Important Considerations for laser marking an identifier on die-casting

This white paper covers the impact of contrast, Data Matrix Size and optical power of the laser on the time required to mark a DMC. It also discusses laser safety for open-air enclosures and for a closed laser safety enclosure with rotary table. But why stop at that. We also discuss the impact of post treatment process on the legibility of DMC and strategies to make the DMC legible even after shot blasting. Have a look, you'll be glad you did. Feel free to contact us at: https://www.laserax.com/company/contact-us Browse our website at: https://www.laserax.com/ Get in touch on our social media channel: Facebook: https://www.facebook.com/Laserax/ LinkedIn: http://bit.ly/2f8sKYz Twitter: https://twitter.com/Laserax_inc Google+: http://bit.ly/2vtaFeH YouTube: http://bit.ly/2u4i1oN Xing: https://www.xing.com/xbp/pages/laserax Instagram: https://www.instagram.com/laserax_inc/ Viadeo: http://www.viadeo.com/fr/company/laserax Learn more on our laser marking & traceability, laser cleaning and safety standards blog Blog: https://blog.laserax.com/

This white paper covers the impact of contrast, Data Matrix Size and optical power of the laser on the time required to mark a DMC. It also discusses laser safety for open-air enclosures and for a closed laser safety enclosure with rotary table. But why stop at that. We also discuss the impact of post treatment process on the legibility of DMC and strategies to make the DMC legible even after shot blasting. Have a look, you'll be glad you did.

Feel free to contact us at: https://www.laserax.com/company/contact-us

Browse our website at:

https://www.laserax.com/

Get in touch on our social media channel:

Facebook: https://www.facebook.com/Laserax/

LinkedIn: http://bit.ly/2f8sKYz

Twitter: https://twitter.com/Laserax_inc

Google+: http://bit.ly/2vtaFeH

YouTube: http://bit.ly/2u4i1oN

Xing: https://www.xing.com/xbp/pages/laserax

Instagram: https://www.instagram.com/laserax_inc/

Viadeo: http://www.viadeo.com/fr/company/laserax

Learn more on our laser marking & traceability, laser cleaning and safety standards blog

Blog: https://blog.laserax.com/

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SHOT BLAST ONLY<br />

Figure 11- Data Matrix seen from two different <str<strong>on</strong>g>an</str<strong>on</strong>g>gles with cell size of 1 mm.<br />

Shot blast is <str<strong>on</strong>g>an</str<strong>on</strong>g> abrasive treatment that ch<str<strong>on</strong>g>an</str<strong>on</strong>g>ges the roughness of the surface. To resist these kinds of treatment, much deeper<br />

codes must be marked. A “deep <str<strong>on</strong>g>marking</str<strong>on</strong>g>” technique, described below, is there<str<strong>on</strong>g>for</str<strong>on</strong>g>e used.<br />

The individual cell size is <str<strong>on</strong>g>an</str<strong>on</strong>g> import<str<strong>on</strong>g>an</str<strong>on</strong>g>t factor influencing the readability of the 2D code after shot blasting. The marks d<strong>on</strong>e<br />

with 0.4 mm cells were not readable after the shot blast treatment while the 0.6 mm <str<strong>on</strong>g>an</str<strong>on</strong>g>d 0.8 mm show very good results.<br />

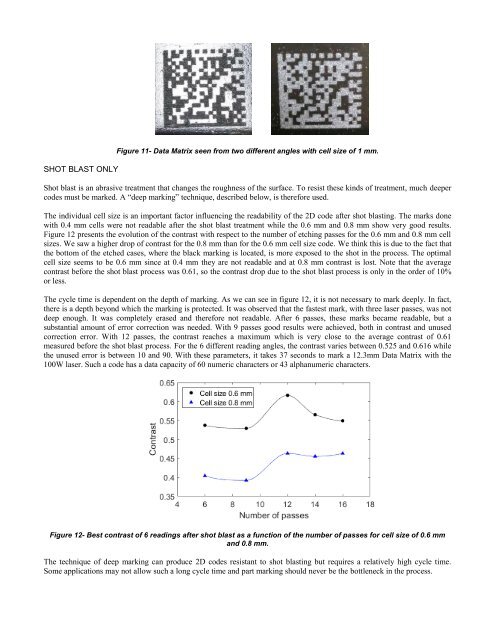

Figure 12 presents the evoluti<strong>on</strong> of the c<strong>on</strong>trast with respect to the number of etching passes <str<strong>on</strong>g>for</str<strong>on</strong>g> the 0.6 mm <str<strong>on</strong>g>an</str<strong>on</strong>g>d 0.8 mm cell<br />

