TOPSERV® 109 PURPUR, high flexible motor cable ... - HELUKABEL

TOPSERV® 109 PURPUR, high flexible motor cable ... - HELUKABEL

TOPSERV® 109 PURPUR, high flexible motor cable ... - HELUKABEL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

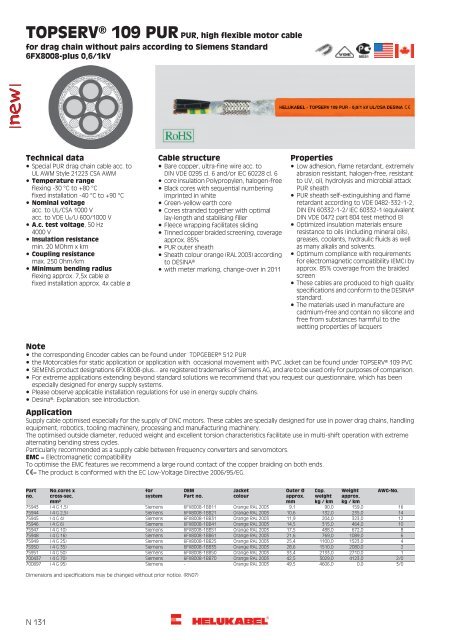

TOPSERV ® <strong>109</strong> PUR PUR, <strong>high</strong> <strong>flexible</strong> <strong>motor</strong> <strong>cable</strong><br />

for drag chain without pairs according to Siemens Standard<br />

6FX8008-plus 0,6/1kV<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� Special PUR drag chain <strong>cable</strong> acc. to � Bare copper, ultra-fine wire acc. to � Low adhesion, flame retardant, extremely<br />

UL�AWM Style�21223 CSA�AWM<br />

DIN�VDE�0295 cl.�6 and/or IEC�60228 cl.�6 abrasion resistant, halogen-free, resistant<br />

� Temperature range<br />

� core insulation Polypropylen, halogen-free to UV, oil, hydrolysis and microbial attack<br />

flexing -30 °C to +80 °C<br />

� Black cores with sequential numbering PUR sheath<br />

fixed installation -40 °C to +90 °C<br />

imprinted in white � PUR sheath self-extinguishing and flame<br />

� Nominal voltage<br />

� Green-yellow earth core<br />

retardant according to VDE�0482-332-1-2,<br />

acc. to UL/CSA 1000 V<br />

� Cores stranded together with optimal DIN EN�60332-1-2/ IEC�60332-1 (equivalent<br />

acc. to VDE U0/U 600/1000 V<br />

lay-length and stabilising filler<br />

DIN�VDE�0472 part�804 test method�B)<br />

� A.c. test voltage, 50 Hz<br />

� Fleece wrapping facilitates sliding<br />

� Optimized insulation materials ensure<br />

4000 V<br />

� Tinned copper braided screening, coverage resistance to oils (including mineral oils),<br />

� Insulation resistance<br />

approx. 85%<br />

greases, coolants, hydraulic fluids as well<br />

min. 20 MOhm x km � PUR outer sheath<br />

as many alkalis and solvents.<br />

� Coupling resistance<br />

� Sheath colour orange (RAL 2003) according � Optimum compliance with requirements<br />

max. 250 Ohm/km<br />

to DESINA for electromagnetic compatibility (EMC) by<br />

®<br />

� Minimum bending radius<br />

� with meter marking, change-over in 2011 approx. 85% coverage from the braided<br />

flexing approx. 7,5x <strong>cable</strong> ø<br />

fixed installation approx. 4x <strong>cable</strong> ø<br />

�<br />

screen<br />

� These <strong>cable</strong>s are produced to <strong>high</strong> quality<br />

specifications and conform to the DESINA ®<br />

�<br />

Note<br />

standard.<br />

� The materials used in manufacture are<br />

cadmium-free and contain no silicone and<br />

free from substances harmful to the<br />

wetting properties of lacquers<br />

�<br />

� the corresponding Encoder <strong>cable</strong>s can be found under� TOPGEBER ® 512�PUR<br />

� the Motor<strong>cable</strong>s for�static application or application with �occasional movement�with PVC Jacket can be found under TOPSERV ® <strong>109</strong> PVC�<br />

� SIEMENS product designations 6FX 8008-plus... are registered trademarks of Siemens AG, and are to be used only for purposes of comparison.<br />

� For extreme applications extending beyond standard solutions we recommend that you request our questionnaire, which has been<br />

especially designed for energy supply systems.<br />

� Please observe appli<strong>cable</strong> installation regulations for use in energy supply chains.<br />

� Desina ® : Explanation: see introduction.<br />

�<br />

Application<br />

Supply <strong>cable</strong> optimised especially for the supply of DNC <strong>motor</strong>s. These <strong>cable</strong>s are specially designed for use in power drag chains, handling<br />

equipment, robotics, tooling machinery, processing and manufacturing machinery.<br />

The optimised outside diameter, reduced weight and excellent torsion characteristics facilitate use in multi-shift operation with extreme<br />

alternating bending stress cycles.<br />

Particularly recommended as a supply <strong>cable</strong> between frequency converters and servo<strong>motor</strong>s.<br />

EMC = Electromagnetic compatibillity<br />

To optimise the EMC features we recommend a large round contact of the copper braiding on both ends.<br />

