Cummins Commentary Issue 50 - December 2017

News and commentary from Cummins South Pacific (Australia, New Zealand and Papua New Guinea)

News and commentary from Cummins South Pacific (Australia, New Zealand and Papua New Guinea)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

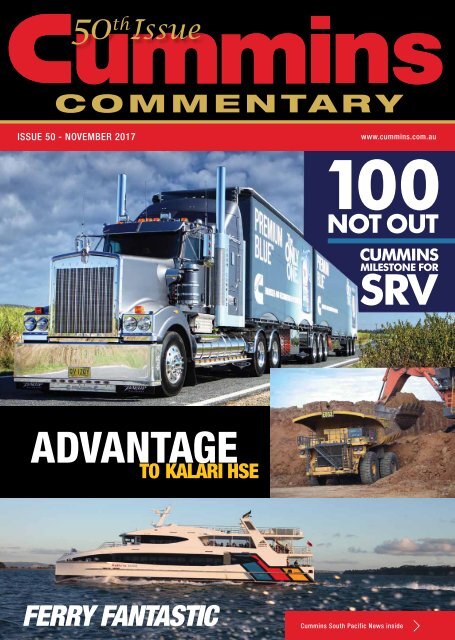

<strong>50</strong> th <strong>Issue</strong><br />

COMMENTARY<br />

ISSUE <strong>50</strong> - NOVEMBER <strong>2017</strong><br />

www.cummins.com.au<br />

ADvantage<br />

to kilari<br />

HSE<br />

FERRY FANTASTIC<br />

<strong>Cummins</strong> South Pacific News inside

2<br />

CUMMINS COMMENTARY NOVEMBER <strong>2017</strong><br />

Contents<br />

4 V903 celebrates <strong>50</strong> years in service<br />

Once a prominent engine in Australia, especially in trucking, marine and agricultural<br />

applications, the V903 continues in production in the US with ratings up to 675 hp.<br />

Innovating for<br />

our customers<br />

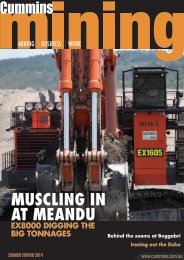

5 <strong>50</strong>th issue of <strong>Cummins</strong> <strong>Commentary</strong><br />

We look back at some of the covers that have graced our popular corporate<br />

magazine <strong>Cummins</strong> <strong>Commentary</strong>.<br />

6 Gaining the advantage<br />

<strong>Cummins</strong>’ QSK60 ‘Advantage’ engine is delivering major environmental and<br />

operational benefits to mining contractor Kalari HSE.<br />

4<br />

5<br />

6<br />

8 Ferry fantastic<br />

Two new $9 million ferries are resetting the efficiency benchmarks for Fullers Group<br />

in Auckland, NZ.<br />

10 Tackling risk head on<br />

Frasers Livestock Transport has won safety awards for its cross-loading system.<br />

11 Cranked up in the cane<br />

A <strong>Cummins</strong> badge on the side of Paul Destro’s John Deere cane harvester hints<br />

that it may well have a new lease of life.<br />

12 Game on<br />

Four <strong>Cummins</strong> generators are at the heart of the emergency power system at the<br />

new $1.6 billion Perth Stadium.<br />

14 100 not out<br />

Errol Cosgrove has put his 100th new <strong>Cummins</strong>-powered truck into service in his<br />

SRV fleet.<br />

16 News<br />

Read all about the happenings in the world of <strong>Cummins</strong> both locally and globally.<br />

19 Electric shock<br />

<strong>Cummins</strong> has committed to electric power as an important part of its future.<br />

20 No cat-napping here<br />

Underpinning search and rescue operations around Australia is an internationally<br />

recognised boatbuilder on Queensland’s Sunshine Coast.<br />

21 Humble beginnings no barrier to ambition<br />

Tegra Australia is a family company success story – a company based in Young,<br />

NSW, which started as a one-truck operation in 1964.<br />

22 World’s most reliable railcar<br />

Another major milestone has been achieved in Victoria’s VLocity rail project with<br />

<strong>Cummins</strong> delivering the 200th QSK19 engine.<br />

23 All in for the haulout<br />

Mio Farming is repowering its sugarcane haulouts with <strong>Cummins</strong> engines to<br />

achieve greater reliability and improved fuel consumption.<br />

24 Passion for pink<br />

Mendi Group has painted its new Kenworth and B-double trailers pink in support of<br />

women in the construction industry as well as two local charities.<br />

8<br />

19<br />

11<br />

10<br />

20<br />

14<br />

Comment by<br />

Steph Disher,<br />

Managing Director<br />

<strong>Cummins</strong> South Pacific<br />

We are rapidly heading towards the festive season and I am certainly looking forward<br />

to spending some time with family and friends over the holiday period. It has been a<br />

very full year and it is encouraging to see some optimism returning to our business in<br />

the South Pacific (Australia, New Zealand, Papua New Guinea).<br />

This optimism is also being experienced across world markets: <strong>Cummins</strong> globally<br />

reported a 26% increase in revenues for the third quarter <strong>2017</strong> over the same period<br />

last year. It has been good to hear from our customers that their businesses are<br />

also seeing signs of growth and we are looking closely at how we will meet the<br />

increasing demand.<br />

We had the pleasure of hosting our <strong>Cummins</strong> Inc. Chairman and CEO, Tom Linebarger,<br />

in Australia recently. We had a full agenda with Tom which included meeting our<br />

customers and employees. We took the opportunity while Tom was here to launch<br />

our new Mission, Vision and Values with 100 of our key leaders across our<br />

South Pacific business.<br />

Importantly, we spoke about our new vision: Innovating for our customers to power<br />

their success. I recognise our customers’ success is our success and I am personally<br />

committed to daily improving this across our business.<br />

We see opportunities to support our customers with innovation in a number of areas.<br />

Examples include fuel efficiency savings through product technologies such as ADEPT<br />

(Advanced Dynamic Efficient Powertrain Technology) on our X15 heavy-duty truck<br />

engine, and the MCRS modular common rail fuel system on our high-horsepower QSK<br />

engines. Other examples are data analytics and connected solutions to improve fleet<br />

utilisation and reduce emergency repairs.<br />

We also see opportunity to continually improve our support and service across<br />

the region.<br />

24<br />

We have introduced a new concept of ‘customer huddles’ in our branches which is an<br />

opportunity for all staff in branch teams to understand our customers’ experience with<br />

a view to continuous improvement. Our success depends on our ability to provide the<br />

best technology, the best value and best support.<br />

22<br />

I hope you enjoy this <strong>50</strong>th edition of <strong>Cummins</strong> <strong>Commentary</strong> which profiles the great<br />

stories of many of our customers and our employees.<br />

To our customers, I sincerely thank you for your valued support and we will continue<br />

to do whatever it takes to keep you as part of the <strong>Cummins</strong> family. I wish you all a very<br />

happy holiday season and look forward to meeting more of you in 2018.<br />

<strong>Cummins</strong> <strong>Commentary</strong> is published by <strong>Cummins</strong> South Pacific<br />

Best wishes<br />

Steph Disher<br />

2 Caribbean Drive, Scoresby Vic 3179 Australia<br />

Tel: 61-3 9765 3222<br />

Editor: Murray Clifford Tel: 0419 268 289 Email: murray.clifford@cummins.com<br />

Follow us on Facebook<br />

<strong>Cummins</strong> South Pacific<br />

<strong>Cummins</strong> New Zealand

4 MILESTONE<br />

5<br />

<strong>50</strong>th<br />

<strong>Issue</strong><br />

19 Years of...<br />

COMMENTARY<br />

Iconic Bradley Fighting<br />

Vehicle has been powered<br />

by VTA903 since 1981.<br />

CUMMINS V903<br />

CELEBRATES <strong>50</strong> YEARS<br />

IN SERVICE<br />

<strong>Cummins</strong> Inc. V903/defense team, from left: Melina Kennedy (Executive Director – Rail & Defense);<br />

Keith Baylor (V903 Product Validation Manager); Tom Terkhorn (Manager – Defense Products);<br />

Andrew Stiles (V903 Chief Engineer).<br />

Once a prominent engine in Australia, especially in trucking,<br />

marine and agricultural applications, the V903 continues in<br />

production in the US with ratings up to 675 hp.<br />

One of the most enduring engines in <strong>Cummins</strong>’ long history, the V903 is this year celebrating<br />

a remarkable <strong>50</strong> years in service.<br />

The V903 platform will continue to support the<br />

armoured vehicle forces for decades to come.<br />

“Many engines have done the <strong>Cummins</strong> name proud and prominent among these is the V903,”<br />

said Tom Terkhorn, Manager of Defense Products for <strong>Cummins</strong> Inc.<br />

