You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

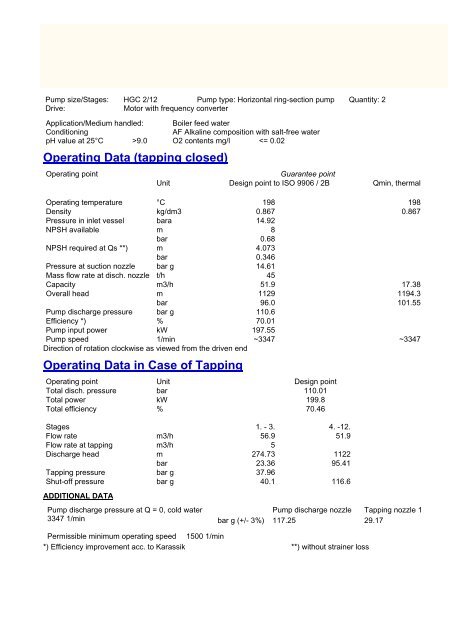

Pump size/Stages: <strong>HGC</strong> 2/<strong>12</strong> Pump type: Horizontal ring-section pump Quantity: 2<br />

Drive:<br />

Motor with frequency converter<br />

Application/Medium handled: Boiler feed water<br />

Conditioning<br />

AF Alkaline composition with salt-free water<br />

pH value at 25°C >9.0 O2 contents mg/l

Type / size Speed [1/min] Temperature [°C] Density [kg/dm3]<br />

HG 2/<strong>12</strong> 4.1 4.1 3347 198 0.867<br />

Qmin, continuous<br />

1000<br />

Qmin, thermal<br />

Qmax<br />

Discharge head<br />

[m]<br />

500<br />

0 20 [m3/h] 40 60 80 100<br />

16<br />

[m]<br />

NPSH req.<br />

10<br />

2<br />

0 20 [m3/h] 40 60 80 100<br />

Efficiency<br />

50<br />

[% ]<br />

0<br />

0 20 [m3/h] 40 60 80 100<br />

300<br />

[kW ]<br />

Power<br />

200<br />

50<br />

0 20 [m3/h] 40 60 80 100

Nozzle Design DN PN Drilled acc to Position [°] *)<br />

Inlet Flange 80 40 EN 1092-1 vertically upwards<br />

Outlet Block flange 65 160 EN 1092-1 vertically upwards<br />

Tapping Flange 40 63 EN 1092-1 45.0<br />

*) clockwise viewed from the driven end ( 0° = top)<br />

Shaft Seal Manufacturer Type Material Cooling<br />

Mech. seal Burgmann H75N AQ1EGG Circulation and jacket cooling<br />

Cooler KSB DWK 10<br />

Axial thrust balancing<br />

Hydraulically by means of Disc<br />

Bearing Design Lubrication Cooling Indicator<br />

Radial Plain bearing Oil ring No Oil level indicator with<br />

marking<br />

Thrust - - -<br />

Pump Feet Arrangement<br />

Centreline<br />

Accessories<br />

Balancing water pipe return to the deaerator tank including angle-way safety relief valve<br />

Internal piping for circulation and jacket cooling<br />

Instrumentation acc. to list of measuring points<br />

Special tools and appliances 1 set<br />

Baseplate for pump and motor (with foundation bolts)<br />

Material<br />

Part No. Description Material<br />

106 Suction casing 1.4317-I<br />

107 Discharge casing S355J2G3+PLATT<br />

108 Stage casing 1.4006+QT<br />

171 Diffuser 1.4008<br />

210 Shaft C45+C+GAL CR<br />

230.01 Suction stage impeller 1.4008.09<br />

230.02 Impeller 1.4008.09<br />

441 Shaft seal housing 1.4021+QT700<br />

502.02 Casing wear ring RWA 350<br />

523.01 Shaft sleeve 1.4138<br />

601.01 Balance disc 1.4024.09<br />

602.01 Balance disc seat RWA 350

Lubricant Quality (recommendation)<br />

ISO high-quality oil VG 32 or VG 46 to DIN ISO 3448, TD 32 or TD 46 to DIN 51515, or equivalent.<br />

