BR5 1LZ<br />

Tel: +44 (0) 1689 616 000<br />

Fax: +44 (0) 1689 82 66 22<br />

SUBSCRIPTIONS:<br />

UK £35/year, £60/two years,<br />

£80/three years;<br />

Europe:<br />

£48/year, £85 two years,<br />

£127/three years;<br />

R.O.W. £62/year<br />

£115/two years, £168/three years.<br />

Single copies can be bought for £8.50<br />

(includes postage & packaging).<br />

Published 6 times a year.<br />

© 2017 Barrow & Thompkins<br />

Connexion Ltd.<br />

All rights reserved.<br />

No part of the magazine may be<br />

reproduced, without prior consent<br />

in writing, from the publisher<br />

For more magazines from BTC, please visit:<br />

www.btc.co.uk<br />

Articles published reflect the opinions of<br />

the authors and are not necessarily those<br />

of the publisher or his employees. While<br />

every reasonable effort is made to ensure<br />

that the contents of editorial and advertising<br />

are accurate, no responsibility can be<br />

accepted by the publisher for errors, misrepresentations<br />

or any resulting effects<br />

Comment<br />

Beyond BIM<br />

by David Chadwick<br />

The last decade in the construction<br />

industry has been dominated by BIM.<br />

Halfway through its implementation and<br />

careering towards the milestones of BIM Level<br />

3 and 4, it's salutary to look back and reflect<br />

on the changes that have already been<br />

accomplished. We've had the benefit of being<br />

involved in two seminars this year dedicated<br />

to BIM, COBie and information management,<br />

and they have given us the opportunity to look<br />

at the subject from a fresh perspective and in<br />

greater depth, with input from some of the<br />

leading experts in the industry.<br />

Two things stand out. The first is the<br />

complete transformation of an industry that,<br />

arguably, has not significantly changed since<br />

the days of Sir Christopher Wren. Wren, who<br />

conceived the original design for St Pauls in<br />

1633 after two earlier failed attempts,<br />

employed specialists Grinling Gibbons for the<br />

woodwork, Francis Bird for some of the<br />

masonry and Sir James Thornhill for the<br />

interior decoration. He spent 35 years on the<br />

project with, presumably, the whole plan<br />

floating around in his head and nary an Excel<br />

spreadsheet in sight.<br />

Fast forward to 2017 and I had the<br />

(dubious?) honour of presenting a much<br />

humbler, aborted project at the Take Control<br />

Seminar on Information Management in<br />

November that had learnt nothing from our<br />

illustrious past, resulting in complete and<br />

utter failure in terms of information<br />

management, collaboration and project<br />

management (see the article on page 18 of<br />

this issue for more on this).<br />

The emphasis on BIM has revitalised the<br />

construction industry with its emphasis on<br />

information sharing and collaboration, the first<br />

fruits of which I remember experiencing when<br />

I visited Mervyn Richards OBE at the Terminal<br />

5 headquarters.<br />

Although it may not have delivered at all<br />

levels, particularly when it comes to asset<br />

management, where traditional methods of<br />

information handling sometimes still hold<br />

sway despite the availability of massive<br />

amounts of digital and strategically structured<br />

information, there is no doubt that BIM has<br />

delivered substantial increases in productivity<br />

and efficiency.<br />

The second important factor, for me, is the<br />

education of a generation of construction<br />

specialists - and the promise of more to<br />

come. We complain about the lack of<br />

experienced workers in the industry, but the<br />

emphasis on BIM and collaboration and<br />

access to integrated architectural,<br />

engineering and analysis tools which have<br />

been developed to leverage such<br />

collaboration, has enhanced the knowledge<br />

and application of every construction worker's<br />

own specialisation. Team members no longer<br />

work in isolation on their own tasks, but have<br />

insight on the total project and where their<br />

contribution fits in - and why.<br />

By way of illustration we have featured two of<br />

the BIM projects nominated for the 2017<br />

Construction Computing Awards in this issue:<br />

the winner of BIM Project of the Year, Bond<br />

Bryan Architects for 'LEGO Architecture meets<br />

BIM', and the runner-up in the same category,<br />

Viewpoint for its BIM for the National College<br />

for High Speed Rail.<br />

We are in the early stages of even greater<br />

utilisation of information at all stages of the<br />

construction process, from initial planning<br />

using resource analysis, demographics and<br />

artificial intelligence to assess future<br />

requirements, and the development of smart<br />

cities, to environmental intelligence and<br />

material capabilities to build and inhabit<br />

sustainable environments - and these two<br />

projects show how training for the future can<br />

be achieved 'in project' and (the best way) as<br />

a 'fun' exercise in and of itself.<br />

You will find much more information on the<br />

winners of the 2017 Construction Computing<br />

Awards on page 26 of this issue, among<br />

them my pick for this year's Editors Choice<br />

award, Human Recognition Systems - a long<br />

overdue acknowledgement of the important<br />

work being done to bring safety and security<br />

to construction sites.<br />

4 November/December 2017

A customisable<br />

costing tool for<br />

projects of all sizes<br />

Combined with<br />

Asta Powerproject BIM,<br />

Bidcon provides a tool kit<br />

for 5D planning<br />

To find out more please visit:<br />

elecosoft.com/bidcon<br />

elecosoft.com/bidcon<br />

Bidcon: The modern approach to cost estimation

INDUSTRY news<br />

FARO SETS THE SCENE WITH VR<br />

FARO has announced the<br />

release of VR-ready FARO<br />

SCENE 7.1 software. FARO<br />

SCENE 7.1 enables an<br />

immersive VR experience with<br />

integration of detailed photographic<br />

textures, i.e., surface<br />

details of an object and rendering<br />

of 3D scan data so<br />

quickly that it appears to be<br />

generated in real time.<br />

While SCENE 7.1 is optimized<br />