“The first V903 crankshaft was laid at the <strong>Cummins</strong> Engine Plant in Columbus, Indiana, in the<br />

fourth quarter of 1967, and since then the engine has progressed from 280 hp for over-the-road<br />

truck use to its current peak output of 675 hp for military equipment.”<br />

As its model designation indicates, the V903 is an eight-cylinder ‘V’ configuration with a 903 cubic<br />

inch (14.8-litre) displacement. Providing high power density, it has four valves per cylinder, is<br />

turbocharged and air-to-water aftercooled, and has a low pressure common rail fuel system.<br />

675 hp version for Bradley.<br />

Today, the VTA903 is produced primarily for military applications, notably the US Army’s iconic Bradley<br />

Fighting Vehicle in which it is rated at 600 hp. In 2018, a 675 hp version will be installed in the<br />

upgraded Bradley ECP 2, Armored Multi-Purpose Vehicle (AMPV) and Paladin M109A7 howitzer.<br />

In actual operations, the VTA903-powered Bradley has showed a combat readiness of over<br />

95% – the highest combat readiness of any armored vehicle in the history of the US Army.<br />

The V903 was originally developed for the on-highway truck and construction markets to meet<br />

the requirements for a lightweight, compact diesel engine in the 280-320 hp range. It went on<br />

to make its mark in other applications such as recreational and commercial boats, mining<br />

equipment, and farm tractors.<br />

During its years as a heavy-duty truck engine, from 1967 to 1984, it proved reliable and durable.<br />

Many engines exceeded <strong>50</strong>0,000 miles (805,000 km) with no major repairs or overhauls.<br />

New life for V903.<br />

The VTA903 began its life in the Bradley Fighting Vehicle in 1981 when <strong>Cummins</strong> upgraded the<br />

power level of the commercial truck engine from 3<strong>50</strong> to <strong>50</strong>0 hp with the addition of air-to-water<br />

aftercooling and modifications to the fuel system.<br />

<strong>Cummins</strong> began production of the 600 hp VTA903 in early 1989 when the Bradley’s full combat<br />

weight increased to 60,000 lb (26.8 long tons) as a result of added armor. This required higher<br />

horsepower to maintain the Bradley’s mobility. The power boost was achieved using technologies<br />

developed for other <strong>Cummins</strong> products. Importantly, there were no changes to the length, width<br />

and height of the engine which had to fit into the Bradley’s notably tight powerpack compartment.<br />

V903 was popular in the International ACCO 3070, Ford Louisville and bonneted<br />

and cabover Kenworth models.<br />

“<strong>Cummins</strong> conducted accelerated wear and abuse tests for final acceptance of the engine’s<br />

revised design and these showed that thermal and mechanical stresses of the 600 hp engine<br />

were actually lower than the <strong>50</strong>0 hp version,” said Keith Baylor, V903 Product Validation Manager.<br />

“This meant the army could expect improved reliability and durability. Field performance of the<br />

600 hp engine confirmed this initial expectation.”<br />

Development of the 675 hp version of the VTA903 was completed in 2013 for the US Army’s<br />

Paladin M109A7 howitzer, and in 2018 it will be fitted in the upgraded Bradley ECP 2 and<br />

Armoured Multi-Purpose Vehicle (AMPV) which replaces the M113 armored personnel carrier.<br />

Again, technologies developed for other <strong>Cummins</strong> engines were used to achieve the 675 hp upgrade,<br />

including a hybrid fuel system utilising a modified fuel pump from the QSK19 family in combination<br />

with an electronic control module. Injectors with step timing control (STC) are also used.<br />

Production of the V903 – both remanufactured and new engines – is carried out on the one line<br />

at <strong>Cummins</strong>’ Seymour Engine Plant in Indiana.<br />

“The V903 platform will continue to support the armored vehicle forces for decades to come,”<br />

said Tom Terkhorn. n<br />

CUMMINS COMMENTARY, THE POWER OF CONVERSATION AND VALIDATION.

6 ENGINE TECHNOLOGY<br />

ENGINE TECHNOLOGY 7<br />

One of six Komatsu 830 trucks powered by the 2<strong>50</strong>0 hp<br />

QSK60 Advantage engine at South Walker Creek mine.<br />

By upgrading to a more<br />

technically efficient engine,<br />

we’re reducing our carbon<br />

footprint and diesel particulate<br />

emissions.<br />

Kalari HSE major components manager John Ross (right) with <strong>Cummins</strong><br />

Mackay site support technician Anthony Civello and <strong>Cummins</strong> field service<br />

engineer Andrea Lucas.<br />

<strong>Cummins</strong>’ QSK60 ‘Advantage’ engine<br />

is delivering major environmental and<br />

operational benefits to mining contractor<br />

Kalari HSE in Queensland’s Bowen Basin.<br />

Mining contractor Kalari HSE, has taken major steps to reduce carbon and diesel particulate<br />

emissions at the South Walker Creek coal mine in Queensland’s Bowen Basin.<br />

By upgrading its Tier 1 <strong>Cummins</strong> QSK60 engines to the newly-engineered ‘Advantage’ solution<br />

in its Komatsu 830E haul trucks, Kalari HSE has slashed diesel particulate emissions by 63 per<br />

cent through in-cylinder combustion technology with no aftertreatment requirement.<br />

Additionally, fuel consumption has been cut by 3 per cent across the six Komatsu 830E trucks,<br />

an important greenhouse gas (GHG) emissions reduction, with carbon dioxide (CO2) reduced<br />

by more than 510,000 kg for the six trucks operating 6000 hours/year.<br />

Sustainability a key value.<br />

“Environmental sustainability is one of our key values,” says John Ross, major components<br />

manager for Kalari HSE. “By upgrading to a more technically efficient engine, we’re reducing<br />

our carbon footprint and diesel particulate emissions.<br />

“At the same time, we’re achieving a major cost efficiency gain for our customer by burning<br />

less fuel.”<br />

The QSK60 ‘Advantage’ solution has been developed specifically for mining customers in<br />

Australia to slash not only emissions but also reduce total cost of ownership through several<br />

factors including longer life-to-overhaul. Development was carried out by <strong>Cummins</strong>’ high<br />

horsepower technical centre in the US and <strong>Cummins</strong>’ engineering team in Australia.<br />

So what exactly is the ‘Advantage’ solution? In simple terms, it’s a rebuild upgrade for the<br />

2<strong>50</strong>0 hp, single-stage QSK60 from the Tier 1 to Tier 2 platform with the addition of some Tier 4<br />

Final component technology. The upgrade features <strong>Cummins</strong>’ Tier 2 modular common rail fuel<br />

system (MCRS) as distinct from the HPI unit injection system on the Tier 1 engine.<br />

Importantly, the ‘Advantage’ solution utilises the original factory 830E cooling system package.<br />

Cost benefit analysis.<br />

Kalari HSE carried out a cost benefit analysis of several engine manufacturers’ upgrade<br />

packages before deciding on the <strong>Cummins</strong> solution as the best value proposal. “We wanted<br />

longer life-to-overhaul and we’ll achieve that with <strong>Cummins</strong>’ solution along with the other<br />

benefits of significantly reduced emissions and reduced fuel consumption,” says Scott Pease,<br />

technical support manager for Kalari HSE’s truck fleet.<br />

The Tier 1 QSK60 HPI engines in the Kalari HSE fleet were being changed out at 22,000<br />

hours. With the ‘Advantage’ engines, supplied by the <strong>Cummins</strong> Master Rebuild Centre in<br />

Brisbane, life-to-overhaul climbs to 30,000 hours and there’s minimal mid-life replacement of<br />

components. The 30,000-hour life eliminates one engine change-out in the 80,000-hour life of<br />

the truck chassis.<br />

Kalari HSE and <strong>Cummins</strong> have had a close association in the Bowen Basin since 2005 when<br />

the mining contractor bought five new K2000 engines to repower Euclid R190 haul trucks at<br />

the Ensham mine.<br />

Commitment to <strong>Cummins</strong> brand.<br />

“The support we get today from Chris Bugeja and his team at <strong>Cummins</strong> Mackay underpins<br />

our commitment to the <strong>Cummins</strong> brand,” says John Ross. He mentions that the 1800 hotline<br />

to the <strong>Cummins</strong> Support Centre has worked well for Kalari HSE, and that having a <strong>Cummins</strong><br />

technician on site fulltime further ensures that “everything is spot on all the time”.<br />

He says an important factor in the success of the ‘Advantage’ MCRS project was the team<br />

work between <strong>Cummins</strong> and Komatsu – the fact they worked together closely to ensure the<br />

project was carried out with a 100 per cent safety record and within the budgeted timeframe<br />

with no impact on production. n<br />

We wanted longer life-to-overhaul and we’ll<br />

achieve that with <strong>Cummins</strong>’ solution.<br />

Kalari HSE and <strong>Cummins</strong> have a close working relationship. From left to right: Scott Pease<br />

(Kalari HSE), Chris Dew (<strong>Cummins</strong> Mackay), John Ross (Kalari HSE), Peter Bond (Kalari HSE),<br />

Ben Clark (<strong>Cummins</strong> Brisbane).