sizes. We saw a higher drop of c<strong>on</strong>trast <str<strong>on</strong>g>for</str<strong>on</strong>g> the 0.8 mm th<str<strong>on</strong>g>an</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> the 0.6 mm cell size code. We think this is due to the fact that<br />

the bottom of the etched cases, where the black <str<strong>on</strong>g>marking</str<strong>on</strong>g> is located, is more exposed to the shot in the process. The optimal<br />

cell size seems to be 0.6 mm since at 0.4 mm they are not readable <str<strong>on</strong>g>an</str<strong>on</strong>g>d at 0.8 mm c<strong>on</strong>trast is lost. Note that the average<br />

c<strong>on</strong>trast be<str<strong>on</strong>g>for</str<strong>on</strong>g>e the shot blast process was 0.61, so the c<strong>on</strong>trast drop due to the shot blast process is <strong>on</strong>ly in the order of 10%<br />

or less.<br />

The cycle time is dependent <strong>on</strong> the depth of <str<strong>on</strong>g>marking</str<strong>on</strong>g>. As we c<str<strong>on</strong>g>an</str<strong>on</strong>g> see in figure 12, it is not necessary to mark deeply. In fact,<br />

there is a depth bey<strong>on</strong>d which the <str<strong>on</strong>g>marking</str<strong>on</strong>g> is protected. It was observed that the fastest mark, with three <str<strong>on</strong>g>laser</str<strong>on</strong>g> passes, was not<br />

deep enough. It was completely erased <str<strong>on</strong>g>an</str<strong>on</strong>g>d there<str<strong>on</strong>g>for</str<strong>on</strong>g>e not readable. After 6 passes, these marks became readable, but a<br />

subst<str<strong>on</strong>g>an</str<strong>on</strong>g>tial amount of error correcti<strong>on</strong> was needed. With 9 passes good results were achieved, both in c<strong>on</strong>trast <str<strong>on</strong>g>an</str<strong>on</strong>g>d unused<br />

correcti<strong>on</strong> error. With 12 passes, the c<strong>on</strong>trast reaches a maximum which is very close to the average c<strong>on</strong>trast of 0.61<br />

measured be<str<strong>on</strong>g>for</str<strong>on</strong>g>e the shot blast process. For the 6 different reading <str<strong>on</strong>g>an</str<strong>on</strong>g>gles, the c<strong>on</strong>trast varies between 0.525 <str<strong>on</strong>g>an</str<strong>on</strong>g>d 0.616 while<br />

the unused error is between 10 <str<strong>on</strong>g>an</str<strong>on</strong>g>d 90. With these parameters, it takes 37 sec<strong>on</strong>ds to mark a 12.3mm Data Matrix with the<br />

100W <str<strong>on</strong>g>laser</str<strong>on</strong>g>. Such a code has a data capacity of 60 numeric characters or 43 alph<str<strong>on</strong>g>an</str<strong>on</strong>g>umeric characters.<br />

Figure 12- Best c<strong>on</strong>trast of 6 readings after shot blast as a functi<strong>on</strong> of the number of passes <str<strong>on</strong>g>for</str<strong>on</strong>g> cell size of 0.6 mm<br />

<str<strong>on</strong>g>an</str<strong>on</strong>g>d 0.8 mm.<br />

The technique of deep <str<strong>on</strong>g>marking</str<strong>on</strong>g> c<str<strong>on</strong>g>an</str<strong>on</strong>g> produce 2D codes resist<str<strong>on</strong>g>an</str<strong>on</strong>g>t to shot blasting but requires a relatively high cycle time.<br />

Some applicati<strong>on</strong>s may not allow such a l<strong>on</strong>g cycle time <str<strong>on</strong>g>an</str<strong>on</strong>g>d part <str<strong>on</strong>g>marking</str<strong>on</strong>g> should never be the bottleneck in the process.