If a gear or geared variable speed coupling is included in the scope of supply, observe the manufacturer's<br />

instructions.<br />

Lubricant Quantities<br />

Bearing Lubrication Quantity Unit<br />

Radial bearing Oil ring 1.5 Liter<br />

Coupling Type Lubricant Quantity Unit<br />

Pump - motor ZIZS 2 Grease 0.16 dm3<br />

Cooling water quality (recommendation)<br />

Only cleaned water not liable to precipitation of salts causing hardness may be used as coolant. The cooling water<br />

temperature at the outlet must not exceed 55 °C. (131 F)<br />

Cooling water requirement<br />

Quantity<br />

Unit<br />

Jacket cooling 3.52 l/min<br />

Circulation 6.49 l/min<br />

Normal<br />

Maximum<br />

Inlet temperature [°C] 20 45<br />

Minimum<br />

Maximum<br />

Cooling water pressure [bar] 2 6

1. Explanatory Notes<br />

The noise data below conform to DIN standard 45635 - Measurement of noise emitted by machines - Part 1 – Airborne noise emission,<br />

Enveloping surface method, Basic method divided into 3 grades of accuracy and Part 24 – Measurement of airborne noise emitted by<br />

machines, Enveloping surface method, Liquid pumps.<br />

The noise data meet the requirements of accuracy grade 2.<br />

DIN 45635 standards for measurement largely correspond to international stipulations such as EN ISO 3744-09.1994 and<br />

ISO 1<strong>12</strong>01-<strong>12</strong>.1995.<br />

The equipment used for measurements meet the requirements placed on precision sound level meters DIN EN 60651.<br />

It was submitted to the standardising authority for examination within the required period of 2 years.<br />

The non-weighted and A-weighted sound pressure levels were used as acoustic measurands expressed in dB.<br />

The frequency weighting curve A is defined in DIN EN 60651.<br />

2. Prerequisites<br />

The noise data refer to the pump without sound insulation.<br />

The data apply without electric motor.<br />

The noise particulars apply to the normal operating range of the pump, i.e. Q/Qopt = 0.8 – 1.2<br />

No allowance is made for operation under extreme part-load, overload or cavitation conditions.<br />

3. Definitions<br />

LpA: The surface sound pressure level is the A-weighted sound pressure level averaged over the measurement surface S, expressed in dB.<br />

LS: The measurement surface ratio is calculated from the measurement surface S, whose size depends on the position of the measuring<br />

points.<br />

The measurement distance is typically chosen to be 1 m from the machine outline. LS is expressed in dB.<br />

LWA: The A-weighted sound power level is the rate of the total noise radiated by the machine into the ambient air, expressed in dB.<br />

The air-borne sound octave spectrum supplements the surface sound pressure level LpA data and provides information on the noise<br />

composition in the acoustic frequency range from 63 Hz to 8 kHz.<br />

This frequency range is subdivided in octave bands characterised by their centre frequency.<br />

4. Noise Characteristic Values<br />

The following values are expected noise values and cannot be warranted. The values indicated do not include the measurement tolerance.<br />

If the values are to be warranted, an allowance for design and measurement tolerances of +3 dB has to be made.<br />

Noise Characteristics for Operating Point (expected values)<br />

Operating point - pump: Q [m3/h] H [m] P [kW]<br />

51.9 1<strong>12</strong>8.4<br />

It. Component Description N LpA LS LWA<br />

[1/min] [dB] [dB] [dB]<br />

1 Pump <strong>HGC</strong> 2/<strong>12</strong> 3347 83 14 97<br />

Total of items 1 83 14 97<br />

Air-borne sound octave spectr. in 63 Hz <strong>12</strong>5 Hz 250 Hz 500Hz 1000 2000 4000 8000<br />

