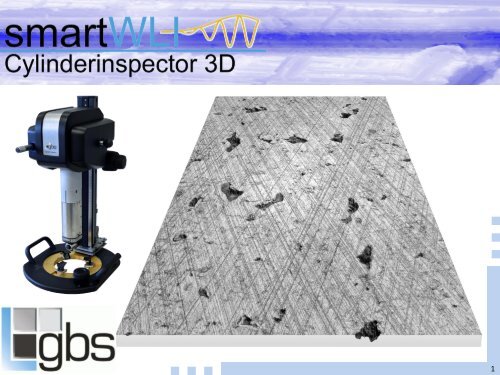

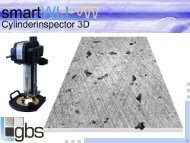

GBS_smartWLI Cylinderinspector 3D

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1

Product Description<br />

Optical 3d measuring device based on white-light interferometry<br />

• designed for the control of inner cylinder surfaces for the automotive industry<br />

• Speedytec<br />

o massive parallel data processing on GPU’s<br />

o extreme fast scanning<br />

o real time 3d evaluation<br />

o optimized for steep structures<br />

o integrated data quality parameter for sample optimized filtering processes<br />

• single objectives<br />

o manual exchangeable<br />

o magnifications from 2.5x ... 100x<br />

• push button scan and evaluation macros using smartVIS <strong>3D</strong> as system- and MountainsMap as<br />

evaluation software<br />

• simplifies handling<br />

• 360° rotation<br />

• manual insertion axis<br />

• optional motorized insertion axis with automated stitching

Intention of the cylinder inspection<br />

Lapping / structuring of inner cylinder running surfaces:<br />

• structures have an essential influence on the friction:<br />

o the oil retaining volume is essential for the necessary lubrication of the friction partners piston and<br />

cylinder surface<br />

o smooth contact areas reduce the wear and friction special on lower revolution speed<br />

o pores can reduce the oil consumption still providing the necessary oil retaining volume for the<br />

lubrication of the friction partners<br />

o honing structures – angle, furrows... have an big influence of the oil transport and the<br />

hydrodynamic lubrication<br />

• the optimization of the structures can reduce the consumption of engines as well as extend the live time<br />

• there are various positive effects as reduction of the environmental pollution and reduction of the<br />

operation costs – this increase the value of cars and has a significant impact on purchase decisions<br />

Typical operation areas of the <strong>Cylinderinspector</strong><strong>3D</strong><br />

• research and development<br />

o optimization of production processes<br />

o assessment of functional behavior on basis of the 3d structures without extended tests<br />

o wear evaluation after running tests<br />

• quality control<br />

o survey of production processes<br />

o optimization of tool exchanges ... in the production

Technical Product Specification<br />

<strong>smartWLI</strong> <strong>Cylinderinspector</strong> <strong>3D</strong><br />

Cylinder Diameter 70 ... 125 mm (standard configuration)<br />

Measurement Technique White-light interferometry<br />

Height resolution / nm 1 nm (all objectives / field of views)<br />

Scanner Precision piezo drive with gauge control<br />

Scan Range 200 µm<br />

Speed up to 20 µm/s<br />

System Software smartVIS <strong>3D</strong> / Speedytec on GPU<br />

Evaluation Software MountainsMap with <strong>GBS</strong> programmed extensions<br />