for the FARO laser<br />

scanning product portfolio,<br />

e.g. FocusS or Freestyle, it is<br />

also device agnostic, so it<br />

can seamlessly accept and<br />

manage 3D scan data from<br />

other, non-FARO laser scanner<br />

products.<br />

SCENE 7.1 enables users to<br />

view an entire project, i.e.,<br />

the full range of related scans<br />

in full 3D virtual reality<br />

through a compatible VR<br />

headset from the comfort of<br />

the user’s office or workstation<br />

chair. This can help to<br />

significantly reduce project<br />

cycle time by enabling architecture,<br />

engineering and construction<br />

professionals, public<br />

safety forensics experts<br />

and product designers to<br />

quickly simulate and compare<br />

reality for such tasks as<br />

evaluating as-built documentation,<br />

reconstructing crime<br />

or accident scenes, or optimising<br />

design plans.<br />

SCENE 7.1 advances<br />

beyond the ''see it better to<br />

understand it better'' concept<br />

common in most industrial<br />

VR solutions. It enhances<br />

productivity by enabling<br />

users to take/capture screenshots,<br />

tag comments or<br />

notes specific to images and<br />

navigate the system overview<br />

map in real time, all without<br />

needing to exit the Virtual<br />

Reality environment.<br />

Historically, the FARO Focus<br />

and Freestyle products have<br />

had their own unique, coded<br />

targets (markers that identify<br />

scan areas/specific targets),<br />

which could not be shared by<br />

the other scanning device.<br />

With SCENE 7.1 enhanced<br />

functionality, not only can<br />

both devices share coded<br />

targets, but they can also<br />

now verify registration of<br />

scans from both devices in a<br />

single, real time registration<br />

report. This ensures a more<br />

cohesive workflow between<br />

these devices and also<br />

enables projects to be completed<br />

faster.<br />

A free 30 day trial of SCENE<br />

7.1 is available for download<br />

at the link below.<br />

www.faro.com/resource/scene<br />

EASYPARK UNVEILS SMART CITY INDEX 2017<br />

Smart parking app, EasyPark,<br />

have released the 2017<br />

Smart City Index, revealing<br />

Copenhagen, Denmark as the<br />

smartest city, followed by Singapore,<br />

and Swedish city Stockholm.<br />

EasyPark undertook the<br />

study not only to highlight those<br />

metropolises which are on the<br />

forefront of smart urban growth,<br />

but also to learn from those<br />

cities which are showing<br />

impressive acceleration towards<br />

making life smoother for their<br />

citizens through digitalisation.<br />

EasyPark first created a list of<br />

500 carefully selected cities.<br />

They were then analysed for 19<br />

factors aiming to define what<br />

makes a city ‘smart’, beginning<br />

with digitalisation - meaning 4G,<br />

high-speed internet and high<br />

smartphone penetration. Next,<br />

they looked into transport and<br />

mobility, which should be knowledge-based<br />

with smart parking,<br />

traffic sensors and car sharing<br />

apps. A smart city should also<br />

be sustainable, with a focus on<br />

BRIDGING THE GAP BETWEEN BIM AND GIS<br />

clean energy and environmental<br />

protection. Lastly, there should<br />

be excellent online access to<br />

governmental services and a<br />

high level of citizen participation.<br />

All of these factors were then<br />

analysed to determine the final<br />

index of 100 cities. To round off<br />

the study, the research team<br />

then asked 20,000 technology<br />

and urban planning journalists<br />

to rate how smart their cities<br />

are. The top ten smartest cities<br />

according to the survey are:<br />

1. Copenhagen, Denmark<br />

2. Singapore<br />

3. Stockholm, Sweden<br />

4. Zurich, Switzerland<br />

5. Boston, United States<br />

6. Tokyo, Japan<br />

7. San Francisco, United States<br />

8. Amsterdam, Netherlands<br />

9. Geneva, Switzerland<br />

10. Melbourne, Australia.<br />

London ranked 17th in the<br />

index. For more details visit:<br />

https://easyparkgroup.com/<br />

smart-cities-index/<br />

Autodesk and Esri have<br />

announced a new relationship<br />

to build a bridge between<br />

BIM and GIS mapping technologies.<br />

The two companies<br />

plan to enable a broad range<br />

of industries to gain better<br />

context by visualising data of<br />

the man-made world, the environment,<br />

citizens and the networks<br />

that weave it all together.<br />

At the recent Autodesk University<br />

2017, Esri Founder and<br />

President Jack Dangermond<br />

and Autodesk CEO Andrew<br />

Anagnost explained how the<br />

new partnership would bring<br />

together the power of building<br />

information modeling and GIS<br />

mapping data.<br />

''It is important to consider<br />

the needs of future generations<br />

during the design and<br />

building of projects today,''<br />

said Jack Dangermond, president,<br />

Esri. ''The benefits of<br />

partnering with Autodesk will<br />

include securing sustainable<br />

resources for the growing<br />

population, a responsible<br />

human footprint on our natural<br />

environment, better use of our<br />

planet’s resources and more<br />

resilient cities.''<br />

''Our goals are to provide<br />

industry and city planners the<br />

ability to design in the context of<br />

the real world. This will allow<br />

communities to build more connected,<br />

resilient cities, and infrastructure<br />

with a focused eye on<br />

sustainability,'' said Andrew<br />

Anagnost, CEO, Autodesk.<br />

www.autodesk.com<br />

6<br />

November/December 2017

From design<br />

to reality<br />

Louis Vuitton Foundation (France)<br />

Tekla Structures is intelligent 3D modelling software at the heart of the digital<br />

construction process. From concept drawing to reality, collaboration between<br />

people and across technologies becomes more efficient and rewarding.<br />

Together we are shaping a smarter future for construction.<br />

www.tekla.com/uk/solutions<br />

TRANSFORMING THE WAY THE WORLD WORKS

SOFTWAREfocus<br />

Bracing stuff<br />

The Braceworks add-on for Vectorworks helps designers ensure that temporary structures are both<br />