= The product is conformed with the EC Low-Voltage Directive 2006/95/EG.<br />

�<br />

�<br />

Part<br />

no.<br />

75943<br />

75944<br />

75945<br />

75946<br />

75947<br />

75948<br />

75949<br />

75950<br />

75951<br />

700437<br />

700897<br />

�<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

(4�G�1,5)<br />

(4�G�2,5)<br />

(4�G�4)<br />

(4�G�6)<br />

(4�G�10)<br />

(4�G�16)<br />

(4�G�25)<br />

(4�G�35)<br />

(4�G�50)<br />

(4�G�70)<br />

(4�G�95)<br />

for<br />

system<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

OEM<br />

Part no.<br />

Dimensions and specifications may be changed without prior notice. (RN07)<br />

N 131<br />

6FX8008-1BB11<br />

6FX8008-1BB21<br />

6FX8008-1BB31<br />

6FX8008-1BB41<br />

6FX8008-1BB51<br />

6FX8008-1BB61<br />

6FX8008-1BB25<br />

6FX8008-1BB35<br />

6FX8008-1BB50<br />

6FX8008-1BB70<br />

-<br />

Jacket<br />

colour<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Outer Ø<br />

approx.<br />

mm<br />

9,1<br />

10,6<br />

11,9<br />

14,5<br />

17,5<br />

21,6<br />

25,4<br />

28,6<br />

33,4<br />

42,5<br />

49,5<br />

Cop.<br />

weight<br />

kg�/�km<br />

90,0<br />

132,0<br />

204,0<br />

315,0<br />

488,0<br />

769,0<br />

1100,0<br />

1510,0<br />

2133,0<br />

3029,0<br />

4606,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

159,0<br />

235,0<br />

323,0<br />

464,0<br />

672,0<br />

1089,0<br />

1523,0<br />

2080,0<br />

2710,0<br />

4123,0<br />

0,0<br />

AWG-No.<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

2/0<br />

3/0

TOPSERV ® 113 PUR PUR, <strong>high</strong> <strong>flexible</strong> servo <strong>cable</strong><br />

for drag chain with 1 signal pair according to Siemens Standard<br />

6FX8008-plus and Lenze 0,6/1kV<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� Special PUR drag chain <strong>cable</strong> acc. to � Bare copper, ultra-fine wire conductors � low capacitance�<br />

UL�AWM�Style�21223, 20234 and CSA�AWM acc. to DIN�VDE�0295 cl.�6 and/or IEC�60228 � PUR outer sheath: low adhesion, extremely<br />

VDE-registered<br />

cl.�6<br />

abrasion resistant, halogen-free, resistant<br />

� Temperature range<br />

� Polypropylene�core insulation, halogen-free to UV-, oil-, hydrolysis and microbial attack<br />

flexing -30 °C to +80 °C<br />

� Black power supply cores with white � PUR sheath: self-extinguishing and flame<br />

fixed installation -40 °C to +80 °C<br />

imprint<br />

retardant according to VDE�0482-332-1-2,<br />

� Nominal voltage<br />

� Green-yellow earth core<br />

DIN EN�60332-1-2/ IEC�60332-1 (equivalent<br />

acc. to UL/CSA 1000 V<br />

� Black control cores with white imprint DIN�VDE�0472 part�804 test method�B)<br />

acc. to VDE<br />

� Screening of the control cores in pairs � Optimized insulation materials ensure<br />

power supply cores U0/U 600/1000 V wrapped with plastic aluminium foil, copper resistance to oils (including mineral oils),<br />

control cores U0/U 300/500 V<br />

drain-wire tinned and tinned copper greases, coolants, hydraulic fluids as well<br />

� A.c. test voltage, 50 Hz<br />

braided screening, approx. coverage 85% as many alkalis and solvents.<br />

power supply cores 4000 V<br />

� Control cores stranded in pairs and laid up � Optimum compliance with requirements<br />

control cores 1000 V<br />

in layers together with the power supply for electromagnetic compatibility (EMC) by<br />

� Insulation resistance<br />

cores with optimal lay length and stabilising approx. 85% coverage from the braided<br />

min. 20 Ohm x km<br />

filler<br />

screen<br />

� Coupling resistance<br />

� These <strong>cable</strong>s are produced to <strong>high</strong> quality<br />

max. 250 Ohm/km<br />

specifications and conform to the<br />

DESINA ® � Fleece wrapping facilitates sliding<br />

Overall screening from tinned copper braid,<br />

� Minimum bending radius<br />

optimal. coverage approx. 85%<br />

-standard<br />

flexing approx. 7,5x <strong>cable</strong> ø<br />

� PUR outer sheath<br />

� The materials used in manufacture are<br />

fixed installation approx. 4x <strong>cable</strong><br />

� Sheath colour orange (RAL 2003) according cadmium-free and contain no silicone and<br />

to DESINA free from substances harmful to the<br />

wetting properties of lacquers<br />

®<br />

�<br />

Note<br />

� with meter marking, change-over in 2011<br />

�<br />

� the corresponding encoder <strong>cable</strong>s with PUR jacket can be found under TOPGEBER ® 512 PUR<br />

� the Servo<strong>cable</strong>s for stativ application oder occasional movements can be found under TOPSERV ® 112 PVC<br />

� Brackets ( ) indicate screen.<br />

� Desina ® : Explanation: see introduction.<br />

� SIEMENS product designations 6FX 8008-�are registered trademarks of Siemens AG, and are to be used only for purposes of comparison.<br />

