Cummins Commentary Issue 49 - May 2017

News and commentary from Cummins South Pacific (Australia, New Zealand and Papua New Guinea)

News and commentary from Cummins South Pacific (Australia, New Zealand and Papua New Guinea)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

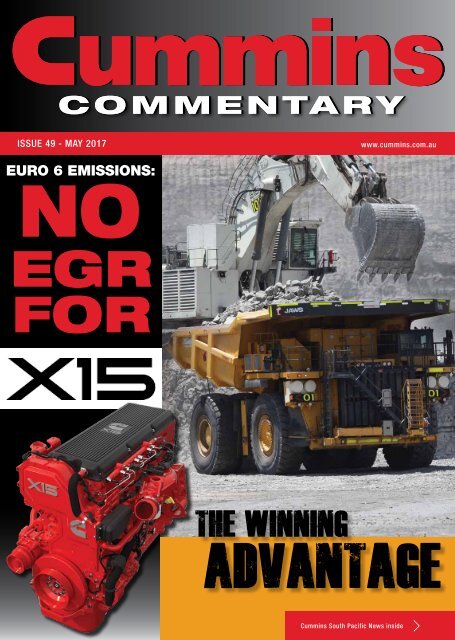

COMMENTARY<br />

ISSUE <strong>49</strong> - MAY <strong>2017</strong><br />

www.cummins.com.au<br />

EURO 6 EMISSIONS:<br />

EGR<br />

FOR<br />

THE WINNING<br />

ADVANTAGE<br />

<strong>Cummins</strong> South Pacific News inside

2 3<br />

CUMMINS COMMENTARY MAY <strong>2017</strong> CUMMINS COMMENTARY ARTICLE MAY THEME <strong>2017</strong> 3<br />

Contents<br />

Ask 50/50: if not,<br />

why not?<br />

4 Keeping the nation crunching on carrots<br />

A <strong>Cummins</strong>-powered B-double fleet is critical to the success of Rocky<br />

Lamattina & Sons which grows, packages and distributes 65,000 tonnes<br />

of carrots a year.<br />

5 Euro 6 emissions: No EGR for X15<br />

<strong>Cummins</strong>’ X15 will not need EGR to meet the next round of on highway<br />

emissions regulations.<br />

5<br />

6 The winning advantage<br />

Yancoal has specified a newly-engineered version of the <strong>Cummins</strong> QSK60 for<br />

major environmental and cost reduction benefits at its Moolarben mine in NSW.<br />

8 Top seed<br />

<strong>Cummins</strong> is the engine of choice for Cotton Seed Distributors, a company that<br />

has played a key role in building the Australian cotton industry.<br />

10 Stronger for longer<br />

Atlas Copco and <strong>Cummins</strong> have worked together closely to extend<br />

life-to-overhaul of the 760 hp QSK19 engine in underground haul trucks.<br />

11 Vintage advantage<br />

The Cordoma name is long established in farming and trucking in the Sunraysia<br />

region of north-west Victoria.<br />

12 All aboard<br />

<strong>Cummins</strong> welcomed 48 new apprentices to its branch operations in Australia<br />

and New Zealand in January.<br />

13 The show goes on at our ABC<br />

<strong>Cummins</strong> has played an important role in the development of the ABC’s new<br />

HQ in Melbourne.<br />

14 Quality in quarrying<br />

The <strong>Cummins</strong> influence is strong throughout the Milbrae Quarries operation<br />

in the NSW Riverina.<br />

16 News<br />

Read all about the latest happenings in the world of <strong>Cummins</strong> South Pacific.<br />

18 The power of reconciliation<br />

<strong>Cummins</strong> South Pacific pledges reconciliation with indigenous Australians.<br />

19 A tribute to war veterans<br />

Western Star prime mover.<br />

20 It’s all in the detail for Nightingale<br />

Glenn Nightingale runs a business built on sensible goals and the<br />

acknowledgement that good people are essential to the success of a company.<br />

21 Pick of the crop<br />

Electronic <strong>Cummins</strong> engines are vital to the success of an expanding cotton<br />

farm in north-west NSW.<br />

22 Be bold for change<br />

The theme for International Women’s Day <strong>2017</strong> – Be Bold for Change – provided<br />

the motivation for the recent <strong>Cummins</strong> Asia Pacific Women’s Leadership<br />

Conference.<br />

18<br />

11<br />

10<br />

The conversation went like this:<br />

“What would you think of the Director of Operations role?”<br />

Comment by Andrew Penca,<br />

Executive Director - <strong>Cummins</strong><br />

Asia Pacific Distribution<br />

“What did you just say? I have been at <strong>Cummins</strong> for two minutes and you are asking<br />

me how I would feel about running the entire operations business for one of<br />

<strong>Cummins</strong>’ largest company-owned distributors. Have you lost your mind?”<br />

No, I hadn’t. But what I had done was to see beyond what others typically get caught<br />

up on. Conscious, or unconscious, biases that creep into our organisations and<br />

systems and ultimately create barriers that limit the success of one group of people<br />

versus another. What are some of these biases that we find in our particular industry<br />

or organisation?<br />

Experience. This is probably one of the biggest barriers to success for many. The<br />

candidate has all the right qualifications, is very capable, smart, excellent with people,<br />

but ...she does not have the “experience”. Experience in what? Experience with doing<br />

things the way they may have always been done (by men) in the organisation or<br />

industry. Hence, she does not have the experience.<br />

Commitment. Another bias that creeps into organisations and limits opportunities.<br />

She has a family she needs to attend to as well as work so she cannot possibly have<br />

the time or ability to commit to both. She is expected to be there for not only her<br />

children, partner, parents, siblings, but she must also be there for her colleagues,<br />

teammates, and customers. Why is she expected to do all this and not “him”?<br />

Merit. The merit trap. The use of “merit” which is often defined by traits,<br />

characteristics or capabilities that are inherently biased by men and their assignment<br />

of exactly what merit is, puts women at a disadvantage from the get go. How often<br />

have you heard things such as, “She is not tough enough” or “she is too aggressive”.<br />

Expectations that leaders should possess a masculine style can put women at a<br />

disadvantage as these are often viewed as negative traits for a women, yet<br />

commercially positive for men. Or, “She’s great but she is just not ready yet”.<br />

There is greater propensity to take risks on appointing a man over a woman.<br />

And the list goes on. We recently held our inaugural Asia Pacific Women’s Leadership<br />

conference in Melbourne where we welcomed over 80 women from 10 countries and<br />

14 cities across the Asia Pacific business. In addition, we had a small group of men<br />

who attended the conference. I had the privilege to attend and was incredibly<br />

honoured, and grateful, for having had the opportunity. I walked away even more<br />

resolute and clear in my belief that we should be regularly asking the question of<br />

“If not 50/50, then why not?” when talking about, and acting on, gender parity.<br />

This was a question keynote speaker Elizabeth Broderick asked time and time again<br />

in her role as Australia’s Sex Discrimination Commissioner and asks now in her<br />

tireless work with the Male Champions of Change initiative.<br />

I grew up around a mother who had a long, 40-plus year career as a teacher and<br />

administrator in some of the toughest and most challenging public school<br />

environments in my hometown of Peoria, Illinois. She grew up on the south side of<br />

Chicago and was very independent at an early age. She was razor sharp, witty, and<br />

had a huge heart for those children who were dealt a pretty tough hand from the start.<br />

My brother and sister and I watched her lead, coach, and develop the children, their<br />

parents, and teachers to new levels in life. We watched her move from a middle<br />

school teacher to principal over the course of her career. We also watched how she<br />

had to overcome many of the biases above, yet still never thought she deserved<br />

anything less than to be the one in charge and be responsible for leading these difficult<br />

schools. Ultimately I was blessed with having the bias of seeing a woman succeed<br />

time and time again when most probably felt, “She’s great, but just not ready yet.”<br />

No I had not lost my mind. I had just seen beyond what others might see.<br />

The rest, they say, is history. The conversation that started this column took place<br />

in September of 2014, some three months after I arrived at <strong>Cummins</strong> South Pacific.<br />

