Order online: www.leitz.com.au - Supplier Woodworking magazine

Order online: www.leitz.com.au - Supplier Woodworking magazine

Order online: www.leitz.com.au - Supplier Woodworking magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SEPT/OCT 2012

Häfele App:<br />

The Complete Häfele <strong>com</strong>es to iPad!<br />

Now you can access everything Häfele has to offer anytime, anywhere. You’ll be able to present the best design<br />

concepts and products to clients, show them how they look in real-life installations and order products for your<br />

project whether you are in the office, on the job site or on the go. Suddenly turning your ideas into reality has<br />

never been easier.<br />

Like us on facebook: <strong>www</strong>.facebook.<strong>com</strong>/hafele<strong>au</strong>stralia<br />

Features:<br />

• Access the entire Häfele Catalogue library, all stored<br />

in one <strong>com</strong>pact and portable location - your iPad!<br />

• Download the catalogues to your iPad and enjoy<br />

fast browsing through catalogue pages.<br />

• Multiple search functions, either by product name,<br />

article number or simply browse through<br />

catalogue’s contents.<br />

• Single page portrait or double page landscape views.<br />

• Zoom or move around pages with simple<br />

touch motions.<br />

• See something interesting? Share the Häfele app<br />

experience and email it to a friend.<br />

• Add articles to your shopping cart, access live <strong>online</strong><br />

pricing and stock availability. Then place your order<br />

on the spot.<br />

Melbourne | Sydney | Newcastle | Brisbane | Adelaide | Perth | Canberra | Hobart | L<strong>au</strong>nceston<br />

info@hafele.<strong>com</strong>.<strong>au</strong> <strong>www</strong>.hafele.<strong>com</strong> 1300 659 728<br />

Download the App FREE<br />

from the Apple App Store ®

FLAP DOOR<br />

FITTINGS FOR<br />

FURNITURE<br />

Häfele<br />

DUO<br />

Lid Stay + Flap Stay<br />

DUO. One lid stay with multiple application<br />

possibilities: Stops in any position or closes with<br />

braking function. Can be mounted on one or both<br />

sides. Need higher load capacity? Choose DUO Forte<br />

for flap heights up to 700 mm.<br />

Both now available in three finishes, nickel, black and white!<br />

<strong>www</strong>.hafele.<strong>com</strong><br />

Häfele<br />

MAXI<br />

Stay Flap Fitting<br />

The fitting for higher load-bearing applications and<br />

creative design: MAXI stands for effortless opening of<br />

heavy flaps with an extensive variety of applications<br />

such as multi-position stopping. “Touch opening” and<br />

“push-to-open” activation for handle-free flaps. And if<br />

desired they close without a sound, thanks to optional<br />

soft-closing mechanism.

Upfront<br />

The long awaited and much anticipated AWISA 2012<br />

exhibition, held in Sydney in July, certainly was a<br />

wel<strong>com</strong>e surprise for the majority of exhibitors struggling<br />

with the economic downturn. The visitors came at a<br />

steady pace throughout the four day event and reports<br />

from all quarters confirmed that the show was successful,<br />

even in these challenging times.<br />

Visually, there were some stunning stands –<br />

particularly in the area designated ‘Design’ by the<br />

show organisers. This area was mainly occupied by<br />

<strong>com</strong>panies supplying hardware, <strong>com</strong>ponents and<br />

decorative products for the cabinet, furniture, kitchen<br />

and fit-out industries – and they were always extremely<br />

busy. <strong>Supplier</strong> Magazine would particularly like to<br />

single out Borg Decorative, Hettich and Hafele for their<br />

exceptional stand displays.<br />

We also noticed that our advertisers’ stands were all<br />

extremely busy – and size did not matter!<br />

Our in<strong>au</strong>gural Gold Star Award nominations at<br />

AWISA were thoroughly scrutinised and we were<br />

impressed by many of the stands, the products and the<br />

activities on them. Eventually though, a final choice had<br />

to be made and the <strong>Supplier</strong> <strong>Woodworking</strong> Magazine’s<br />

Gold Star Awards went to Beyond Tools, Weinig, Holz-<br />

Her, Hettich, Altendorf and Wood Tech.<br />

Congratulations to all the exhibitors at the show – your<br />

hard work was obviously well worth all the effort.<br />

Dave Kahle<br />

Advisory Panel Member<br />

Vicky Cammiade - Publisher<br />

Ph: 03 9890 0815; Fax: 03 9890 0087 or<br />

Email: vicky.cammiade@elitepublishing.<strong>com</strong>.<strong>au</strong><br />

