- Page 2 and 3: WELCOME! Aircraft Spruce & Specialt

- Page 4 and 5: Bob and Flo Irwin 201 West Truslow

- Page 6 and 7: THE AIRCRAFT SPRUCE MANAGEMENT STAF

- Page 8 and 9: FRIENDLY, FAST, & EFFICIENT ORDER P

- Page 10 and 11: THE AIRCRAFT SPRUCE CATALOG FREE ON

- Page 12 and 13: SHIPPING INFORMATION UNITED PARCEL

- Page 14 and 15: STARDUSTER TOO SA 300 AIRCRAFT KITS

- Page 16 and 17: AIRCRAFT KITS WITTMAN BUTTERCUP We

- Page 18 and 19: ACRO SPORT Designed by Paul Poberez

- Page 20 and 21: PIETENPOL AIRCAMPER AIRCRAFT KITS F

- Page 22 and 23: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 24 and 25: CM WP ME HA AP LG EP CS IN EL AV TO

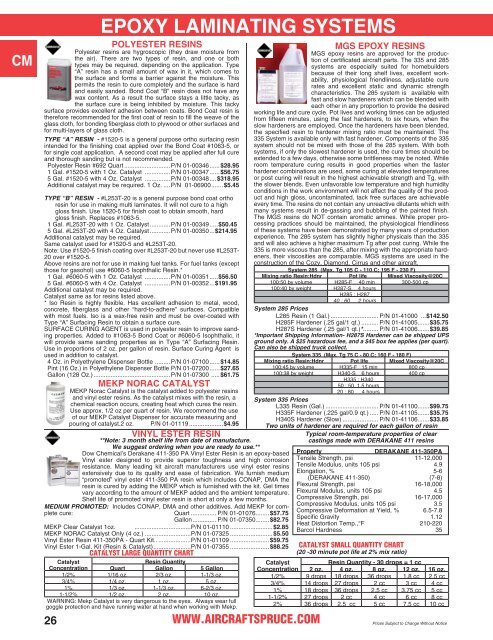

- Page 26 and 27: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 30 and 31: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 32 and 33: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 34 and 35: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 36 and 37: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 38 and 39: CM WP ME HA AP LG COMPOSITE TOOLS A

- Page 40 and 41: CM WP ME HA AP LG EP CS IN EL ROTAR

- Page 42 and 43: CM WP ME HA AP LG EP CS IN EL AV SA

- Page 44 and 45: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 46 and 47: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 48 and 49: INSTANT GLUES - POLYFIX GLUES CM WP

- Page 50 and 51: CM WP ME HA AP INSTANT GLUES & ADHE

- Page 52 and 53: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 54 and 55: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 56 and 57: ALUMINUM - THE MOST COMMON GRADES C

- Page 58 and 59: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 60 and 61: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 62 and 63: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 64 and 65: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 66 and 67: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 68 and 69: CM WP ME HA AP LG EP CS IN EL AV TO

- Page 70 and 71: NAS SHEAR BOLTS CM WP ME HA AP LG E

- Page 72 and 73: CM ENGINE BOLTS MS20073/MS20074 ENG

- Page 74 and 75: CM HARDWARE KITS ECONOMY AN BOLT AS

- Page 76 and 77: CM WP ME HA AP LG CAD-PLATED COTTER

- Page 78 and 79:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 80 and 81:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 82 and 83:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 84 and 85:

CM FILLISTER HEAD SCREWS - MACHINE

- Page 86 and 87:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 88 and 89:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 90 and 91:

CM SOCKET HEAD CAP SCREWS SOCKET HE

- Page 92 and 93:

CM WP ME HA AP LG EP CS IN NAS7403

- Page 94 and 95:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 96 and 97:

CM CHERRY COMMERCIAL RIVETS CHERRY

- Page 98 and 99:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 100 and 101:

CM WP ME HA AP LG The A-T Series In

- Page 102 and 103:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 104 and 105:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 106 and 107:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 108 and 109:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 110 and 111:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 112 and 113:

AN FITTINGS CM WP ME HA AP AN822 (M

- Page 114 and 115:

CM WP ME HA AP LG EP CS IN EL AN914

- Page 116 and 117:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 118 and 119:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 120 and 121:

NYLO-SEAL FITTINGS CM WP ME HA AP L

- Page 122 and 123:

CM WP ME HA BRASS POLY-FLO FITTINGS

- Page 124 and 125:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 126 and 127:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 128 and 129:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 130 and 131:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 132 and 133:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 134 and 135:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 136 and 137:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 138 and 139:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 140 and 141:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 142 and 143:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 144 and 145:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 146 and 147:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 148 and 149:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 150 and 151:

CM SADDLES - FITTINGS - TANGS - BRA

- Page 152 and 153:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 154 and 155:

CM BEARINGS AN 946 MS 21151 AN 951

- Page 156 and 157:

CM WP BEARINGS REGREASERS - GREASE

- Page 158 and 159:

CM WP ME HA AP LG EP CS IN EL Rod E

- Page 160 and 161:

CM HFE M SERIES BEARINGS UNIFLON LI

- Page 162 and 163:

AURORA BEARINGS CM WP ME HA AP LG E

- Page 164 and 165:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 166 and 167:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 168 and 169:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 170 and 171:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 172 and 173:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 174 and 175:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 176 and 177:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 178 and 179:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 180 and 181:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 182 and 183:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 184 and 185:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 186 and 187:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 188 and 189:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 190 and 191:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 192 and 193:

SENSENICH METAL PROPELLERS CM WP ME

- Page 194 and 195:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 196 and 197:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 198 and 199:

WHIRLWIND PROPELLERS — GOVERNORS

- Page 200 and 201:

CM DYNAVIBE PROPELLER BALANCERS DYN

- Page 202 and 203:

RAPCO DE-ICERS CM WP ME HA AP LG EP

- Page 204 and 205:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 206 and 207:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 208 and 209:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 210 and 211:

CM SEAT BELTS & SHOULDER HARNESSES

- Page 212 and 213:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 214 and 215:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 216 and 217:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 218 and 219:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 220 and 221:

CM WP ME HA AP LG EP CS IN AIRCRAFT

- Page 222 and 223:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 224 and 225:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 226 and 227:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 228 and 229:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 230 and 231:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 232 and 233:

PMA PRODUCTS REPLACEMENT PARTS CM W

- Page 234 and 235:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 236 and 237:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 238 and 239:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 240 and 241:

CM CESSNA FLAP - ELEVATOR - RUDDER

- Page 242 and 243:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 244 and 245:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 246 and 247:

CM REPLACEMENT CESSNA PARTS FLAP TR

- Page 248 and 249:

CESSNA ENGINE BAFFLES CM WP ME HA A

- Page 250 and 251:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 252 and 253:

CM WP CESSNA FIBERGLASS REPLACEMENT

- Page 254 and 255:

CM WP ME HA CESSNA FIBERGLASS REPLA

- Page 256 and 257:

CM WP ME HA AP LG EP CS CESSNA FIBE

- Page 258 and 259:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 260 and 261:

KNOTS 2U PIPER REPLACEMENT PARTS CM

- Page 262 and 263:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 264 and 265:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 266 and 267:

CM PIPER NOSE COWLING (ALL METAL) P

- Page 268 and 269:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 270 and 271:

CM WP PIPER SUPERCUB PARTS PA18 LAN

- Page 272 and 273:

CM LUSCOMBE PARTS (FAA/PMA APPROVED

- Page 274 and 275:

CM WP ALUMINUM NOSE COWL STINSON PA

- Page 276 and 277:

CM WP ME HA AP LG AERONCA/ BELLANCA

- Page 278 and 279:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 280 and 281:

CM WP AERONCA/ BELLANCA REPLACEMENT

- Page 282 and 283:

CM AERONCA/ BELLANCA REPLACEMENT PA

- Page 284 and 285:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 286 and 287:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 288 and 289:

CM WP ME HA AP NAVION - TAYLORCRAFT

- Page 290 and 291:

CM WP ME HA CLEVELAND WHEELS & BRAK

- Page 292 and 293:

CM WHEELS & BRAKES FAA-APPROVED CLE

- Page 294 and 295:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 296 and 297:

CM ABI WHEELS & BRAKES - RAPCO BRAK

- Page 298 and 299:

