NUKON-USA-Presentation2015

In the dynamic and constantly changing industrial market, NUKON USA is aware of the value in a respectable brand name, high quality production and excellent after-salesservice. Certainly every NUKON machine that you purchase will be a long-term investment in your company’sfuture! We invite you to be a part of the family of NUKON and help us in our mission of changing the future!

In the dynamic and constantly changing industrial market, NUKON USA is aware of the value in a respectable

brand name, high quality production and excellent after-salesservice.

Certainly every NUKON machine that you purchase will be a long-term investment in your company’sfuture!

We invite you to be a part of the family of NUKON and help us in our mission of changing the future!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Presentation 2015<br />

Fiber Laser Cutting Machines<br />

1

2<br />

<strong>NUKON</strong> <strong>USA</strong><br />

In the dynamic and constantly changing industrial market, <strong>NUKON</strong> <strong>USA</strong> is aware of the value in a respectable<br />

brand name, high quality production and excellent after-sales service.<br />

Certainly every <strong>NUKON</strong> machine that you purchase will be a long-term investment in your company’s future!<br />

We invite you to be a part of the family of <strong>NUKON</strong> and help us in our mission of changing the future!<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

Criteria when choosing a 3<br />

machine tool<br />

Cutting capacity<br />

according to<br />

material thickness<br />

Fiber Laser .007”-1”<br />

Plasma<br />

Cutting<br />

Oxy-flame<br />

Cutting<br />

.25”-1.25”<br />

1”-14”<br />

Fiber Laser<br />

Ø for cutting holes<br />

Plasma Cutting<br />

Oxy-flame Cutting<br />

Min Ø = Half of<br />

Material<br />

thickness<br />

Min Ø = Material<br />

thickness<br />

Min Ø = Twice<br />

Material<br />

thickness<br />

Positioning accuracy<br />

Fiber Laser +0.002<br />

Plasma Cutting +0.005<br />

Oxy-flame Cutting +0.005<br />

Repeatability<br />

Fiber Laser +0.0007<br />

Plasma Cutting +0.001<br />

Oxy-flame Cutting +0.001

Fiber Laser Cutting Technology 4<br />

1 2 3<br />

Pump diode modules<br />

pumps the light radiation<br />

into the active fiber<br />

Optical active fiber<br />

with doped core (ytterbium)<br />

and cable cladding,<br />

where the pumped light excites the core<br />

Transport optical fiber<br />

bringing out the power<br />

from the module<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

Comparison between fiber laser 5<br />

cutting machine and CO2 laser<br />

Power: 3kW CO 2 Fiber Laser<br />

Laser System<br />

Reflectivity<br />

Laser based on a gas mixture in which light is amplified by carbon dioxide molecules.<br />

CO2 lasers are less effective for cutting highly reflective materials, since much of the beam is<br />

reflected back towards the source and not absorbed by the substrate. As a result, higher<br />

power levels are required for cutting as compared to fiber lasers.<br />

Diode Pumped Laser with a doped fiber as gain medium where most<br />

of the laser module is made of fiber.<br />

Much less power is required for cutting reflective materials like<br />

aluminum or copper since more of the laser energy is absorbed by<br />

the substrate. This allows for intricate high quality cutting at higher<br />

efficiencies than comparable laser cutting systems.<br />

Reliability Only around 20,000 hours 75,000 to 100,000 hours<br />

Electrical Consumption<br />

Maintenance<br />

High Power Consumption<br />

Laser Consumption: 54 kW<br />

Chiller Consumption: 32 kW (Estimate)<br />

Maintenance & Service Costs:<br />

$35,000 per year<br />

Estimated Purge Gas Consumables:<br />

Nitrogen, Carbon Dioxide, Helium<br />

Estimated Gas Cost: 4.95/per hour<br />

Calculation: 4.95/h * 20h/per day * 250 days<br />

24,750 /yearly<br />

Power Efficiency Only as high as 6-7% Greater than 35%<br />

Optical Path/Beam Path<br />

Mirrors and optical path<br />

Loss of beam quality and significant power drop<br />

Very Low Power Consumption<br />

Laser Consumption: 14 kW<br />

Chiller Consumption: 11kW (Estimate)<br />

• Minimum Maintenance<br />

• Low Consumables<br />

• No cleaning of or alignment of mirrors for beam path<br />

Flexible Cable: Up to 150’ without loss of quality in beam

Comparison between 6<br />

fiber laser cutting machine and CO2 laser<br />

CO 2<br />

› Phase Retarder Mirror – 1 pc<br />

› Collimator Optics – 2 pcs<br />

› Bender Mirror – 1-5 pcs<br />

› AFC Mirror – 1 pc<br />

› Beam Alignment Issue<br />

Fiber Laser<br />

› Process Fiber Cable<br />

› Collimator Optic – 1 pc<br />

› No beam alignment required<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Energy consumption comparison between<br />