8 FERRY EFFICIENCY<br />

FERRY EFFICIENCY 9<br />

FERRY FANTASTIC<br />

Total cost of ownership has been a key element<br />

in the company’s decision to specify <strong>Cummins</strong><br />

QSK engines.<br />

Korora running at 29 knots with amazingly little wake.<br />

<strong>Cummins</strong> was<br />

the only engine<br />

supplier to give us<br />

a straight answer<br />

on life-to-overhaul.<br />

Fullers skipper Ben Hart discussing the performance of the QSK<strong>50</strong><br />

engines with, from left, <strong>Cummins</strong> NZ sales executive Keith Hitchcock<br />

and <strong>Cummins</strong> NZ general manager Dan Gallagher.<br />

Two new $9 million ferries are<br />

resetting the efficiency benchmarks<br />

for Fullers Group as they transport<br />

hundreds of commuters and tourists<br />

daily within Auckland Harbour and<br />

the Hauraki Gulf.<br />

Powered by twin 1800 hp <strong>Cummins</strong> QSK<strong>50</strong> engines, the new<br />

sister ferries – Korora and Torea – are running swiftly, quietly<br />

and with amazingly little wake. This is clearly evident in the<br />

photos with this article which show Korora cruising at 29<br />

knots on its way to Waiheke Island.<br />

Importantly, the QSK<strong>50</strong> – an electronically-controlled <strong>50</strong>-litre<br />

V16 – also aligns with Fullers’ business values in a world<br />

increasingly challenged by environmental compliance, meeting<br />

the most stringent marine exhaust emissions regulations in<br />

the world.<br />

The new vessels jog the memory of Doug Hudson, whose<br />

father George Hudson bought the Auckland ferry business in<br />

the early 1980s. Doug is currently on Fullers’ board of<br />

directors after serving as CEO for 10 years.<br />

The Hudsons set about rejuvenating what was a fleet of old<br />

wooden ferries and in 1986 built their first vessel – the $3.5<br />

million, 34-metre Quickcat which could carry 6<strong>50</strong> passengers.<br />

At that stage, it was the largest passenger ferry to have been<br />

built in Australasia.<br />

”Building Quickcat – a large catamaran – was revolutionary at<br />

the time,” says Doug. “George knew little about designing<br />

ferries, but what he did know from his experience with buses<br />

was that they had to be fit for purpose.”<br />

Quickcat is still in service with Fullers and may be used as a<br />

viewing boat at the 2021 America’s Cup in Auckland.<br />

Tales of skulduggery.<br />

The history of Fullers Group is fascinating and includes tales<br />

of competitors’ skulduggery as they tried to oust the company<br />

from the Auckland ferry business. Doug Hudson recalls with<br />

a wry smile: “There were days that could only be described<br />

as ferry wars.”<br />

Today, the focus is on a Fullers organisation that is<br />

privately owned by Scottish businessman and entrepreneur<br />

Sir Brian Souter, co-founder of the internationally successful<br />

StageCoach company which operates 13,000 buses,<br />

coaches, trains and trams in the UK and North America.<br />

Fullers Group is the largest public transport ferry operator in<br />

New Zealand, transporting over 5.3 million passengers a year<br />

with its Auckland-based fleet of 21 vessels.<br />

Total cost of ownership has been a critical element in the<br />

company’s decision to specify <strong>Cummins</strong> QSK engines. The<br />

two new ferries, each with twin 1800 hp QSK<strong>50</strong> engines,<br />

follow Te Kotuku which went into service in 2014 powered by<br />

twin 1400 hp QSK38 engines.<br />

<strong>Cummins</strong> QSK… the best option.<br />

“We looked at three different engines for Te Kotuku and<br />

the <strong>Cummins</strong> QSK emerged as the best option in terms<br />

of overhaul frequency, parts pricing, physical footprint and<br />

horsepower rating,” says Doug Hudson.<br />

“The performance of Te Kotuku gave us the confidence to<br />

build the two sister ferries with QSK<strong>50</strong> engines. There ain’t<br />

no perfect boat but I think we’re pretty close to it with<br />

Kororaāand Torea.”<br />

The performance of the new ferries has exceeded Fullers’<br />

expectations. Fullers’ requirement is for an average speed of<br />

27 knots at 85% of maximum continuous rating (MCR) with<br />

typical deadweight. Kororaāachieved 29 knots at 85% MCR<br />

during sea trials.<br />

The higher horsepower <strong>50</strong>-litre QSK<strong>50</strong> engines were<br />

considered necessary because the new vessels are 7.0 tonnes<br />

heavier with the addition of a sundeck while passenger capacity<br />

has increased from 335 to 401.<br />

Significantly, the QSK<strong>50</strong> engines are using only slightly more<br />

fuel – 13 litres/hour per engine more than the 38-litre QSK38<br />

units – while achieving a higher cruise speed with greater<br />

passenger capacity.<br />

Life-to-overhaul.<br />

“<strong>Cummins</strong> was the only engine supplier to give us a straight<br />

answer on life-to-overhaul,” says Doug Hudson. Based on<br />

fuel burn – the key indicator of engine workload – the QSK<strong>50</strong>s<br />

will achieve life-to-overhaul of 32,000 hours.<br />

Fullers’ initial expectation for life-to-overhaul with the QSK38<br />

engines in Te Kotuku was 20,000 hours, but <strong>Cummins</strong> New<br />

Zealand’s marine sales executive Keith Hitchcock has upped<br />

that expectation to 27,000 hours based on fuel burn.<br />

Another Fullers vessel with twin QSK38 engines is Adventurer<br />

which originally had two-stroke Detroits. The repowered<br />

27-metre Adventurer – much lighter than the Te Kotuku –<br />

entered service in 2014 and has astonishingly low fuel burn;<br />

its QSK38 engines are expected to exceed 40,000 hours<br />

before overhaul.<br />

The Te Kotuku, Kororaā and Torea – also equipped with 100<br />

kVA <strong>Cummins</strong> gensets – were designed by Incat Crowther<br />

and built by Q-West in Wanganui. “We’ve deliberately had the<br />

ferries built in New Zealand,” says Doug Hudson. “We could<br />

have had them built cheaper in Australia but we wanted to<br />

invest money back into the New Zealand economy.<br />

“That said, we’re very happy with Q-West. Their workmanship<br />

is the key for us.” n<br />

Doug Hudson… “There were days that<br />

could only be described as ferry wars.”

10 SAFETY<br />

REPOWERING 11<br />

TACKLING RISK HEAD ON<br />

CRANKED UP IN THE CANE<br />

Paul Destro… “<strong>Cummins</strong>…the best solution.”<br />

<strong>Cummins</strong>-powered Kenworths dominate in the Frasers fleet.<br />

Established 73 years ago, Frasers<br />

Livestock Transport may well be the<br />

oldest substantial livestock trucking<br />

business in Australia still under<br />

original ownership.<br />

Frasers today runs a fleet of <strong>50</strong> prime movers and 1<strong>50</strong><br />

trailers operating as single, B-double, B-triple and roadtrain<br />

configurations. Home base is at Warwick in Queensland<br />

and the company transports more than four million head of<br />

livestock a year between cattle properties, feedlots, sale yards,<br />

abattoirs and ports.<br />

Ross Fraser is managing director, with trucks and livestock<br />

having been locked permanently into his life for many years.<br />

In fact, he has been directly involved in the family business for<br />

over <strong>50</strong> years. His brothers Les and Peter were also bred into<br />