MATCO WHEELS & BRAKES CM WP ME HA A

- Page 300 and 301:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 302 and 303:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 304 and 305:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 306 and 307:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 308 and 309:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 310 and 311:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 312 and 313:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 314 and 315:

CM WP ME HA AP LG EP GOODYEAR TIRES

- Page 316 and 317:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 318 and 319:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 320 and 321:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 322:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 326:

SK2003-42 A SK2003-24 A SK2003-14 A

- Page 329 and 330:

Quality, Innovation and Performance

- Page 331 and 332:

Prices Subject to Change Without No

- Page 333 and 334:

MIL FRESH SHOCK RINGS An endless el

- Page 335 and 336:

TAILWHEELS LANG TAILWHEEL PARTS Ref

- Page 337 and 338:

SCOTT MODEL 2600 8-INCH PNEUMATIC T

- Page 339 and 340:

P/N 06-01615 P/N 06-01620 P/N 06-00

- Page 341 and 342:

SHIMS - VALVE CORES - FLOATS AIRCRA

- Page 343 and 344:

MARVEL-SCHEBLER CARBURETORS Prices

- Page 345 and 346:

BENDIX STROMBERG NA-S3A1 CARBURETOR

- Page 347 and 348:

MAIN JET 125 = Part No. R268-978 12

- Page 349 and 350:

LYCOMING & CONTINENTAL FUEL PUMPS P

- Page 351 and 352:

Prices Subject to Change Without No

- Page 353 and 354:

WELDON OVERHAULED FUEL PUMPS Descri

- Page 355 and 356:

REFUELING PUMPS - HARTZELL FUEL PUM

- Page 357 and 358:

FUEL PUMPS - SPRAYING SYSTEMS ELECT

- Page 359 and 360:

BENDIX MAGNETOS OVERHAULED BENDIX M

- Page 361 and 362:

BENDIX-SCINTILLA MAGNETOS BENDIX BR

- Page 363 and 364:

REPAIR KIT 1 - Contact Assy. Kit (3

- Page 365 and 366:

SLICK MAGNETOS Prices Subject to Ch

- Page 367 and 368:

SLICK MAGNETOS OVERHAULED SLICK MAG

- Page 369 and 370:

SLICK MAGNETO PARTS CM 6300 SERVICE

- Page 371 and 372:

SLICK IGNITION HARNESSES BY CHAMPIO

- Page 373 and 374:

KELLY AEROSPACE IGNITION HARNESSES

- Page 375 and 376:

ELECTROAIR - IGNITION HARNESSES ELE

- Page 377 and 378:

LIGHT SPEED ENGINEERING PLASMA IGNI

- Page 379 and 380:

Prices Subject to Change Without No

- Page 381 and 382:

REGULATORS - ALTERNATORS LAMAR (ELE

- Page 383 and 384:

HARTZELL ENGINE TECH. ALTERNATORS H

- Page 385 and 386:

HARTZELL ENGINE TECH. ASG ALTERNATO

- Page 387 and 388:

HARTZELL STARTER OVERHAUL KITS HART

- Page 389 and 390:

PLANE POWER CONVERSION KITS BELT DR

- Page 391 and 392:

AEROTECH OVERHAULED ALTERNATORS Aer

- Page 393 and 394:

FALCON OVERHAULED ALTERNATORS FALCO

- Page 395 and 396:

L-40 ALTERNATOR The L-40 is a high-

- Page 397 and 398:

HARTZELL ENGINE TECHNOLOGIES STARTE

- Page 399 and 400:

SKY-TEC ST2 & KCST2 MODEL STARTERS

- Page 401 and 402:

ZEFTRONICS VOLTAGE REGULATORS Photo

- Page 403 and 404:

LAMAR # DESCRIPTION APPLICATIONS OU

- Page 405 and 406:

SUPERIOR GASKETS - CYLINDERS SUPERI

- Page 407 and 408:

SUPERIOR AIR PARTS Superior PN# Des

- Page 409 and 410:

ENGINE PARTS CONTINENTAL ENGINE PAR

- Page 411 and 412:

CHALLENGER AVIATION HIGH-FLOW AIR F

- Page 413 and 414:

Prices Subject to Change Without No

- Page 415 and 416:

Prices Subject to Change Without No

- Page 417 and 418:

Prices Subject to Change Without No

- Page 419 and 420:

Prices Subject to Change Without No

- Page 421 and 422:

AIRCRAFT HEATERS - ENGINE PREHEATER

- Page 423 and 424:

CH48110-1 CH48111-1 Aircraft Aircra

- Page 425 and 426:

CHRISTEN 801 INVERTED OIL SYSTEM Ch

- Page 427 and 428:

OIL FILTER SYSTEMS/ ADAPTERS/ SEPAR

- Page 429 and 430:

OIL COOLER APPLICATION CHART Aircra

- Page 431 and 432:

X-SERIES OIL COOLERS BY AIRFLOW SYS

- Page 433 and 434:

Prices Subject to Change Without No

- Page 435 and 436:

Prices Subject to Change Without No

- Page 437 and 438:

model 112 model 415 model 428 Price

- Page 439 and 440:

PIG® OIL ABSORBENT PRODUCTS PIG®

- Page 441 and 442:

Prices Subject to Change Without No

- Page 443 and 444:

Prices Subject to Change Without No

- Page 445 and 446:

DYNAFOCAL ENGINE MOUNT RINGS & KITS

- Page 447 and 448:

Prices Subject to Change Without No

- Page 449 and 450:

Prices Subject to Change Without No

- Page 451 and 452:

Prices Subject to Change Without No

- Page 453 and 454:

NICROCRAFT EXHAUST PARTS Applicatio

- Page 455 and 456:

POWER FLOW SYSTEMS INC. EXHAUST SYS

- Page 457 and 458:

EXHAUST SYSTEM FOR OSPREY AIRCRAFT

- Page 459 and 460:

EXHAUST SYSTEMS VETTERMAN RV EXHAUS

- Page 461 and 462:

GASKETS CONTINENTAL LYCOMING Style

- Page 463 and 464:

Prices Subject to Change Without No

- Page 465 and 466:

EXHAUST MANIFOLD NUTS Thread Engine

- Page 467 and 468:

EXHAUST PRODUCTS - PT6 100 HOUR KIT

- Page 469 and 470:

POLY-FIBER AIRCRAFT COATINGS POLY-B

- Page 471 and 472:

Prices Subject to Change Without No

- Page 473 and 474:

Star Flight Aircraft ULTRALIGHT SAI

- Page 475 and 476:

DACRON TAPE / PEEL PLY A layer of 2

- Page 477 and 478:

Prices Subject to Change Without No

- Page 479 and 480:

SPECIALITY PAINTS POLYURETHANE - EN

- Page 481 and 482:

RANDOLPH AIRCRAFT COATINGS Prices S

- Page 483 and 484:

SUPERFLITE FABRIC COVERING SUPERFLI

- Page 485 and 486:

REALCLEAN PRODUCTS - SANDING PRODUC

- Page 487 and 488:

3M STIKIT DISC PAD 05575 For use wi

- Page 489 and 490:

3M SCOTCH-WELD EPOXY ADHESIVE 2216

- Page 491 and 492:

3M FASTENERS - SAFETY - TAPE 3M SCO

- Page 493 and 494:

3M NOVEC 3M NOVEC FLUX REMOVER - Ef

- Page 495 and 496:

MEGUIAR’S PRODUCTS MEGUIARS ULTIM

- Page 497 and 498:

MEGUIAR’S PRODUCTS MEGUIAR’S CL

- Page 499 and 500:

PAINT ACCESSORIES - REPAIR KITS SUP

- Page 501 and 502:

ALUMINUM PREPAINT PRODUCTS ALUMIPRE

- Page 503 and 504:

NUVITE POLISH - PROTECTANT SYSTEMS

- Page 505 and 506:

XHAUST & SOOT REMOVER A powerful, c

- Page 507 and 508:

ROLITE POLISHING PRODUCTS ROLITE HE

- Page 509 and 510:

PLEXIGLASS CLEANERS & POLISHES NOVU

- Page 511 and 512:

VELOCITY VISION CLEANING PRODUCTS V

- Page 513 and 514:

M-RON GLASS CLEANER / WAX M-Ron Gla

- Page 515 and 516:

GRANITIZE CLEANING PRODUCTS GRANITI

- Page 517 and 518:

Prices Subject to Change Without No

- Page 519 and 520:

SPRAY NINE CLEANERS & DEGREASERS SP

- Page 521 and 522:

Prices Subject to Change Without No

- Page 523 and 524:

AIRCRAFT GRADE MICROFIBER WASH MITT

- Page 525 and 526:

TOWELS — CLEANERS MICROFIBER CLEA

- Page 527 and 528:

Prices Subject to Change Without No

- Page 529 and 530:

BF GOODRICH AGE MASTER RUBBER NO. 1

- Page 531 and 532:

LPS LOW SURFACE TENSION (LST) A dee

- Page 533 and 534:

CRC AVIATION MAINTENANCE PRODUCTS C

- Page 535 and 536:

BOELUBE® BL70200-13 SOLIDS LUBRICA

- Page 537 and 538:

LOGO DECALS Black .................

- Page 539 and 540:

AC-001 - 7”h x 8”w P/N 09-01967

- Page 541 and 542:

09-42803 09-42802 $4.95 ea. $4.50 e

- Page 543 and 544:

PLACARDS Made of aluminum foil with

- Page 545 and 546:

AIRCRAFT PLACARD KITS INTERIOR PLAC

- Page 547 and 548:

RC ALLEN DI REC TIONAL GYROS (ELECT

- Page 549 and 550:

SIGMA-TEK 5000E/L SERIES AUTOPILOT

- Page 551 and 552:

MID-CONTINENT INSTRUMENTS AND AVION

- Page 553 and 554:

TURN COORDINATORS - TURN & BANKS RC

- Page 555 and 556:

TEMPEST PNEUMATIC COMPONENTS Prices

- Page 557 and 558:

VACUUM PUMP FITTINGS - VACUUM PUMPS

- Page 559 and 560:

SUCTION REGULATORS - PNEUMATIC FILT

- Page 561 and 562:

3-1/8” TSO’d Single Scale Part

- Page 563 and 564:

AIRSPEED INDICATORS - ALTIMETERS WI

- Page 565 and 566:

ALTIMETERS - BUGS - REDUCING MASKS

- Page 567 and 568:

SKYSPORTS NON-TSO’D INSTRUMENTS S

- Page 569 and 570:

SKYSPORTS NON-TSO’D INSTRUMENTS S

- Page 571 and 572:

INSTRUMENT MOUNTING & ADAPTER KITS

- Page 573 and 574:

THE REDDISH STALL WARNER Developed

- Page 575 and 576:

Prices Subject to Change Without No

- Page 577 and 578:

MID-CONTINENT INSTRUMENTS AND AVION

- Page 579 and 580:

2-1/4 inch UMA Electronic Oil Press

- Page 581 and 582:

UMA 1-1/4” ENGINE INSTRUMENTS CM

- Page 583 and 584:

HOUR METERS - ENGINE GAUGES HONEYWE

- Page 585 and 586:

FLIGHT DATA SYSTEM ELECTRIC TACHOME

- Page 587 and 588:

DAVTRON INSTRUMENTS DIGITAL CHRONOM

- Page 589 and 590:

3-1/8” Tach Prices Subject to Cha

- Page 591 and 592:

ALCOR EGT & CHT SYSTEMS FAA and PMA

- Page 593 and 594:

WESTACH INSTRUMENTS 2-1/4” ENGINE

- Page 595 and 596:

WESTACH INSTRUMENTS MADE IN THE U.S

- Page 597 and 598:

MITCHELL INSTRUMENTS MITCHELL AIRCR

- Page 599 and 600:

Prices Subject to Change Without No

- Page 601 and 602:

MGL INSTRUMENTS MGL VEGA AIRSPEED I

- Page 603 and 604:

BELITE INSTRUMENTS BELITE RADIANT F

- Page 605 and 606:

MICROFLIGHT GAUGES / VDO GAUGES MIC

- Page 607 and 608:

Prices Subject to Change Without No

- Page 609 and 610:

AEROSPACE LOGIC FOUR CYLINDER EGT/C

- Page 611 and 612:

Prices Subject to Change Without No

- Page 613 and 614:

JPI ENGINE SCANNERS JPI EDM-740 INS

- Page 615 and 616:

ELECTRONICS INTERNATIONAL INSTRUMEN

- Page 617 and 618:

ELECTRONICS INTERNATIONAL INSTRUMEN

- Page 619 and 620:

ELECTRONICS INTERNATIONAL INSTRUMEN

- Page 621 and 622:

FLIGHT/ENGINE MONITORS - SKYSPORTS

- Page 623 and 624:

FUEL TOTALIZERS - FUEL GAUGES SHADI

- Page 625 and 626:

TELEDYNE SEALED BATTERIES The Gill

- Page 627 and 628:

Prices Subject to Change Without No

- Page 629 and 630:

P/N 11-03153 Prices Subject to Chan

- Page 631 and 632:

BATTERY CHARGERS AND TESTERS GILL 1

- Page 633 and 634:

AVIATION BATTERY CHARGER Industrial

- Page 635 and 636:

AVTEK PRODUCTS — BATTERY CHARGERS

- Page 637 and 638:

POWER BARS - GPU’S POWER PRODUCTS

- Page 639 and 640:

Prices Subject to Change Without No

- Page 641 and 642:

START PAC® STARTERS - POWER SUPPLI

- Page 643 and 644:

BYCAN POWER SYSTEMS - GPU’S BYCAN

- Page 645 and 646:

POWER PANELS FOR HOMEBUILTS Mini Po

- Page 647 and 648:

VOLTAGE CONVERTERS - POWER PANELS T

- Page 649 and 650:

CIGARETTE LIGHTER RECEPTACLE This 1

- Page 651 and 652:

INNOVATION The Better Performing Se

- Page 654 and 655:

Save on purchases at Aircraft Spruc

- Page 656 and 657:

888-685-4874

- Page 659 and 660:

POWER PANELS - FLAP CONTROLLERS - G

- Page 661 and 662:

RAC ELECTRIC TRIM SERVOS Ray Allen

- Page 663 and 664:

SMARTSTART MODULE An electronic con

- Page 665 and 666:

STARTING COMPONENTS - SWITCHES ELEC

- Page 667 and 668:

KLIXON 7270 & 7271 CIR CUIT BREAKER

- Page 669 and 670:

ULTRA-MINIATURE TOGGLE SWITCHES Ult

- Page 671 and 672:

• SILVER SWITCH CONTACTS (MOST) 1

- Page 673 and 674:

AIRCRAFT WIRE UNSHIELDED WIRE MIL-W

- Page 675 and 676:

BNC/TNC CONNECTORS — AVIONICS CON

- Page 677 and 678:

SEAL-ALL CONNECTORS Seal-All Connec

- Page 679 and 680:

Prices Subject to Change Without No

- Page 681 and 682:

LANDING STRIP LIGHT KITS P/N 11-079

- Page 683 and 684:

WHELEN AVIATION LIGHTING WHELEN ORI

- Page 685 and 686:

WHELEN MODEL 90044 SERIES 90044 ser

- Page 687 and 688:

WHELEN AVIATION LIGHTING HOW TO CHO

- Page 689 and 690:

WHELEN AVIATION LIGHTING MODEL 7028

- Page 691 and 692:

Model # Description Part No. Price

- Page 693 and 694:

VOLT AND VAC ALERT *Provides an ins

- Page 695 and 696:

Aeroflash Original P/N Current P/N

- Page 697 and 698:

Prices Subject to Change Without No

- Page 699 and 700:

AVEOFLASH LIGHTING - ROCKRACK SWITC

- Page 701 and 702:

Prices Subject to Change Without No

- Page 703 and 704:

EXPERIMENTAL AEROLEDS LIGHTING AERO

- Page 705 and 706:

Prices Subject to Change Without No

- Page 707 and 708:

Parts Sold Separately COCKPIT LIGHT

- Page 709 and 710:

LED LIGHTING - INSTRUMENT LIGHTING

- Page 711 and 712:

DIMMING SYSTEMS - COCKPIT LIGHTS SO

- Page 713 and 714:

INSTRUMENT LIGHTING UMA INSTRUMENT

- Page 715 and 716:

LED LANDING LIGHTS ALPHABEAM II PAR

- Page 717 and 718:

PULSE LIGHT SYSTEMS - LANDING/TAXI

- Page 719 and 720:

REPLACEMENT LAMPS CM GE Lamp No. Vo

- Page 721 and 722:

GE REPLACEMENT LAMPS GE MINIATURE L

- Page 723:

GTN 750 GTX 345 GTX 345. The all-

- Page 726 and 727:

+ = +02 -03 N430G N1129S -12 N65927

- Page 728 and 729:

An opportunity like this only comes

- Page 730 and 731:

Attitude awareness you can bank on.