fiber laser and CO2 laser<br />

7<br />

CO2<br />

Fiber laser<br />

Mild Steel<br />

0,8mm<br />

Mild Steel<br />

1,5mm<br />

Aluminum<br />

1mm<br />

Stainless Steel<br />

2mm<br />

Brass 2mm<br />

Copper 5mm

Fiber laser cutting technology advantages 8<br />

Light Source: cable from laser diodes with low energy consumption<br />

Active medium: doped ytterbium ions<br />

Active fiber: double coated fiber cable with fiber Bragg grating (FBG)<br />

Wave legnth: 1,0nm (Near-infrared)<br />

Speed: extreme speed in thin sheets cutting<br />

Optical path: the laser beam is delivered through cable, no mirrors<br />

Energy efficiency: 35%<br />

Low operating costs<br />

Low-cost maintenance in the long run<br />

Optimum absorption rate of the beam<br />

Seamless cutting of non-ferrous metals and alloys<br />

Simplified structure<br />

Environmental conditions do not affect the workflow (humidity, dust, vibrations)<br />

Guiding of the laser beam is not necessary<br />

Extended working hours of laser diodes : 100 000 hours<br />

Extra space and an option for laser power upgrade<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

+1 385 900 4811| info@nukon.us | http://nukon.us<br />

Motors and drives in fiber laser 9<br />

Servo motors<br />

+ rack and pinion<br />

Linear drives<br />

Acceleration Speed (G) 1,5G 3G<br />

Axis Speed 7086”/min 7874”/min<br />

Additional Energy Consumption 0kW/h +20kW/h<br />

Positioning Speed ±0.002” ±0.0004<br />

Repeatability ±0.0007 ±0.00043<br />

Linear drives disadvantages:<br />

› Non-continuous process – they go back to home position every time<br />

› High technology with a high amount of after-sales service<br />

› Magnetizes and attracts metal dust<br />

› High energy consumption<br />

› Require an additional chiller<br />

Why does <strong>NUKON</strong> use rack and pinion driven by servo motors?<br />

› Best system for uninterrupted operations/very little service<br />

› Precise and well-tested<br />

› After reaching it’s peak the speed is reduced, but it does not affect the<br />

cutting speed at all<br />

› Energy consumption optimization

Cutting capacity of <strong>NUKON</strong> fiber laser 10<br />

Resonator 1 KW 2 KW 2 KW 3 KW 4 KW 5 KW 6 KW<br />

MATERIAL<br />

GAS<br />

MODEL ECO ECO PRO & REX<br />

VENTO<br />

PRO & REX<br />

VENTO<br />

PRO & REX<br />

VENTO<br />

PRO & REX<br />

VENTO<br />

PRO & REX<br />

VENTO<br />

Mild Steel O₂ .315” .625” .625” .709” .780” .860” .980”<br />

Stainless Steel N₂ .157” .236” .236” .394” .470” .590” .780”<br />

Aluminum N₂ .118” .197” .197” .315” .394” .315” .590”<br />

Brass N₂ .078” .118” .118” .197” .236” .315” .393”<br />

Copper O₂ .078” .118” .118” .197” .236” .315” .393”<br />

Energy consumption 13 KW 16 KW 19 KW 24 KW 32 KW 45 KW 60 KW<br />

Laser beam Ø .00393” .00393” .00393” .00393” .00393” .00393” .00393”<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

ECO S LINE 315 11<br />

› Standard working table dimensions: 5’ x 10’<br />

› Laser power source: 1000W/2000W<br />

› Very fast pneumatic exchange of the cutting table<br />

› Low energy consumption: 7kW/13kW/16kW<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