� LENZE product designations��are registered trademarks of LENZE AG, and are to be used only for purposes of comparison.<br />

�<br />

Application<br />

The combination of supply cores with the control cores for the braking function in these <strong>cable</strong>s is ideal. Precision servo<strong>motor</strong>s, as used<br />

today in many areas of <strong>high</strong>ly-automated manufacturing processes, call for <strong>high</strong>-quality, reliable and long-lasting <strong>cable</strong>s. These requirements<br />

are met to a <strong>high</strong> degree by these <strong>cable</strong>s. The <strong>cable</strong>s have an additional overall screen to ensure EMC compatibility, i.e. for protection against<br />

electromagnetic interference. Production is based on the specifications of established manufacturers of servo-drives and controls, as well<br />

as on various VDE, UL and CSA standards. Applications include machine, plant and robot construction, automation, drive, control and<br />

production engineering.<br />

Attractive for export-oriented mechanical and system engineering.<br />

Please observe appli<strong>cable</strong> installation regulations for use in energy supply chains.<br />

EMC = Electromagnetic compatibillity<br />

To optimise the EMC features we recommend a large round contact of the copper braiding on both ends.<br />

= The product is conformed with the EC Low-Voltage Directive 2006/95/EG.<br />

�<br />

�<br />

Continuation �<br />

N 132<br />

N

TOPSERV ® 113 PUR PUR, <strong>high</strong> <strong>flexible</strong> servo <strong>cable</strong><br />

