a complete line of quality seals - Mechanical Parts Suppliers ...

a complete line of quality seals - Mechanical Parts Suppliers ...

a complete line of quality seals - Mechanical Parts Suppliers ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

148<br />

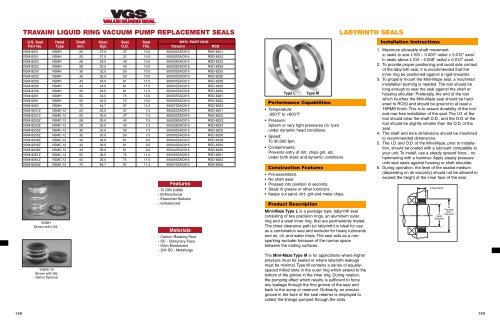

TRAVAINI LIQUID RING VACUUM PUMP REPLACEMENT SEALS<br />

U.S. Seal Head Shaft Oper. Seat Seat MFG. PART NOS.<br />

Part No. Type mm. Hgt. O.D. Thk. Travaini RSD<br />

VGM-8251 VGMH 22 27.5 37 10.0 950022SAC915 RSD-8251<br />

VGM-8251 VGMH 22 27.5 37 10.0 950022SAC916 RSD-8252<br />

VGM-8253 VGMH 28 32.5 43 10.0 950028SAC915 RSD-8253<br />

VGM-8253 VGMH 28 32.5 43 10.0 950028SAC916 RSD-8254<br />

VGM-8255 VGMH 35 32.5 50 10.0 950035SAC915 RSD-8255<br />

VGM-8255 VGMH 35 32.5 50 10.0 950035SAC916 RSD-8256<br />

VGM-8258 VGMH 43 34.0 61 11.0 950043SAC912 RSD-8258<br />

VGM-8258 VGMH 43 34.0 61 11.0 950043SAC915 RSD-8259<br />

VGM-8258 VGMH 43 34.0 61 11.0 950043SAC916 RSD-8260<br />

VGM-8261 VGMH 55 34.5 75 13.0 950055SAC915 RSD-8261<br />

VGM-8261 VGMH 55 34.5 75 13.0 950055SAC916 RSD-8262<br />

VGM-8263 VGMH 75 44.7 97 15.3 950075SAC915 RSD-8263<br />

VGM-8251Z VGMC-12 22 30.0 37 7.5 950022SAC915 RSD-8251<br />

VGM-8251Z VGMC-12 22 30.0 37 7.5 950022SAC916 RSD-8252<br />

VGM-8253Z VGMC-12 28 35.0 43 7.5 950028SAC915 RSD-8253<br />

VGM-8253Z VGMC-12 28 35.0 43 7.5 950028SAC916 RSD-8254<br />

VGM-8255Z VGMC-12 35 35.0 50 7.5 950035SAC915 RSD-8255<br />

VGM-8255Z VGMC-12 35 35.0 50 7.5 950035SAC916 RSD-8256<br />

VGM-8258Z VGMC-12 43 36.0 61 9.0 950043SAC912 RSD-8258<br />

VGM-8258Z VGMC-12 43 36.0 61 9.0 950043SAC915 RSD-8259<br />

VGM-8258Z VGMC-12 43 36.0 61 9.0 950043SAC916 RSD-8260<br />

VGM-8261Z VGMC-12 55 36.5 75 11.0 950055SAC915 RSD-8261<br />

VGM-8261Z VGMC-12 55 36.5 75 11.0 950055SAC916 RSD-8262<br />

VGM-8263Z VGMC-12 75 48.7 97 11.3 950075SAC915 RSD-8263<br />

VGMH<br />

Shown with LS3.<br />

VGMC-12<br />

Shown with G6.<br />

G60 is Optional<br />

Features<br />

- To DIN 24960<br />

- Bi-Directional<br />

- Elastomer Bellows<br />

- Unbalanced<br />

Materials<br />

- Carbon Rotating Face<br />

- SC - Stationary Face<br />

- Viton Elastomers<br />

- 304 SS - Metallurgy<br />

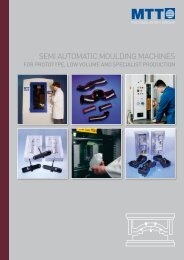

Type L Type M<br />

Performance Capabilities<br />

• Temperature:<br />

-350°F to +600°F<br />

• Pressure:<br />

Splash or very tight pressures (to 1psi)<br />

under dynamic head conditions.<br />

• Speed:<br />

To 30,000 fpm.<br />

• Contaiminants:<br />

Prevents entry <strong>of</strong> dirt, chips grit, etc.<br />

under both static and dynamic conditions.<br />

Construction Features<br />

• Pre-assembled.<br />

• No shaft wear.<br />

• Pressed into position in seconds.<br />

• Seals in grease or other lubricant.<br />

• Keeps out sand, dirt, grit and metal chips.<br />

Product Description<br />