- Page 732 and 733:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 734 and 735:

CM WP ME HA AP LG EP CS KING KGX 15

- Page 736 and 737:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 738 and 739:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 740 and 741:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 742 and 743:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 744 and 745:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 746 and 747:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 748 and 749:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 750 and 751:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 752 and 753:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 754 and 755:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 756 and 757:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 758 and 759:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 760 and 761:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 762 and 763:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 764 and 765:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 766 and 767:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 768 and 769:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 770 and 771:

CM WP ME HA AP SPECIALTY MOUNTS Ord

- Page 772 and 773:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 774 and 775:

CM WP ME HA AP LG EP HANDHELD RECEI

- Page 776 and 777:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 778 and 779:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 780 and 781:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 782 and 783:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 784 and 785:

CM WP ME HA AP LG EP CS IN EL AV DY

- Page 786 and 787:

DYNON CM WP ME HA AP LG EP CS IN EL

- Page 788 and 789:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 790 and 791:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 792 and 793:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 794 and 795:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 796 and 797:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 798 and 799:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 800 and 801:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 802 and 803:

DORNE & MARGOLIN ANTENNAS - ANTENNA

- Page 804 and 805:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 806 and 807:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 808 and 809:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 810 and 811:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 812 and 813:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 814 and 815:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 816 and 817:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 818 and 819:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 820 and 821:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 822 and 823:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 824 and 825:

CM SOFTCOMM HEADSETS SOFTCOMM C-10

- Page 826:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 829 and 830:

NEW LIFETIME WARRANTY * TA102 & TA2

- Page 831 and 832:

NEW A25 Series Powerful NAV/COM Air

- Page 833:

YOUR LOW-COST, LONG-TERM ADS-B SOLU

- Page 836 and 837:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 838 and 839:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 840 and 841:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 842 and 843:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 844 and 845:

CM WP ME HA PLUGS & PANEL JACKS PLU

- Page 846 and 847:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 848 and 849:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 850 and 851:

CM WP ME HA AP THE SEEKER 100 USB V

- Page 852 and 853:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 854 and 855:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 856 and 857:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 858 and 859:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 860 and 861:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 862 and 863:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 864 and 865:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 866 and 867:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 868 and 869:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 870 and 871:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 872 and 873:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 874 and 875:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 876 and 877:

CM WP BUCKING BARS Our bucking bars

- Page 878 and 879:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 880 and 881:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 882 and 883:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 884 and 885:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 886 and 887:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 888 and 889:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 890 and 891:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 892 and 893:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 894 and 895:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 896 and 897:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 898 and 899:

CM WP ME HA AP LG EP CS METAL WORKI

- Page 900 and 901:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 902 and 903:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 904 and 905:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 906 and 907:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 908 and 909:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 910 and 911:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 912 and 913:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 914 and 915:

CM WP ME HA AP LG EP CS IN EL AV NO

- Page 916 and 917:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 918 and 919:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 920 and 921:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 922 and 923:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 924 and 925:

CM COBALT DRILL BIT SETS COBALT DRI

- Page 926 and 927:

VISE GRIPS - UNIBITS CM WP ME HA AP

- Page 928 and 929:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 930 and 931:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 932 and 933:

CM WP ME HA AP LG EP CS WRENCHES -

- Page 934 and 935:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 936 and 937:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 938 and 939:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 940 and 941:

CM WP WORK LIGHTS - INSPECTION MIRR

- Page 942 and 943:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 944 and 945:

ABRASIVE TOOLS - POLISHERS - SANDER

- Page 946 and 947:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 948 and 949:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 950 and 951:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 952 and 953:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 954 and 955:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 956 and 957:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 958 and 959:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 960 and 961:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 962 and 963:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 964 and 965:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 966 and 967:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 968 and 969:

CM WP ME HA AP Sidewinder attached

- Page 970 and 971:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 972 and 973:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 974 and 975:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 976 and 977:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 978 and 979:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 980 and 981:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 982 and 983:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 984 and 985:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 986 and 987:

CM WP ME HA AP LG EP FLIGHT COMPUTE

- Page 988 and 989:

CM WP ME HA AP LG EP CS IN EL PLOTT

- Page 990 and 991:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 992 and 993:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 994 and 995:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 996 and 997:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 998 and 999:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1000 and 1001:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1002 and 1003:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1004 and 1005:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1006 and 1007:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1008 and 1009:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1010 and 1011:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1012 and 1013:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1014 and 1015:

CM WP ME HA AP JEPPESEN CASES & FLI

- Page 1016 and 1017:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1018 and 1019:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1020 and 1021:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1022 and 1023:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1024 and 1025:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1026 and 1027:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1028 and 1029:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1030 and 1031:

CM WP ME HA AP LG EP CS IN EL PITOT

- Page 1032 and 1033:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1034 and 1035:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1036 and 1037:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1038 and 1039:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1040 and 1041:

CM WP GLOVES - SURVIVAL KITS GENERA

- Page 1042 and 1043:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1044 and 1045:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1046 and 1047:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1048 and 1049:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1050 and 1051:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1052 and 1053:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1054 and 1055:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1056 and 1057:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1058 and 1059:

CM WP ME HA AP FLASHLIGHT HOLDERS -

- Page 1060 and 1061:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1062 and 1063:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1064 and 1065:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1066 and 1067:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1068 and 1069:

CM WP ME HA AP LG AIRCRAFT SPRUCE A

- Page 1070 and 1071:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1072 and 1073:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1074 and 1075:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1076 and 1077:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1078 and 1079:

CM WP ME HA AP JEPPESEN AIRWAY SERV

- Page 1080 and 1081:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1082 and 1083:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1084 and 1085:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1086 and 1087:

CM ASA FLIGHT TRAINING FAA TEST & C

- Page 1088 and 1089:

CM ASA FLIGHT TRAINING PILOT BOOKS

- Page 1090 and 1091:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1092 and 1093:

CM WP ME HA AP LG EP CS IN JEPPESEN

- Page 1094 and 1095:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1096 and 1097:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1098 and 1099:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1100 and 1101:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1102 and 1103:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1104 and 1105:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1106 and 1107:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1108 and 1109:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1110 and 1111:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1112 and 1113:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1114 and 1115:

BOOKS CM WP ME HA AP LG EP CS IN EL

- Page 1116 and 1117:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1118 and 1119:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1120 and 1121:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1122 and 1123:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1124 and 1125:

CM WP ME HA AP LG EP CS IN EL AV TO

- Page 1126 and 1127:

BOOKS CM WP ME HA AP LG EP CS IN EL

- Page 1128 and 1129:

CONVERSION CHARTS FRACTIONAL INCHES

- Page 1130 and 1131:

CUSTOM AIRCRAFT HOSE ASSEMBLY EATON

- Page 1132 and 1133:

NOTES

- Page 1134 and 1135:

A CONT. ALUMINUM DEOXIDIZER- 512 AL

- Page 1136 and 1137:

C CONT. CALENDARS- 1068 CALIBRATION

- Page 1138 and 1139:

D CONT. DC-4 COMPOUND- 188 DC-AC IN

- Page 1140 and 1141:

F CONT. FIRE DETECTOR SHIELDS- 172

- Page 1142 and 1143:

H CONT. HEADSET ADAPTERS AND EXTENS

- Page 1144 and 1145:

L CONT. LIQUID ELECTRICAL TAPE- 658

- Page 1146 and 1147:

P CONT. PAINT ACCESSORIES- 489 PAIN

- Page 1148 and 1149:

R CONT. RANDOLPH FLOAT LACQUER- 471

- Page 1150 and 1151:

S CONT. SMARTPHONE DIGITAL AUDIO AD

- Page 1152 and 1153:

T CONT. TIMING JUMPERS- 872 TIMING

- Page 1154 and 1155:

W CONT. WING WALK- 141 WING WALK CO