spectacular and safe<br />

Vectorworks Designer and Vectorworks<br />

Spotlight, which both already include the<br />

design tools you need to model<br />

entertainment and event rigs, are<br />

supported by the Braceworks load<br />

analysis add-on module, aimed<br />

specifically at designers and riggers<br />

working on temporary entertainment<br />

structures. Braceworks provides an easy<br />

way to gauge the performance and<br />

satisfy designers of the safety and<br />

compliancy of these temporary structures<br />

under load.<br />

It's been a while since we looked at the<br />

application of Finite Element Analysis<br />

(FEA) in construction projects, and I<br />

am delighted that the release of<br />

Vectorworks 2018 gives me the<br />

opportunity to cover it again. It has to be<br />

said though that this particular form of<br />

FEA won't be for everyone, as it is very<br />

much aimed at designers of those<br />

colossal structures that are now de<br />

rigueur for concerts, gigs, outdoor<br />

performances, and indeed any temporary<br />

structures for TV and film production,<br />

sporting events and exhibitions,<br />

complete with lighting, seating and other<br />

components. It's a limited field perhaps,<br />

but one that has more than its fair share<br />

of safety challenges.<br />

Vectorworks Braceworks was never<br />

going to be a mass-market product, but<br />

its appeal as a set of unique problems to<br />

be solved is fascinating. Designing<br />

temporary structures that are capable of<br />

carrying assorted lighting and other<br />

equipment in myriad venues and hooked<br />

up to temporary power sources, whilst<br />

occasionally catering to the wilder<br />

ambitions of the artists themselves,<br />

demands the highest levels of safety in<br />

design and construction.<br />

VECTORWORKS SPOTLIGHT<br />

Spotlight is an intuitive design tool,<br />

allowing users to transform their creative<br />

concepts into award-winning and<br />

stunning productions. It's aptly named<br />

too, as the finished creations, illuminated<br />

by dazzling light shows, pyrotechnics<br />

and animations, are often every bit as<br />

interesting as the artists themselves!<br />

The software includes 2D/3D hybrid<br />

lighting symbol libraries of conventional,<br />

LED, and moving lights, video screens,<br />

diffusers and other lighting effects. There<br />

are additional lighting features within the<br />

Vectorworks' Renderworks feature set<br />

(based on Cinema 4D) which allow<br />

designers to visualise their work as they<br />

develop the design, before using Vision -<br />

a previsualisation solution made by<br />

Vectorworks - to see how all the bells and<br />

whistles come together for a full<br />

performance.<br />

Spotlight has libraries of objects - lights,<br />

TVs, projector screens, LED screens,<br />

speakers - that can be hung on to the<br />

trusses and pipes for inclusion in the<br />

Braceworks analysis either singly or in<br />

arrays, as well as cables and soft goods<br />

like drapes and screens, which all<br />

contribute to the load on the truss.<br />

Cross-sections, used to strengthen parts<br />

of the structure, or hoists for moving<br />

8<br />

November/December 2017

TRANSFORM THE WORLD.<br />

DESIGN WITH<br />

VECTORWORKS.<br />

The Vectorworks ® line of design software and BIM solutions<br />

delivers a robust suite of capabilities that will enhance your<br />

modelling process and simplify your workflows.<br />

VISIT US AT VECTORWORKS.NET/UK<br />

CALL US TO FIND OUT MORE ON 01635 580318<br />

EMAIL US AT UKSALES@VECTORWORKS.NET<br />

IMAGE COURTESY OF CAIQUE NIEMEYER.