the trucking business, and they play key roles in the day-today<br />

operations as directors.<br />

Their parents, Charlie and Edna Fraser, started the company<br />

in 1944 with a LendLease Ford carting poultry, grain, wood<br />

and hay in the Warwick district before focusing on livestock<br />

transport.<br />

Cross-loading safety awards.<br />

<strong>Cummins</strong> South Pacific managing director Stephanie Disher<br />

was recently introduced to the Frasers business, watching the<br />

company’s cross-loading in action with a module system that<br />

won two Queensland Safe Work Awards and also a National<br />

Safe Work Australia Award for ‘Best Solution to an Identified<br />

Workplace Health and Safety <strong>Issue</strong>’.<br />

“The dangers of cross-loading cattle between roadtrains are<br />

enormous. It’s one of the most dangerous activities in the<br />

cattle transport supply chain… we needed to do something<br />

that didn’t put our drivers at risk,” says Ross Fraser.<br />

Frasers designed and custom-built a cross-loading module, a<br />

simple but highly functional piece of equipment that provides<br />

significant improvements to animal welfare, driver safety and<br />

stock handling efficiency. It removes the need for drivers to<br />

work within the stockcrates, or climb or stand on them. The<br />

module incorporates a series of elevated platforms, over-trailer<br />

walkways, sliding gates and barriers.<br />

“The acceptance has been unreal,” says fleet manager Mark<br />

Collins, pointing out the company now has three cross-loading<br />

modules, at Toowoomba, Roma and Rockhampton.<br />

He also reveals big time savings: “We recently transferred 42<br />

decks of cattle from Curley (Cattle Transport) to seven of our<br />

triples in Roma and it took 2 hours 10 minutes. Without the<br />

system it would have taken us half a day at least.”<br />

Long-standing employees.<br />

In an industry as fiercely demanding as livestock transport,<br />

staff are a key component to business success, and Frasers<br />

has a long list of long-standing employees.<br />

“You can’t run a business like livestock transport from a<br />

boardroom. You need the right people on the ground. Bringing<br />

people up through the business is a huge advantage,” says<br />

Ross Fraser.<br />

“How many multinational companies are involved in livestock<br />

transport? None, because it’s too difficult. Nearly all livestock<br />

transporters are family businesses and they have that close<br />

affinity with animals.<br />

“Recognising the value of having the right people working for<br />

you is critical. We’re no different to anyone else. Being away<br />

from home a lot puts pressure on families… but we have good<br />

driver retention – we actually have a third generation driver<br />

here – and we value that retention greatly.”<br />

Mark Collins has been with Frasers for 35 years. He started as<br />

a mechanic, had a stint as a driver, and is now fleet manager.<br />

“We’re lucky having Mark,” says Ross Fraser. “He’s taken an<br />

interest in industry issues. It’s important that people who are<br />

involved in the industry associations have had experience on<br />

the ground and use that experience to run a strong agenda for<br />

the industry.”<br />

You can’t run a business<br />

like livestock transport from<br />

a boardroom.<br />

Ross Fraser has always had a close affinity with associations.<br />

He was chairman of the Australian Trucking Association<br />

from 2004-2006 and is also a past president of the<br />

Australian Livestock Transporters Association and Livestock<br />

Transporters Association of Qld.<br />

Special demands, special equipment.<br />

<strong>Cummins</strong>-powered Kenworths dominate in the Frasers<br />

fleet today while Byrne is the favoured trailer brand. “We<br />

bought our first new Kenworth in 1986 and have continued<br />

buying Kenworths. Product reliability and service support are<br />

important… we know that the right part will turn up when we<br />

ask for it,” says Ross Fraser.<br />

“It’s not in our interest to put another brand into the fleet. That<br />

would be inefficient. We like the T6<strong>50</strong> series Kenworth. It’s<br />

easy to work on, it’s easy to change a gearbox, and the cab<br />

sits higher on the chassis for better air circulation.”<br />

Frasers’ relationship with <strong>Cummins</strong> extends back to the early<br />

1980s, and today there’s a mix of Signature Gen II, ISX EGR<br />

and ISXe5 engines in the fleet. Again, service support geared<br />

to the special demands of livestock transport operations has<br />

been a key element in the preference for <strong>Cummins</strong>. n<br />

<strong>Cummins</strong> South Pacific managing director Steph Disher<br />

with Frasers fleet manager Mark Collins discussing the<br />

cross-loading system (in background).<br />

A <strong>Cummins</strong> badge on the side of Paul Destro’s cane<br />

harvesting machine – a John Deere 3510 – hints that<br />

it may well have a new lease of life.<br />

This is confirmed by Paul, a member of the well-known Destro family who have been involved<br />

in sugarcane farming and harvesting in the Babinda region of north Queensland for close to<br />

<strong>50</strong> years.<br />

Paul, the son of Stephen and Rose Destro who started the business, runs the contract<br />

harvesting operation which cuts around 80,000 tonnes a year. He has been in the business<br />

20 years after starting his career as a cane bin hauler at the age of 19.<br />

More productive, especially in wet.<br />

Well into his second season with the repowered John Deere machine, Paul comes straight<br />

to the point when discussing the <strong>Cummins</strong> influence on his business. “I’ve now got a more<br />

productive harvesting machine, especially when operating in wet conditions,” he says.<br />

“The original 8.1 litre John Deere engine had run its race at just over 9000 hours.<br />

“I decided to repower the machine because I wanted an engine that wasn’t stretched…<br />

that’s where the <strong>Cummins</strong> QSM11 came into play.<br />

“I looked at a number of options and the 400 hp <strong>Cummins</strong> definitely looked the best solution<br />

in terms of engine displacement (10.8 litres), performance, fuel consumption and ease of<br />

installation.”<br />

High rainfall – the highest in Australia, in fact – is a critical factor in the performance and fuel<br />

consumption equation. “We cut in the wet a lot so we’re dragging through mud which means<br />

high engine load factors and higher than normal fuel consumption,” Paul Destro points out.<br />

Rainfall in the region is measured in metres rather than millimetres. Average annual rainfall is<br />

3-4 metres while up to 7.5 metres have been recorded in a year.<br />

Decent outcome for Destro.<br />

Destro points out that the 10.8-litre QSM11 is on a par with the 8.1-litre John Deere engine in<br />

terms of fuel usage, typically in the range of 55-60 litres/hour in dry conditions and higher than<br />

60 litres/hour in the wet. “With the <strong>Cummins</strong> I’ve gained more horsepower while using the same<br />

amount of fuel – that’s a decent outcome,” he says.<br />

<strong>Cummins</strong> Cairns’ Peter Burnell<br />

(left) worked closely with Paul<br />

Destro on repower requirements.<br />

<strong>Cummins</strong> QSM11 now powers the Deere.<br />

I’ve now got a more productive harvesting<br />

machine…<br />

Engine load factor in the Destro operation averages 80%, a demanding application in anyone’s<br />

language, and one that impacts engine longevity – another factor that influenced Paul’s decision<br />

to specify the larger displacement QSM11 in the quest for improved reliability and durability.<br />

At the end of the current season, he plans to re-ratio the hydraulics system on the John Deere<br />

to reduce engine speed from 2100 to 1900 rpm to further underpin engine durability while<br />

improving fuel economy.<br />

The current hydraulics system is set up for 2100 rpm operation to suit the Deere engine. Regearing<br />

the pump drive box will allow the QSM11 to operate at 1900 rpm while maintaining<br />

hydraulic system performance. The power curve for the QSM11 shows no loss of power at the<br />

lower rpm, with 400 hp on tap from 1700 to 2100 rpm.<br />

Ross Fraser (far left) with, from left to right, Peter Fraser, Les Fraser, Warwick Fraser,<br />

Peter Somerville (workshop manager) and <strong>Cummins</strong> account manager Nathan Usher.<br />

Peter Burnell from <strong>Cummins</strong> Cairns worked closely with Paul Destro to ensure the repower was<br />

as straightforward as possible. “I did the basic installation myself,” says Paul. “The engine just<br />

basically bolted in and then required some re-wiring and re-plumbing. There were no changes<br />

to the cooling system.” n<br />

QSM11 repower was a straightforward job.

12 POWER GENERATION<br />

POWER GENERATION 13<br />

GAME ON!<br />

<strong>Cummins</strong> Perth team that spearheaded the project (from left) Aek Chatnund, Koen Redfern,<br />

Shahan Jerejian, Jon Beazley, Boon Hong and Rukmin Rathnasinghe.<br />

The new $1.6 billion, 60,000-seat Perth Stadium is a<br />

world-class venue capable of hosting AFL, rugby union,<br />

rugby league, soccer, cricket and entertainment events.<br />

Encased in a sleek metallic sheath that rises out of an impressive park setting on a bend of<br />

the Swan River at Burswood, the stadium – Australia’s third largest – will be officially opened in<br />

January 2018.<br />

The commitment to a ‘fans first’ stadium includes two giant 340 sq m video screens, more than<br />

1000 TV screens throughout the interior of the complex, over <strong>50</strong> food and beverage outlets,<br />

and state-of-the-art LED lighting to show home team colours at night on the external façade<br />

and roof canopy.<br />

The five-tiered stadium – its striking bronze façade reflecting West Australia’s geology – sits on<br />

2000 concrete piles driven to a depth of up to 35 metres and was under construction from late<br />

2014 till October <strong>2017</strong>.<br />

<strong>Cummins</strong>’ technical and service support is<br />

highly respected and the company is quick<br />

to respond if there are any issues.<br />

Four <strong>Cummins</strong> QSK60 generators are split between two substations.<br />

High-output <strong>Cummins</strong> power.<br />

Hidden in the bowels of the stadium are four <strong>Cummins</strong> generator sets. At the heart of the<br />

stadium’s emergency power system, they have a standby rating of 1.8 MW at 1<strong>50</strong>0 rpm and<br />

are powered by one of <strong>Cummins</strong>’ most widely-used high-output diesel engines globally – the<br />