dB for item 1 75 71 73 76 Hz 79 Hz 78 Hz 74 Hz 71

Pump - motor<br />

Manufacturer<br />

FLENDER<br />

Type / size ZIZS 2<br />

Coupling type<br />

Tooth coupling<br />

Mass 23.1 kg<br />

Quantity 2<br />

Spacer for shaft distance 180 mm<br />

Retaining ring<br />

No<br />

Lubrication<br />

Grease<br />

Max. bore 80 mm<br />

Spacer plates<br />

1 set<br />

Coupling guard<br />

Sheet steel<br />

Balancing quality Q 2,5

The minimum flow valve protects the pump against overheating during operation in the low load range. Increased<br />

wear on the pump and the minimum flow system is not avoidable.<br />

If the installation's mode of operation requires low load, at flow rates below 1.35 x Qmin (e.g. operation at extremely<br />

low flow, filling of the boiler, stand-by heating and minimum flow rate, etc.), notification thereof shall be given. In this<br />

case, a minimum flow valve with branch for manual operation must be used.<br />

The characteristics of the boiler control valve can influence the behaviour of the minimum flow valve, and the valve<br />

must be suitable for low flow operation.<br />

2 Minimum flow control valve<br />

Manufacturer:<br />

SCHROEDER<br />

Type series: SSV 18 A Scheme No. UA429759<br />

Inlet branch DN 65 PN 160 EN 1092-1<br />

Outlet branch DN 65 PN 160 EN 1092-1<br />

Bypass DN 40 PN 160 EN 1092-1<br />

including screws/bolts and seal elements for the connection pump – minimum flow control valve

INDEX<br />

MINDESTFÖRDERSTROMVENTIL UND ENTLASTUNGSFLÜSSIGKEITSRÜCKFÜHRUNG<br />

MINIMUM FLOW DEVICE AND BALANCING LIQUID RETURN<br />

Entlastungsflüssigkeit-Rückführung zum Zulaufbe<br />

hälter.<br />

Bei Leitungslängen >10 m ist eine Erweiterung von<br />

DN25 auf DN40 bzw. von DN40 auf DN50 erforder<br />

lich. Max. Länge 30 m.<br />

Balancing liquid return to feed water tank.<br />

Return line length >10 m require an enlargement from<br />

DN25 to DN40 resp. from DN40 to DN50.<br />

Max. length 30 m.<br />

Blende zur Vermeidung<br />

der Verd<strong>amp</strong>fung in der<br />

Leitung. So nahe wie<br />

möglich am Zulaufbe<br />

hälter.<br />

Orifice to prevent evapo<br />

ration in the line. Located<br />

as close as possible to<br />

the feed water tank.<br />

Dp = 2.5 bar<br />

Dp = 36.25 psi<br />

Zulaufbehälter<br />

Feed water tank<br />

Mindestförderstrom zum Zulaufbehälter<br />

Minimum flow outlet to feed water tank<br />

B<br />

A<br />

A B<br />

B<br />

A<br />

B<br />

A<br />

nur bei Mindestförder<br />

stromventil SMA63<br />

only for minimum flow<br />

valve SMA63<br />

B<br />

A<br />

Absperrventil, geschweißt<br />

Stop valve, welded<br />

A<br />

B<br />

Rückschlagventil, geschweißt<br />

Non-return valve, welded<br />

Kundenseitige Abführung an<br />

einen sicheren Ort.<br />

Discharge to a safe place to<br />

be provided by the customer.<br />

B<br />

A<br />

Sicherheitsventil<br />

Safety valve<br />

Blende<br />

Orifice<br />

Flanschverbindung<br />

Flange connection<br />

Liefergrenze, A = KSB, B = Kunde<br />

Limits of scope of supply, A = KSB, B = Customer<br />

05<br />

neues Original<br />

ÄNDERUNG<br />

ALTERATION<br />

NORM<br />

STANDARD<br />

GEPRÜFT<br />

APPROVED<br />

BEARB.<br />

PREPARED<br />

T-MP132-G<br />

02.04.03<br />

02.04.03<br />

DATUM<br />

DATE<br />

02.04.03<br />

DATUM<br />

DATE<br />

Meyer<br />

Stahl<br />

NAME<br />

Stahl<br />

NAME<br />

BENENNUNG/DENOMINATION<br />

Fließschema<br />

Flow Diagram<br />

NR./NO.<br />

UA4 29759 01 EN<br />

SCHUTZVERMERK ISO 16016<br />

COPYRIGHT ACCORDING TO ISO 16016<br />

ERS. FÜR/REPL. FOR<br />

ENTST. AUS/ORIGINAT. FROM<br />

BLATT-NR.<br />

SHEET-NO.<br />

1<br />

ANZ. D.<br />

BLÄTTER<br />

NO. OF<br />

SHEETS<br />

1

The strainer in the inlet pipe serves as an additional pump protection and is destined to hold back welding beads,<br />