It took place with the then Director of Finance Stephanie Disher, who had joined the<br />

company 10 months earlier. I sat down next to her in the back of a room of 30-plus<br />

people from around the business brainstorming and debating what the future should<br />

look like for <strong>Cummins</strong> South Pacific, and calmly asked the question at the beginning<br />

of this column. And the rest, as they say, is history. I have had some great moments<br />

during my time as Managing Director of <strong>Cummins</strong> South Pacific, but there are two<br />

moments that certainly stand out. The first was announcing Steph as the new Director<br />

of Operations for <strong>Cummins</strong> South Pacific in February 2015 and the second was<br />

announcing her as the new Managing Director for <strong>Cummins</strong> South Pacific two and a<br />

bit years later.<br />

We are very early in our journey towards gender parity but are not short on intent,<br />

ambition or purpose in our focus to reach this destination.<br />

Andrew Penca<br />

<strong>Cummins</strong> South Pacific’s new managing<br />

director Steph Disher (right) with<br />

<strong>Cummins</strong> Inc. VP Marya Rose and<br />

Peter Jensen-Muir, executive managing<br />

director of <strong>Cummins</strong> Asia Pacific.<br />

23 In the line of fire<br />

<strong>Cummins</strong> FirePaks are a core offering from one of Australia’s leading fire pump<br />

suppliers Hass Pumps.<br />

<strong>Cummins</strong> <strong>Commentary</strong> is published by <strong>Cummins</strong> South Pacific<br />

2 Caribbean Drive, Scoresby Vic 3179 Australia<br />

Tel: 61-3 9765 3222<br />

Editor: Murray Clifford Tel: 0419 268 289 Email: murray.clifford@cummins.com<br />

20<br />

Follow us on Facebook<br />

<strong>Cummins</strong> South Pacific<br />

<strong>Cummins</strong> New Zealand<br />

Andrew Penca with former Australian Sex Discrimination<br />

Commissioner Elizabeth Broderick at the<br />

<strong>Cummins</strong> Asia Pacific Women’s Leadership Conference.<br />

Expectations that leaders should<br />

possess a masculine style can put<br />

women at a disadvantage…

4 FLEET EFFICIENCY ENGINE ARTICLE TECHNOLOGY THEME<br />

5<br />

Keeping the nation<br />

crunching on carrotS<br />

EURO 6 EMISSIONS:<br />

EGR<br />

FOR<br />

Standard wastegate turbo.<br />

Simplicity of the Euro 6 engines is further emphasised with<br />

a standard wastegate turbocharger used on both engines.<br />

Exhaust aftertreatment on the X15 and X12 includes a diesel<br />

particulate filter (DPF). On the X15 Euro 6, the DPF is part of<br />

<strong>Cummins</strong>’ new ‘Single Module’ aftertreatment technology –<br />

a one-piece design that integrates both the DPF and SCR<br />

system and is up to 40% lighter and 60% smaller compared<br />

with existing multi-module systems.<br />

The smaller size enables better heat management and<br />

retention for improved fuel economy capability, while the<br />

simple single-pass exhaust flow design delivers low back<br />

pressure. The single module design – released in the<br />

US in 2016 – also results in a more robust and reliable<br />

aftertreatment system.<br />

<strong>Cummins</strong>’ expertise in aftertreatment solutions is further<br />

demonstrated in the new high performance ‘Compact Box’<br />

for the X12 Euro 6 which integrates the DPF and SCR system<br />

and is considerably smaller than the most compact Euro<br />

6 systems already on the market. Optimised catalysts and<br />

advanced urea dosing achieve higher NOx conversion rates<br />

and further improve fuel efficiency.<br />

Lamattinas use their own fleet of <strong>Cummins</strong>-powered<br />

Kenworths to deliver their carrots to markets.<br />

“How long have you been at <strong>Cummins</strong>?”<br />

Angelo Lamattina asks me. “Seventeen<br />

years,” I respond. “Have you been here<br />

before?” he queries. “No,” I reply. “Well you<br />

should be ashamed of yourself,” he says.<br />

His light-hearted reprimand is perhaps a hint that the<br />

Lamattina story should have been told before now in the<br />

<strong>Cummins</strong> corporate magazine.<br />

Angelo is one of the sons in the company Rocky Lamattina<br />

& Sons which grows, packages and distributes around<br />

65,000 tonnes of carrots a year.<br />

All the transport is carried out by Lamattina & Sons’ own fleet<br />

of <strong>Cummins</strong>-propelled Kenworths – 19 B-doubles splashed<br />

with the motto ‘Australia’s Favourite Carrots’ which deliver<br />

directly to supermarkets as well as wholesale markets in<br />

Melbourne, Sydney and Brisbane.<br />

Carrots for Coles<br />

supermarkets are<br />

‘personalised’<br />

with a photo<br />

of one of the<br />

Lamattina<br />

sons and the<br />

message…<br />

‘Proudly growing<br />

carrots for Coles<br />

since 2003’.<br />

Flexibility with own fleet.<br />

“Having our own fleet gives us the flexibility to deliver carrots<br />

from harvest to supermarket shelves in less than 24 hours,”<br />

says John Lamattina, another of Rocky’s sons. “We’ve looked<br />

a number of times at sub-contracting out our transport but<br />

we’ve always come to the conclusion that we can do it more<br />

efficiently ourselves.”<br />

The family company is based at Wemen, near Robinvale, on<br />

the banks of the Murray River in northern Victoria and also<br />

has another property at Kaniva in the state’s far west. All up,<br />

2550 hectares (6300 acres) are irrigated for carrot production.<br />

Establishing year-round growing capacity has been key to the<br />

family’s success. In winter, carrots are grown at the Wemen<br />

property, and in summer at its Kaniva property.<br />

I’d heard that Rocky Lamattina & Sons was big business, but<br />

didn’t quite grasp the extent of their operation until I headed<br />

to their Wemen HQ with <strong>Cummins</strong> regional branch manager<br />

Tyson Coffey. I mean, how many carrots do you have to grow<br />

to get your own road sign?<br />

Rocky’s remarkable story.<br />

It’s a remarkable story: Rocky Lamattina came to Australia<br />

from Italy in the early 1950s as a three-year-old and his family<br />

bought their first Australian farm – a mere three-hectare lot –<br />

in Clayton, a suburb of Melbourne, in the early 1960s.<br />

Rocky Lamattina started his own business with sons Angelo,<br />

Phil and John in Wemen in 1991 with 500 acres of land which<br />

had sheep grazing on it at the time of purchase.<br />

Today, apart from their farmland and fleet of B-doubles,<br />

the Lamattina enterprise includes a 16,000 square metre<br />

production facility at Wemen with the latest sorting and<br />

packing technology from around the world to process around<br />

1000 tonnes of carrots a week. It’s a facility that needs to be<br />

seen to be believed.<br />

<strong>Cummins</strong> regional branch manager<br />

Tyson Coffey (left) with John Lamattina.<br />

Pride and professionalism.<br />

When you’re running hundreds of tonnes of produce to<br />

markets each week with a fleet of stand-out B-doubles,<br />

your operational standards need to be of the highest order.<br />

In recent years, the Lamattinas have focused on instilling<br />

pride and professionalism in their transport operation while<br />

implementing greatly improved maintenance practices.<br />

The Lamattinas haven’t always been in the <strong>Cummins</strong> corner,<br />

preferring another brand until emissions technology saw<br />

<strong>Cummins</strong> as the only remaining supplier to Kenworth.The<br />

ISXe5 rated at 600 hp with peak torque of 2050 lb ft spearheads<br />

the Lamattina fleet of mainly T909 and K200 Kenworths.<br />

“The ISXe5 is a very good engine and we get very good<br />

support from <strong>Cummins</strong>,” acknowledges John Lamattina.<br />

“They’re a good group of guys at <strong>Cummins</strong> Swan Hill. They’re<br />

very flexible…they’ll spend a day here and do tune-ups on<br />

four or five trucks at a time.” n<br />

Euro 6 X15<br />

uses standard<br />

wastegate turbo.<br />

While Australia’s next round<br />

of on-highway emissions<br />

regulations is still several<br />

years away, <strong>Cummins</strong><br />

has revealed that its<br />

next generation X15 will<br />

not require exhaust gas<br />

recirculation (EGR) to meet<br />

the regulations.<br />

“The X15 will use only selective catalytic reduction (SCR)<br />

technology to meet Euro 6 NOx emissions requirements,<br />

not a combination of SCR and EGR,” Mike Fowler, <strong>Cummins</strong><br />

South Pacific’s director of engine business, announced at the<br />

Brisbane Truck Show in <strong>May</strong>.<br />

<strong>Cummins</strong> has unveiled its Euro 6 engines, X15 and also X12,<br />

at the show. While an implementation date for Euro 6 in<br />

Australia has yet to be confirmed, Fowler says <strong>Cummins</strong> will<br />