QSK60, a 60-litre V16.<br />

Nilsen, the head electrical services contractor for the stadium project, selected <strong>Cummins</strong> to<br />

install the generators sets, exhaust system, fuel system and room acoustics, as well as carrying<br />

out the commissioning.<br />

Proven product reliability along with technical and aftersales support were key reasons for<br />

<strong>Cummins</strong> being awarded the job, according to <strong>Cummins</strong> Perth sales executive Bhavani<br />

Sambhara.<br />

“Nilsen and <strong>Cummins</strong> have a close working relationship as a result of a number of successfully<br />

executed projects,” says Nilsen WA operations manager Mark Cassady. “<strong>Cummins</strong>’ technical<br />

and service support is highly respected and the company is quick to respond if there are any<br />

issues.”<br />

Prior to the Perth Stadium project, <strong>Cummins</strong> and Nilsen successfully delivered the emergency<br />

power system at the Perth Children's Hospital.<br />

Complex but successful project.<br />

Rukmin Rathnasinghe has headed up the successful stadium project for <strong>Cummins</strong> Perth,<br />

managing a complex stakeholder environment that included Nilsen, Brookfield Multiplex<br />

(builder), and Wood & Grieve Engineers (project consultant).<br />

The four <strong>Cummins</strong> generator sets – C22<strong>50</strong>D5 (QSK60) units – are split between two<br />

substations, each substation delivering power to half the stadium. One generator in each<br />

substation can cater for 100% of the section power requirements in the event one unit fails,<br />

providing an N+1 redundancy.<br />

The generator capacity also allows the stadium to be operated purely on the generators when<br />

needed, easing the demand on the local electrical utility.<br />

In the event of a power outage, both generators start automatically and operate in parallel<br />

to supply emergency power to the stadium. The <strong>Cummins</strong> PowerCommand controllers<br />

continuously monitor the generators and provide status signals to the stadium building<br />

management system. They provide the added benefit of signalling an overload on the<br />

generators to shut down the non-essential equipment during critical situations.<br />

Each substation has one 7000-litre bulk fuel tank providing nine hours of operation at 100%<br />

capacity, while two 1000-litre day tanks are also installed at each substation. One fuel system<br />

controller per substation provides a control centre for the fuel transfer pumps, solenoid fuel<br />

valves and tank alarms. All the alarms are interfaced with the building management system.<br />

Primary and secondary mufflers meet the room acoustics requirements of 65 dBA at specific<br />

locations outside the generator substations. Catalytic converters are installed inside the primary<br />

muffler to reduce the overall emission levels.<br />

Value of teamwork.<br />

The value of teamwork has been clearly evident at Perth Stadium from a <strong>Cummins</strong> Perth<br />

standpoint.<br />

In addition to senior project manager Rukmin Rathnasinghe, other key members of the<br />

<strong>Cummins</strong> team have been lead engineer Boon Hong who provided excellent technical support<br />

from the tendering to the commissioning phase; lead commissioning technician Aek Chatnund<br />

who successfully led a team that included Jon Beazley and Koen Redfern; and supporting<br />

project manager Shahan Jerejian who provided valuable contributions on the exhaust system<br />

design/building integration. n<br />

Multi-purpose stadium has 60,000-seat capacity.

14 FLEET FOCUS<br />

FLEET FOCUS 15<br />

If you expect a supplier to be loyal to<br />

you, you should be loyal to the supplier.<br />

<strong>Cummins</strong> Diesel ‘Iron Cross’ logo features on the truck<br />

Errol Cosgrove has put his<br />

100th new <strong>Cummins</strong>-powered<br />

truck into service in his SRV fleet,<br />

a journey that started with a<br />

Signature 620 in 2000.<br />

"My first Signature was in a Kenworth K104 which I had until<br />

last year (2016),” he recalls enthusiastically. “It had done over<br />

3.5 million kilometres. The oldest Signature I have now is in a<br />

2006 T904. It was rebuilt at 1.4 million kilometres and has since<br />

done another 1.2 million.”<br />

Errol Cosgrove considers the secret of his company’s success<br />

to be service, reliability and value for money. In fact, that’s<br />

what SRV stands for. The Brisbane-based operation currently<br />

comprises an interstate express fleet of 74 <strong>Cummins</strong>-powered<br />

Kenworths and 155 trailers. <strong>Cummins</strong>’ ISXe5 dominates in the<br />

fleet, rated at 600 hp/20<strong>50</strong> lb ft.<br />

SRV trucks are instantly recognisable for their customization<br />

and presentation, obvious factors that underpin driver morale.<br />

100th new truck – ‘Most Wanted’.<br />

The 100th new truck, a T909 aptly named Most Wanted, is<br />

propelled by an X15 rated at 600 hp/20<strong>50</strong> lb ft, and is suitably<br />

‘dressed’ to highlight its 100th <strong>Cummins</strong> status.<br />

Wayne Ball is piloting the T909, the result of his second<br />

placing in SRV’s driver rewards program which is held each<br />

year. Each driver starts the year with 1200 points and then<br />

has points added or deducted according to various criteria.<br />

The usual rewards for the winners are two weeks fully paid<br />

in the US for two people (1st place); two weeks fully paid in<br />

Thailand or Bali for two people (2nd place); and a fully paid<br />

weekend at the Bathurst 1000 or $1000 in cash (3rd place).<br />

This year, in addition to receiving their rewards program<br />

prizes, the three winning drivers were presented with new<br />

trucks – Wayne Ball with the 100th new <strong>Cummins</strong>-powered<br />

truck, 1st placed Laurence Smith with SRV’s new Kenworth<br />

T900 Legend which made its grand entrance in September,<br />

and 3rd placed Aaron Reid with a new Kenworth T909.<br />

After serving in senior management roles for various interstate<br />

transport companies, Errol Cosgrove started SRV in 1997<br />

and it remains a family company today. SRV is an accredited<br />

operator in mass and maintenance management under<br />

the Heavy Vehicle Accreditation Scheme. The fleet is also<br />

accredited in Advanced Fatigue Management.<br />

For Cosgrove, loyalty received is deserving of loyalty in return:<br />

“If you expect a supplier to be loyal to you, you should be<br />

loyal to the supplier. Good suppliers are critical to having a<br />

successful business.”<br />

<strong>Cummins</strong> support…second to none.<br />

He says SRV is “treated like family” by both <strong>Cummins</strong> and<br />

Kenworth.<br />

“<strong>Cummins</strong>’ support network is second to none,” he says.<br />

“That underpins the efficiency of our business. If <strong>Cummins</strong><br />

wants us to service an engine a particular way, we service it<br />

that way and we achieve very good life.”<br />

The new T909 is coupled to trailers promoting Premium Blue<br />

8100 oil which is specifically blended to achieve extended<br />

oil drain intervals – up to 60,000 km – with ISXe5 and X15<br />

engines.<br />

Cosgrove is a long-time user of Premium Blue oil, describing<br />

it as “value for money”. He points out that SRV regularly<br />

achieves in excess of one million kilometres with its 15-litre<br />

<strong>Cummins</strong> engines pulling B-doubles. n<br />

Errol Cosgrove (left) and wife Mel hold a commemorative <strong>Cummins</strong><br />

plaque. On the right is <strong>Cummins</strong> national account manager Nathan Usher.<br />

SRV owner Errol Cosgrove is a long-time user of Premium Blue oil.

16 NEWS<br />

NEWS<br />

17<br />

<strong>Cummins</strong> CEO applauds<br />

Male Champions of Change<br />

Australian Elizabeth Broderick, a powerful and influential global<br />

voice for gender equality, met with <strong>Cummins</strong> Chairman and CEO<br />

Tom Linebarger during his recent visit to Australia.<br />

Australia’s longest serving Sex Discrimination Commissioner (2007-2015), Broderick was<br />

recently appointed by the United Nations Human Rights Council in Geneva as an Independent<br />

Expert on discrimination against women.<br />

In 2010, Broderick founded the Male Champions of Change (MCC) movement in which<br />

<strong>Cummins</strong> South Pacific is now playing a key role through the leadership of Andrew Penca,<br />

Executive Director – <strong>Cummins</strong> Asia Pacific Distribution.<br />

The heart of the MCC strategy involves men of power and influence forming a high profile<br />

coalition to achieve change on gender equality issues in organisations and communities.<br />

Around 160 leaders across Australia – from business, government, the military and federal<br />

police – are now involved in the coalition.<br />

Andrew Penca has been instrumental in setting up a new group within MCC which brings<br />

together CEOs and managing directors from industries including transport, construction,<br />

heavy industry, chemicals, motor vehicles and technology.<br />

The group met for the first time recently, confirming their focus on advancing gender equality,<br />

inclusive cultures and achieving significant and sustainable improvements in the representation<br />

of women in their workplaces including senior leadership positions. The group includes leaders<br />

from PACCAR Australia, Komatsu, Meritor, General Motors Holden, Aggreko, BASF, Hanson<br />