SOFTWAREfocus<br />

equipment during a performance, can be<br />

added from previously defined libraries<br />

or, if appropriate, designed and added<br />

from scratch.<br />

Each object comes with its own symbol,<br />

which is recognised and included in the<br />

Braceworks calculations. If additional<br />

objects are created and added to the<br />

design then custom symbols have to be<br />

made, and taken through a number of<br />

steps within the software to make them<br />

Braceworks compatible.<br />

BRACEWORKS<br />

Using Vectorworks Spotlight gives users<br />

the means to produce stage sets<br />

capable of providing the ultimate in<br />

performance, and to fine-tune the<br />

spectacle using Renderworks and<br />

Vision. Just as important, however, is<br />

ensuring that the structure is strong<br />

enough to carry the weight of its<br />

equipment throughout a complete<br />

performance. To this end, Braceworks<br />

allows designers to calculate the forces<br />

involved in complex 3D structural<br />

systems in unique, and widely different,<br />

configurations.<br />

Braceworks includes algorithms that<br />

can analyse point and distributed loads,<br />

straight and curved structural members<br />

and multiple materials, using FEA to<br />

perform static analyses. As the intended<br />

users are not always going to be<br />

seasoned FEA professionals, the results<br />

of the different analyses are displayed<br />

graphically on the model for easy<br />

reference, and to test different truss and<br />

load configurations.<br />

After the design has been established,<br />

detailed reports can be created and<br />

exported in either DSTV and PDF formats<br />

to allow structural engineers to check<br />

them out, or to perform more detailed<br />

analysis using other FEA software.<br />

So do you need to pass the model on<br />

to the professional structural engineer,<br />

as Braceworks appears to cover all of<br />

the loads involved? Well, yes and no.<br />

Braceworks does allow designers to<br />

create designs to EC3 standards for<br />

steel structures and EC9 for aluminium<br />

structures, but if you want to get the<br />

structural drawings certified or stamped<br />

in order to satisfy local safety standards,<br />

then that will have to be done by a<br />

qualified structural engineer.<br />

Braceworks uses standard, authorised<br />

FEA calculations, but that alone doesn't<br />

allow the software to replace the<br />

structural certification process. It does<br />

however save the designer, or even the<br />

in-house structural engineer if you are<br />

designing larger and more complex<br />

projects, a huge amount of time, by<br />

being able to generate the calculations<br />

directly from the model instead of having<br />

to do it by hand - the current situation in<br />

most of the industry.<br />

As designers, however, you would be<br />

ultimately responsible for ensuring that<br />

all loads, forces, connections and<br />

calculations comply with manufacturer's<br />

load tables, equipment labels and<br />

engineering specifications, and that<br />

equipment, structures and designs<br />

comply with applicable standards -<br />

ANSI, Eurocode, etc. - as well as local<br />

rules and regulations.<br />

You can get a bit of help here. To<br />

reassure users of the accuracy of the<br />

software, Vectorworks has checked the<br />

results of Braceworks calculations<br />

against well-known structural<br />

engineering packages - Dlubal RSTAB<br />

and SCIA Engineer - and have published<br />

the results in the Vectorworks<br />

knowledgebase, the support site which<br />

enables Vectorworks and its users to<br />

share information on all aspects of<br />

Vectorworks software.<br />

Some of the major truss manufacturers<br />

have already agreed to provide truss<br />

information ready for use by Braceworks,<br />

and if the ones you want to use aren't<br />

included then you can always create<br />

your own truss library. If you wish to<br />

collaborate with other set designers, you<br />

can share 3D models and add objects if<br />

you are both using Vectorworks<br />

Spotlight, but only those users licensed<br />

to use Spotlight with Braceworks will be<br />

able to carry out calculations.<br />

VECTORWORKS SOLUTIONS<br />

Braceworks is a significant step forward<br />

for Vectorworks. The software is already<br />

well known for its range of features,<br />

which cover all aspects of architectural<br />

design and construction, from terrain<br />

development, concept design and<br />

landscaping to the latest visualisation,<br />

cloud and collaboration tools, including<br />

its handling of BIM and Information<br />

Management. Braceworks takes it into<br />

the realms of design and structural<br />

analysis, and whilst the focus of the<br />

software is on Vectorwork's<br />

entertainment set and stage design<br />

tools, it whets the appetite to see similar<br />

analysis software emerge for use with<br />

Vectorworks Architect.<br />

www.vectorworks.co.uk<br />

10<br />

November/December 2017

LINDE AG Engineering<br />

embraces HP PageWide XL<br />

Thomas Riedl,<br />

Reprographic Department Manager at Linde AG<br />

The installation of a HP PageWide<br />

XL 8000 Printer plus online folder<br />

marks the end of a time consuming<br />

and costly printing process<br />

at Linde AG Engineering. With HP<br />

PageWide XL the overall costs for<br />

printing large format documents<br />

could be reduced by 40%.<br />

Prior to installing the HP Page-<br />

Wide XL 8000 MFP plus online<br />

folder back in October 2015, the<br />

company was using three large<br />

format printers to manage their<br />

print volume which in peak times<br />

could reach up to 10.000m² per<br />

month. One black & white LED<br />

printer was used for printing pages<br />

and two additional color printers<br />

based on waxed toner pearls were<br />

needed to print an ever increasing<br />

number of coloured pages. “In the<br />

past technical drawings used to<br />

be printed only in black and white<br />

but lately we have seen a significant<br />

increase of colour pages,”<br />

says Thomas Riedl, Reprographic<br />

Department Manager at the Linde<br />

Headquarter in Pullach, Germany.<br />

The value of color<br />

“Already five years ago we were<br />

dreaming of a large format printer<br />

who could produce black and white<br />

and colour pages in one go. However<br />

the available solutions back<br />

then didn’t meet our expectations<br />

in terms of cost and quality”, remembers<br />

Mr. Riedl.<br />

It has been proven that color documents<br />

are more easily understood<br />

and the information is retained at<br />

higher rates versus monochrome<br />

documents - it can decrease human<br />

error rates 1) .<br />

Significant cost savings from<br />

day one<br />

The consolidation of the previous<br />

printers into one HP PageWide XL<br />

8000 plus online folder has paid off<br />

rapidly: the internal reprographic<br />

department could cut their overall<br />

large format printing costs by<br />

40%. In addition Linde AG is very<br />

satisfied that there is no minimum<br />

purchase commitment anymore.<br />

“The price per square meter is very<br />

competitive and we have gained<br />

a lot of flexibility”. Another positive<br />

side-effect is the low energy<br />

consumption compared to LED<br />

technology. “We are very conscious<br />

about our environmental impact<br />

including energy consumption, resources<br />

and materials,” confirms<br />

Mr. Riedl.<br />

Seamless integration with existing<br />

output management system<br />

Another argument in favor of the<br />

HP solution was the seamless integration<br />

into Linde’s corporate<br />

output management system called<br />

Plossys Netdome. The System<br />

now meets Linde’s requirements<br />

for enterprise-wide print and distribution<br />

of documents and information.<br />

The HP PageWide XL 8000 printer<br />

offers the fastest large-format<br />

printing available in color<br />

and black-and-white with speeds<br />

up to 30 D/A1-size prints per<br />

minute, as well as two 775 milliliter<br />

ink cartridges per color 2) .<br />

HP PageWide Technology consists<br />

of more than 200,000 nozzles on a<br />

stationary print bar and spans the<br />

width of the page, enabling breakthrough<br />

printing speeds. Extended<br />

time between service station cycles<br />

also enables outstanding sustained<br />

productivity capacity.<br />

More information: www.linde.com • www.hp.com/go/pagewidexl<br />

HP 841 PageWide XL Print head<br />

1)<br />

According to “Why Color Matters,” by Jill Morton, 2010. 2) Printing at up to 30 D/A1 pages/minute and up to 1500 D/A1 pages/hour, the HP PageWide XL 8000 Printer is faster than alternatives for large-format printing of<br />

technical documents, GIS maps, and point-of-sale (POS) posters under $200,000 USD as of March, 2015 including 36-inch wide LED printers (printing up 22 D/A1 pages/minute) and wide-format printers based on Memjet<br />

technology (printing up to 800 D/A1 pages/hour). Based on internal HP testing of the HP PageWide XL 8000 Printer in line drawing print mode on uncoated bond paper printing in D/A1 landscape.

CASE study<br />

Grandfather's Bridge<br />

A recent Tekla based project tested BIM fully from conception to completion, aiming to deliver a full<br />