be prepared well in advance. “An extensive field test program<br />

for our Euro 6 product will begin later this year,” he reveals.<br />

With the complexity of cooled EGR eliminated, the SCR-only<br />

solution for both the X15 and X12 will be a huge benefit for<br />

operators. SCR exhaust aftertreatment doses urea (AdBlue)<br />

into the exhaust stream to reduce NOx emissions.<br />

X15 Euro 6 features<br />

<strong>Cummins</strong>’ new ‘Single<br />

Module’ aftertreatment<br />

technology – a one-piece<br />

design that integrates both<br />

the DPF and SCR system.<br />

Broad range of ratings.<br />

While peak outputs for the Euro 6 engines have yet to<br />

be confirmed, Fowler says there will be ratings flexibility.<br />

“There will be a broad range of ratings… for automated<br />

transmissions to enable engine down speeding for fuel<br />

economy optimisation, and for high GCM applications where<br />

performance is critical,” he reveals.<br />

The Euro 5 X12, which has been on test in Australia since early<br />

2015 rated at 500 hp and 1700 lb ft of torque, has the highest<br />

power-to-weight ratio of any engine in the 10-to-16-litre class.<br />

“The results of the field test have exceeded all expectations,”<br />

says Fowler. “As industry and government shift their focus to<br />

energy productivity, the X12 hits the target.”<br />

The innovative architecture of the X12 results in a remarkably<br />

low engine weight of 862 kg, achieved through a sculptured<br />

block design and the use of high-strength composite materials.<br />

The X12 incorporates <strong>Cummins</strong>’ XPI (Extreme Pressure<br />

Injection) common rail fuel system, derived from the 15-litre<br />

ISX. Generating injection pressures in excess of 30,000 psi,<br />

the XPI system improves combustion and fuel economy,<br />

reduces noise and enables fast response at low rpm.<br />

The use of a rear geartrain also contributes to overall engine<br />

refinement by reducing vibration and lowering noise.<br />

“For a number of years our product development has been<br />

driven by emissions, but now it is inspired by customer needs and<br />

application requirements,” says Mike Fowler. “The technology<br />

incorporated in our engines today is just the start of what’s<br />

to come from <strong>Cummins</strong> in terms of significant fuel economy<br />

improvements derived from a combination of optimised ratings<br />

and improved vehicle and transmission integration.” n<br />

For a number of<br />

years our product<br />

development has<br />

been driven by<br />

emissions, but now<br />

it is inspired by<br />

customer needs<br />

and application<br />

requirements.<br />

MIKE FOWLER,<br />

director of ENGINE BUSINESS<br />

CUMMINS SOUTH PACIFIC<br />

X12, which has been on test in<br />

Australia since early 2015 rated at<br />

500 hp and 1700 lb ft of torque,<br />

has the highest power-to-weight<br />

ratio of any engine in the<br />

10-to-16-litre class.<br />

The ISXe5 is a very good engine and we get very good<br />

support from <strong>Cummins</strong>… they’re a good group of<br />

guys at <strong>Cummins</strong> Swan Hill.<br />

The complexity of EGR<br />

is eliminated with the<br />

SCR-only Euro 6 X15.

6 ARTICLE ENGINE TECHNOLOGY<br />

THEME ENGINE ARTICLE TECHNOLOGY THEME 7<br />

THE WINNING<br />

ADVANTAGE<br />

Yancoal’s maintenance manager at Moolarben Liam Whittaker (centre) with <strong>Cummins</strong> mining<br />

business manager Jason Linke (left) and Komatsu regional service manager Andy Wiggan (right).<br />

Yancoal’s first Komatsu 830E fitted with QSK60<br />

‘Advantage’ engine.<br />

Extended engine life.<br />

“The original life-to-overhaul target was 24,000 hours, but the decision was made to extend life<br />

to 30,000 hours – a realistic engine life as long as the maintenance history is top notch,” says<br />

<strong>Cummins</strong>’ Jason Linke.<br />

Teardown of Moolarben’s first 30,000-hour QSK60 HPI engine at <strong>Cummins</strong>’ Master Rebuild<br />

Centre in Brisbane proved this extended life was achievable.<br />

The introduction of the MCRS ‘Advantage’ engine at Moolarben now sees further extension of<br />

targeted life-to-overhaul out to 36,000 hours – and with minimal mid-life change out of components.<br />

While significant total cost of ownership benefits are calculated for the ‘Advantage’ engine,<br />

Moolarben’s Liam Whittaker is quick to point out the environmental benefits as well: “We are<br />

committed to the highest environmental standards across our operation, and the QSK60<br />

‘Advantage’ engine is contributing to those standards with its reduced emissions.”<br />

The Moolarben mine, which has both open cut and underground operations, is producing 13<br />

million tonnes per annum of ROM coal from its open cut operations. <strong>Cummins</strong> engines total 45,<br />

ranging from the 60-litre V16 QSK60 in the Komatsu haul trucks to the 3.3-litre four cylinder<br />

QSB used in pit pumps.<br />

Liam Whittaker describes <strong>Cummins</strong>’ service support as “excellent” – support that is headed up<br />

by <strong>Cummins</strong> regional branch manager Phil Wright and mine site representative Ashley Waugh.<br />

“Our own maintenance people take a lot of pride in their work,” says Whittaker. He points out<br />

availability of the Komatsu 830E fleet is averaging 92% - “a terrific number for trucks that have<br />

done 25,000-plus hours”. n<br />

One of Australia’s largest coal miners,<br />

Yancoal has specified a newly-engineered<br />

version of the <strong>Cummins</strong> QSK60 for major<br />

environmental and cost reduction benefits<br />

at its Moolarben mine in NSW.<br />

The <strong>Cummins</strong> QSK60 ‘Advantage’ engine has been engineered to deliver both lower total cost<br />

of ownership and significantly reduced emissions – the key factors behind Yancoal’s decision<br />

to specify the engine as part of the upgrade of its haul truck fleet for extended life.<br />

With the ‘Advantage’ engine – the single-stage QSK60 rated at 2500 hp – <strong>Cummins</strong> has<br />

achieved a huge particulate matter (PM) reduction of 63% through in-cylinder combustion<br />

technology with no aftertreatment. This reduction is over the existing Tier 1 QSK60 engine.<br />

Additionally, a fuel economy benefit of up to 3% – dependent on duty cycle – has been<br />

calculated as well as longer life-to-overhaul.<br />

Yancoal is the first miner in NSW to put the QSK60 ‘Advantage’ engine into service – an engine<br />

developed specifically for Australian conditions by <strong>Cummins</strong>’ high horsepower technical centre<br />

in the US and the <strong>Cummins</strong> engineering team in Australia.<br />

As at the end of January <strong>2017</strong>, the miner had three ‘Advantage’ engines powering Komatsu<br />

830E haul trucks at its Moolarben mine, and will progressively upgrade the rest of its Komatsu<br />

830E fleet – 14 units – when the QSK60 engines are ready for change out at 30,000 hours.<br />

The ‘Advantage’ rebuild package.<br />

So what precisely is the ‘Advantage’ engine? In simple terms, it is a rebuild upgrade for<br />

the QSK60 from Tier 1 to the latest generation Tier 2 platform with the addition of Tier 4<br />

component technology. The upgrade features <strong>Cummins</strong>’ Tier 2 modular common rail fuel<br />

system (MCRS) as distinct from the HPI unit injection system on the Tier 1 engine.<br />

Importantly, the MCRS ‘Advantage’ solution utilises the original factory cooling system package.<br />

Liam Whittaker, maintenance manager at Yancoal’s Moolarben mine, has worked closely with<br />

<strong>Cummins</strong> mining business manager Jason Linke and Komatsu regional service manager Andy<br />

Wiggan to develop a plan to meet ambitious cost saving targets.<br />

In fact, the joint customer-focused approach of <strong>Cummins</strong> and Komatsu and the major<br />

engineering effort put in by both companies has been critical to meeting Yancoal’s requirements.<br />

Even before the <strong>Cummins</strong> ‘Advantage’ engine came into being, extending life of the original<br />

QSK60 HPI engines in the Komatsu 830E fleet at Moolarben was examined.<br />

Teardown of Moolarben’s first 30,000-hour QSK60 engine at <strong>Cummins</strong>’ Master<br />