Australia, Viva Energy, Konica Minolta and Transdev.<br />

“Three women in my life – my mother, wife and mother-in-law – have provided inspiration for<br />

me and I feel an obligation to ensure those who follow have it easier than they did and have<br />

the chance to reach their full potential,” said Penca.<br />

“The benefits of diversity and inclusion have been proven time and time again by empirical and<br />

anecdotal data alike. You get better outcomes from a more diverse group of people. Gender<br />

diversity is where we are starting with our MCC group as it is the one area that engages<br />

everyone.”<br />

In her meeting with Tom Linebarger, Broderick, who was keynote speaker at the <strong>Cummins</strong><br />

Asia Pacific Women’s Leadership Conference early this year, acknowledged <strong>Cummins</strong>’ long<br />

standing commitment to diversity. “It’s fantastic to look at the heritage of <strong>Cummins</strong> and the<br />

vision of J Irwin Miller, particularly for building a strong and diverse organisation,” she said.<br />

Linebarger said he was excited <strong>Cummins</strong> was involved in the Male Champions of Change<br />

program in the South Pacific. “<strong>Cummins</strong> is a company of values… those values are why<br />

I joined the company and what I care about as a leader,” he said. “Before I joined <strong>Cummins</strong><br />

I read a quote by Irwin Miller talking about the business case for diversity and I realised this<br />

was a company thinking about changing not only the workplace but also how to change the<br />

world in a positive way.<br />

“Diversity and inclusion is one of our major focus areas in our new Vision, Mission, Values<br />

statement. Why inclusion? To recognise that our leaders need to be proactive and reach<br />

out and include to create the right environment where diversity can thrive.<br />

“I believe that a diverse and inclusive workplace creates growth opportunities not just for<br />

women but for everyone and will enable all employees to meet their potential.” n<br />

<strong>Cummins</strong> Chairman and CEO Tom Linebarger (left) with Elizabeth Broderick<br />

and Andrew Penca.<br />

<strong>Cummins</strong> unveils electrified powertrain for buses<br />

<strong>Cummins</strong> revealed electrified power technology for transit bus<br />

applications at the recent APTA (American Public Transportation<br />

Association) show in Atlanta, US.<br />

<strong>Cummins</strong> displayed a new powertrain, configurable for either a full battery electric vehicle<br />

(BEV) or a range extended electric vehicle (REEV) incorporating a compact engine-generator.<br />

<strong>Cummins</strong>’ electrified power systems are ideally suited for integration into transit, shuttle and<br />

commuter buses enabling direct drive-by-wire continuous acceleration. With the bus operating<br />

in battery-only mode, the system achieves zero emissions at the point of use.<br />

Enhanced energy storage for both the BEV and REEV systems is achieved using <strong>Cummins</strong>’<br />

high-density battery enclosures, which are compact and modular allowing for both on-roof<br />

and chassis integration. <strong>Cummins</strong>’ unique design fits into existing bus designs.<br />

<strong>Cummins</strong>’ proprietary control technology enables the zero-emissions bus range to be extended<br />

by optimally managing subsystems, allowing the charge of the battery to be extended.<br />

Operational flexibility is also improved with fast recharge capability using a plug-in connection,<br />

as well as options for enroute charging when a pantograph or charge plate infrastructure is<br />

available.<br />

The standard-size <strong>Cummins</strong> battery enclosure provides a 70-kWh storage capability with<br />

up to eight enclosure units (560 kWh) suited for installation within the BEV bus. This enables<br />

a zero-emissions range of up to 360 km on a single charge.<br />

<strong>Cummins</strong>’ REEV system has a battery pack of three enclosures (210 kWh) which can provide<br />

a zero-emissions range of up to 135 km - a significant advantage over current hybrid bus<br />

capability. When the battery pack depletes to a low state-of-charge, the REEV system brings<br />

online a 1<strong>50</strong> kW (201 hp) engine-generator to recharge the batteries and continue operations<br />

with ultra-low emissions capability.<br />

Enhanced energy<br />

storage for both<br />

the BEV and REEV<br />

systems is achieved<br />

using <strong>Cummins</strong>’<br />

high-density battery<br />

enclosures.<br />

The REEV system’s ability to switch between shorter-range battery-only mode and extendedrange<br />

generator mode allows transit authorities to geofence specific downtown areas by<br />

utilizing <strong>Cummins</strong> over-the-air connected technology.<br />

“A key focus in the design of both our BEV and REEV systems ensures the electrified<br />

architecture is modular and adaptable to enable an easier technology transition for bus<br />

manufacturers,” said Brian Wilson, <strong>Cummins</strong> General Manager - Global Bus Business.<br />

“This allows transit authorities to continue using the same preferred bus models and retain<br />

fleet commonality.”<br />

The BEV and REEV systems incorporate the same traction motor and power electronics<br />

to deliver a continuous torque output of 18<strong>50</strong> Nm (1365 lb ft), eliminating the need for gear<br />

shifting and dramatically reducing powertrain noise. When the vehicle requires additional<br />

tractive power during rapid acceleration or while climbing gradients, the system can deliver<br />

an instant peak torque boost of up to 3400 Nm (2<strong>50</strong>8 lb ft) for a short period.<br />

Both systems provide a continuous electrical output of 225 kW (302 hp), increasing to a peak<br />

output of 3<strong>50</strong> kW (469 horsepower) when it senses the need for a power boost. The highvoltage<br />

system operates at a nominal 660V when battery state-of-charge is around <strong>50</strong> percent.<br />

Battery energy storage levels are boosted on-route by accepting “free” energy recovered<br />

through regenerative braking. On a frequent stop/start bus duty cycle, this could contribute<br />

the equivalent of 20% to the total state-of-charge. Electrical energy is also exportable from<br />

the <strong>Cummins</strong> system to all electric-powered accessories featured on the bus, such as e-power<br />

steering, e-HVAC, e-air compressors and e-cooling fans, adding up to a typical 25 kW (33 hp)<br />

load at any one time. n<br />

<strong>Cummins</strong> range<br />

extended electric<br />

vehicle (REEV)<br />

incorporating<br />

a compact<br />

engine-generator.<br />

New director for<br />

parts, service sales<br />

in South Pacific<br />

Julia Utan<br />

Julia Utan has been appointed<br />

Director - Parts and Service Sales<br />

for <strong>Cummins</strong> South Pacific.<br />

Prior to joining <strong>Cummins</strong> Julia was<br />

head of special original equipment for<br />

Hella Australia where she was responsible<br />

for sales and product management<br />

in the mining, construction, agriculture,<br />

marine, leisure vehicle and transportation<br />

industries.<br />

Before joining Hella, Julia held a variety<br />

of positions with Caterpillar over 12 years.<br />

A 6 Sigma Black Belt, she held roles in<br />

equipment management marketing, parts<br />

and services territory management and<br />

as a product support engineer.<br />

Julia holds a Bachelor of Engineering<br />

and MBA (Masters of Business<br />

Administration). n<br />

New branch managers in<br />

Darwin, Adelaide<br />

John Rhodes<br />

Philippa Heath<br />

John Rhodes has been appointed <strong>Cummins</strong> branch manager<br />

in Darwin with responsibility for operations in the Northern<br />

Territory, including Alice Springs.<br />

He was previously operations manager for <strong>Cummins</strong><br />

Campbellfield (Melbourne).<br />

John has been with <strong>Cummins</strong> for 13 years. He served his<br />

apprenticeship at <strong>Cummins</strong> Laverton (Melbourne) before<br />

becoming service advisor at the branch. He then moved to<br />

Campbellfield branch to become workshop manager and this<br />

was followed by roles as service manager and operations<br />

manager.<br />

John recently completed an MBA (Masters of Business<br />

Administration). n<br />

Philippa Heath has been appointed regional branch manager,<br />

based in Adelaide. She is responsible for <strong>Cummins</strong>’ operations<br />

in South Australia in Pooraka (Adelaide), Mt Gambier and Port<br />

Lincoln.<br />

Philippa has a proven track record in operations leadership,<br />

general management, business development, and human<br />

resources. She worked for Ai Automotive, led the Australian<br />

operations for Saxon (a Schlumberger company), and most<br />

recently was ‘Manager – People and Culture’ at Onkaparinga<br />

Council.<br />

She holds a Professional Diploma in Human Resources, a<br />

Diploma in Work Health and Safety, and Certificate IV TAE. n<br />

<strong>Cummins</strong> ups the ante in efforts to become electrified power leader<br />