for drag chain with 1 signal pair according to Siemens Standard<br />

6FX8008-plus and Lenze 0,6/1kV<br />

�<br />

Part<br />

no.<br />

707228<br />

707229<br />

707230<br />

707231<br />

707232<br />

707746<br />

707747<br />

�<br />

�<br />

Part<br />

no.<br />

78948<br />

78949<br />

78950<br />

78951<br />

78952<br />

75956<br />

75957<br />

75958<br />

75959<br />

�<br />

�<br />

Part<br />

no.<br />

77376<br />

700199<br />

74506<br />

74507<br />

74508<br />

74514<br />

74509<br />

74510<br />

74511<br />

74512<br />

74513<br />

�<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

(4�G�1 + (2 x 0,5))<br />

(4�G�1,5 + (2 x 0,5))<br />

(4�G�2,5 + (2 x 0,5))<br />

(4�G�4 + (2 x 1,0))<br />

(4�G�6 + (2 x 1,0))<br />

(4�G�10 + (2 x 1,0))<br />

(4�G�16 + (2 x 1,0))<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

(4�G�1,5 + (2 x 1,5))<br />

(4�G�2,5 + (2 x 1,5))<br />

(4�G�4 + (2 x 1,5))<br />

(4�G�6 + (2 x 1,5))<br />

(4�G�10 + (2 x 1,5))<br />

(4�G�16 + (2 x 1,5))<br />

(4�G�25 + (2 x 1,5))<br />

(4�G�35 + (2 x 1,5))<br />

(4�G�50 + (2 x 1,5))<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

(4�G�1 + (2 x 0,75))<br />

(4�G�1,5 + (2 x 0,5))<br />

(4�G�1,5 + (2 x 1,0))<br />

(4�G�2,5 + (2 x 1,0))<br />

(4�G�4 + (2 x 1,0))<br />

(4�G�6 + (2 x 1,0))<br />

(4�G�10 + (2 x 1,0))<br />

(4�G�16 + (2 x 1,0))<br />

(4�G�25 + (2 x 1,0))<br />

(4�G�35 + (2 x 1,0))<br />

(4�G�50 + (2 x 1,0))<br />

for<br />

system<br />

Lenze<br />

Lenze<br />

Lenze<br />

Lenze<br />

Lenze<br />

Lenze<br />

Lenze<br />

for<br />

system<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

for<br />

system<br />

Dimensions and specifications may be changed without prior notice.<br />

N 133<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

OEM<br />

Part no.<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

OEM<br />

Part no.<br />

6FX8008-1BA11<br />

6FX8008-1BA21<br />

6FX8008-1BA31<br />

6FX8008-1BA41<br />

6FX8008-1BA51<br />

6FX8008-1BA61<br />

6FX8008-1BA25<br />

6FX8008-1BA35<br />

6FX8008-1BA50<br />

OEM<br />

Part no.<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Jacket<br />

colour<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Jacket<br />

colour<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Jacket<br />

colour<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Outer Ø<br />

approx.<br />

mm<br />

10,5<br />

11,5<br />

13,2<br />

14,6<br />

16,8<br />

20,1<br />

23,8<br />

Outer Ø<br />

approx.<br />

mm<br />

11,6<br />

13,4<br />

14,8<br />

16,8<br />

19,4<br />

23,1<br />

26,6<br />

30,9<br />

34,0<br />

Outer Ø<br />

approx.<br />

mm<br />

11,5<br />

11,5<br />

11,5<br />

13,6<br />

15,0<br />

16,1<br />

20,2<br />

23,8<br />

27,0<br />

31,9<br />

36,7<br />

Cop.<br />

weight<br />

kg�/�km<br />

88,0<br />

106,0<br />

152,0<br />

229,0<br />

312,0<br />

508,0<br />

751,0<br />

Cop.<br />

weight<br />

kg�/�km<br />

148,0<br />

187,0<br />

268,0<br />

358,0<br />

584,0<br />

825,0<br />

1283,0<br />

1850,0<br />

2540,0<br />

Cop.<br />

weight<br />

kg�/�km<br />

134,0<br />

127,0<br />

138,0<br />

177,0<br />

258,0<br />

348,0<br />

574,0<br />

815,0<br />

1273,0<br />

1840,0<br />

2530,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

161,0<br />

186,0<br />

263,0<br />

337,0<br />

488,0<br />

688,0<br />

1046,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

228,0<br />

346,0<br />

393,0<br />

519,0<br />

849,0<br />

1260,0<br />

1620,0<br />

2166,0<br />

3039,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

250,0<br />

240,0<br />

254,0<br />

328,0<br />

462,0<br />

596,0<br />

912,0<br />

1194,0<br />

1499,0<br />

1992,0<br />

2880,0<br />

AWG-No.<br />

AWG-No.<br />

AWG-No.<br />

16<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1<br />

17<br />

16<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

1

TOPSERV ® 121 PUR PUR, <strong>high</strong> <strong>flexible</strong> servo <strong>cable</strong><br />

for drag chain with 2 Signal pairs according to Indramat-Standard INK<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� Special PUR drag chain <strong>cable</strong> acc. to � Bare copper, ultrafine wire conductors acc. � low capacitance�<br />

UL�AWM�Style�20234 and CSA�AWM<br />

to DIN�VDE�0295 Kl.�6 bzw. IEC�60228 cl.�6 � PUR outer sheath: low adhesion, extremely<br />

� Temperature range<br />

� core insulation Polypropylen until 6mm² abrasion resistant, halogen-free, resistant<br />

flexing -30 °C to +80 °C<br />

� Black power supply cores with white<br />

to UV-, oil-, hydrolysis and microbial attack<br />

fixed installation -40 °C to +80 °C<br />

imprint � PUR sheath: self-extinguishing and flame<br />

� Nominal voltage<br />

� Green-yellow earth core<br />

retardant, test method B acc. to<br />

acc. to UL/CSA 1000 V<br />

� Black control cores with white imprint DIN�VDE�0472 part�804 and IEC�60332-1<br />

acc. to VDE<br />

� Screening of the control cores in pairs � Optimum compliance with requirements<br />

power supply cores U0/U 600/1000 V wrapped with plastic aluminium foil, copper for electromagnetic compatibility (EMC) by<br />

control cores U0/U 300/500 V<br />

drain-wire tinned and tinned copper approx. 85% coverage from the braided<br />

� A.c. test voltage, 50 Hz<br />

braided screening, approx. coverage 85% screen<br />

power supply cores 4000 V<br />

� These <strong>cable</strong>s are produced to <strong>high</strong> quality<br />

control cores 1000 V<br />

specifications and conform to the<br />

DESINA ® � Control cores stranded in pairs and laid up<br />

in layers together with the power supply<br />

� Insulation resistance<br />

cores with optimal lay length and stabilising<br />

-standard<br />

min. 20 Ohm x km filler<br />

� The materials used in manufacture are<br />

� Coupling resistance<br />

� Overall screening from tinned copper braid, cadmium-free and contain no silicone and<br />

max. 250 Ohm/km<br />

optimal. coverage approx. 85% free from substances harmful to the<br />

� Minimum bending radius<br />

� PUR outer sheath<br />

wetting properties of lacquers<br />

flexing approx. 7,5x <strong>cable</strong> ø<br />

� Sheath colour orange (RAL 2003) according �<br />

fixed installation approx. 4x <strong>cable</strong> ø<br />

to DESINA ®<br />

�<br />

Note<br />

� with meter marking, change-over in 2011<br />

�<br />

� the corresponding Encoder <strong>cable</strong>s�can be found under TOPGEBER ® 512 PUR<br />

� the Servo<strong>cable</strong>s for stativ application oder occasional movements can be found under TOPSERV ® 119 PVC<br />

� Indramat Artikelbezeichnungen INK sind eingetragene Warenzeichen der Bosch Rexroth AG und dienen nur zu Vergleichszwecken<br />

�<br />

Application<br />

The combination of supply cores with the control cores for the braking function and the thermal protection in these <strong>cable</strong>s is ideal. Precision<br />

servo<strong>motor</strong>s, as used today in many areas of <strong>high</strong>ly-automated manufacturing processes, call for <strong>high</strong>-quality, reliable and long-lasting<br />

<strong>cable</strong>s. These requirements are met to a <strong>high</strong> degree by these <strong>cable</strong>s. The <strong>cable</strong>s have an additional overall screen to ensure EMC compatibility,<br />

i.e. for protection against electromagnetic interference. Production is based on the specifications of established manufacturers of servo-drives<br />

and controls, as well as on various VDE, UL and CSA standards. Applications include machine, plant and robot construction, automation,<br />

drive, control and production engineering.<br />

Attractive for export-oriented mechanical and system engineering.<br />

Please observe appli<strong>cable</strong> installation regulations for use in energy supply chains.<br />

EMC = Electromagnetic compatibillity<br />

To optimise the EMC features we recommend a large round contact of the copper braiding on both ends.<br />