Meet the team<br />

Vicky Cammiade<br />

Publisher<br />

Sean O’Sullivan<br />

Advisory Panel Member<br />

Phil Ashley<br />

Advisory Panel Member<br />

Jennifer Curtis<br />

Group Managing Editor<br />

Dr Greg Chapman<br />

Advisory Panel Member<br />

Michael Buckley<br />

Advisory Panel Member<br />

Contents<br />

Member of the International <strong>Woodworking</strong> and<br />

Furniture <strong>Supplier</strong> Magazine Association<br />

SEPT/OCT 2012 vol. 28 no.5<br />

☞News<br />

06 New all Australian furniture<br />

show<br />

08 Timalac Coatings celebrates<br />

20th birthday<br />

10 New worldwide timber<br />

legality requirements<br />

☞Design & Trends<br />

14 KDBi Australian Kitchen and<br />

Bathroom Designer Awards<br />

20 Nikpol – helping to ensure a<br />

healthy environment<br />

☞Business<br />

24 Times are tough: who can<br />

afford an ad agency?<br />

26 Is your business running you?<br />

☞Associations<br />

27 CMA news<br />

☞AWISA Review<br />

30 AWISA 2012 – the return<br />

☞Manufacturing<br />

50 Turning a business on<br />

its head<br />

54 Finishing innovations at<br />

IWF 2012<br />

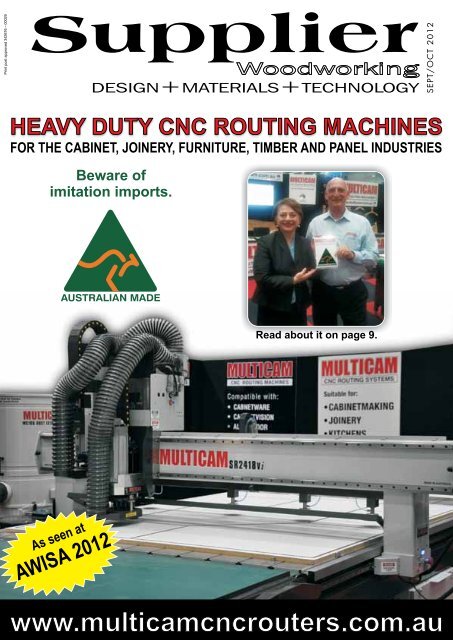

☞Front Cover<br />

Multicam Systems Newcastle<br />

<strong>www</strong>.multicamcncrouters.<strong>com</strong>.<strong>au</strong><br />

The only specialist business publication<br />

servicing the Furniture, Kitchen, Shop/Office<br />

Fittings, Cabinetmaking, Joinery and the<br />

related timber and panel product industries in<br />

Australasia for over 26 years!<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

Akron<br />

The Akron 400 series of edgebanders<br />

are highly versatile and flexible.<br />

With features suitable<br />

for up to 12mm solid<br />

timber, and processing<br />

times of up to<br />

18m/min Akron<br />

Edgebanders are<br />

second to none.<br />

Windows based touch screen control<br />

Innovative glue pot technology - requires<br />

no greasing!<br />

Quick melt gluing system<br />

High quality HSD electrospindle<br />

CNC 4 motor servo-driven trimming units<br />

Two motor corner rounding units with<br />

<strong>au</strong>tomatic 4 position set up via control<br />

We have a Biesse<br />

Showroom near you!<br />

NSW E: nsw@biesse<strong>au</strong>stralia.<strong>com</strong>.<strong>au</strong><br />

VIC E: vic@biesse<strong>au</strong>stralia.<strong>com</strong>.<strong>au</strong><br />

QLD E: qld@biesse<strong>au</strong>stralia.<strong>com</strong>.<strong>au</strong><br />

SA E: sa@biesse<strong>au</strong>stralia.<strong>com</strong>.<strong>au</strong><br />

WA E: wa@biesse<strong>au</strong>stralia.<strong>com</strong>.<strong>au</strong><br />