Array 1624 x 1234 measuring points<br />

Weight app. 12 ... 14 kg<br />

Power Supply 100 to 240 VAC, 50/60 Hz<br />

4

Optional configuration<br />

standard<br />

extended<br />

motorized<br />

Insertion System<br />

manual down to app. 188 mm<br />

manual down to app. 270 mm<br />

automated z axis down to app. 200 mm<br />

Optical Configuration<br />

Magnification 5x 10x 20x 50x<br />

Field of View / mm 2.8 x 2.08 1.4 x 1.04 0.7 x 0.52 0.28 x 0.21<br />

Point Distance / µm 1.6 0.8 0.4 0.16<br />

5

Modern technologies require a detailed quality control<br />

Aluminum engine blocks*<br />

monolithic quasi - monolithic heterogenous - liner<br />

coated bores<br />

local material<br />

engineering<br />

dry<br />

cast-in pressed in slip-fit<br />

wet<br />

hypereutectic<br />

Al-Si alloy<br />

galvanic Ni-SiC<br />

dispersion<br />

Al matrix<br />

compound<br />

grey iron<br />

machined<br />

grey iron<br />

plasma coating<br />

AlSi/PM<br />

hypereutectic<br />

AlSi<br />

PVD thin layer<br />

TiN, TiAlN<br />

grey iron as<br />

cast with rough<br />

outer surface<br />

galvanic Ni-SiC<br />

dispersion<br />

grey iron<br />

coated<br />

laser alloying<br />

with Si<br />

plasma spayed<br />

AlSi/PM<br />

There are many competitive technologies used (green) new on<br />

the marked (yellow) or under development (red). All technologies<br />

have several production steps and need a sophisticated and<br />

adapted quality control.<br />

*Source Kolbenschmidt 2011 / Al Automotiv manual<br />

6

Evaluation parameters for inner cylinder running surfaces<br />

Honing structures:<br />

• Honing angle<br />

• Honing grooves<br />

o directional classification (rising,<br />

falling, across)<br />

o numbers, depth, area, volume<br />

o Distance between groove<br />

o Cross grooves<br />

Plateaus:<br />

• contact roughness<br />

Functional 2D Parameters<br />

• Rk, Rpk, Rvk<br />

Structure evaluation<br />

Surface Roughness<br />

Cavities / pores:<br />

• numbers / distances<br />

• volume<br />

• area<br />

• depth<br />

• distribution of cavities (according<br />

volume, area and depth)<br />

Marbling:<br />

• % over surrounding surface<br />

Functional <strong>3D</strong> Parameters<br />

• Sk, Spk, Svk<br />

7

Different surfaces and a wide range of priorities for measurements<br />

Technologies get optimized in the same directions:<br />

• lower friction<br />

• wear resistance<br />

• lower oil consumption<br />

• weight reduction<br />

...but measuring devices are use for different purposes...<br />

R&D:<br />

• detailed analysis for technology optimization<br />

Quality control:<br />

• fast survey of predetermined parameters<br />

• different priorities for the used technology<br />

8

Scans with various magnifications<br />

2,5 x Objective<br />

10 x Objective<br />

50 x Objective<br />

more structures per scan – more details from each structure<br />

5 x Objective 20 x Objective 100 x Objective<br />

9

Sample: many cavities but not enough details of honing structures<br />

Partial area of a single scan using the 2.5x Objective<br />

FOV: 7.2 x 4.5 mm²<br />

time:

Sample: many detail but only a single (large) groove inside<br />

Single scan using the 50x Objective<br />

FOV: 0.28 x 0.21 mm²<br />

time:

Sample: local variation of cavities, multiple scans necessary<br />

mm<br />

2.0<br />

1.5<br />

1.0<br />

FOV: 7,2 x 4,5 mm²<br />

time:

Recommendation for the correct field of view<br />

Check list to select the correct system configuration:<br />

• min. 10x higher resolution in xyz than the feature which should be measured<br />

• min. 10 evaluation features inside the scanning area<br />

• min. 10 measuring positions for statistical analysis<br />

feature parameter reality* required system parameter<br />

seize depth density xy res. z res. area<br />

cavities area 500 µm² > 1 µm 10 / mm² 1 / mm

Robust form filtering<br />

cylinder surface<br />

filtered surface (z-range reduced)<br />

surface with out marked cavities<br />

robust filtered surface (z-range reduced)<br />

Robust filters (polynomial, gaussian and combinations) are the basis for all following evaluation processes.<br />

“Robust” are filters, which eliminate the influence of cavities and avoid local waves on the filtered surface.<br />

14

Structure separation<br />

robust filtered cylinder surface<br />

honing<br />

cavities<br />

marbling<br />

Structure characteristics (directional orientation, depth, height, seize) can be used to separate the<br />