= The product is conformed with the EC Low-Voltage Directive 2006/95/EG.<br />

�<br />

�<br />

Part<br />

no.<br />

706003<br />

73774<br />

76103<br />

73579<br />

700561<br />

73580<br />

78955<br />

74094<br />

700562<br />

78956<br />

74095<br />

700563<br />

78957<br />

74096<br />

700564<br />

78958<br />

75978<br />

75979<br />

75980<br />

700565<br />

�<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

(4�G�0,75 + (2 x 0,5))<br />

(4�G�1 + 2 x (2 x 0,75))<br />

(4�G�1,5+ 2x (2x 0,5))<br />

(4�G�1,5+ 2x (2x 1,0))<br />

(4�G�1,5 + 2 x (2 x 0,75))<br />

(4�G�2,5+ 2x (2x 1,0))<br />

(4�G�2,5+ 2x (2x 1,5))<br />

(4�G�4 + 2 x (2 x 1,0))<br />

(4�G�4 + (2 x 1,0) + (2 x 1,5))<br />

(4�G�4 + 2 x (2 x 1,5))<br />

(4�G�6 + 2 x (2 x 1,0))<br />

(4�G�6 + (2 x 1,0) + (2 x 1,5))<br />

(4�G�6 + 2 x (2 x 1,5))<br />

(4�G�10 + 2 x (2 x 1,0))<br />

(4�G�10 + (2 x 1,0) + (2 x 1,5))<br />

(4�G�10 + 2 x (2 x 1,5))<br />

(4�G�16 + 2 x (2 x 1,5))<br />

(4�G�25 + 2 x (2 x 1,5))<br />

(4�G�35 + 2 x (2 x 1,5))<br />

(4�G�50 + 2 x (2 x 2,5))<br />

for<br />

system<br />

Indramat<br />

Indramat<br />

-<br />

-<br />

Indramat<br />

Indramat<br />

-<br />

-<br />

Indramat<br />

-<br />

-<br />

Indramat<br />

-<br />

-<br />

Indramat<br />

-<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

OEM<br />

Part no.<br />

INK-0670<br />

INK-0653<br />

-<br />

-<br />

INK-0650<br />

INK-0602<br />

-<br />

-<br />

INK-0603<br />

-<br />

-<br />

INK-0604<br />

-<br />

-<br />

INK-0605<br />

-<br />

INK-0606<br />

INK-0607<br />

INK-0667<br />

INK-0668<br />

Dimensions and specifications may be changed without prior notice. (RN07)<br />

Jacket<br />

colour<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Orange RAL 2003<br />

Outer Ø<br />

approx.<br />

mm<br />

10,0<br />

11,5<br />

12,4<br />

12,6<br />

12,2<br />

14,6<br />

15,6<br />

16,2<br />

16,0<br />

16,7<br />

18,2<br />

18,8<br />

19,0<br />

21,5<br />

22,4<br />

22,4<br />

26,9<br />

28,0<br />

32,5<br />

37,0<br />

Cop.<br />

weight<br />

kg�/�km<br />

77,0<br />

148,0<br />

145,0<br />

182,0<br />

170,0<br />

229,0<br />

241,0<br />

312,0<br />

318,0<br />

324,0<br />

437,0<br />

445,0<br />

450,0<br />

609,0<br />

610,0<br />

625,0<br />

904,0<br />

1323,0<br />

1621,0<br />

2600,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

166,0<br />

254,0<br />

250,0<br />

262,0<br />

290,0<br />

336,0<br />

350,0<br />

475,0<br />

485,0<br />

490,0<br />

606,0<br />

615,0<br />

621,0<br />

905,0<br />

915,0<br />

925,0<br />

1226,0<br />

1595,0<br />

2196,0<br />

3000,0<br />

AWG-No.<br />

17<br />

17<br />

17<br />

16<br />

16<br />

14<br />

14<br />

12<br />

12<br />

12<br />

10<br />

10<br />

10<br />

8<br />

8<br />

8<br />

6<br />

4<br />

2<br />

1<br />

N 134<br />

N

TOPGEBER ® 512 PUR PUR, <strong>high</strong> <strong>flexible</strong> Feedback<br />

<strong>cable</strong> for drag chain according to Siemens, Indramat, Lenze and other<br />

Standards<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� Special PUR drag chain feedback <strong>cable</strong> acc. � tinned copper, ultra-fine wire conductors � PUR outer sheath: low adhesion, extremely<br />

to UL�AWM style�20233 and 20236�and CSA acc. to DIN�VDE�0295 cl.�6<br />

abrasion resistant, halogen-free, resistant<br />

� Temperature range<br />

� Core insulation of special polypropylene to UV-, oil-, hydrolysis and microbial attack<br />

flexing -30 °C to +80 °C<br />

� Special feature: These <strong>cable</strong>s are produced<br />

fixed installation -40 °C to +80 °C<br />

to <strong>high</strong> quality specifications and conform<br />

to the DESINA ® � Core colours on demand<br />

� Fleece wrapping facilitates sliding<br />

� Nominal voltage<br />

� Overall screening of tinned copper wire<br />

-standard<br />

acc. to UL 300 V<br />

braid with tinned drain wire, coverage � Due to the <strong>high</strong> grade special core<br />

0,14-0,34 mm²: 350 V<br />

approx. 85%<br />

insulation, the PUR sheath and the <strong>high</strong>ly<br />

0,5-1,0 mm²: 500 V<br />

� Polyester foil<br />

<strong>flexible</strong> conductor, these <strong>cable</strong>s are ideally<br />