An important milestone in <strong>Cummins</strong>’ efforts to become a global<br />

electrified power leader has been achieved with its acquisition of<br />

Brammo, Inc which designs and develops battery packs for mobile<br />

and stationary applications.<br />

"To be a leading provider of electrified power systems, just as we are with diesel and natural<br />

gas driven powertrains, we must own key elements and subsystems of the electrification<br />

network," said Tom Linebarger, Chairman and CEO, <strong>Cummins</strong> Inc.<br />

"By adding the expertise of Brammo and its employees to <strong>Cummins</strong>, we are taking a step<br />

forward in our electrification business and differentiating ourselves from our competition.<br />

As always, when markets are ready, <strong>Cummins</strong> will bring our customers the right power solution<br />

at the right time to power their success."<br />

Operations from the Brammo acquisition will continue to be based in Talent, Oregon.<br />

Founded in 2002, Brammo has made great strides in developing electric energy storage<br />

technology for mobile and stationary applications.<br />

“Brammo’s expertise across a broad range of applications uniquely positions us to enhance<br />

<strong>Cummins</strong>’ efforts to be a leader in the electrified power space,” said Craig Bramscher,<br />

Chairman and CEO of Brammo. “We see this as a very exciting opportunity to continue<br />

changing the way the world moves and stores power.”<br />

Frasers’ Mark Collins wins ATA award<br />

This acquisition adds to <strong>Cummins</strong>’ unmatched portfolio of solutions and provides an entry<br />

point into new markets. <strong>Cummins</strong> recently revealed a fully electric heavy-duty demonstration<br />

prime mover called Aeos (see article ‘Electric Shock’ on p.19). n<br />

Mark Collins from Frasers Livestock Transport has won the ATA’s prestigious <strong>2017</strong> Craig<br />

Roseneder Award which recognises technical and maintenance excellence and celebrates the<br />

professionalism of men and women who work behind the scenes in the trucking industry’s<br />

workshops.<br />

Collins, who has been with Warwick Qld-based Frasers for 35 years, won the award for his<br />

dedication to workshop and driver training, including TruckSafe inductions. n<br />

<strong>2017</strong> Craig Roseneder Award winner Mark Collins (second from right) with, from left,<br />

ATA chair Geoff Crouch; Deon Roseneder and Katerina Hickson; and Castrol’s Rod<br />

Barrett. Deon and Katerina are Craig Roseneder’s son and daughter.

18 ARTICLE NEWS THEME<br />

ARTICLE TECHNOLOGY THEME 19<br />

Frank Caddy:<br />

A <strong>Cummins</strong> legend<br />

Long serving <strong>Cummins</strong> WA state manager Frank Caddy passed away recently at the age of 82.<br />

Frank worked for <strong>Cummins</strong> for 32 years. He started in 1965, working for the then <strong>Cummins</strong><br />

Australia distributor, Blackwood Hodge, which operated as <strong>Cummins</strong> Diesel Sales & Service.<br />

He soon worked his way through the business into management and took on the role of<br />

national service manager working out of the Lansvale headquarters in Sydney.<br />

Frank was set the task of returning to Perth in 1972 to become the first WA state manager, a<br />

role he held until his retirement on June 30, 1997.<br />

During his tenure, Frank navigated <strong>Cummins</strong> in WA through significant growth periods in the<br />

iron ore and gold mining booms. He was pivotal in expanding the <strong>Cummins</strong> footprint in WA by<br />

opening branches in Kalgoorlie, Karratha and Bunbury. The growth was often rapid and Frank<br />

lead the only way he knew, from the front.<br />

In retirement Frank continued his volunteer work with the Fremantle War Museum, specialising<br />

in researching wartime history.<br />

He also worked on a publication to celebrate <strong>50</strong> years of <strong>Cummins</strong> in Western Australia and<br />

in 2000 ‘Moving Forward Looking Back’ was published – a tribute to Frank’s dedication and<br />

contribution to <strong>Cummins</strong> in this<br />

region.<br />

Frank Caddy’s<br />

book ‘Moving<br />

Forward<br />

Looking Back’<br />

celebrates<br />

<strong>50</strong> years<br />

of <strong>Cummins</strong><br />

in WA.<br />

“Frank was a kind and wonderful man<br />

of great knowledge and foresight.<br />

He lived a very full life right up until<br />

his passing and could talk with<br />

authority on any subject. He was a<br />

strong leader and a great mentor to<br />

many who he worked with, including<br />

myself,” said <strong>Cummins</strong> Perth’s Geoff<br />

Ironmonger. n<br />

Tracie is Trucking Industry<br />

Woman of the Year<br />

Tracie Dickenson of Daryl Dickenson Transport (Archerfield, Qld) is the ATA’s Trucking<br />

Industry Woman of the Year, an award sponsored by <strong>Cummins</strong> South Pacific.<br />

<strong>Cummins</strong> South Pacific managing director Stephanie Disher (left) with <strong>2017</strong> Trucking<br />

Industry Woman of the Year Tracie Dickenson and ATA Chair Geoff Crouch.<br />

Tracie’s father was a long-haul owner driver, so her association with road transport began early<br />

in her life. In 1990, she met Daryl, an interstate driver, and started travelling with him full-time,<br />

where she learnt about working interstate transport.<br />

ELECTRIC SHOCK<br />

Aeos unveiling at <strong>Cummins</strong> tech centre in<br />

Columbus, Indiana.<br />

Frank Caddy (left) with Geoff Ironmonger.<br />

Buddo’s tragic loss to livestock industry<br />

Alan ‘Buddo’ Grant.<br />

Queensland’s livestock trucking industry has<br />

mourned the passing of Alan “Buddo” Grant,<br />

one of its most iconic members. His death in<br />

Winton was described as a “tragic loss” by<br />

Ian Wild, Livestock and Rural Transporters<br />

Association of Queensland president.<br />

“He was a long-time member of our<br />

organisation and a strong advocate for anything<br />

rural transport related,” Wild said. “We will miss<br />

him for all his knowledge and support.”<br />

Buddo’s direct manner and can-do attitude saw his exploits become the stuff of folklore,<br />

spearheaded by his 1995 world record for Australia’s longest roadtrain. Achieved at the Winton<br />

Outback Festival that year, Buddo coordinated the feat, pulling 34 trailers, measuring 498<br />

metres, for two kilometres.<br />

Born and raised in Winton, Buddo was 55 at the time of his death.<br />

“Buddo was not only a great supporter and customer of <strong>Cummins</strong>, he was an even better mate<br />

to all of us at <strong>Cummins</strong> and his friendship will surely be missed,” said Col Baker, on-highway<br />

account manager for <strong>Cummins</strong> South Pacific. “The transport industry is very much relationship<br />

driven and Buddo was always willing to help our customers if in need around the Winton area<br />

and many will never forget this support.” n<br />

In 2001, operating from home, Tracie and Daryl formed Daryl Dickenson Transport with one<br />

truck and one full-time employee. In 2003, Daryl Dickenson Transport set up operation from its<br />

first depot in Wacol. Today the company has grown to a fleet of 40 trucks and more than 60<br />

employees with storage facilities in Yatala.<br />

Tracie is a hardworking, tenacious and passionate transport woman. She takes every<br />

opportunity to highlight the industry and promote its opportunities. To increase the<br />

professionalism of her personnel, Tracie supports workforce skilling and training in her<br />

business.<br />

Tracie is also a long-time supporter of RACQ LifeFlight. n<br />

Students revved up at truckload of generosity<br />

A partnership between TAFE NSW Wagga Wagga and <strong>Cummins</strong> has turned the key on a<br />

host of new hands-on learning opportunities for local students.<br />

The landmark deal has seen <strong>Cummins</strong> South Pacific hand over a state-of-the-art ISXe5<br />

training engine to the Wagga campus for use by apprentices studying Certificate III in<br />

Heavy Vehicle Mechanical Technology.<br />

In a further boost to students, Eaton has supplied a heavy vehicle transmission, and<br />

Wagga-based trucking firm Rodney’s Transport has pledged a special chassis to hold<br />

the engine and transmission.<br />

TAFE NSW regional general manager, Kerry Penton, said the donations were a stunning<br />

coup for the Wagga Wagga campus and thanked the companies for investing in the<br />

future of heavy vehicle maintenance in the region.<br />

“This is wonderful news for TAFE NSW and it shows what great corporate citizens<br />

<strong>Cummins</strong>, Eaton and Rodney’s Transport are,” Ms Penton said. “Attracting and training<br />

regionally based apprentices in heavy vehicle mechanics has long been a challenge, so<br />

anything that makes training easier is most welcome.”<br />

<strong>Cummins</strong>’ Asia Pacific technical training manager Warick Meldrum said the company<br />

was honoured to forge such an important industry partnership with TAFE NSW.<br />