Mini-Maze Type L is a package type, labyrinth seal<br />

consisting <strong>of</strong> two precision rings, an aluminum outer<br />

ring and a steel inner ring, that are permanently mated.<br />

The close clearance path (or labyrinth) is ideal for use<br />

as a combination seal and excluder for heavy lubricants<br />

and air, oil, and water mists. The seal acts as a nonsparking<br />

excluder because <strong>of</strong> the narrow space<br />

between the mating surfaces.<br />

The Mini-Maze Type M is for applications where higher<br />

pressure must be sealed or where labyrinth leakage<br />

must be minimal. Type M contains a series <strong>of</strong> equallyspaced<br />

milled slots in the outer ring which extend to the<br />

bottom <strong>of</strong> the groove in the inner ring. During rotation,<br />

the pumping effect which results is sufficient to force<br />

any leakage through the first groove <strong>of</strong> the seal and<br />

back to the sump or reservoir. Ordinarily, an annular<br />

groove in the bore <strong>of</strong> the seal retainer is employed to<br />

collect the linkage pumped through the slots.<br />

LABYRINTH SEALS<br />

Installation Instructions<br />

1. Maximum allowable shaft movement:<br />

a: <strong>seals</strong> to size L100 – 0.005" radial ± 0.012" axial.<br />

b: <strong>seals</strong> above L100 – 0.008" radial ± 0.012" axial.<br />

2. To provide proper positioning and avoid side contact<br />

<strong>of</strong> the labyrinth seal, it is recommended that the<br />

inner ring be positioned against a rigid shoulder.<br />

3. To properly mount the Mini-Maze seal, a machined<br />

installation bushing is needed. The tool should be<br />

long enough to seat the seal against the shaft or<br />

housing shoulder. Preferably, the end <strong>of</strong> the tool<br />

which touches the Mini-Maze seal should be hardened<br />

to RC50 and should be ground to at least a<br />

16RMS finish. This is to assure durability <strong>of</strong> the tool<br />

and mar-free installation <strong>of</strong> the seal. The I.D. <strong>of</strong> the<br />

tool should clear the shaft O.D., and the O.D. <strong>of</strong> the<br />

tool should be slightly smaller than the O.D. <strong>of</strong> the<br />

seal.<br />

4. The shaft and bore dimensions should be machined<br />

to recommended dimensions.<br />

5. The I.D. and O.D. <strong>of</strong> the Mini-Maze, prior to installation,<br />

should be coated with a lubricant compatible to<br />

your unit. To install, use a steady upward force... no<br />

hammering with a hammer. Apply steady pressure<br />

until seal seats against housing or shaft shoulder.<br />

6. During operation, the level <strong>of</strong> the sealed medium<br />

(depending on its viscosity) should not be allowed to<br />

exceed the height <strong>of</strong> the inner face <strong>of</strong> the seal.<br />

149