Rebuild Centre in Brisbane proved extended life was achievable.<br />

THE BOTTOM LINE<br />

QSK60 MCRS ‘Advantage’ engine v<br />

QSK60 HPI Tier 1 engine delivers:<br />

63% particulate emissions reduction<br />

Up to 3% reduction in fuel consumption<br />

Extended life-to-overhaul<br />

No change to original Komatsu engineered cooling<br />

system package

8 ARTICLE IRRIGATION THEME ARTICLE IRRIGATION THEME 9<br />

CSD Farms manager Mark Cathcart checks the running<br />

hours on one of the oldest <strong>Cummins</strong> powerpacks…over<br />

10,000 hours.<br />

UNDER THE PUMP<br />

Jim Spain, owner of irrigation solutions company Irritek, could<br />

be excused for occasionally feeling ‘spaced out’.<br />

TOP<br />

SEED<br />

<strong>Cummins</strong> is the engine<br />

of choice for Cotton<br />

Seed Distributors, a<br />

company that has<br />

played a key role in<br />

building the Australian<br />

cotton industry.<br />

The valuable seeds behind Australia’s<br />

reputation for having the best cotton in<br />

the world for quality and yield.<br />

He runs Irritek out of a facility he owns – a facility that was<br />

part of history when it was known as ‘OTC Satellite Earth<br />

Station Moree NSW’. In July 1969, when Apollo 11 landed<br />

on the moon, the station provided the live TV broadcast<br />

communication link of the moon walk back to the US.<br />

Today, Jim Spain’s Moree-based business is far removed<br />

from the NASA space missions that were once tracked at the<br />

facility, his focus being on providing products and services to<br />

the irrigation industry with a special emphasis on pump stations<br />

for cotton farms.<br />

An example of Irritek’s pump station work is at a property<br />

owned by Cotton Deed Distributors (CSD), a company that has<br />

played a key role in building the Australian cotton industry (see<br />

accompanying article ‘Top Seed’).<br />

Jim Spain set up Irritek nearly 25 years ago when a business<br />

opportunity in irrigation presented itself. “I was actually a<br />

brickie by trade, travelling around building things,” he recalls. “I<br />

worked in the Northern Territory and met my wife up there. She<br />

was a Moree girl… I came back to Moree without any idea of<br />

what I was going to do.”<br />

The rest, as they say, is history. Irritek is proud of its track<br />

record of pump station concept and design. The company<br />

has designed and built many pump stations for different<br />

applications and sizes throughout the irrigation areas of NSW,<br />

Qld and even up to the Kimberley in WA.<br />

<strong>Cummins</strong> the choice for pumping.<br />

Fifteen <strong>Cummins</strong> engines, set up as self-contained<br />

powerpacks and designed and built by <strong>Cummins</strong> in Australia,<br />

are performing various pumping duties at CSD Farms as part<br />

of the irrigation system.<br />

“<strong>Cummins</strong> is our engine of choice,” says CSD Farms manager<br />

Mark Cathcart. “We are operating several other engine brands<br />

as well but these will eventually be changed out for <strong>Cummins</strong>.”<br />

“A pump station isn’t exactly rocket science,” he says.<br />

“Listening to the customer is what it’s all about… what the<br />

customer wants, what the customer doesn’t want, and come<br />

up with a solution.<br />

“We can do with pipes what others can’t do. We roll our own<br />

pipes with large diameter tooling.”<br />

Irritek also designs and builds its own irrigation channel gates,<br />

ranging in size from 600 to 2400 mm. n<br />

The latest <strong>Cummins</strong> engines at CSD Farms are electronic<br />

Tier 3 QSB3.3 and QSB4.5 units and their fuel efficiency<br />

immediately became clear to Mark Cathcart.<br />

The move to electronic engine control has allowed CSD<br />

to specify smaller, more fuel efficient engines that are<br />

doing exactly the same job as the larger, older generation<br />

mechanical units.<br />

Mark Cathcart with <strong>Cummins</strong><br />

Brisbane’s Steve Micallef<br />

Smaller, more efficient engines.<br />

CSD and the CSIRO have invested<br />

millions in cotton breeding and<br />

research since 2007.<br />

The latest <strong>Cummins</strong> engines at CSD Farms are electronic<br />

Tier 3 QSB3.3 and QSB4.5 units which are proving their<br />

fuel efficiency.<br />

Australia’s only cotton seed supplier,<br />

Cotton Seed Distributors (CSD)<br />

has partnered with the CSIRO for a<br />

number of years developing improved<br />

cotton varieties for the domestic and<br />

international markets.<br />

Our oldest mechanical <strong>Cummins</strong> engines have<br />

done in excess of 10,000 hours and haven’t<br />

been touched apart from routine servicing.<br />

Australian cotton is considered the best in the world for<br />

quality and yield. In fact, Australian growers using CSD-CSIRO<br />

varieties enjoy yields three times the world average and more<br />

than twice that of the US, which is Australia’s nearest competitor.<br />

Under a joint venture agreement, CSD and the CSIRO have<br />

invested more than $70 million in cotton breeding and research<br />

since 2007. By 2024 this investment will have exceeded<br />

$140m in total.<br />

The key challenge now for CSD, which is celebrating its<br />

50th anniversary this year, is providing varieties to meet the<br />

demands of the burgeoning cotton industry. New varieties<br />

take up to 13 years to bring to market.<br />

CSD undertakes early stage seed multiplication, as well as<br />

some of its research and development, on ‘CSD Farms’, an<br />

amalgamation of three properties located between Narrabri<br />

and Wee Waa in north west NSW. CSD also supports R&D<br />

undertaken by the CSIRO and several of its other commercial<br />

partners on is farming asset of 1,170 hectares, 620 hectares<br />

of which are irrigated.<br />

For example, the 4.5-litre QSB rated at 160 hp is more fuel<br />

efficient than the larger, mechanical 5.9-litre 6BT rated at 150<br />

hp, and also delivers higher torque at lower rpm – 460 lb ft at<br />

1500 rpm versus 417 lb ft at 1600 rpm.<br />

“The QSB4.5 is pumping 20 megalitres (20 million litres) a<br />

day out of storage into the main supply channel and is using<br />

only 10 litres an hour,” Mark Cathcart reveals. Importantly, the<br />

high-torque engine is operating as low as 1200 rpm which is<br />

in the ‘sweet spot’ and conducive to best fuel economy.<br />

One of the key benefits of the electronic engine control is that<br />

instantaneous fuel consumption data is available as a digital<br />

readout on the operator interface panel, allowing the most fuel<br />

efficient revs to be set in relation to pumping demand.<br />

“Anything that is available to help us improve fuel efficiency<br />

is important,” says Mark Cathcart.<br />

Reliability, ease of service.<br />

There are other reasons for the choice of <strong>Cummins</strong>. “As the<br />

varieties of the future for Australia’s growers are screened and<br />

produced on our farm, engine reliability along with ease of<br />

service and parts availability are critical,” says Mark Cathcart.<br />

“Our oldest mechanical <strong>Cummins</strong> engines have done in<br />

excess of 10,000 hours and basically haven’t been touched<br />

apart from routine servicing.”<br />

The QSB engines are set up as ComPak powerpacks which<br />

incorporate a cooling system that provides continuous full<br />

power operation in ambient temperatures up to 50°C. n<br />

<strong>Cummins</strong> is our<br />

engine of choice…<br />

we are operating<br />

several other<br />

brands as well but<br />

these will<br />

eventually be<br />

changed out for<br />

<strong>Cummins</strong>.<br />

Irritek pumping station at CSD Farms.<br />

Jim Spain… his Irritek facility in<br />

Moree is part of history.

10 ARTICLE ENGINE LIFE THEME ENGINE ARTICLE RELIABILITY THEME 11<br />

FOR<br />

Vintage Advantage<br />

Atlas Copco’s 60-tonne payload capacity<br />

MT6020 has been powered by the <strong>Cummins</strong><br />

QSK19 since the truck’s release in 2008.<br />

<strong>Cummins</strong> ISXe5 is dominant in the LRT/VCT fleet.<br />

Atlas Copco and <strong>Cummins</strong> have worked together<br />

closely to extend life-to-overhaul of the 760 hp QSK19<br />

engine in underground haul trucks at a remote gold<br />

mine in the Tanami Desert in northern Australia.<br />

Underground haul trucks have one of the toughest jobs in mining. High engine load factors are<br />

the norm, with the trucks operating at full power for long periods on punishingly steep grades<br />

at fully loaded weights in excess of 100 tonnes.<br />

When <strong>Cummins</strong>’ 19-litre QSK19 was approved for underground operations in 2000 it didn’t<br />

take long for the engine to start making its mark as a high-productivity powerhouse.<br />

Smaller capacity competitor engines in underground haul trucks were cast aside to make way<br />

for the big inline six <strong>Cummins</strong> with its significantly improved reliability and durability.<br />

Atlas Copco’s 60-tonne payload capacity MT6020 has been powered by the QSK19 since<br />

the truck’s release in 2008, and the new 65-tonne MT65 – the world’s largest capacity<br />

underground haul truck – is also propelled by the 760 hp <strong>Cummins</strong>.<br />

Lower total cost of ownership.<br />

At Newmont Tanami Operations’ gold mine in the remote Tanami Desert, in a key initiative<br />

aimed at lowering total cost of ownership, life-to-overhaul of the QSK19 has been extended in<br />

a fleet of MT6020 trucks. One engine has achieved just over 16,500 hours before scheduled<br />

change out, while two have each clocked up close to 18,000 hours.<br />

All three engines were still performing strongly at the time of change out.<br />