scale and other impurities (>500µm) from the pump. It is not intended to as a filtration system, since the gaps within<br />

the pumps are smaller than 500µm. A strainer with smaller mesh width can be quoted as an additional option. In any<br />

case, a filtration system must be installed by customer, independent from the mesh size of the strainer.<br />

Main pump<br />

Type<br />

Conical strainer<br />

Standard ZN 1364<br />

Manufacturer<br />

FIEDLER<br />

Type<br />

AF<br />

Quantity 2<br />

Installation<br />

Vertical<br />

Weight kg 1.3<br />

DN DN: <strong>12</strong>5<br />

Type<br />

Perforated plate with fine wire mesh<br />

(0.5x0.25 mm)<br />

Material<br />

CrNiSt<br />

Length mm 500<br />

Head loss m 0.34 (with clean strainer)<br />

Strainer casing<br />

Length<br />

555 mm<br />

DN / PN <strong>12</strong>5 / 40

Meas.<br />

point<br />

No.<br />

Location of measuring point<br />

Medium/Material<br />

PI 101 Pump suction pressure<br />

Suction nozzle<br />

Feed pump<br />

Feed water<br />

PI 102 Pump discharge pressue<br />

Discharge nozzle<br />

Feed pump<br />

Feed water<br />

PI 103 Tapping pressure<br />

Tapping nozzle<br />

Feed pump<br />

Feed water<br />

PI 104 Balancing water pressure<br />

Balancing water line<br />

Feed pump<br />

Feed water<br />

PDIA<br />

101<br />

TI 103<br />

TI 104<br />

TAZ<br />

105<br />

TAZ<br />

106<br />

Differential pressure<br />

Strainer<br />

Feed pump<br />

Feed water<br />

Oil temperature<br />

Radial bearing, DE<br />

Feed pump<br />

Oil<br />

Oil temperature<br />

Radial bearing, NDE<br />

Feed pump<br />

Oil<br />

Bearing temperature<br />

Radial bearing, DE<br />

Feed pump<br />

Metal<br />

Bearing temperature<br />

Radial bearing, NDE<br />

Feed pump<br />

Metal<br />

YE 103 Shock pulse measurement<br />

Driven end<br />

YE 104 Shock pulse measurement<br />

Non-driven end<br />

Type<br />

Scope of supply<br />

Pressure gauge<br />

KSB<br />

Pressure gauge<br />

KSB<br />

Pressure gauge<br />

KSB<br />

Pressure gauge<br />

KSB<br />

Measuring<br />

range<br />

Housing<br />

diameter<br />

Threaded<br />

connect.<br />

0 - 25 bar<br />

100 mm<br />

G 1/2 A<br />

0 - 160 bar<br />

100 mm<br />

G 1/2 A<br />

0 - 100 bar<br />

100 mm<br />

G 1/2 A<br />

0 - 25 bar<br />

100 mm<br />

G 1/2 A<br />

Differential pressure 0-1,0 bar<br />

gauge with magnetic 100 mm<br />

snap-action contact G 1/2<br />

KSB<br />

Thermometer<br />

KSB<br />

Thermometer<br />

KSB<br />

RTD, 1 x PT 100<br />

KSB<br />

RTD, 1 x PT 100<br />

KSB<br />

SPM nipple<br />

KSB<br />

SPM nipple<br />

KSB<br />

0 - 100 ° C<br />

150 mm<br />

G 1/2A<br />

0 - 100 ° C<br />

150 mm<br />

G 1/2A<br />

-<br />

-<br />

M18 x 1,5<br />

x 11<br />

-<br />

-<br />

M18 x 1,5<br />

x 11<br />

M8<br />

M8<br />

Measuring Instrument<br />

Sensor Indication /<br />