� A.c. test voltage, 50 Hz<br />

� PUR outer sheath<br />

suitable for use in drag chains and provide<br />

core/core 2000 V<br />

core/screen 1000 V<br />

� Sheath colour green (RAL 6018) acc. to<br />

DESINA<br />

<strong>high</strong> functional reliability<br />

® � Mutual capacitance at 800 Hz<br />

core/core approx. 70 nF/km<br />

core/screen approx. 110 nF/km<br />

or orange<br />

� with meter marking, change-over in 2011<br />

�<br />

� Optimum compliance with requirements<br />

for electromagnetic compatibility (EMC) by<br />

approx. 85% coverage from the braided<br />

screen<br />

� Insulation resistance<br />

� Particularly attractive for export-oriented<br />

min. 20 MOhm x km<br />

markets due to UL/CSA approval<br />

� Coupling resistance<br />

� The materials used in manufacture are<br />

max. 250 Ohm<br />

cadmium-free and contain no silicone and<br />

� Minimum bending radius<br />

free from substances harmful to the<br />

flexing approx. 10x <strong>cable</strong> ø<br />

wetting properties of lacquers<br />

fixed installation approx. 6x <strong>cable</strong> ø<br />

�<br />

Note<br />

�<br />

� �the corresponding Motor- and Servo<strong>cable</strong>s can be found under TOPSERV ® <strong>109</strong> respectively 113 PUR<br />

� Encoder <strong>cable</strong>s�for static application with PVC Jacket can be found under TOPGEBER ® 511 PVC<br />

� Brackets ( ) indicate screen.<br />

� SIEMENS product designations 6FX 8008-... are registered trademarks of Siemens AG, and are to be used only for purposes of comparison.<br />

� INDRAMAT product designations INK- are registered trademarks of Bosch-Rexroth AG, and are to be used only for purposes of comparison.<br />

� Desina ® : Explanation: see introduction.<br />

�<br />

Application<br />

These low-capacitance incremental encoder <strong>cable</strong>s or position feedback <strong>cable</strong>s transmit the control pulses for positioning and operating<br />

characteristics of servo<strong>motor</strong>s. These <strong>cable</strong>s are used as connecting <strong>cable</strong>s for tachos, brakes and pulse generators in applications subjected<br />

to heavy mechanical stresses in industrial equipment, machine tools, control and automation equipment.<br />

Please observe appli<strong>cable</strong> installation regulations for use in energy supply chains.<br />

EMC = Electromagnetic compatibillity<br />

To optimise the EMC features we recommend a large round contact of the copper braiding on both ends.<br />

= The product is conformed with the EC Low-Voltage Directive 2006/95/EG.<br />

�<br />

�<br />

N 135<br />

Continuation �

TOPGEBER ® 512 PUR PUR, <strong>high</strong> <strong>flexible</strong> Feedback<br />

<strong>cable</strong> for drag chain according to Siemens, Indramat, Lenze and other<br />

