MI 2020 Solutions FINAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SECTION 02<br />

RENEWABLE ENERGY<br />

05<br />

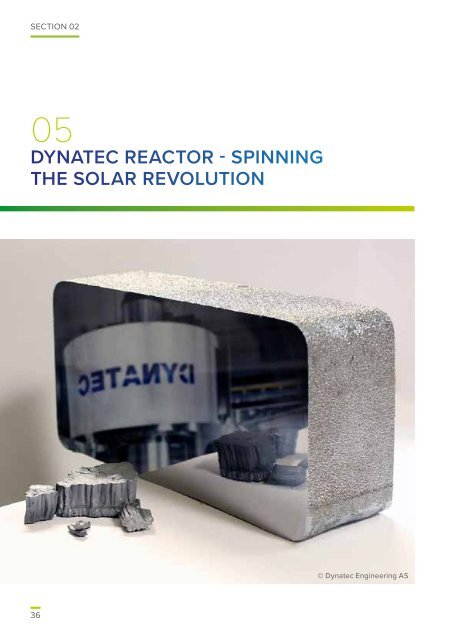

DYNATEC REACTOR - SPINNING<br />

THE SOLAR REVOLUTION<br />

© Dynatec Engineering AS<br />

CHALLENGE<br />

Producing solar panels requires<br />

the purification of silicon, which<br />

is a slow and energy intensive<br />

process. Currently production<br />

of solar grade silicon is primarily<br />

carried out using the Siemens<br />

reactor. Silicon rods are heated to<br />

between 800 and 1,100 degrees<br />

Celsius, and a silicon containing<br />

gas is injected and thermally<br />

decomposed releasing silicon<br />

that is deposited onto the rods.<br />

To prevent silicon growth on the<br />

walls, these are kept at below<br />

200 degrees Celsius.<br />

INNOVATION<br />

Dynatec has produced a<br />

centrifugal reactor which lowers<br />

the energy intensity of refining<br />

silicon in solar panel production<br />

by 90% compared to the<br />

decomposition reactors currently<br />

in use.<br />

Instead of keeping hot elements<br />

inside a cool chamber, with<br />

Dynatec’s reactor the deposition<br />

takes place on the walls. The<br />

whole reactor is also set into<br />

rotation and built as a centrifuge.<br />

By inverting the process, it is<br />

possible to grow the silicon<br />

without maintaining large<br />

temperature differences.<br />

ACTION<br />

With support from the Research<br />

Council of Norway, Dynatec<br />

has built two demonstration<br />

reactors. The energy consumption<br />

of a decomposition reactor is<br />

currently about 70 kwh/kg, while<br />

the new centrifugal reactor has<br />

demonstrated production of<br />

first grade silicon at less than<br />

5kwh/kg.<br />

POTENTIAL<br />

Having already built two<br />

successful demonstration reactors<br />

the company is now building a<br />

full-scale industrial reactor in<br />

cooperation with a customer.<br />

Dynatec has also founded two<br />

spin off companies where the<br />

centrifugal reactor is to be used<br />

differently and refitted to make<br />

silicon nano-particles of similar<br />

shape and size for both battery<br />

and medical applications.<br />

USEFUL LINKS:<br />

sciencenordic.com/speedyproduction-silicon-solar-cells<br />

NORWAY<br />

36 37