length Interlocking<br />

Diameter<br />

d<br />

Local<br />

Local<br />

Local<br />

Local<br />

Make<br />

Drawing No.<br />

DIN No.<br />

Ident. No.<br />

WIKA<br />

ZN 16064<br />

00402207<br />

WIKA<br />

ZN 16064<br />

00402211<br />

WIKA<br />

ZN 16064<br />

00402210<br />

WIKA<br />

Remarks<br />

With<br />

pressure<br />

gauge valve<br />

With<br />

pressure<br />

gauge valve<br />

With<br />

pressure<br />

gauge valve<br />

With<br />

pressure<br />

gauge valve<br />

ZN 16064<br />

00402207<br />

Local with contact WIKA With<br />

pressure<br />

gauge valce<br />

160 mm SIKA oder WIKA<br />

DIN 16185<br />

00402376<br />

160 mm SIKA oder WIKA<br />

<strong>12</strong>0 mm<br />

4 / 6 mm<br />

<strong>12</strong>0 mm<br />

4 / 6 mm<br />

PB alarm T => 90 °C<br />

PB switch-off T =><br />

100 °C<br />

PB alarm T => 90 °C<br />

PB switch-off T =><br />

100 °C<br />

DIN 16185<br />

00402376<br />

WIKA oder<br />

RECKMANN<br />

ZN 1477<br />

01058630<br />

WIKA oder<br />

RECKMANN<br />

ZN 1477<br />

01058630<br />

-<br />

ZN 407<br />

00<strong>12</strong>9477<br />

-<br />

ZN 407<br />

00<strong>12</strong>9477

Quality Class according to ZN 35 – 4<br />

EN<br />

Coating<br />

type<br />

Permissible<br />

temperature<br />

range<br />

Surface<br />

preparation<br />

Primer<br />

Finish coat<br />

A<br />

B<br />

C<br />

-30 to +80 [°C]<br />

-22 to +176 [F]<br />

-30 to +80 [°C]<br />

-22 to +176 [F]<br />

+80 to +400 [°C]<br />

+176 to +752 [F]<br />

Degreased by<br />

solvent<br />

Sand-blasting<br />

SA 1<br />

Degreased by<br />

solvent<br />

Product name<br />

Luberhyd 1K<br />

Luberhyd 1K<br />

Colour type and film<br />

thickness [µm]<br />

Hydro dip primer,<br />

water-thinned<br />

1 x approx. 40-50<br />

Hydro dip primer,<br />

water-thinned<br />

1 x approx. 40-50<br />

Product name<br />

Luberhyd<br />

Luberhyd<br />

- - Lubersil 1-<br />

component<br />

varnish paint<br />

Colour type and film<br />

thickness [µm]<br />

Acrylate-alkyd<br />

compound, waterthinned<br />

1 x approx. 40-50<br />

Acrylate-alkyd<br />

compound, waterthinned<br />

1 x approx. 40-50<br />

Silicon resin compound,<br />

water-thinned<br />

1 x approx. 30-40<br />

Colour<br />

RAL<br />

5002<br />

ultramarine<br />

blue<br />

RAL<br />

5002<br />

ultramarine<br />

blue<br />

Metallic<br />

silver<br />

Coating Type and Colour<br />

Item *) Coating type RAL No.<br />

Pump C RAL 9006<br />

Coupling guard A RAL 5002<br />

Oil lines A RAL 5002<br />

Cooling water lines A RAL 5002<br />

Baseplate B RAL 5002<br />

Balancing water pipe, pressure gauge line, C RAL 9006<br />

pre-warming line<br />

Min. flow control valve with auxiliary valves Manufacturer's standard Manufacturer's standard<br />

Gear / variable speed coupling Manufacturer's standard Manufacturer's standard<br />