Standards<br />

�<br />

Part<br />

no.<br />

700655<br />

78081<br />

707400<br />

700657<br />

700540<br />

700654<br />

700653<br />

78079<br />

802473<br />

706333<br />

705413<br />

707403<br />

707404<br />

707405<br />

707406<br />

707407<br />

702050<br />

78080<br />

77741<br />

707738<br />

707739<br />

707740<br />

707408<br />

707418<br />

707409<br />

77743<br />

79513<br />

707410<br />

700560<br />

77753<br />

78963<br />

78828<br />

79613<br />

77744<br />

78372<br />

77750<br />

705221<br />

�<br />

No.cores x<br />

cross-sec.<br />

mm²<br />

( 8 x 2�x�0,18)<br />

( 4 x 2�x�0,38 + 4 x 0,5)<br />

(3x (2�x�0,14) + 2 x 0,5)<br />

(3x (2�x�0,14) + 4 x 0,14 + 2 x 0,5)<br />

(3x (2�x�0,14) + 4 x 0,14 + 4 x 0,25 + 2 x 0,5)<br />

( 4 x 2�x�0,18)<br />

( 2 x 2�x�0,18)<br />

(12�x�0,25)<br />

( 2 x 2�x�0,15 + 2 x 0,38)<br />

( 5 x 2�x�0,25 + 2 x 0,5)<br />

( 3 x 2�x�0,25 + 2 x 0,5)<br />

( 3 x 2�x�0,25)<br />

( 5 x 2�x�0,14 + 2 x 0,5)<br />

3 x (2 x 0,14) + (2 x 0,5)<br />

4 x (2 x 0,14) + (2 x 1,0)<br />

3 x (2 x 0,14) + (3 x 0,14)<br />

(4 x 2 x 0,25 + 2 x 1,0)<br />

( 4 x 2�x�0,25 + 2 x 0,5)<br />

(9�x�0,5)<br />

( 4 x 2�x�0,25 + 2 x 1,0)<br />

( 4 x 2�x�0,25 + 2 x 0,5)<br />

(9�x�0,5)<br />

(4 x 2 x 0,14 + 4 x 1,0 + (4 x 0,14))<br />

(3 x (2 x 0,25) + 3 x 0,25 + 2 x 1,0)<br />

(2 x 2 x 0,25 + 2 x 0,5)<br />

(3x (2�x�0,14) + 2 x (1 x 0,5))<br />

( 4 x 2�x�0,14 + 4 x 0,5)<br />

( 3 x 2�x�0,14 + 2 x 1,0)<br />

(4 x 2 x 0,14 + (4 x 0,14) + 4 x 0,5)<br />

(10�x�0,14 + 2 x 0,5)<br />

( 5 x 2�x�0,14 + 2 x 0,5)<br />

( 3 x 2�x�0,25)<br />

( 5 x 2�x�0,38 + 2 x 0,5)<br />

(3x (2�x�0,14) + 2 x 1,0)<br />

( 3 x 2�x�0,14 + 2 x 0,5)<br />

(4x (2�x�0,25) + 2 x 1,0)<br />

( 4 x 2�x�0,25)<br />

for<br />

system<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Siemens<br />

Berger Lahr<br />

Elau<br />

B+R<br />

B+R<br />

Lenze<br />

Lenze<br />

Lenze<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Indramat<br />

Heidenhain<br />

Heidenhain<br />

Heidenhain<br />

Heidenhain<br />

Heidenhain<br />

Baumüller<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

OEM<br />

Part no.<br />

Dimensions and specifications may be changed without prior notice. (RN07)<br />

6FX 8008-1BD11<br />

6FX 8008-1BD21<br />

6FX 8008-1BD31<br />

6FX 8008-1BD41<br />

6FX 8008-1BD51<br />

6FX 8008-1BD61<br />

6FX 8008-1BD71<br />

6FX 8008-1BD81<br />

6FX 8008-2DC00<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

INK-0209 grün<br />

INK-0448 grün<br />

INK-0208 grün<br />

INK-0209<br />

INK-0448<br />

INK-0208<br />

INK-0532<br />

INK-0280<br />

INK-0750<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Jacket<br />

colour<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Orange<br />

Orange<br />

Orange<br />

Orange<br />

Orange<br />

Orange<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Green<br />

Outer Ø<br />

approx.<br />

mm<br />

7,8<br />

9,8<br />

9,0<br />

8,9<br />

9,6<br />

6,4<br />

5,0<br />

7,5<br />

7,0<br />

8,8<br />

7,4<br />

6,5<br />

8,7<br />

9,8<br />

11,3<br />

10,3<br />

8,8<br />

8,5<br />

8,8<br />

8,8<br />

8,5<br />

8,8<br />

9,7<br />

9,0<br />

7,2<br />

8,4<br />

8,5<br />

9,1<br />

8,3<br />

7,2<br />

9,0<br />

7,2<br />

8,6<br />

8,2<br />

7,2<br />

10,5<br />

7,5<br />

Cop.<br />

weight<br />

kg�/�km<br />

54,0<br />

83,0<br />

74,0<br />

66,0<br />

75,0<br />

35,0<br />

24,0<br />

65,0<br />

41,0<br />

69,0<br />

43,0<br />

31,0<br />

48,0<br />

42,0<br />

66,0<br />

41,0<br />

64,0<br />

51,0<br />

69,0<br />

64,0<br />

51,0<br />

69,0<br />

81,0<br />

84,0<br />

38,0<br />

54,0<br />

52,0<br />

72,0<br />

81,0<br />

43,0<br />

72,0<br />

55,0<br />

69,0<br />

71,0<br />

35,0<br />

93,0<br />

39,0<br />

Weight<br />

approx.<br />

kg�/�km<br />

79,0<br />

135,0<br />

119,0<br />

120,0<br />

138,0<br />

57,0<br />

42,0<br />

74,0<br />

72,0<br />

127,0<br />

82,0<br />

60,0<br />

98,0<br />

98,0<br />

144,0<br />

127,0<br />

99,0<br />

106,0<br />

124,0<br />

99,0<br />

106,0<br />

124,0<br />

142,0<br />

134,7<br />

79,0<br />

<strong>109</strong>,0<br />

100,0<br />

132,0<br />

104,0<br />

83,0<br />

98,0<br />

83,0<br />

130,0<br />

107,0<br />

67,0<br />

175,0<br />

88,0<br />

AWG-No.<br />

24<br />

21<br />

21<br />

26<br />

-<br />

-<br />

-<br />

24<br />

-<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

24<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

-<br />

26<br />

26<br />

-<br />

26<br />

26<br />

24<br />

21<br />

26<br />

26<br />

24<br />

24<br />

N 136<br />

N

TOPSERV ® 600 VFD EMC-preferred type, <strong>flexible</strong> <strong>motor</strong><br />

power supply <strong>cable</strong>, oil-resistant, NFPA 79 Edition 2007<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� PVC <strong>motor</strong> supply <strong>cable</strong> according to � Tinned copper conductor, extra fine wire � Self-extinguishing and flame retardant in<br />

UL�1277<br />

stranded with AWG measures<br />

accordance with CSA FT4<br />

� Temperature range<br />

� Special PVC core insulation with transparent � The materials used in manufacture are free<br />

-25ºC to +90ºC<br />

nylon skin<br />

of silicone, cadmium and substances that<br />

� Nominal voltage<br />

� Black cores with continuous white<br />

impair paint wetting<br />

TC 600 V<br />

numbering<br />

� UV-resistant<br />

WTTC 1000 V<br />

� Green-yellow earth core in the outer layer Tests�<br />

� Test voltage 4000 V � Cores stranded in layers with optimal UL:<br />

� Minimum bending radius<br />

lay-lenghts<br />

TC-ER, WTTC 1000 V, MTW, NFPA 79 2007,<br />

Flexing 5x <strong>cable</strong> ø<br />

� Fleece<br />

UL 1277, PLTC-ER (AWG 18 - AWG 12), ITC-ER<br />

Permanently flexing 7,5 <strong>cable</strong> ø<br />

� 1. Screening with special aluminium foil (AWG 18 - AWG 12) OIL RES I & II, 90º C dry<br />