Atlas Copco and <strong>Cummins</strong> have worked together closely to meet the life-to-overhaul<br />

expectations of Newmont which is operating 17 MT6020 trucks at its Tanami mine. The<br />

first Atlas Copco units went into service in 2013, replacing a competitor brand after a trial to<br />

determine best tonne/kilometre per hour productivity.<br />

Eliminating prolonged periods of engine overspeeding – a common problem on the steep<br />

declines in underground mines – has been the key to extending life through electronic<br />

control improvements.<br />

An indication of how hard the 100-tonne-plus trucks are working climbing out of the mine is<br />

the fact they are operating constantly at 100% throttle for up to one hour per cycle.<br />

Wear of critical components.<br />

The new 65-tonne MT65 – the<br />

world’s largest capacity<br />

underground haul truck – is<br />

propelled by the 760 hp <strong>Cummins</strong>.<br />

To determine the condition of critical wear components, the QSK19 that did over 16,500 hours at<br />

Newmont’s Tanami mine was dismantled for analysis. All bearings, pistons, piston rings and liners<br />

were within the acceptable wear limits according to <strong>Cummins</strong> guidelines. The photo shows main<br />

bearings and big-end rod bearings.<br />

Vince Cordoma with wife Fiona.<br />

The best thing about<br />

<strong>Cummins</strong> is the quick<br />

response to any issues...<br />

The Cordoma name is long<br />

established in the Sunraysia region<br />

of north-west Victoria and south-west<br />

NSW – a flourishing region noted for<br />

its horticulture, especially<br />

grape production.<br />

The Cordoma family businesses today encompass both<br />

farming and trucking, the latter business spearheaded by a<br />

fleet of <strong>Cummins</strong>-powered Kenworths carrying the branding<br />

LRT or VCT.<br />

LRT/VCT had its origins in the 1970s when six brothers<br />

started a trucking business, Cordoma Bros Transport, in<br />

Robinvale with two trucks. The produce they carted was<br />

grown by themselves.<br />

The brothers got out of the trucking business in 2004 but the<br />

Cordoma name was to survive in transport when Vince – son<br />

of one of the original company’s brothers, Louie – set up<br />

LRT/VCT with brother-in-law Dean Leslie.<br />

The company name today reflects this partnership – Leslie<br />

Refrigerated Transport (LRT) and Vince Cordoma Transport (VCT).<br />

Sunraysia to the supermarkets.<br />

Vince Cordoma is managing director of LRT/VCT, an<br />

operation that runs 34 prime movers and 64 trailers out<br />

of facilities in Robinvale and Irymple (near Mildura) in<br />

north-west Victoria.<br />

At any one time, LRT/VCT has 29 B-doubles on the road<br />

at 68.5 tonnes, transporting produce from the Sunraysia<br />

region to Coles and Woolworths supermarkets, and<br />

wharves for export.<br />

“LRT/VCT was created with the intention of having only five<br />

trucks,” says Vince Cordoma. “However, our business has<br />

grown in line with growth of the area. We’re servicing one of<br />

the biggest fruit bowls in Australia.”<br />

All but four trucks in the fleet have <strong>Cummins</strong> power, with the<br />

ISXe5 powering 17 units. The preferred rating is 600 hp with<br />

peak torque of 2050 lb ft.<br />

<strong>Cummins</strong>’ quick response.<br />

“The best thing about <strong>Cummins</strong> is the quick response to any<br />

issues by Tyson Coffey (regional branch manager) and his<br />

team,” says Vince Cordoma with obvious conviction. “Service<br />

support and product reliability are the key when you’re<br />

transporting perishable freight.”<br />

He points out the LRT/VCT fleet was initially 50/50 <strong>Cummins</strong><br />

and Cat. “However, we made the decision to standardise on<br />

<strong>Cummins</strong> because of <strong>Cummins</strong>’ technology. That has been<br />

proven with the ISXe5,” he says.<br />

“The ISXe5 is an excellent engine and we’re converting the whole<br />

fleet to this generation of 15-litre <strong>Cummins</strong>.” New Kenworths<br />

coming into the fleet will have the X15 which uses exactly the<br />

same hardware and emissions technology as the ISXe5.<br />

LRT/VCT trucks typically clock up around 300,000 km a year.<br />

The maintenance plan is for an in-chassis engine rebuild at 1.2<br />

million km or four years, and then for the truck to do a further<br />

three years before trade-in.<br />

Vince Cordoma, who is supported by wife Fiona in the<br />

business, doesn’t hesitate when asked about the keys to a<br />

successful operation. “You need good people around you to<br />

succeed and you also need good suppliers. The big thing is<br />

loyalty. Loyalty received is deserving of loyalty in return,” he<br />

says. “We like to support local suppliers which is why we buy<br />

our Kenworths through Mildura Truck Centre.” n<br />

To determine the condition of critical wear components, the QSK19 that achieved just over<br />

16,500 hours was dismantled at <strong>Cummins</strong>’ Master Rebuild Centre in Perth for analysis. The<br />

bottom line was that all bearings, pistons, piston rings and liners were within the acceptable<br />

wear limits according to <strong>Cummins</strong> guidelines.<br />

Engine maintenance at the remote mine is carried out by on-site <strong>Cummins</strong> technicians in<br />

partnership with Atlas Copco to ensure correct servicing quidelines are adhered to and that any<br />

issues are resolved quickly. Atlas Copco provides product support advisors and product support<br />

technicians to assist with truck maintenance under a contract with Newmont Tanami Operations.<br />

The Tier 2 QSK19 in both the MT6020<br />

and MT65 is rated at 760 hp and<br />

features <strong>Cummins</strong>’ modular common<br />

rail fuel system (MCRS) which enables<br />

cleaner, quieter and faster power<br />

delivery.<br />

Atlas Copco’s new 65-tonne capacity MT65 – the world’s largest capacity underground haul<br />

truck – has been on trial at Newmont’s Tanami mine, achieving the KPIs set for it. The QSK19<br />

was selected for the MT65 for its proven robustness and strong performance on grade.<br />

The QSK19 in both the MT6020 and MT65 is the Tier 2 version with the modular common rail<br />

fuel system (MCRS). This enables cleaner, quieter and faster power delivery. The system also<br />

prevents unbalanced fuelling between cylinders to significantly reduce engine vibration, noise<br />

and harshness.<br />

The 19-litre platform is one of the most successful ever developed by <strong>Cummins</strong> and today is<br />

a benchmark mining engine, sharing the development focus and latest technologies that are<br />

seen in other high horsepower engines in the <strong>Cummins</strong> family such as the 3000 hp QSK60<br />

and 4200 hp QSK95. n<br />

Atlas Copco’s new 65-tonne capacity MT65 – the<br />

world’s largest capacity underground haul truck – on<br />

trial at the Gwalia gold mine in WA.<br />

Vince Cordoma (left) with <strong>Cummins</strong> regional branch manager Tyson Coffey<br />

(centre) and <strong>Cummins</strong> Mildura operations manager Cambell Carmichael.

12 ARTICLE APPRENTICESHIPS<br />

THEME<br />

EMERGENCY ARTICLE POWER THEME<br />

13<br />

ALL<br />

ABOARD<br />

<strong>Cummins</strong> welcomed 48 new<br />

apprentices to its branch operations in<br />

Australia and New Zealand in January.<br />

These apprentices were selected from<br />

more than 300 candidates.<br />

Apprentices at <strong>Cummins</strong><br />

South Pacific HQ in<br />

Scoresby (Melbourne).<br />

The show goes on at<br />

our ABC<br />

The <strong>2017</strong> intake includes six female apprentices. Diversity is<br />

further highlighted among the new recruits in age range (16 to 27),<br />

ethnicity and Aboriginal and Torres Strait Islander backgrounds.<br />

Whilst most of the new apprentices are employed in the heavy<br />

commercial vehicle mechanic trade, there are some parts<br />

interpreter and electrical apprentices.<br />

QSK60 genset about to be lowered<br />

on to seismic spring mounts.<br />

<strong>Cummins</strong> now has around 200 apprentices in its South Pacific<br />

branch operations in Australia, New Zealand and Papua New Guinea.<br />

“<strong>Cummins</strong> has 35 company branches across the South Pacific<br />

requiring highly skilled technicians, parts interpreters, and power<br />

generation electricians,” says Raman Badekar, regional apprentice<br />

program manager for <strong>Cummins</strong> South Pacific. “It’s therefore<br />

important we recruit high calibre apprentices to ensure a<br />

steady supply of best-in-industry technicians into the future.<br />

“<strong>Cummins</strong>’ recruitment process is comprehensive,” he explains.<br />