VENTO 315 12<br />

› Standard working table dimensions: 5’ x 10’<br />

› Laser power source: 2kW/3kW/4kW/5kW/6kW<br />

› Fast hydraulic table exchange, Nozzle Cleaning/Changing<br />

› Low energy consumption: 19kW/24kW/32kW/45kW/60kW<br />

› High speed and cutting capacity<br />

› Innovative industrial design<br />

+1 385 900 4811| info@nukon.us | http://nukon.us

› Different options for working table dimensions: Up to 150’ in length<br />

› Laser power source: 2kW/3kW/4kW/5kW/6kW<br />

› Fast hydraulic table exchange<br />

› Low energy consumption: 19kW/24kW/32kW/45kW/60kW<br />

› High speed and cutting capacity<br />

› Conveyer system for collecting of cut details, scrap and dust<br />

NF PRO Series 13

› Standard working table dimensions: 5’x10’<br />

› Laser power source: 2kW/3kW/4kW/5kW/6kW<br />

› Fast hydraulic table exchange<br />

› Low energy consumption: 19kW/24kW/32kW/45kW/60kW<br />

› High speed and cutting capacity<br />

› Rotary module for pipe cutting:Ø1.18”-Ø5.11”max.length10’<br />

Wall thickness: .315”, 3.93” min remainder)<br />

REX 315 PP 14

Standard equipment 15<br />

Laser resonator:<br />

› Laser output power 1000-6000W<br />

› Minimum operating costs<br />

› High quality laser beam<br />

› Large working range even with little focus Ø<br />

› Energy efficiency above 35%<br />

› Modular structure with an option for power upgrade<br />

› “Connect and start”<br />

› Easy installation and operation<br />

› Flexible and durable fiber cable for beam transition<br />

› Continuous operation of diodes: over 100,000 working hours<br />

› Minimum cooling requirements<br />

Example:<br />

Module<br />

500W<br />

Module<br />

500W<br />

ECO<br />

1000W

Dust and slag collection system 16<br />

VENTO and NF PRO:<br />

› Conveyer system<br />

› Separated transport lines<br />

› Easy cut details collection<br />

› Easy slag and dust collection<br />

› Clean working process<br />

guaranteed<br />

ECO S LINE and REX PP:<br />

› Automatic flap below the working area<br />

› Automatic gate opening and closing<br />

› Cutting head movement synchronization<br />

› Straightaway cut details and dust collection<br />

› Clean working process guaranteed<br />

› Energy consumption optimization

Cutting head <strong>NUKON</strong> Bimo-FSC 17<br />

Specification:<br />

› Configured for 2D cutting<br />

› High cutting speed on vertical movements (up to 787”/min)<br />

› High acceleration speed: up to 6 G<br />

› Rugged mechanical design<br />

› Modular structure<br />

› Protected sealed optical system<br />

› Automatic focus adjustment: Ø and position<br />

› Reduced laser beam diffraction<br />

› Capacitive height sensing (update cycle: 100µsec)<br />

› Optical collation indication<br />

› 6“ optical lens for cutting of both thin and thick materials<br />

› Gas circulation for prevention of optical damages<br />

Focus position adjustment<br />

Diameter adjustment

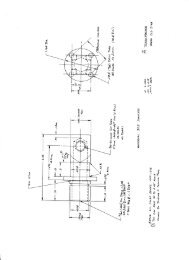

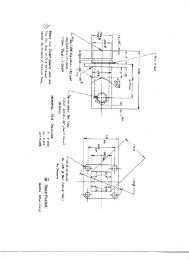

Scheme of cutting head <strong>NUKON</strong> Bimo-FSC 18<br />

Laser Light Cable Receiver<br />

Optical Collimation<br />

System with z<br />

Focus Movement<br />

Cover Slide<br />

Cartridge<br />

x,y Adjustment of<br />

the Focus Position<br />

Cutting Nozzle & Adaptor<br />

Assembly<br />

Long Cover Slide<br />

Stand-Off

Components of cutting head <strong>NUKON</strong> Bimo-FSC 19<br />

Fiber cable input Protective Glass Collimation module Protective Glass<br />

Cartridge<br />

Cutting assembly: Nozzle and adaptor<br />

Designed by <strong>NUKON</strong> duo consumables for additional protection of the cutting head.<br />

Consumables are a subject of amortization and usually they can be changed separately.<br />

In rare occasions as a result of heat and other external influences, consumables may<br />

stick to each other as welded and they have to be changed together.<br />

The ceramic cover of the adaptor protects the cutting head from damages.