� Coupling resistance<br />

� 2. Screening with braid of tinned copper / 75º C wet, Cold Bend Test -40ºC<br />

Max. 250 Ohm/km<br />

wires, optimal coverage, approx. 85% CSA:<br />

� Separator<br />

c (UL) CIC-TC FT4,<br />

� Special PVC outer jacket<br />

AWM I/II A/B FT4<br />

� Sheath colour - black (RAL 9005) or orange<br />

(RAL 2003)<br />

� With length marking in feet�<br />

�<br />

�<br />

Note<br />

� VFD = Variable Frequency Drive<br />

�<br />

Application<br />

Flexible, extremly oil-resistant <strong>motor</strong> supply <strong>cable</strong> for modern servo<strong>motor</strong>s; the double-screening with special aluminium foil (100% coverage)<br />

and tinned copper braid (approx. 85% coverage) provides effective protection against electrical disturbance and the resultant failures.<br />

Approved to NFPA 79 2007 for open, unprotected installation on <strong>cable</strong> trays and from <strong>cable</strong> trays to the machine. The special TPE sheath is<br />

extremly resistant to oil, coolants and solvents and hence the perfect solution for industrial applications with open installation, installation<br />

in pipes and in the earth.<br />

EMC = Electromagnetic compatibility<br />

To optimise EMC characteristics, we recommend a large contact area for the copper braiding around the entire circumference on both<br />

ends.<br />

= The product conforms to the EG Low-Voltage Directive 2006/95/EG<br />

�<br />

Dimensions and specifications may be changed without prior notice. (RN01)<br />

N 139

TOPSERV ® 650 VFD EMC-preferred type, <strong>flexible</strong> <strong>motor</strong> power<br />

supply <strong>cable</strong> with control cores, oil-resistant, NFPA 79 Edition 2007<br />

�<br />

�<br />

Technical data<br />

Cable structure<br />

Properties<br />

� TPE <strong>motor</strong> supply <strong>cable</strong> according to UL � Tinned copper conductor, fine wire � Self-extinguishing and flame retardant in<br />

1277<br />

stranded, with AWG measures<br />

accordance with CSA FT4<br />

� Temperature range<br />

� Special PVC core insulation with transparent � The materials used in manufacture are free<br />

Flexing -25ºC to +105ºC<br />

nylon skin<br />

of silicone, cadmium and substances that<br />

� Nominal voltage<br />

� Black supply cores with continuous white impair paint wetting<br />

TC 600 V<br />

numbering<br />

� UV-resistant<br />

WTTC 1000 V�<br />

� Green-yellow earth core in the outer layer Tests<br />

� Test voltage<br />

� 2 black control cores with marking 5 and 6 UL:<br />

Power supply cores 4000 V<br />

� Control cores screened in pairs with<br />

TC-ER, WTTC 1000 V, MTW, NFPA 79 2007,<br />

Control cores 2000 V��<br />

plastic-coated aluminium foil, tinned drain UL 1277, PLTC-ER (AWG 18 - AWG 12), ITC-ER<br />

� Minimum bending radius<br />

wire (AWG 18 - AWG 12) OIL RES I & II, 90º C dry<br />

Flexing 5x <strong>cable</strong> ø<br />

� Control cores stranded in pairs and laid up / 75º C wet<br />

Permanently flexing 7,5 <strong>cable</strong> ø<br />

in layers with optimal lay-length with the Class 1 Div. 2 per NEC Art. 336, 392, 501<br />

� Coupling resistance<br />

power supply cores<br />

Cold Bend Test -40ºC<br />

Max. 250 Ohm/km � 1. Screening with plastic-coated aluminium CSA:<br />

foil<br />

c (UL) CIC-TC FT4<br />

� 2. Screening from tinned Cu-braid, optimal AWM I/II A/B FT4<br />

�<br />

Note<br />

� VFD = Variable Frequency Drive<br />

� with meter marking in feet<br />

coverage approx. 85%<br />

� Separator<br />

� Special TPE outer jacket<br />

� Sheath colour - black (RAL 9005) or orange<br />

(RAL 2003)<br />

�<br />

�<br />

Application<br />

Highly-<strong>flexible</strong>, extremly oil-resistant <strong>motor</strong> supply <strong>cable</strong> for modern servo<strong>motor</strong>s; the double-screening with special aluminium foil (100%<br />

coverage) and tinned copper braid (approx. 85% coverage) provides effective protection against electrical disturbance and the resultant<br />

failures. Approved to NFPA 79 2007 for open, unprotected installation on <strong>cable</strong> trays and from <strong>cable</strong> trays to the machine. The special TPE<br />

sheath is extremly resistant to oil, coolants and solvents and hence the perfect solution for industrial applications with open installation,<br />

installation in pipes and in the earth.<br />

�<br />

EMC = Electromagnetic compatibillity<br />

To optimise EMC characteristics, we recommend a large contact area for the copper braiding around the entire circumference on both<br />

ends.<br />

= The product is conformed with the EC Low-Voltage Directive 2006/95/EG.<br />

�<br />

Dimensions and specifications may be changed without prior notice. (RN01)<br />

N 140<br />

N