“We want to support training institutions like TAFE NSW that do such a great job training<br />

our apprentices,” Mr Meldrum said. “We know how hard it is to get good quality, upto-date<br />

resources for training and this engine will help apprentices get the hands-on<br />

learning experiences they need.” n<br />

From left: Warick Meldrum – <strong>Cummins</strong> Asia<br />

Pacific technical training manager; Peter<br />

Gostelow – TAFE NSW; Raman Badekar –<br />

<strong>Cummins</strong> regional apprentice program manager;<br />

Alistair Whitsed – operations manager, <strong>Cummins</strong><br />

Wodonga; Jackson Meredith – operations<br />

manager, <strong>Cummins</strong> Leeton; Wayne Sibrey –<br />

TAFE NSW Wagga Wagga.<br />

<strong>Cummins</strong> has unveiled a concept truck with an<br />

all-electric powertrain, highlighting the company’s<br />

commitment to electric power as an important part<br />

of its future.<br />

The zero-emissions two-axle urban delivery prime mover - dubbed Aeos - was revealed at<br />

<strong>Cummins</strong>’ technical center in Columbus, Indiana, USA, featuring a production-intent <strong>Cummins</strong><br />

electric power module.<br />

The Aeos demonstration truck - named for one of the four flying horses in Greek mythology<br />

that pulled the chariot of the sun god Helios across the sky - will mainly be an engineering tool,<br />

but there are also plans to put the vehicle into commercial service with a few carriers.<br />

The company also announced plans to introduce a revolutionary heavy-duty diesel engine<br />

design in 2022. A prototype was on display at the event.<br />

<strong>Cummins</strong> is determined to be the supplier of choice for whatever powertrain technologies<br />

customers demand - conventional diesel, alternative fuels and various electric architectures.<br />

Massive torque, zero emissions.<br />

Julie Furber, executive director of <strong>Cummins</strong>’ electrified power business, said Aeos weighs no<br />

more than its diesel-powered counterparts but provides greater performance and generates<br />

zero emissions.<br />

Range with its single 140 kilowatt-hour battery pack is 160 km, which can be boosted to 480<br />

km with a second battery. The battery’s lighter, denser design enables it to hold a longer charge<br />

for improved range and faster charging to reduce downtime.<br />

With today’s technology, the battery takes an hour to charge, but <strong>Cummins</strong> is predicting that<br />

battery advances in the interim will cut this charge time to 20 minutes by 2019.<br />

Furber said <strong>Cummins</strong> is not interested in becoming a truck manufacturer but is keen to help<br />

manufacturers develop electric powertrains.<br />

The electric motor offers peak power of 470 hp (3<strong>50</strong> kW) and a continuous rating of 300 hp<br />

(225 kW) with a massive 2<strong>50</strong>0 lb ft (3400 Nm) of torque at peak and 1365 lb ft (18<strong>50</strong> Nm)<br />

continuously. With this torque, the truck accelerates 25-35% faster than a 12-litre diesel<br />

powered equivalent vehicle.<br />

Diesel…for years to come.<br />

For many markets, <strong>Cummins</strong> believes diesel engines will be the best solution for years to<br />

come. However, the company’s energy-diverse products demonstrate it is prepared to win with<br />

new and future technologies.<br />

<strong>Cummins</strong> has previously stated that by the time the company celebrates its 100th birthday in<br />

2019, it will have launched a fully electric powertrain.<br />

The electric architectures <strong>Cummins</strong> is pursuing include pure electric using only batteries,<br />

electric powertrain with range-extending power generation that could someday use fuelcell<br />

technology from supplier partners, and hybrid power systems with smaller diesels<br />

complemented by electric drive. n<br />

Aeos accelerates 25-35% faster than a 12-litre<br />

diesel powered equivalent vehicle.<br />

Where’s the engine?<br />

<strong>Cummins</strong> will launch a fully electrified powertrain in 2019.

20 BOATBUILDING<br />

FLEET EFFICIENCY 21<br />

THERE’S NO CAT-NAPPING HERE!<br />

HUMBLE BEGINNING<br />

NO<br />

BARRIER<br />

TO<br />

AMBITION<br />

Craig Sargent (centre) with <strong>Cummins</strong> Leeton’s Jackson<br />

Meredith (left) and Inland Truck Centres’ David Warren.<br />

Visiting the <strong>Cummins</strong> Tech<br />

Centre was mind-blowing…<br />

Volunteer Marine Rescue vessel<br />

powered by twin 480 hp <strong>Cummins</strong><br />

QSB6.7 engines.<br />

Underpinning search and rescue<br />

operations around Australia is<br />

an internationally recognised<br />

boatbuilder on Queensland’s<br />

Sunshine Coast that builds a range<br />

of vessels noted for their rough<br />

water performance.<br />

More than most boats, a Noosa Cat is going to be used in<br />

rough water. It’s part of the Noosa Cat DNA.<br />

The latest vessel built by Noosa Cat for this type of operation<br />

is a <strong>Cummins</strong>-powered 12-metre flybridge for Volunteer Marine<br />

Rescue (VMR) Whitsunday – a squadron of Marine Rescue<br />

Queensland based at Shute Harbour near Airlie Beach. The<br />

squadron, which typically has around 80 ‘activations’ a year,<br />

states its main objective is to ‘save lives at sea’.<br />

The $800,000 vessel is propelled by dual <strong>Cummins</strong> QSB6.7<br />

engines rated at 480 hp, punching out a cruise speed of 25<br />

knots and a top speed of 28.5 knots.<br />

“We had high expectations for the Noosa Cat and it has met<br />

those expectations,” says Ray Lewis, president of<br />

VMR Whitsunday.<br />

Rough water performance.<br />

He points out that VMR Whitsunday contacted every Coast<br />

Guard and VMR squadron with a Noosa Cat to get feedback<br />

on the brand before deciding to buy its vessel. “Noosa Cat’s<br />

reputation for rough water performance was one of the key<br />

reasons we opted for the brand,” says Lewis.<br />

The performance of the 6.7-litre <strong>Cummins</strong> engines hasn’t<br />

disappointed either. “There’s plenty of horsepower available,”<br />

he adds. The QSB’s reputation for reliability and durability<br />

along with <strong>Cummins</strong>’ service support capability were other<br />

important factors in the purchasing decision.<br />

So what’s the story behind Noosa Cat? It’s really a story about<br />

Wayne Hennig and the success he has achieved in one of the<br />

most volatile industries on the planet. He has charted a steady<br />

course through downturns, recessions and whatever other<br />

hurdles have been thrown up.<br />

At the time of writing (mid-July), Noosa Cat had orders that<br />

would take until late 2018 to complete.<br />

Noosa Cat vessels are now in use all over Australia: Search<br />

and rescue services, water police, Coast Guards and<br />

other such organisations consistently turn to the fibreglass<br />

catamaran manufacturer for vessels. It’s not surprising as the<br />

build quality and performance for intended purpose are second<br />

to none.<br />

In addition, the Noosa company has built hundreds more<br />

vessels – from 5.0 to 15 metres – for various other levels of<br />

Noosa Cat owner Wayne Hennig (right) with<br />

<strong>Cummins</strong> Brisbane’s Justin Kelty.<br />

commercial and leisure usage. Many owners would claim<br />

Noosa Cat builds the best fishing boat in the country, and it’s<br />

easy to understand why.<br />

Mechanic turned pro fisherman.<br />

Wayne Hennig takes up the story: “I was a professional<br />

fisherman and also owned a service station at Nambour<br />

(on Queensland’s Sunshine Coast) before getting into<br />

boatbuilding,” he recalls. “I’m actually a mechanic by trade.<br />

“Why did I start building boats? Basically, I couldn’t get exactly<br />

what I wanted as a fisherman. I started pro fishing in 1978<br />

with an alloy cat but it started cracking after 19 hours. That’s<br />

how I learned to weld aluminium.”<br />

One of the first vessels he built was a 7.0-metre crab boat<br />

powered by a single diesel engine. He went on to build six all<br />

up as the business started growing through word-of-mouth<br />

We had high<br />

expectations for<br />

the Noosa Cat and<br />

it has met those<br />

expectations.<br />

marketing. In 1990 Noosa Cat was established at a factory in<br />

Noosaville, where the business is still based today.<br />

The basis of the Noosa Cat range was the famous Shark Cat<br />

design, with Wayne Hennig buying all the Shark Cat moulds<br />

for vessels up to 8.0 metres. However, what he purchased<br />

back then has almost no relationship to what Noosa Cat is<br />

producing today – a vastly more sophisticated vessel.<br />

He says Noosa Cat has “upped the ante” in development over<br />

the last 10 years. “There haven’t been massive changes,” he<br />

states. “Rather, our boats have evolved… an evolution that<br />

has been subtle and constant. Our structures have become<br />

stronger but lighter, our hulls have become more efficient in a<br />

speed-for-horsepower equation.”<br />

Vessels in the Noosa Cat range today cost from around<br />

$<strong>50</strong>,000 to $1.5 million – a small price to pay for the<br />

seaworthiness, stability, speed and rough water capability that<br />