structures from each other and evaluate them separately.<br />

15

Honing Structure FFT Analysis<br />

mm<br />

1.0<br />

0.8<br />

0.6<br />

µm<br />

1<br />

0<br />

mm<br />

1.0<br />

0.8<br />

0.6<br />

µm<br />

1<br />

0<br />

-1<br />

-2<br />

0.4<br />

0.2<br />

0.0<br />

0.0 0.5 1.0 mm<br />

-1<br />

-2<br />

-3<br />

0.4<br />

0.2<br />

0.0<br />

0.0 0.5 1.0 mm<br />

-3<br />

-4<br />

-5<br />

-6<br />

Parameters Value Unit<br />

Honing Angle - Honing Structure FFT Analysis 18.20 °<br />

Rising Grooves - Honing Structure FFT Analysis 16.20 °<br />

Falling Grooves - Honing Structure FFT Analysis 20.20 °<br />

Rising Structures - Honing Structure FFT Analysis 26.11 %<br />

Falling Structures - Honing Structure FFT Analysis 34.52 %<br />

Cross Structures - Honing Structure FFT Analysis 2.00 %<br />

Closed Structures - Honing Structure FFT Analysis 37.37 %<br />

Parameters Value Unit<br />

Honing Angle - Honing Structure FFT Analysis 18.05 °<br />

Rising Grooves - Honing Structure FFT Analysis 17.20 °<br />

Falling Grooves - Honing Structure FFT Analysis 18.90 °<br />

Rising Structures - Honing Structure FFT Analysis 8.86 %<br />

Falling Structures - Honing Structure FFT Analysis 14.05 %<br />

Cross Structures - Honing Structure FFT Analysis 4.52 %<br />

Closed Structures - Honing Structure FFT Analysis 72.57 %<br />

Comment:<br />

The <strong>GBS</strong> programmed Honing Structure FFT Analysis allowed a separate analysis of rising and falling structures. The<br />

sample on the right site shows a higher percentage of closed structures because of the cavities (positive) but also more<br />

cross structures. The scan on the left side shows a more falling structures and on the right side more rising structures.<br />

16

Key cavities<br />

1.00 µm<br />

Number of islands 44<br />

Threshold 1.00 µm<br />

Parameters Unit Grain #1 Grain #2 Grain #3 Grain #4 Grain #5 Grain #6 Grain #7 Grain #8 Grain #9 Grain #10 Grain #11 Grain #12 Grain #13<br />

Area mm² 0.0056 0.00515 0.00307 0.00291 0.00235 0.0017 0.00169 0.00159 0.00158 0.0013 0.00113 0.000941 0.000933<br />

Aspect ratio 1.53 1.58 3.41 2.92 2.73 3.83 2.02 2.19 4.03 2.42 2.98 2.67 1.91<br />

Volume µm³ 13995 20813 6088 8015 2807 2576 4531 3282 2414 2432 1116 2045 3372<br />

Max height µm 4.74 9.98 4.00 6.73 2.70 4.67 4.54 3.31 2.89 4.36 2.67 4.29 9.11<br />

Height/Surface ratio µm/mm² 847 1937 1304 2310 1148 2740 2688 2086 1831 3358 2365 4557 9767<br />

Status 0 0 0 0 0 0 0 0 0 0 0 0 0<br />

Separated cavities could be counted and statistically<br />

evaluated.<br />

Many classificatory operator – as depth, volume, form<br />

factors ... can be used to analyze many partial aspects<br />

from the cavities.<br />

17

Key aspect “marbling”<br />

photorealistic 3d plot<br />

grey coded 3d plot<br />

Marbling – the camera image shows an texture as could be seen on marble surfaces. The black lines are<br />

cracks in the surface. Inner tensions could cause that surface plateaus standing out of the surrounding<br />

areas.<br />

18

Key aspect “marbling”<br />

0.20000 µm<br />

NM<br />

Number of islands 23<br />

Threshold 0.20000 µm<br />

Parameters Stat. Value Unit<br />

Area Mean 0.0014092 mm²<br />

Volume Mean 328.36 µm³<br />

Marbling – areas which are standing up can be detected and evaluated.<br />

19

Key 2d parameters<br />

µm<br />

5<br />

0<br />

-5<br />

-10<br />

Context Mean Std dev Min Max<br />

ISO 4287<br />

Amplitude parameters - Roughness profile<br />

Rp µm Robust Gaussian filter, 0.8 m … 0.786 0.328 0.332 1.80<br />

Rv µm Robust Gaussian filter, 0.8 m … 3.07 2.73 0.192 14.5<br />

Rz µm Robust Gaussian filter, 0.8 m … 3.86 2.86 0.773 15.5<br />

Rt µm Robust Gaussian filter, 0.8 m … 5.09 2.96 0.873 16.0<br />

Ra µm Robust Gaussian filter, 0.8 m … 0.318 0.269 0.118 1.65<br />

Rq µm Robust Gaussian filter, 0.8 m … 0.587 0.594 0.146 3.50<br />

ISO 13565<br />

ISO 13565-2<br />

Rk µm Robust Gaussian filter, 0.8 m … 0.489 0.0688 0.344 0.809<br />

Rpk µm Robust Gaussian filter, 0.8 m … 0.280 0.155 0.0951 1.03<br />

Rvk µm Robust Gaussian filter, 0.8 m … 1.81 1.73 0.106 11.3<br />

-15<br />

-20<br />

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 mm<br />

Information<br />

Profile<br />

T-axis<br />

honing with cavities > Mirrored (in Z) > Filtered (Median Denoising 5x5) > Resampled (812 points x 617 line…<br />