“Apprentices are sourced through our work experience<br />

programs which allow school students and adult candidates<br />

to experience the <strong>Cummins</strong> workplace and then go through<br />

the aptitude testing and interview processes.”<br />

After completing local onboarding at their respective branches,<br />

all 48 new apprentices travelled to <strong>Cummins</strong> South Pacific<br />

headquarters in Melbourne to attend the five-day <strong>2017</strong> central<br />

onboarding program.<br />

Executive director of <strong>Cummins</strong> Asia Pacific Distribution<br />

Andrew Penca and <strong>Cummins</strong> South Pacific managing director<br />

Stephanie Disher welcomed the apprentices to the <strong>Cummins</strong> family<br />

and wished them all the best for a great career at the company.<br />

Program highlights included diesel engine fundamentals<br />

training (dismantling/assembly of an engine); hands-on JSA<br />

(Job Safety Analysis) training and hazard identification on a<br />

truck; a tour of the Kenworth manufacturing plant; and a visit<br />

to the P.A.R.T.Y (Prevention of Alcohol and Risk Related<br />

Trauma in Youth) program facilitated by the Alfred Hospital.<br />

“The P.A.R.T.Y program had a visible impact on the<br />

apprentices,” says Raman Badekar. “They spent time in the<br />

Alfred Hospital’s intensive care unit getting an up-front,<br />

true-to-life experience of the impact of injury, trauma and<br />

disability on people a similar age to themselves.”<br />

The initial part of the onboarding program focused on<br />

<strong>Cummins</strong>’ proud history (100 years old in 2019) along with the<br />

company’s vision, mission and values, while core curriculum<br />

modules such as code of conduct, treatment of others and<br />

spectrum diversity training were also delivered to set the<br />

expectations of right environment and workplace behaviour.<br />

<strong>Cummins</strong> has 35<br />

company branches<br />

across the South<br />

Pacific requiring highly<br />

skilled technicians.<br />

Three of the six female apprentices who were part of the<br />

<strong>2017</strong> intake. They are shown in front of <strong>Cummins</strong> most<br />

powerful diesel engine, the 4000 hp QSK95, a 95-litre V16.<br />

Diesel engine fundamentals training included<br />

disassembly/assembly.<br />

Job Safety Analysis training and hazard identification on a<br />

truck were an important part of the training.<br />

Apprentices with <strong>Cummins</strong>’ smallest diesel engine, the<br />

2.8-litre ISF, and <strong>Cummins</strong>’ largest generator set powered<br />

by the 95-litre QSK95.<br />

The <strong>Cummins</strong> onboarding team (back row, from left) Steve<br />

Ellul, Chris Burns, Paul Anscombe, Kristina Lambkin, Stuart<br />

Walsh; (front row, from left) Amy Jacobs, Raman Badekar,<br />

Warick Meldrum, Gus Meyer-Jones, Sarah Bilston.<br />

Comments from apprentices who took<br />

part in the onboarding program:<br />

Janae Wilson – Palmerston North, NZ: “I feel privileged to be<br />

part of the <strong>Cummins</strong> family. After attending the onboarding<br />

program, I realised that I can have global career opportunities.”<br />

Athol Muller – Carole Park, Brisbane: “I was amazed to see<br />

senior leaders taking time from their busy schedule to take part<br />

in the onboarding program and talk to us. I found them to be<br />

down to earth and approachable in spite of their positon in<br />

the organisation.”<br />

Alison Haillay – Laverton, Melbourne: “Being one of the six<br />

female apprentices it feels great to have an equal opportunity<br />

in a non-traditional trade for women. The tour of the Kenworth<br />

truck assembly plant was a highlight for me, especially seeing<br />

their quality standards and so many <strong>Cummins</strong> engines being<br />

installed in the trucks.” n<br />

The Australian Broadcasting<br />

Corporation (ABC) has moved into<br />

its new Melbourne headquarters on<br />

Southbank Boulevard, with <strong>Cummins</strong><br />

having played an important role in the<br />

$176 million development.<br />

The new ABC Centre features state-of-the-art television<br />

studios for the production of local, national and international<br />

news and current affairs, as well as a host of other programs.<br />

The development includes construction of a new five-storey<br />

building as well as refurbishment of the existing ABC facility,<br />

built in the early 1990s. The refurbished facility is being fully<br />

integrated with the new building to create a single, purposebuilt<br />

complex.<br />

<strong>Cummins</strong> installed the emergency power system at the ABC<br />

Elsternwick facility in Melbourne back in 2005, and has worked<br />

with the ABC once again to provide the critical back-up power<br />

for the national broadcaster’s radio and television operations<br />

at Southbank.<br />

No power glitches, please.<br />

ABC’s electrical infrastructure must meet stringent criteria to<br />

allow for a 24-hour broadcasting with an emergency power<br />

supply. A television studio is a technically complex facility<br />

where a lot can go wrong, especially if there are power glitches.<br />

<strong>Cummins</strong> was contracted by Maxim Electrical to provide the<br />

back-up power system for the new complex. A 2250 kVA<br />

<strong>Cummins</strong> generator set and <strong>Cummins</strong> digital master controller<br />

(DMC) are the centerpiece of the system which meets stringent<br />

performance requirements.<br />

The DMC is designed to directly interface with the generator<br />

set, automatic transfer switches and downstream switchgear.<br />

The DMC system enables seamless system integration to<br />

provide failsafe performance. Use of the DMC ensured the<br />

installation was less complex, leading to shortened project<br />

implementation and commissioning time. The DMC interface<br />

to the Building Management System (BMS) keeps the building<br />

management team informed of the generator system status at<br />

all times.<br />

Noise, vibration control critical.<br />

Noise and vibration control are critical, especially with the<br />

generator set – powered by <strong>Cummins</strong>’ 60-litre QSK60 diesel<br />

engine – mounted on the roof and close to a residential area.<br />

The genset mounting actually spans both the refurbished and<br />

new buildings.<br />

The genset was mounted in such a way that no vibration<br />

would be transmitted through the buildings. This required the<br />

use of seismic spring mounts for the genset, special plinths<br />

for the genset enclosure to sit on, and also an insulated<br />

concrete slab.<br />

Noise suppression was also important, which required the use<br />

of an acoustic enclosure and an air gap between the genset<br />

enclosure and insulated slab. This ensures that when the<br />

generator is running at full load, it can’t be heard at street level<br />

with normal background noise.<br />

In view of the importance of acoustics and vibration control,<br />

<strong>Cummins</strong> contracted Exhaust Control Industries (ECI) to install<br />

Services manager for head contractor Probuild, Dean Stokes (left), with<br />

Russell Slocomb from the <strong>Cummins</strong> Laverton power generation team.<br />

the generator set and exhaust system – work carried out in<br />

consultation with <strong>Cummins</strong> Laverton application engineers<br />

Kevin Baxter and Nick Rousch.<br />

The commissioning, which included black start and load<br />

testing, was very successful in that it was carried out during<br />

the project’s full construction phase.<br />

It was vital that <strong>Cummins</strong> and ECI kept the lines of<br />

communication open during the project with status updates,<br />

which was successfully achieved. n<br />

<strong>Cummins</strong><br />

digital master<br />

controller (DMC)<br />

meets stringent<br />

performance<br />

requirements.<br />

New ABC headquarters in Melbourne…<br />

a $176 million development.

14 ARTICLE QUARRYING THEME<br />

ARTICLE QUARRYING THEME<br />

15<br />

QUALITY<br />

IN QUARRYING<br />

Milbrae’s quarry fleet totals 24 Kenworths.<br />

The <strong>Cummins</strong> influence<br />

is strong throughout<br />

the Milbrae Quarries<br />

operation in the<br />

NSW Riverina.<br />

The Woods family established Milbrae Quarries 30 years ago<br />

and continue as owners of the business today with their base<br />

in Leeton in the NSW Riverina region.<br />

Peter Woods is founding director of Milbrae, having earlier<br />

been in a completely different business as PA Woods & Co.<br />

“We were actually a plumbing business,” he recounts. “Both<br />

my sons, Brett and Chris, did their apprenticeship with me.<br />

We’re not academics, we’re plumbers by trade.”<br />

While Peter takes a back seat today, both Brett and Chris are<br />

involved in the day-to-day running of Milbrae as directors.<br />

Milbrae is obviously a company with a strong family culture and<br />

it is important this is maintained. However, as Peter Woods notes,<br />

Milbrae’s tipper fleet moves around one<br />

million tonnes of quarry products a year.<br />

the company has brought in management expertise from<br />

outside, with strength in specific areas, to put process and<br />

structure into the business. “As you get larger as a company<br />

this is critical,” he says.<br />

A case in point is Tracey Cotter who has been with the company<br />

for four years as business services manager. With a background<br />

in communications, HR and IT, she is an important member of<br />

the Milbrae leadership team. “It’s an exciting time at Milbrae,”<br />

she says, citing the work the company is doing on “work tools<br />

of the future”, including technologies to improve communications<br />

with their people in the field, especially in remote locations.<br />

<strong>Cummins</strong> Leeton’s operations manager Jackson Meredith (left) with,<br />

