PMCI - October 2017

Welcome to the latest issue of PMCI - the only publication dedicated to Private Military Contractors. This time the PMCI team bring you their report from one of the biggest Defence Industry shows in the world, the might behemoth that is DSEI. As usual though, you'll find the mix of training, equipment, tools and firearms articles that you've come to expect. Our good friend Eli from Project GECKO once again joins us with his unique perspective on things tactical, Trampas builds his ultimate "Instructors Rifle" and, of course, the rest of the team pitch with their take on all the things that make a contractor tick!

Welcome to the latest issue of PMCI - the only publication dedicated to Private Military Contractors.

This time the PMCI team bring you their report from one of the biggest Defence Industry shows in the world, the might behemoth that is DSEI. As usual though, you'll find the mix of training, equipment, tools and firearms articles that you've come to expect.

Our good friend Eli from Project GECKO once again joins us with his unique perspective on things tactical, Trampas builds his ultimate "Instructors Rifle" and, of course, the rest of the team pitch with their take on all the things that make a contractor tick!

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PROJECT PLANNING<br />

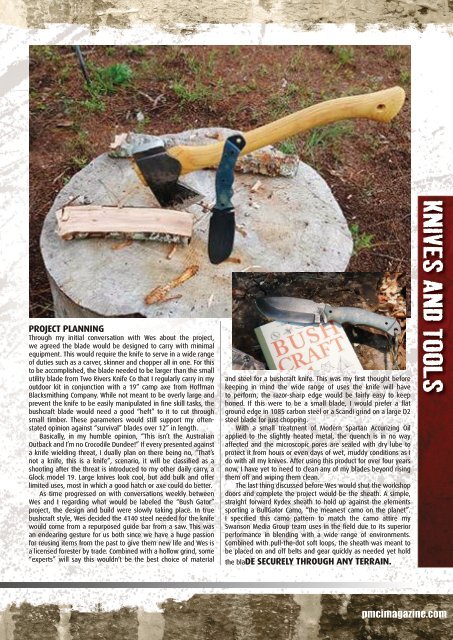

Through my initial conversation with Wes about the project,<br />

we agreed the blade would be designed to carry with minimal<br />

equipment. This would require the knife to serve in a wide range<br />

of duties such as a carver, skinner and chopper all in one. For this<br />

to be accomplished, the blade needed to be larger than the small<br />

utility blade from Two Rivers Knife Co that I regularly carry in my<br />

outdoor kit in conjunction with a 19” camp axe from Hoffman<br />

Blacksmithing Company. While not meant to be overly large and<br />

prevent the knife to be easily manipulated in fine skill tasks, the<br />

bushcraft blade would need a good “heft” to it to cut through<br />

small timber. These parameters would still support my oftenstated<br />

opinion against “survival” blades over 12” in length.<br />

Basically, in my humble opinion, “This isn’t the Australian<br />

Outback and I’m no Crocodile Dundee!” If every presented against<br />

a knife wielding threat, I dually plan on there being no, “That’s<br />

not a knife, this is a knife”, scenario, it will be classified as a<br />

shooting after the threat is introduced to my other daily carry, a<br />

Glock model 19. Large knives look cool, but add bulk and offer<br />

limited uses, most in which a good hatch or axe could do better.<br />

As time progressed on with conversations weekly between<br />

Wes and I regarding what would be labeled the “Bush Gator”<br />

project, the design and build were slowly taking place. In true<br />

bushcraft style, Wes decided the 4140 steel needed for the knife<br />

would come from a repurposed guide bar from a saw. This was<br />

an endearing gesture for us both since we have a huge passion<br />

for reusing items from the past to give them new life and Wes is<br />

a licensed forester by trade. Combined with a hollow grind, some<br />

“experts” will say this wouldn’t be the best choice of material<br />

and steel for a bushcraft knife. This was my first thought before<br />

keeping in mind the wide range of uses the knife will have<br />

to perform, the razor-sharp edge would be fairly easy to keep<br />

honed. If this were to be a small blade, I would prefer a flat<br />

ground edge in 1085 carbon steel or a Scandi grind on a large D2<br />

steel blade for just chopping.<br />

With a small treatment of Modern Spartan Accurizing Oil<br />

applied to the slightly heated metal, the quench is in no way<br />

affected and the microscopic pores are sealed with dry lube to<br />

protect it from hours or even days of wet, muddy conditions as I<br />

do with all my knives. After using this product for over four years<br />

now, I have yet to need to clean any of my blades beyond rising<br />

them off and wiping them clean.<br />

The last thing discussed before Wes would shut the workshop<br />

doors and complete the project would be the sheath. A simple,<br />

straight forward Kydex sheath to hold up against the elements<br />

sporting a BullGator Camo, “the meanest camo on the planet”.<br />

I specified this camo pattern to match the camo attire my<br />

Swanson Media Group team uses in the field due to its superior<br />

performance in blending with a wide range of environments.<br />

Combined with pull-the-dot soft loops, the sheath was meant to<br />

be placed on and off belts and gear quickly as needed yet hold<br />

the blaDE SECURELY THROUGH ANY TERRAIN.<br />

KNIVES AND TOOLS<br />

pmcimagazine.com