'paperless project'<br />

Grandfather's Bridge in Finland is<br />

a full-blown BIM project that<br />

progressed from the initial call<br />

for bids to its public opening and<br />

beyond, aiming at paperless design<br />

and construction, and creating new<br />

practices for transferring BIM data<br />

between project members. The project<br />

utilises 3D modelling throughout the<br />

planning phase allowing participants to<br />

minimise errors and to make the<br />

transfer of information faster and<br />

clearer. Throughout the project<br />

significant savings were achieved in<br />

time and other resources.<br />

SMOOTH START TO BIM<br />

The general contractor, Kreate, was<br />

fairly new to BIM when they started<br />

working on the project, but being<br />

experienced Tekla users meant that<br />

using the software in a full-blown BIM<br />

project felt natural for them.<br />

Aki Kopra, Project Engineer at Kreate,<br />

explains how Building Information<br />

Modelling was used all the way from<br />

the tender phase to delivery. "In the<br />

tendering phase of the project, the<br />

Building Information Model was an<br />

official and binding document. I think<br />

that this type of method is becoming<br />

more common, but for me, this was my<br />

first BIM project. As it turned out, the<br />

well-built bridge model supported our<br />

tender calculations throughout the<br />

tendering phase."<br />

SHARED UNDERSTANDING<br />

In the Grandfather's Bridge project BIM<br />

was not only used for design but also<br />

for setting up schedules and monitoring<br />

and supporting the fabrication and<br />

erection of structures. For example,<br />

steel structures were given three<br />

different statuses for scheduling -<br />

design, fabrication and installation -<br />

and concrete pours were scheduled in<br />

the model. The model was used by the<br />

client for visualising the various phases<br />

of the project, and also by the<br />

workshop, which manufactured the<br />

steel structures, facilitating scheduling<br />

and fluent collaboration between the<br />

site and fabrication operations.<br />

Kopra stresses that visualising the<br />

structure in 3D with Tekla was a<br />

significant help in processing the<br />

information; for example for managing<br />

site operations. The bridge planning<br />

process was similarly streamlined, and,<br />

allowing the project team to avoid<br />

errors, resulted in time savings.<br />

"The planning process is simpler and<br />

clearer with BIM, and also more<br />

transparent for the different members of<br />

the project - for instance, BIM allowed<br />

the site crew to see and understand the<br />

bridge structure and the way it was to<br />

be erected. This makes planning work,<br />

as it allows the entire project to<br />

become more fluent, quicker and errorfree,"<br />

says Jarkko Savolainen, the<br />

project's building information specialist<br />

at A-Insinöörit Oy.<br />

The project parties chose Tekla Model<br />

Sharing to access the combined<br />

model. As a result, the model was<br />

always up to date and team members<br />

were able to access the accurate<br />

information they needed, when they<br />

needed it.<br />

FABRICATION, PROCUREMENT<br />

AND DELIVERY<br />

The project used BIM throughout its<br />

fabrication processes for manufacturing<br />

the different challenging steel<br />

structures, which were modelled<br />

originally as workshop models to test<br />

design and fabrication, and to sort out<br />

12<br />

November/December 2017

CASEstudy<br />

possible erection issues. After these<br />

temporary steel structures were<br />

removed the whole steel structure was<br />

able to take on its final shape as<br />

designed by the architect, and<br />

subsequently the steel elements of the<br />

bridge were successfully fitted to the<br />

concrete abutments erected earlier.<br />

Using BIM, the reinforcement was<br />

designed correctly from the beginning,<br />

and the overall coordination of the<br />

installation in construction phase was<br />

especially smooth. Aki Kopra says that<br />

the procurement and delivery of<br />

materials was made more efficient by<br />

using the Building Information Model,<br />

as the reinforcement for certain parts of<br />

the bridge was able to be delivered<br />

reliably, and on time, to the<br />

construction site. "With the schedule,<br />

timing the deliveries correctly has been<br />

easy, and the site is never on hold due<br />

to a lack of material, but instead the<br />

work keeps proceeding. In addition,<br />

punctual deliveries and logistics are a<br />

great help on a site where space is<br />

limited."<br />

Model information also benefits the<br />

client and owner of the bridge - the City<br />

of Helsinki. Ville Alajoki, Senior Project<br />

Manager at the Public Works<br />

Department of the City of Helsinki,<br />

considers the project extremely<br />

successful, saying "Everything in the<br />

project was done correctly from the<br />

very beginning, in other words faults<br />

were anticipate and thus no extra repair<br />

GRANDFATHER'S BRIDGE IN FIGURES<br />

Location: Helsinki, capital of Finland<br />

Longest span: 144.3 meters<br />

Bridge width: 4 meters<br />

Shape of the bridge: The bridge widens at the other end, where the traffic<br />

lanes branch into two directions<br />

Height under bridge: 4.7 meters<br />

Cover structure: all steel<br />

Bridge deck: Hung with 22 tension-rod pairs<br />

Deck’s installation blocks: Welded together on site<br />

rounds were necessary. I believe that<br />

new technology enables new<br />

innovations, and efficiency will further<br />

be improved in many areas in<br />

construction, such as producing<br />

reinforcement elements off-site."<br />

GRANDFATHER'S BRIDGE<br />

The Grandfather's Bridge (the reason<br />

for the name was not provided, but I<br />

am sure it harks back to Finnish<br />

folklore) is located in Helsinki, and<br />

comprises a number of spans, the<br />

longest of which is 144.3 metres and is<br />

4 metres wide overall, but with one end<br />

widening to enable traffic lanes to<br />

branch in two directions. It is a steel<br />

structure supporting the deck with 22<br />

tension-rod pairs, with the deck's<br />

installation blocks welded on site.<br />

TRIMBLE BUILDINGS<br />

Tekla, now part of Trimble, was used<br />

throughout the project, and includes a<br />

number of separate applications<br />

covering all elements of the design,<br />

analysis and fabrication of steel<br />

structures. Tekla Structures makes<br />

accurate constructible modelling of any<br />

structure possible. The whole suite also<br />

comprises: Tekla Structural Designer,<br />

which gives engineers the power to<br />

analyse and design buildings efficiently<br />

and profitably; Tekla Tedds for<br />

automating repetitive structural<br />

calculations; Tekla BIMsight, a free<br />

professional tool for construction<br />

project collaboration allowing anyone to<br />

combine models, check for clashes<br />

and share information, and Tekla<br />

Field3D, an easy to use 3D tool for<br />

utilising BIM on mobile devices.<br />

In addition to Tekla, Trimble Buildings<br />

brands include names like SketchUp<br />

and Manhattan Software, targeting<br />

architects, engineers, fabricators, MEP<br />

contractors, general contractors and<br />

construction managers and building<br />

owners.<br />

www.trimble.com<br />

November/December 2017 13

SOFTWARE focus<br />

Warboard strategies<br />

Warboard enables users to marshall the information in model analytical tools in order to track<br />