Cutting head movements 20<br />

Right choice of a cutting method:<br />

› Optimizes the work flow<br />

› Guarantees high quality results<br />

› Depends on the material type and thickness<br />

Fly cutting:<br />

1) Rectangle<br />

2) Frog Jump<br />

3) Fast Cut<br />

Application:<br />

- Serial cutting of details with same shape and dimensions<br />

- Details with advanced contours<br />

Movements: linear or parallel<br />

First, all the contours from same side are cut than the cutting head moves to the other side and<br />

when finished all contours cut the cutting head makes a frog jump and makes the outline.<br />

Fast Cut Frog Jump Rectangle<br />

When moving from one contour to another the cutting head doesn’t move on the z-axis, but it<br />

moves with a turned off light.

Software: RADAN Radprofile 21<br />

Advantages in a glance:<br />

Drag and drop data input<br />

Batch processing of DXF/DWG<br />

Smart order lead-ins – maximize<br />

safety/reduce runtimes<br />

Automatic hazard avoidance, maintaining<br />

head safety<br />

Intelligent tagging of components and scrap<br />

Bridge cutting – reduced costs/times<br />

Automatic common line cutting<br />

Automatic remnants, sheet scrapping and<br />

off-cuts<br />

Project nesting, incorporating user definable<br />

reports<br />

Graphical program verification<br />

Quick estimates for parts or nests<br />

Simple intuitive interface with clear simple<br />

icons<br />

Reduced lead times and increased production<br />

Seamless programming

Software: RADAN Radprofile 22<br />

Seamless programming:<br />

Seamlessly integrates the whole programming process: geometry<br />

creation, nesting, cut path profiling, sequencing, code generation<br />

and finally DNC connectivity to the machine controller<br />

Easier to use experience for operators<br />

MDB stores: material, lead-ins, lead-outs, tagging, and machine<br />

tool specific cutting technology data<br />

Readiness for instantaneous distribution when required to assist<br />

an operator or automated process<br />

Accuracy and consistency of programming<br />

Collation of process critical data in the Manufacturing Database<br />

(MDB)<br />

Optimize your manufacturing capacity to the limits<br />

machine tool individually<br />

The key to efficiency<br />

of each

CNC: Power Automation 23<br />

Machine functions:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Sheet database for cutting<br />

parameters<br />

Marking<br />

Film burning (removing of existing<br />

oil layer by laser)<br />

Various piercing options<br />

Y-Joint generation<br />

Fast Cut (cutting without piercing)<br />

Fly Cut (cutting with a constant<br />

speed without piercing)<br />

Multiple cutting qualities selectable<br />

per contour<br />

Automatic and manual plate angle<br />

determination<br />

Sequential processing of several<br />

NC jobs<br />

Sequential processing of several<br />

sheets<br />

Laser pointer function for<br />

determining starting point<br />

Stop of NC process with the<br />

following options:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Moving backward on the contour<br />

and restart<br />

Manually move of the axes and<br />

restart<br />

Complex C2C (contour to contour)<br />

handling<br />

Selectable motion types between<br />

the contours (without stroke,<br />

square, triangle, ramp, parabolic)<br />

Consumables handling<br />

Start at working piece or contour<br />

Change of the cutting parameters<br />

on the fly<br />

Automatically selectable vacuum<br />

areas

Sheet loading system OCTOPUS 315 24<br />

Business partners lift each other up.<br />

OCTOPUS is distinctive in its class as a sheet loading system.<br />

Easy to operate, reduces damage on the plate and accelerates<br />

the loading process.<br />

Plate comes right and scratch-free in the correct position on the cutting table<br />

Manual system with an ideal work position for the operator<br />

Also lifts plates and large pieces unscratched from the cutting table<br />

Fits any cutter and shear

Business partners lift each other up. 25<br />

Technical Data<br />

Lift speed High speed + low speed<br />

Supply air pressure, 4-6 Bar (max. 7 bar)<br />

adjusted with pressure regulator<br />

Supply air type Dry compressed air<br />

Electrical power 220/440<br />

Building plug 16A, 5-pole<br />

Feeding 3 phase<br />

Signaling “Alarm”, “vacuum reached” and “in<br />

operation”<br />

Lifting capacity max.1984 lbs.<br />

Signaling for venting the plate through 2-hand control<br />

Steering through PLC<br />

Air consumption 416 Nl/min.<br />

Max. flow rate 1,448 Nl/min.<br />

Max. vacuum level -75 kPa<br />

Weight Approx. 4200 lbs<br />

Max. plate size 5’ x 10’

26<br />

THANK YOU<br />

for your time and attention!