from left, Milbrae director Brett Woods, business services manager<br />

Tracey Cotter, and mine and quarry project manager Peter Sullivan.<br />

Showing their metal.<br />

Milbrae was the name of the first quarry bought by the family<br />

– well, it wasn’t actually a quarry at the time of purchase but a<br />

farm property in the Leeton area with the Milbrae name.<br />

Today, the business includes 20 satellite quarries in the<br />

Riverina region providing road base, four blue metal quarries,<br />

10 mobile crushing plants, four fixed crushing plants, a fleet<br />

of 24 Kenworths for dog trailer, B-double, heavy haulage float<br />

and roadtrain quarry operations, and a fleet of 20 concrete<br />

agitators on Kenworth and Freightliner chassis.<br />

There is numerous other equipment – loaders, excavators,<br />

graders, dump trucks, concrete batching plants and so on.<br />

Brett Woods estimates the company would have at least 500<br />

pieces of equipment.<br />

The Milbrae business just doesn’t focus on quarry operations<br />

in the Riverina region. The company is involved in a number<br />

of mining projects, including contract crushing at Glencore’s<br />

Mt Isa and McArthur River mines in Queensland, and at<br />

Aurelia Metals’ Nymagee project in NSW.<br />

Strong <strong>Cummins</strong> influence.<br />

The <strong>Cummins</strong> influence is strong throughout the<br />

Milbrae organisation.<br />

“We like to source our equipment locally and we see <strong>Cummins</strong><br />

as being local having a branch in Leeton,” says Milbrae<br />

operations director Brett Woods. “Our experience is that<br />

<strong>Cummins</strong>’ back-up, technical expertise and experience put<br />

them in front of the competition.”<br />

Of the 24 Kenworths in Milbrae’s quarry fleet, 20 are engaged<br />

in tipper work. “The tippers move one million tonnes of quarry<br />

products a year which translates to around 26,000 loads,”<br />

says Peter Sullivan, Milbrae’s mine and quarry project manager.<br />

<strong>Cummins</strong>’ ISXe5 spearheads the Milbrae fleet. Six quad dog<br />

combinations – T409 SAR Kenworths with ISXe5 engines<br />

rated at 550 hp – are well utilised, each averaging 4000 km<br />

a week with payloads of 38.5 tonnes. “Reliability of the ISXe5<br />

is very good,” says Sullivan, adding that the highest-kilometre<br />

ISXe5s are around the 800,000 mark.<br />

Four of Milbrae’s mobile crushing plants are powered by<br />

<strong>Cummins</strong> generator sets that have one of <strong>Cummins</strong>’ biggest<br />

six cylinder engines, the 19-litre QSK19. Two of the fixed<br />

crushing plants have an even bigger in-line six <strong>Cummins</strong><br />

engine powering their gensets, the 23-litre QSK23. The<br />

reliability durability of these engines in 24/7 operations rate<br />

highly with Peter Sullivan.<br />

Milbrae is obviously a company committed to quality in all<br />

aspects of its business, its strong growth dictating this focus<br />

as it moves into the future. Equipment suppliers such as<br />

<strong>Cummins</strong> have a vital role in ensuring strong service support<br />

so that the company can meet its equipment utilisation and<br />

total cost of ownership goals. n<br />

Our experience is<br />

that <strong>Cummins</strong>’<br />

back-up, technical<br />

expertise and<br />

experience put them<br />

in front of the<br />

competition.<br />

Milbrae founding director Peter Woods<br />

started in business as a plumber.<br />

One of the four mobile crushing plants powered<br />

by a <strong>Cummins</strong> QSK19 generator set.<br />

Reliability and durability of <strong>Cummins</strong> gensets rate<br />

highly at Milbrae. The photo shows a QSK23 that<br />

powers a fixed crushing plant.

16 17<br />

NEWS<br />

ARTICLE THEME NEWS 17<br />

Andrew Penca’s new<br />

Asia Pacific role<br />

Steph Disher new<br />

MD of <strong>Cummins</strong><br />

<strong>Cummins</strong>, Eaton announce 50/50 joint<br />

venture for automated transmissions<br />

South Pacific<br />

Andrew Penca at the recent <strong>Cummins</strong> Asia Pacific Women’s Leadership Conference.<br />

Andrew Penca has been appointed executive director of Asia Pacific Distribution for<br />

<strong>Cummins</strong> Inc. He was previously managing director of <strong>Cummins</strong> South Pacific.<br />

In his expanded role, he will lead the broader <strong>Cummins</strong> sales, service and support business<br />

in the Asia Pacific region of Australia, New Zealand, Papua New Guinea (<strong>Cummins</strong> South<br />

Pacific), Singapore, Malaysia, Philippines, Korea and Japan.<br />

Penca joined <strong>Cummins</strong> South Pacific as managing director in 2014 and has led the<br />

organisation through a myriad of strategy and effectiveness initiatives. These include<br />

significant systemic and behavioural based improvements in OHS&E, product improvements<br />

in both the on-highway and off-highway markets, and improvements in overall sales, service,<br />

and support capabilities.<br />

Stephanie Disher is the new<br />

managing director of <strong>Cummins</strong><br />

South Pacific, replacing Andrew<br />

Penca who has taken on a<br />

<strong>Cummins</strong> Asia Pacific role.<br />

Disher was previously operations<br />

director for <strong>Cummins</strong> South Pacific.<br />

In this role she led a number of<br />

strategic and operational initiatives,<br />

including key customer service<br />

and support technology initiatives,<br />

continued improvements in<br />

customer satisfaction, and<br />

continued growth in aftermarket<br />

sales and support business.<br />

Prior to joining <strong>Cummins</strong>, Disher<br />

spent 13 years as an executive in<br />

the oil and gas industry. She held<br />

business and functional<br />

management roles with BP in<br />

Australia and Asia Pacific.<br />

Steph Disher<br />

Disher has a bachelor’s degree in Commerce from University of Western Sydney and<br />

an MBA from Melbourne Business School. She is a Certified Practising Accountant<br />

(CPA) and a Graduate, Australian Institute of Company Directors (GAICD). n<br />

<strong>Cummins</strong> and Eaton are to form a 50/50 joint venture for<br />

automated transmissions for heavy-duty and medium-duty<br />

commercial vehicles. The joint venture will be named Eaton<br />

<strong>Cummins</strong> Automated Transmission Technologies.<br />

Under the terms of the agreement, Eaton will receive $600 million in cash from <strong>Cummins</strong><br />

for 50 percent interest in the joint venture.<br />

The global joint venture will provide customers with industry-leading transmission<br />

technologies and solutions that deliver best-in-class fuel efficiency, performance and<br />

uptime while leveraging both <strong>Cummins</strong>’ and Eaton’s global service and support networks.<br />

The joint venture will design, assemble, sell and support all future medium-duty and<br />

heavy-duty automated transmissions for the commercial vehicle market.<br />

For Australia, NZ<br />

Locally, the joint venture is not expected to impact the Australian and New Zealand markets<br />

for some time, though <strong>Cummins</strong> and Eaton will continue to work closely on product<br />

development and customer support as they have done for a number of years.<br />

In the future, however, the joint venture will provide automated transmissions for commercial<br />

vehicle applications in Australia and New Zealand.<br />

“Our growth strategy includes expanding our product offerings and extending our global<br />

footprint by becoming the world’s leading powertrain supplier,” said Tom Linebarger,<br />

chairman and CEO,<br />

<strong>Cummins</strong> Inc.<br />

“Our JV with Eaton will deliver the most advanced automated transmissions and develop<br />

an integrated powertrain and service network that supports our customers like never before.<br />

Just as we’ve done for the past 100 years, we will use our experience in partnerships and<br />

technological expertise to ensure our customers’ success.”<br />

Superior technology<br />

Eaton chairman and CEO Craig Arnold said: “Customers are focused on powertrain<br />

solutions that provide the best combination of technology, performance and quality.<br />