progress on a project<br />

The name might bring to mind a<br />

videogame, but Warboard is<br />

actually a useful tool for<br />

organising, presenting and collaborating<br />

on clash detection information. If you<br />

are familiar with Navisworks then you will<br />

know all about its clash detection<br />

capabilities, the ability to merge<br />

separate 3D models (architectural,<br />

structural and MEP) to create a<br />

federated model and to facilitate<br />

walkthroughs, and other model<br />

inspections to detect clashes - points<br />

where the geometry of one component<br />

interferes with that of another.<br />

You will also know that each<br />

component comes with an identification<br />

code and a ream of information, and<br />

that you can tag such clashes and mark<br />

them for remedial action.<br />

The clash report is available<br />

in a number of different styles<br />

Navisworks has been around for quite<br />

a while, and it is probably the most<br />

widely used software of its type. It has<br />

its limitations though. Back in 2013, BIM<br />

Technologies were developing BIM<br />

solutions for some of their clients<br />

working on major projects. It was in the<br />

early days of BIM and, although their<br />

clients used Navisworks, they had no<br />

way of evaluating the progress of the<br />

project and their investment BIM.<br />

Much of the information they needed to<br />

get at was already available in the BIM,<br />

but BIM Technologies remained<br />

unimpressed by the practical access to<br />

data within Navisworks and the<br />

software's reporting capabilities. You<br />

could use Navisworks to produce a<br />

basic list of clashes compiled from the<br />

3D model, with a thumbnail that<br />

displayed the elements involved,<br />

accompanied by its attributes. How you<br />

dealt with them, of course, was left to you.<br />

Realising that more could be made of<br />

the information, BIM Technologies<br />

enlisted the aid of Space Applied<br />

Technologies, whose SAT team set<br />

about developing a front-end dashboard<br />

that could track issues and attributes in<br />

the model, using graphs to show how a<br />

project had progressed to become a<br />

fully coordinated model: i.e. all issues<br />

fully resolved. The dashboard was to be<br />

supported by details of current projects,<br />

with team members invited to<br />

collaborate on them and the tasks<br />

assigned to each.<br />

BIM Technologies used the resulting<br />

application to handle issues raised by<br />

their clients, who were most impressed<br />

by the platform's ability to enhance the<br />

communication and management of<br />

Navisworks data.<br />

Initially an in-house tool, architects,<br />

engineers and contractors started<br />

asking for their own access to<br />

Warboard, building up a commercial<br />

demand for the product. BIM<br />

Technologies worked with SAT to rebuild<br />

Warboard from the ground up, retaining<br />

all of the original features and adding a<br />

couple of new ones, and rolled it out in<br />

September this year, available on<br />

subscription and priced according to<br />

usage. The new features included a new<br />

user interface, multiple project<br />

management capabilities and advanced<br />

expandable clash results for<br />

customised reporting.<br />

With real-time reporting on iPads and<br />

tablets, Warboard also enabled users to<br />

produce complete PDF reports with<br />

detailed information on outstanding<br />

tasks, who was working on them, and all<br />

associated communications.<br />

The name, Warboard, was originally<br />

14<br />

November/December 2017

SOFTWARE focus<br />

Adding Warboard Projects<br />

The Warboard Dashboard<br />

tongue-in-cheek because of its similarity<br />

to the display of information you would<br />

expect in such an environment, but it<br />

proved a popular choice - and stuck!<br />

WARBOARD IN ACTION<br />

The simple display that pops up when<br />

you load the software is indicative of<br />

the simplicity of signing up for a<br />

subscription - at 6 different levels of<br />

usage for a monthly fee or as a single<br />

user which is free, but which limits the<br />

user to just 50 issues - and the ease<br />

with which projects and team members<br />

can be added. As an administrator of a<br />

project you can invite others to join<br />

your team, either as a guest, where<br />

your commenting abilities are limited,<br />

or a team member with full inclusion in<br />

the process.<br />

The Warboard dashboard is divided<br />

into a number of sections. At the top,<br />

once a project is loaded, are a graph<br />

and pie chart that display current<br />

progress levels, and a simple indication<br />

of the number of projects you are<br />

involved with, outstanding tasks, and<br />

how many messages are waiting for<br />

your attention. For convenience, a<br />

project can have two or more<br />

administrators to cater for those<br />

occasions when one or other team<br />

member is unavailable.<br />

The main display has thumbnails for all<br />

current projects, and collaborators for<br />

each project. Projects are added by<br />

selecting a suitable thumbnail image for<br />

identification in the display, and<br />

uploading and synchronising issues with<br />

the model from Navisworks in one<br />

operation in XML format. Once loaded in<br />

Warboard, each clash instance is<br />

displayed, enabling the administrator to<br />

allocate which team member is<br />

responsible for dealing with it and<br />

recording all related communications<br />

and comments, along with its priority -<br />

high, medium of low - until it is resolved.<br />

You can display all of the issues in<br />

Navisworks using its Clash Detective,<br />

which shows the quantities of different<br />

categories and whether they are new,<br />

active, reviewed, approved or resolved,<br />

along with a description of each.<br />

Selecting the report function here<br />

brings up a list of data available with<br />

each. All of these must be ticked<br />

because that is the information that will<br />

be required by Warboard - except for<br />

Resolved, as the software then has no<br />

further use for that issue.<br />

Although the process is quite<br />

straightforward, recent enhancements to<br />

Warboard allow it to be integrated within<br />

Navisworks as a plug-in, allowing<br />

automatic and seamless<br />

synchronisation with the application.<br />

Both of these activities are brilliantly<br />

explained in a series of six YouTube<br />

videos hosted by Adam Ward of BIM<br />

Technologies, with a promise of a further<br />

one to come to explain how best to find<br />

and upload issues within Navisworks.<br />

Adding team members is quick and<br />

easy, and once added you can assign<br />

work, share comments and instructions,<br />

and record their completion -<br />

information that is aggregated and<br />

displayed in graphs and charts and the<br />

familiar red/amber/green symbology,<br />

showing how far each project has<br />

progressed in achieving a perfectly<br />

coordinated model.<br />

Below these two lists is a calendar of<br />

scheduled events and a list of tasks. To<br />

the left of the main display is a browser<br />

that allows users to switch between<br />

different actions.<br />

SOLIBRI AND BCF FILES<br />

Warboard is not just restricted to<br />

Navisworks and Revit. It can be utilised<br />

by any 3D modeller that is able to export<br />

data in BCF (BIM Collaboration Format)<br />

including Solibri. The effect is just the<br />

same. This means that, theoretically, the<br />

software can be used for multiple other<br />

purposes besides managing clashes.<br />

You can take a Revit model, for instance,<br />

and highlight a section of it - perhaps<br />

the detailing around one of the windows<br />

- download it into Warboard, attach<br />

comments, and assign one of the team<br />

to deal with it.<br />

WARBOARD DEVELOPMENT<br />

This release is only the start of the<br />

development of Warboard, and both<br />

BIM Technologies and Space Group see<br />

it becoming a central project tool for the<br />

monitoring and management of design<br />

information. Rob Charlton, CEO of<br />

Space Group said; "We initially<br />

developed Warboard to allow clients to<br />

monitor project progress through a<br />

simple dashboard. Over the years the<br />

platform has grown into something<br />

much more valuable, the functionality<br />

has devolved from many users on many<br />

live projects and this latest release is<br />

particularly focused on helping<br />

designers' workflows."<br />

www.warboard.co.uk<br />

November/December 2017 15

TECHNOLOGYfocus<br />

iModelHub<br />

Introduced at the 2017 Year in Infrastructure Conference in October, Bentley's iModelHub has been<br />

conceived to leverage change rather than fight it and represents an evolution in the way model<br />