Strainer body C RAL 9006<br />

*) if included in scope of supply<br />

Preservation for pump removed from system (indoor storage). Period and measures.<br />

Storage of pump < <strong>12</strong> months<br />

Pump is preserved after performance test<br />

(Anticorit 87, Fuchs Mineralölwerke GmbH)

Documentation, drawings Scheduled date *)<br />

Installation plan + forces and moments<br />

Sectional drawing<br />

List of components<br />

Standard P+ I diagram<br />

List of measuring points<br />

PO+4<br />

PO+<strong>12</strong><br />

PO+<strong>12</strong><br />

PO+8<br />

PO+8<br />

Language:<br />

English<br />

Quality documentation Scheduled date *)<br />

Declaration of quality<br />

D<br />

Test curve, record D-1<br />

Balancing record<br />

Pressure test record<br />

Language:<br />

German / English<br />

Kind of documentation<br />

Quantity<br />

Documentation on CD-ROM 1<br />

Instruction manual Scheduled date Quantity<br />

Instruction manual on CD-ROM D 1<br />

Language:<br />

English<br />

*) PO+n: n weeks after purchase order<br />

D: on delivery, D-n: n weeks before delivery

Material inspections<br />

Standard QCP / acceptance class ZN 57 117 / 1<br />

Certification<br />

Declaration of quality<br />

Language of certificate<br />

German / English (depending on supplier)<br />

Pressure test (dynamic)<br />

Standard pressure test plan UA4 11390 02<br />

Test pressure<br />

1.3 x nominal pressure<br />

Suction casing 19 barg<br />

Chamber to disch. casing<br />

Different for each stage<br />

Tapping casing 57.73 barg<br />

Discharge casing 165 barg<br />

Seal housing / balancing water chamber 19 barg<br />

Hydraulic performance test<br />

Performance test procedure<br />

Test curve no.<br />

Test class<br />

ISO 9906 / 2B<br />

No. of Q/H curve meas. points 5 No. of NPSH flow points 0<br />

Pumps per order inspected/tested Quantity - non-witnessed Quantity - witnessed<br />

Pressure test 2 0<br />

Performance test *) 2 0<br />

NPSH test 0 0<br />

Invitation time for witnessed inspections/tests 5 Working days<br />

For witn. and special insp./tests: take into account delivery time<br />

*) Pumps will be tested with closed tapping, tapping pressure will be recorded

1. Explanations<br />

DE vert.<br />

NDE vert.<br />

DE horiz.<br />

axial<br />

NDE horiz.<br />

KSB’s HG pumps are designed for compliance with the vibration velocity limits according to nach DIN ISO 10816-7, category I. These are<br />

determined as overall root-mean-square values v eff [mm/s] in the frequency range of 10 – 1000 Hz.<br />

The permissible root-mean-square value of the vibration velocity is determined by the type of assembly and the evaluation zone B.<br />

The following applies to HG pumps, all values in mm/s<br />

Preferred operating range<br />

Permitted operating range<br />

200 kW / 268 hp 200 kW / 268 hp<br />

Site of installation 2,5 3,5 4,0 5,0<br />

Acceptance test in KSB test bed 3,3 4,3 4,0 5,0<br />

The measurement points are schematically represented in the figure above.<br />

NDE: Non Drive End DE: Drive End<br />

2. Prerequisites<br />

The above-mentioned vibration velocity values shall apply under the following conditions:<br />

1. Measurement of vibrations in steady-state operation at nominal speed or within the specified speed range (not under transient<br />

operating conditions, not with changing speeds or loads).<br />

Measurement at nominal flow rate or in the preferred operating range of between 0.7 .... 1.2 x Q opt (extreme part load or overload as<br />

well as operation at cavitation are excluded), permitted operating range is defined as 0,5 .... 1.25 x Q opt .<br />

2. The measurements are performed at the positions indicated using vibration velocity sensors. Only measuring instruments that were<br />

calibrated within the framework of the applicable quality assurance system are used.<br />

3. Measurement of vibration velocity in the installation/plant:<br />

For operation in the installation/plant, the machine has to be installed in compliance with the instruction manual.