Y-axis = -0.549 mm<br />

Parameters Value Unit<br />

Length 1.44 mm<br />

All available lines can be analyzed parallel and statistically classified to increase the significance of results.<br />

20

Key 3d parameters<br />

Sk<br />

Spk<br />

Svk<br />

0<br />

1<br />

2<br />

3<br />

0 10 20 30 40 50 60 70 80 90 100 %<br />

10.0<br />

Vmp<br />

%<br />

80.0 % Vvc<br />

Vmc<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

Vvv<br />

0 20 40 60 80 100 %<br />

Sr1<br />

Sr2<br />

Information<br />

Filter settings Unfiltered.<br />

Parameters Value Unit<br />

Sk 0.532 µm<br />

Spk 0.313 µm<br />

Svk 2.10 µm<br />

Sr1 10.2 %<br />

Sr2 88.2 %<br />

Sa1 16049 µm³/mm²<br />

Sa2 123864 µm³/mm²<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

µm<br />

Parameters Value Unit<br />

Vmp 0.0147 ml/m2<br />

Vmc 0.187 ml/m2<br />

Vvc 0.264 ml/m2<br />

Vvv 0.138 ml/m2<br />

Parameters as Spk can be used to evaluate the contact roughness.<br />

21

Gehring is using the <strong>smartWLI</strong>’s to optimize production processes<br />

Gehring today:<br />

• Expert for functional surface optimization<br />

• since 1926 worldwide leader for lapping<br />

technologies<br />

• partner for many automotive companies<br />

• worldwide 9 locations with app. 800 employers<br />

• head quarter in Ostfildern near Stuttgart<br />

Technologies:<br />

Technological motivation<br />

EU 2020<br />

95 g CO 2 /km<br />

fuel consumption<br />

optimized<br />

friction<br />

optimized<br />

functional surfaces<br />

honing machines<br />

honing tools<br />

abrasives<br />

Laser systems<br />

Lapping Thermal spraying Laser structuring<br />

22

friction coefficient µ<br />

Structures with high retaining volume and reduced oil consumption<br />

Stribeck-curve<br />

the friction will be reduced and the<br />

minimum achieved on lower speed<br />

(revolution) speed / v<br />

23

Surfaces with functional optimized laser structures<br />

Spk: 0.19 µm<br />

bearing shells will be fixed on elevated<br />

laser structures (much higher friction<br />

and nearly 20x larger Spk values)<br />

Spk: 3.52 µm<br />

24

Rz / nm<br />

Ra / nm<br />

Proven system accuracy<br />

certificate<br />

Rz: 128.4 (113.0 ... 143.8) nm<br />

Ra: 24.1 (21.4 ... 26.8) nm<br />

measurement results:<br />

Rz: 144.6 nm (std. Rz: 3 nm)<br />

Ra: 24.7 nm (std. Ra: 0.7 nm)<br />

field of view: 1.4 x 1.04 mm²<br />

scan time: < 2 s<br />

point density: 0.8 µm<br />

mode:<br />

high resolution<br />

VSI<br />

28<br />

27<br />

26<br />

25<br />

24<br />

23<br />

160<br />

155<br />

repetition<br />

0 5 10 15 20 25 30 35<br />

repetition<br />

150<br />

145<br />

140<br />

0 5 10 15 20 25 30 35<br />

25

Advantages of the <strong>smartWLI</strong> technology<br />

General advantages of the <strong>smartWLI</strong> <strong>Cylinderinspector</strong> <strong>3D</strong><br />

• easy handling<br />

• short scanning time<br />

• complete software based on MountainsMap with customized evaluation macros and <strong>GBS</strong> programmed<br />

functional extensions for the evaluation of honing structures<br />

• insertion depth up to 270 mm<br />

Compared to systems based on confocal measuring technologies<br />

• extreme height resolution of 1 nm for all magnification / objectives<br />

• no reduction of the height resolution for larger scanning areas in single scans<br />

• independent height calculation of direct neighborhood points for improved xy resolution<br />

• without limitations as pinhole density of confocal microscopes<br />

• using of high resolution matrix cameras<br />

Compared to competitive systems with based on similar White-light interferometric technology<br />

• Speedytec use the power of high speed graphic cards or FPGA’s and provides always real time<br />

calculation of the point cloud even for high speed high resolution matrix cameras<br />

• improved algorithms using the high speed image processing of graphic cards or FPGA’s provide a lower<br />

noise and better data quality on geometries with steep slopes and samples with extreme black white<br />

differences<br />

„leading company’s recommend the white light interferometry as preferred method<br />

for cylinder inspections...“<br />

26