information is shared between project team members, writes David Chadwick<br />

concept in infrastructure - Keith Bentley<br />

argued in his keynote that we need a new<br />

method of managing change, a better<br />

solution for synchronising work in<br />

infrastructure projects.<br />

Having spent many years watching<br />

the industry evolve - more even than<br />

Keith Bentley, the founder and Chief<br />

Technology Officer of Bentley Systems - I sat<br />

up and took notice at the keynote speech at<br />

this year's Year in Infrastructure Conference<br />

when Keith announced that, instead of<br />

fighting change and trying to force a natural<br />

occurrence to behave as we would like it to,<br />

the time has come for us to accept it and<br />

manage it in a more mature manner.<br />

Each new technological breakthrough,<br />

software development and working process<br />

involves change, and with it attempts to<br />

minimise its impact by setting up standards<br />

and formats for users to adopt: from the<br />

very first operating systems and BASIC<br />

programming languages, through<br />

generations of floppy, hard and silicon disc<br />

drives, to CAD, BIM and collaborative<br />

worksharing. Bentley have taken part in this<br />

process as well of course, with releases<br />

such as the CONNECT Edition, which<br />

integrates applications and information in a<br />

CDE Connected Data Environment.<br />

The latest of these breakthroughs is the<br />

growth of cloud-based services, used to<br />

share a 'single source of information', soon<br />

followed, as Keith Bentley highlighted in his<br />

keynote, by big data analytics, machine<br />

learning, artificial intelligence, and<br />

blockchain - the latest buzzwords for Chief<br />

Information Officers and other technology<br />

leaders in Infrastructure.<br />

The problem is that people take on new<br />

technological ideas and methods at<br />

different rates. By the time the most Luddite<br />

of us has adopted the latest technology, the<br />

innovation leaders have moved on to the<br />

next big thing - and companies behave in<br />

much the same way, despite the pressures<br />

to work collaboratively.<br />

This is exacerbated by the increasing<br />

complexity of infrastructure projects, with<br />

many collaborating disciplines where work is<br />

interconnected. As Keith Bentley explained,<br />

these can require ''Thousands of<br />

asynchronous decisions and changes for<br />

material choices, design, aesthetics,<br />

structural integrity, safety, and more.''<br />

Constant and unrelenting change<br />

characterises infrastructure projects, but<br />

Instead of trying to fight that fact, Bentley<br />

believes we should be designing our<br />

systems from the ground up to manage<br />

change. Instead of trying to maintain a<br />

single model of a design as 'the current<br />

record' - current being an ephemeral<br />

A MODEL FOR THE FUTURE<br />

The infrastructure industry has recognised<br />

the value of the information being collected<br />

from myriad technologies, tools and<br />

workflows, believing that they can be<br />

combined to form a conceptual database of<br />

engineering decisions, processes and other<br />

information, which can be used to minimise<br />

risk and improve project efficiency by<br />

leveraging new cloud-based services.<br />

Project Managers and Asset owners<br />

believe that new insights and benefits will<br />

accrue from being able to leverage their<br />

unstructured data through the<br />

implementation of machine learning,<br />

Artificial Intelligence and big data analytics<br />

(those three buzzwords again).<br />

The digital workflows they envision,<br />

however, are simply impractical with the<br />

current generation of engineering design<br />

and information management tools that<br />

were conceived and developed for local<br />

networks of personal computers. The<br />

conceptual database they worship is in fact<br />

a disconnected array of ever-changing files<br />

in formats defined by their authoring<br />

applications, stored on servers in indivisible<br />

and indigestible units.<br />

The problem is how to retain a database of<br />

consistent units, semantics and structure<br />

that any authorised user can access without<br />

impacting other users, and which operates<br />

under the premise that the only constant is<br />

change? I suppose we could address the<br />

problem using quantum physics, but we are<br />

still in the infancy of its application.<br />

THE IMODEL 2.0 CLOUD PLATFORM<br />

Thanks to the power of the cloud, Bentley<br />

16<br />

November/December 2017

TECHNOLOGYfocus<br />

Keith Bentley<br />

has been able to introduce the iModel 2.0<br />

Cloud Platform, iModelHub, which<br />

maintains a timeline of changes and an<br />

accountable record of who did what, and<br />

when, in a distributed relational database of<br />

the entire project. It includes physical and<br />

functional models and related drawings,<br />

specifications, analytical models and so on.<br />

Unlimited copies can be made from the<br />

iModelHub - users saving copies to their<br />

own servers or workstations or cloud-based<br />

services, which can be synchronised to the<br />

iModel if they subscribe to iModelHub's<br />

timeline of changes - a distributed cloudbased<br />

database with unlimited scale-out of<br />

clients and services.<br />

Subscribers can access, and even name,<br />

any version of the iModel from the<br />

iModelHub to suit their own needs and rate<br />

of progress during the project - or even<br />

those who may just not want to work with<br />

the latest version of information - secure in<br />

the knowledge that, when appropriate, they<br />

can synchronise it with the original model<br />

with almost no disruption to it, and without<br />

risk. Bentley likens this to a bank statement.<br />

Not only can you see the final balance, but<br />

how it was achieved. If you want to look at a<br />

breakdown of the transactions leading up<br />

to the balance you can, and even run a<br />

couple of calculations on those that you<br />

have influence over, knowing that the final<br />

balance will not be affected.<br />

THE VALUE OF CHANGE<br />

Change can be a source of value as well as<br />

risk. The iModelHub maintains a timeline of<br />

changes stored as a sequence of<br />

immutable ChangeSets that capture how,<br />

when, and by whom the engineering data<br />

has been changed. This semantically rich<br />

timeline of changes shows how engineering<br />

data is changing in a meaningful way, and<br />

can be shared with project teams in both<br />

connected and disconnected workflows.<br />

The iModelHub facilitates distributed<br />

working - either across multiple<br />

organisations, individuals or locations,<br />

including remote locations with poor<br />

access to the Internet and field workers with<br />

limited WiFi capabilities. Work is done<br />

separately until it can be synchronised at<br />

appropriate milestones.Portable databases<br />

that can be synchronised when required<br />

eliminate the disadvantages that<br />

centralised databases pose, and as the<br />

iModelHub is designed to facilitate<br />

distributed cloud scale-out, it avoids the<br />

bottlenecks that normally occur when<br />

additional and unforeseen activity arrives at<br />

a central database.<br />

PIPE DREAM OR REALITY?<br />

This all sounds absolutely splendid, but<br />

how does it work in practice? What<br />

applications run on the iModelHub, and<br />

how will the system develop? The iModel<br />

web access services will make information<br />

from iModels accessible to cloud services,<br />

with the iModel Web SDK allowing third<br />

parties to create custom web applications<br />

to put together iModels, reality context from<br />

ProjectWise ContextShare, and information<br />

from other connected data environment<br />

sources, with full 3D navigation, filtering and<br />

property browsing. This enables, for<br />

instance, Navigator Web to enable viewing<br />

of any named version of an iModel from any<br />

web browser, without having to install plugins<br />

or download the iModel.<br />

Mobile apps enable complete copies of<br />

iModels to be downloaded for<br />

disconnected operation in the field -<br />

ChangeSets significantly reduce the<br />

amount of data needed to be downloaded.<br />

CONNECT Edition desktop applications<br />

can attach models from iModels as<br />

'reference attachments and receive<br />

notifications of changes added to the<br />

timeline. The ability to extract timeline<br />

related and unstructured information from<br />

the relational database allows users to<br />

extract aligned information from the<br />

wonderfully named iModel Data Lake for<br />

analytics and AI solutions.<br />

Being able to extract any configuration of<br />

iModel from the data allows project<br />

managers to provide a proper, as-built<br />

representation of the asset - the 'as-is<br />

iModel'. Using the facilities of the<br />

iModelHub, the aligned as-is iModel can be<br />

maintained in exactly the same way as all<br />

other named iModels, rather more easily<br />

and cheaply than heretofore, and without<br />

the applications that created them.<br />

So how do we maintain the viability of the<br />

asset model after handover? As Keith<br />

Bentley explained, the iModel's timeline will<br />

be reset at handover, but the iModel will<br />

continue to evolve as changes to the<br />

infrastructure are made. The iModelHub will<br />

hold the living history of the physical and<br />

functional models of the asset.<br />

www.bentley.com<br />

November/December 2017 17

EVENTfocus<br />

A civil day out<br />

The Construction Computing Take Control seminar, held in association with Newforma, raised some<br />