Our joint venture with <strong>Cummins</strong> will leverage the technical strengths and experience of<br />

two industry leaders with long histories and deep industry expertise to provide superior<br />

automated transmission technology for our global customers.”<br />

Eaton’s current medium-duty automated transmission, Procision, and next generation<br />

heavy-duty automated transmissions, will be part of the joint venture. In addition, the joint<br />

venture will market, sell, and support Eaton’s current generation of automated heavy-duty<br />

transmissions to OEM customers in North America.<br />

Eaton’s Vehicle Group will retain its global manual transmission business, global clutch<br />

business, current generation medium-duty and heavy-duty automated transmission<br />

business outside of North America, global aftermarket business, light-duty transmission<br />

business, agricultural transmission business, and global automotive business and<br />

associated product lines.<br />

The formation of the joint venture is subject to regulatory approvals and customary<br />

closing conditions. The parties expect the transaction to close in the third quarter<br />

of <strong>2017</strong>. <strong>Cummins</strong> will consolidate joint venture results as part of its Components<br />

business segment. n<br />

Penca, who will remain based in Melbourne, has a bachelor’s degree in Business<br />

Administration, with honours in International Management, from Butler University (Indianapolis),<br />

and an MBA in finance and accounting from the University of Southern California. n<br />

New operations director<br />

Ben Lister has been appointed director<br />

of operations for <strong>Cummins</strong> South Pacific.<br />

National award for Zoe Bull<br />

Zoe Bull with her awards<br />

<strong>Cummins</strong> Brisbane’s Zoe Bull took out<br />

the inaugural National Apprentice of<br />

the Year award presented by Heavy<br />

Vehicle Industry Australia (HVIA).<br />

Zoe, now a fully qualified diesel<br />

technician, was presented with a<br />

trophy and tools to the value of $1300<br />

and earned the right for a perpetual<br />

trophy to be displayed in her<br />

workplace for the next 12 months.<br />

According to her citation, Zoe was<br />

applauded for her attitude and<br />

commitment to her role at <strong>Cummins</strong>.<br />

“Perhaps it’s a carryover from her time<br />

in the Navy, but Zoe’s punctuality,<br />

preparation and attention to detail,<br />

particularly with regards safety, is<br />

exemplary,” the citation said.<br />

“Zoe’s excellent troubleshooting skills<br />

and use of diagnostic tools are highly<br />

regarded in the <strong>Cummins</strong> workshop.<br />

“To complement her apprenticeship (as a diesel engine specialist), Zoe has also<br />

completed a Certificate IV in Business and Frontline Management and is working<br />

through a Diploma of Leadership and Management.” n<br />

Ben Lister<br />

Major awards for <strong>Cummins</strong> Darwin<br />

<strong>Cummins</strong> Darwin won the 2016 Employer of the Year<br />

Award, edging out three other contenders including<br />

Hastings Deering. Service manager Troy Hosking<br />

accepted the award.<br />

Thomas Mitchell was also named 1st year Apprentice<br />

of the Year for 2016 in the awards, made by the<br />

Motor Trades Association (NT) and sponsored by the<br />

Department of Transport and Charles Darwin University.<br />

“Thomas’s award is testament to <strong>Cummins</strong>’ support of<br />

apprentices and also reflects our engagement with VET<br />

(Vocational Education & Training) student programs in the<br />

region,” said Troy Hosking. n<br />

Lister joined <strong>Cummins</strong> in 2015 as aftermarket<br />

director and in his new role takes over from<br />

Steph Disher who is now managing director<br />

of <strong>Cummins</strong> South Pacific.<br />

Prior to joining <strong>Cummins</strong>, Lister held senior<br />

management roles in sales and marketing,<br />

operations and engineering fields. These included<br />

time in the oil and gas sector at Shell where he<br />

served as the national mining and construction<br />

sales manager, and at Renold, an international<br />

engineering group, where he ran its national sales<br />

and marketing and branch operations.<br />

Lister has a Bachelor of Engineering<br />

(Manufacturing Systems) from the Royal<br />

Melbourne Institute of Technology and an MBA<br />

from the University of Western Australia. n<br />

Thomas Mitchell (right)<br />

won 1st year Apprentice<br />

of the Year award.<br />

Tom Linebarger, <strong>Cummins</strong> Inc CEO<br />

<strong>Cummins</strong> releases more efficient QSK60 lean burn gas generator set<br />

Upgraded QSK60 lean<br />

burn gas generator set.<br />

<strong>Cummins</strong> has launched its latest<br />

generation QSK60 lean burn natural gas<br />

generator set in Australia.<br />

Rated at 1540 kW and supplying electrical<br />

efficiency of up to 43.8 per cent, the<br />

upgraded 60-litre V16 QSK60 gas engine<br />

reduces total cost of ownership for<br />

customers by delivering world-class<br />

power efficiency.<br />

“Given fuel costs equate to<br />

up to 80 per cent of the total<br />

cost of ownership, any<br />

improvement in efficiency yields<br />

measurable savings,” said<br />

Birol Guler, general manager<br />

of <strong>Cummins</strong> South Pacific’s<br />

power generation business.<br />

“This is especially relevant to<br />

remote power applications<br />

where we have seen a big<br />

push for gas-fired generation.”<br />

In today’s competitive energy generation<br />

market, where profits are being squeezed<br />

from all sides and reliability in hardware<br />

is critical, this cost saving can be<br />

re-channelled into other areas of a<br />

customer’s core business.<br />

“In base load applications, where fuel<br />

becomes a considerable cost to the<br />

customer, efficiency is a key driver in the<br />

decision-making process. We are excited<br />

to be demonstrating world class efficiency<br />

which is ultimately supporting our customers<br />

in this market,” said Birol Guler.<br />

The newest member of the QSK60 series,<br />

the C1540 N5CC offers customers options<br />

that make it a perfect fit for both independent<br />

power producers (IPP) and combined heat<br />

and power (CHP) applications.<br />

<strong>Cummins</strong> is a global provider of power<br />

generation systems, with a global support<br />

network. As a full system provider,<br />

<strong>Cummins</strong> provides end-to-end solutions<br />

for a number of applications such as base<br />

load power and combined heat and<br />

power to meet the needs of a diverse<br />

customer base.<br />

The QSK60 lean burn gas generator set<br />

leverages <strong>Cummins</strong>’ ‘Power of One’ capability<br />

with single-company design and manufacture<br />

of all key systems. This offers a direct<br />

factory to market path with solutions<br />

tailored to suit specific customer needs.<br />

According to Birol Guler this enables<br />

customers to recognise increased ‘time<br />

per year availability’ with reduced<br />

downtime and cost of maintenance to<br />

meet their objectives.<br />

The upgraded QSK60 series is ideal<br />

for integration into new or existing<br />

cogeneration, prime power and<br />

trigeneration plants. n

18 RECONCILIATION A TRIBUTE 19<br />

THE<br />

POWER<br />

OF<br />

RECONCILIATION<br />

Western Star roadtrain prime<br />

mover was unveiled on<br />

Vietnam Veterans Day in 2016<br />

to mark the 50th anniversary<br />

of the Battle of Long Tan.<br />

The Australian, Aboriginal<br />

and Torres Strait Islander<br />

flags flying outside <strong>Cummins</strong><br />

South Pacific headquarters<br />

in Melbourne.<br />

WESTERN STAR PRIME MOVER<br />

A TRIBUTE TO<br />

WAR VETERANS<br />

A <strong>Cummins</strong>-powered Western Star road train prime mover<br />

operated by Longreach Regional Council in central western<br />

Queensland commands a special place in the hearts<br />

and minds of war veterans.<br />

Special artwork was created to highlight <strong>Cummins</strong>’<br />

commitment to the Reconciliation Action Plan.<br />

Aboriginal elder Aunty Marg<br />

acknowledged <strong>Cummins</strong>’ “long<br />

history of community involvement”.<br />

“When the decision was made to purchase a truck in 2015 I saw it as the perfect opportunity<br />

to name the truck ‘Gallipoli’ as it was the 100th anniversary of the battle that forged<br />

Australian history and the beginning of the ANZAC legend,” says David Hislop, workshop<br />

supervisor for Longreach council.<br />

“So I set in the plan in motion, with assistance from John Smeeton who sold us the truck,<br />

to have a mobile, working tribute, to the people who served our country.”<br />

A moving ceremony in which <strong>Cummins</strong> South Pacific pledged<br />

a commitment to reconciliation with Aboriginal and Torres<br />

Strait Islander peoples was held recently at the company’s<br />

headquarters in Melbourne.<br />

The ceremony marked the launch of <strong>Cummins</strong>’ Reflect Reconciliation Action Plan (RAP) and<br />

was attended by Aboriginal community leaders and elders together with <strong>Cummins</strong> customers<br />

and employees.<br />

The RAP, ratified by Reconciliation Australia and proudly described by executive director of<br />

<strong>Cummins</strong> Asia Pacific Distribution, Andrew Penca, as a historic moment in <strong>Cummins</strong>’ 97-year<br />

history, is about implementing practical actions that build respectful relationships and create<br />

opportunities for Aboriginal and Torres Strait Islander peoples.<br />