interesting questions about Information Management, writes David Chadwick<br />

Following the successful CAD User<br />

Seminar on COBie in May, we<br />

decided that the role of information<br />

within the construction industry should be<br />

explored further in an event of its own -<br />

hence the Take Control Seminar on<br />

Information Management, which was held<br />

on November 1st at the Institute of Civil<br />

Engineers in association with Newforma.<br />

The aim of the Take Control Seminar was<br />

to take a detailed look at the burgeoning<br />

mass of information being thrown at the<br />

construction industry, how much of it is<br />

relevant and how it should be handled.<br />

Following the same format of the CAD User<br />

COBie seminar, the morning sessions were<br />

used to set the scene with a series of<br />

presentations, look at the issues involved<br />

and present a couple of alternative<br />

solutions, followed in the afternoon by a full<br />

Q and A session where attendees could<br />

quiz the assembled experts.<br />

The presentations ranged from proposing<br />

a complete reorganisation of a company's<br />

processes to accommodate an integrated<br />

project and information management<br />

system, through to a solution proposed by<br />

Newforma that provided an organisation<br />

with the means to leverage the information<br />

already held within its various departments<br />

and servers, and which could be up and<br />

running within days - at much lower cost.<br />

INFORMATION MISMANAGEMENT<br />

Before we looked at improving our<br />

information management capabilities, I<br />

thought it would be salutary to look at a<br />

project where the basic rules of information<br />

management were ignored - namely where<br />

does it come from, is it accurate, is it<br />

appropriate and who needs it.<br />

I didn't need to look any further than my<br />

own back yard, or more literally, harbour for<br />

inspiration. The Watchet Marina Project in<br />

Somerset involves an incompetent local<br />

Council which contracted the job of<br />

constructing the Marina in a notoriously<br />

mudbound location to a company that<br />

delivered the most convenient, and<br />

presumably cheapest quotation, based on<br />

erroneous survey data that misrepresented<br />

the viability of the project. Vital measures to<br />

extract the mud were not implemented and<br />

although the information was conveyed to<br />

the Council executive in charge of the<br />

project, it was not passed on to other<br />

Council members.<br />

With the project falling apart the plug was<br />

pulled unilaterally by the CEO of the<br />

Council, resulting in a project that has not<br />

been signed off, a Council unable to sue<br />

the contractor and a mudbound Marina<br />

that is unusable except at peak tide times.<br />

The full story and the lessons to be learned<br />

are worthy of exploring in detail in a future<br />

issue of the magazine.<br />

The second presentation was given by<br />

Andy Stanton at Transport for London, who<br />

elaborated on the role of information in the<br />

management of TfL's assets. A recipient of<br />

COBie information, he explained the<br />

difficulty of relating that information to the<br />

most common tasks assigned to his staff -<br />

to whit, unblocking toilets, which formed the<br />

largest portion of tasks (around 43%!) and<br />

which, if left in an unusable state, can<br />

render whole sections of a building<br />

uninhabitable.<br />

The most telling explanation, though, was<br />

the difficulty in changing a light bulb, which,<br />

contrary to that asset maintenance joke,<br />

really does require a team to accomplish!<br />

Paul showed us a room full of attractive<br />

ornamental lights. Should one of these fail,<br />

the wiring has to be located through the<br />

suspended ceiling, back to the appropriate<br />

junction box and thence to the switch<br />

panel, requiring stepladders and the<br />

removal of numerous panels.<br />

AN ERP SOLUTION<br />

The scale of the problem was neatly<br />

expressed by Kenny Ingram of IFS, who<br />

described how building information<br />

accrues on every project even before the<br />

first concept sketch is made. In the very<br />

simplest terms, you have a need to fulfil<br />

and a certain amount of money you can<br />

spend in the pursuit of doing so. Once<br />

those parameters are established,<br />

architects and contractors have to be<br />

selected, schedules arranged, funding<br />

organised, and tenders and contracts<br />

drawn up. By this point a considerable<br />

amount of critical information has already<br />

accumulated - and we haven't even begun<br />

to speak of BIM.<br />

All of this information is held within the<br />

various servers and applications of the<br />

departments involved, which have<br />

developed over the years to satisfy<br />

18<br />

November/December 2017

EVENTfocus<br />

individual storage and archival<br />

requirements. When architects and<br />

contractors are subsequently chosen, the<br />

information they create is added to the list<br />

as BIM data.<br />

To make sense of what is happening<br />

within a project at any time - to see whether<br />

it is on time or budget - information has to<br />

be collated from a number of different<br />

sources and applications, in different<br />

formats and in different types of media, in<br />

order to produce an accurate report. IFS<br />

believes that the best way to accomplish<br />

this is to provide an all-embracing<br />

Enterprise Resource Planning (ERP)<br />

document that collates the information from<br />

all sources and uses it to populate reports,<br />

dashboards and other distributable<br />

information templates to keep every<br />

member of a project up to date. This can<br />

require considerable analysis of an<br />

organisation’s requirements and practices,<br />

and you have to ensure all project<br />

members are on board - but you will end<br />

up with an all-embracing, efficient and costeffective<br />

management solution.<br />

REUSE OF EXISTING DATA<br />

Newforma, on the other hand, has taken a<br />

different approach to the problem of<br />

managing the growing information<br />

mountain. The accumulated information<br />

from each project is aggregated according<br />

to the needs of each individual department.<br />

However, instead of requiring massive<br />

changes within an organisation to<br />

accommodate an all-embracing solution,<br />

such as ERP and the various shades of<br />

project, document and other management<br />

solutions currently available, Newforma<br />

proposes to reutilise the data in its existing<br />

formats and locations, using an advanced<br />

search engine to locate, extract and<br />

reformat every scrap of information relating<br />

to every information request.<br />

Paul Daynes of Newforma concurred with<br />

Kenny Ingram that the issue is hugely<br />

complex, but rather than trying to shoehorn<br />

all of a company's processes into a rigid<br />

and proprietary database, which requires<br />

you to migrate project data into the system<br />

before you can search it, you connect all of<br />

your best-in-class solutions, access project<br />

data regardless of where it is stored, and<br />

work the way you want to work. Instead of<br />

breaking and rebuilding xrefs to<br />

accommodate a centralised and uniquely<br />

vulnerable single point of failure, Newforma<br />

Project Center preserves BIM linkages to<br />

reference files.<br />

As Paul explained, no data is stored or<br />

moved - Newforma Project Center simply<br />

connects and creates relationships<br />

between information and file types. This,<br />

when all is said and done, is why we save<br />

information: to understand what has<br />

happened and why, and if there is an issue<br />

to be resolved, to examine how it came<br />

about. Uniting, or even reuniting, people<br />

with information reduces risk, provides<br />

transparency and accountability and<br />

improves the decision-making process - a<br />

simpler and more direct process.<br />

To emphasise the benefits of this<br />

approach, Paul presented a video from one<br />

of the company's clients, SimpsonHaugh<br />

and Partners, who chose the Newforma<br />

platform for London's Battersea Power<br />

Station project. In the video, Dave Moyes,<br />

Information Management Partner at<br />

SimpsonHaug, explained that "Newforma<br />

helps me by just giving me more time to<br />

actually do the things I want to do; to spend<br />

with other people, looking at problems, and<br />

talking about the practice and architecture."<br />

And, as Paul explained at the end of his<br />

presentation - use the recycling bin, don't<br />

waste the information you already have.<br />

GODZILLA!<br />

The final presentation of the morning gave<br />

Stefan Mordu of AECOM the opportunity to<br />

introduce us to the awesome destructive<br />

power of Godzilla! Godzilla is, of course,<br />

the iconic monster from Japanese film and<br />

TV that periodically emerges up from the<br />

depths to destroy urban landscapes -<br />

symbolic of the sort of seismic events that<br />

you can't actually plan for!<br />

Stefan also brought attendees up to<br />

speed on the trends that will affect the<br />

construction industry over the next 20 or 30<br />

years, and which will fundamentally change<br />

the way we design and build our<br />

infrastructure. This is a huge subject in itself,<br />

and proved so popular with our attendees<br />

that we are giving space to Stefan in the<br />

next issue to expand on it further. We will<br />

also explore the issues raised in the Q & A<br />

session in our Jan/Feb edition.<br />

www.constructioncomputing.co.uk/seminar<br />

November/December 2017 19

CASEstudy<br />

LEGO meets BIM<br />

Bond Bryan Architects, early adopters of the principles of BIM and its application through their use of<br />

Graphisoft's ARCHICAD, have produced the 'LEGO Architecture meets BIM' guide, using LEGO's<br />

popular building blocks as its focus<br />

If you have any children that you wish<br />

to steer towards a career in the<br />

construction industry, or if you still<br />

consider yourself a bit of a child at<br />

heart, then Bond Bryan has produced<br />

the perfect solution for Christmas. No<br />

need to risk stepping on sharpcornered<br />

bits of plastic this year when<br />

the family gets together - simply switch<br />

on your laptop and dive into the 'LEGO<br />

Architecture meets BIM' guide from the<br />

hallowed offices of the Leeds-based<br />

architectural practice!<br />

Bond Bryan Architects' LEGO-based<br />

BIM Guide won BIM project of the Year<br />

at this year's Construction Computing<br />

Awards. Bond Bryan have won this<br />

award in the past, but the sheer delight<br />

in going through the LEGO BIM Guide,<br />

made their work stand out once again.<br />

'LEGO Architecture meets BIM' was<br />

developed originally by Rob Jackson,<br />

Bond Bryan's BIM Manager, and then<br />

supported by other colleagues within<br />

the company. Support soon followed<br />

from other companies such as Hobs<br />

Studio, who printed the 3D models,<br />