NZ P: +64 (0)9 278 1870<br />

E: sales@biessenewzealand.co.nz<br />

Call 1300 BIESSE<br />

400 SERIES<br />

Edgebanding Solutions<br />

Two position scraping unit for <strong>au</strong>tomatic<br />

processing of 1mm and 2mm edge strip<br />

Glue joint scraping unit<br />

Hot air blower unit<br />

Skill<br />

G FT<br />

SERIES<br />

Biesse makes the Nesting decision EASY<br />

– start with stand alone nesting machine<br />

and upgrade to <strong>au</strong>tomatic loading<br />

and unloading machine or fully<br />

<strong>au</strong>tomated labeling<br />

cells at anytime.<br />

Table sizes from 2400 x<br />

1200mm to 3600 x 1800mm<br />

Windows based PC control<br />

Automatic table zoning<br />

10 vertical spindle drill head<br />

On board tool change – 12 positions<br />

300 m3 Oil cooled vacuum pump<br />

Sensors on all stop pins<br />

Full Yaskawa digital drive system (patented)<br />

HSD 16HP electrospindle<br />

Presetter for the measurement of the tool length<br />

Easy to use and fully integrated software Including<br />

BiesseWorks and BiesseNest

News<br />

Just Pure Australian made<br />

The Queensland Furnishing<br />

Industry Association (FIAA<br />

Qld) is organising a new,<br />

boutique trade show exclusively<br />

showcasing Australian Made<br />

furniture and bedding products.<br />

The show, called Pure Australia<br />

2013, will be held from 18 to 20<br />

April 2013 in the Exhibition Hall at<br />

the RNA Showgrounds, Brisbane.<br />

Pure Australia will be all about<br />

showcasing the benefits of buying<br />

quality Australian Made furniture and<br />

bedding products and will project<br />

the industry’s vigour, purpose and<br />

determination to stay <strong>com</strong>mitted<br />

to creative, colourful, professional<br />

Australian excellence, with quality<br />

and design that cannot be matched.<br />

“Australian manufacturers offer<br />

the finest, most creative and highest<br />

quality furniture with the uniqueness<br />

of customised versatility bec<strong>au</strong>se we<br />

proudly make it here,” explained<br />

Gerry Murray, General Manager<br />

of FIAA (Qld.) “Anyone wishing to<br />

exhibit at the show will have to be a<br />

designated Australian manufacturer<br />

and all products exhibited must be<br />

Australian Made – no imports – as<br />

per the ACCC criteria,” he said.<br />

Bec<strong>au</strong>se this is the only dedicated<br />

Australian Made furniture and<br />

bedding trade show in the country,<br />

visitors in attendance will be there<br />

for the sole purpose of viewing<br />

Blum showroom opens in Queensland<br />

BLUM has relocated its Queensland<br />

operation to a new 1000m² office<br />

and showroom in Underwood.<br />

Due to recent growth, Blum required<br />

a larger property for training and<br />

presentations, but also used the move<br />

as an opportunity to increase exposure<br />

to end consumers. Blum’s Queensland<br />

showroom now presents the most current<br />

innovations consistent with Blum’s other<br />

showrooms across Australia.<br />

Blum’s new Queensland showroom<br />

has been divided into specific functions<br />

creating three separate areas within the<br />

main showroom covering the three main<br />

6 | <strong>Supplier</strong>Sept/Oct 2012<br />

Australian Made products, so<br />

exhibitors will be promoting their<br />

latest ranges to a very targeted<br />

<strong>au</strong>dience.<br />

The show is aimed at premium<br />

furniture and bedding retailers,<br />

high end design retailers, interior<br />

designers, decorators and specifiers.<br />

It should also be of great interest to<br />

property, hospitality and healthcare<br />

sector corporate buyers together<br />

with State Government procurement<br />

specifiers and international buyers.<br />

“This is an excellent opportunity<br />

for Australian manufacturers to<br />

raise their industry profile and<br />

create an awareness of their<br />

brands in the absence of imports.<br />

They can also support the buying<br />

process by answering the buyers’<br />

questions face-to-face,” said<br />

Gerry. “We believe the industry<br />

will benefit from this excellent<br />

value-for-money way of promoting<br />

Australian Made furniture.”<br />

Geoff Manson, Managing Director<br />

of Contour Furniture and chairman<br />

of the show <strong>com</strong>mittee believes<br />

this exciting event will capture the<br />

passion of the Australian furniture and<br />

bedding industry and be a catalyst in<br />

the industry’s resurgence.<br />

“I urge all Australian<br />

manufacturers to participate in this<br />

event and all buyers or potential<br />

buyers to attend,” said Geoff. ●<br />

product lines. Blum’s home application<br />

displays are located nearby displaying<br />

products in a variety of scenarios,<br />

including bathroom, home office,<br />

wardrobe and home entertainment.<br />

Further to this a Dynamic Space kitchen<br />

demonstrates the benefits of designing a<br />

kitchen with functionality and a workflow<br />

in mind.<br />

Mark Hahn, Blum State Sales Manager<br />

<strong>com</strong>mented: “The Kitchen-Test Drive is<br />

also a fantastic brand new concept to<br />

our Queensland showroom. The room<br />

consists of functional and movable<br />

cabinetry allowing visitors to set up their<br />

Employee or contractor:<br />

helping you make the right<br />

decision<br />

BeFORe your business engages workers, you<br />

need to check whether they are employees<br />

or contractors by examining the details of the<br />

working arrangements.<br />

It is important that you get the decision right as you<br />

will need to meet different tax and super obligations<br />

depending on whether your workers are employees<br />

or contractors.<br />

Many businesses are getting the employee or<br />

contractor decision wrong as they are not checking<br />

whether they have set up their arrangements correctly.<br />

A significant number of businesses the ATO visited last<br />

year got it wrong.<br />

The ATO Employee or contractor homepage offers<br />

<strong>com</strong>prehensive, easy to understand information<br />

you can rely on to determine if your workers are<br />

employees or contractors.<br />

The homepage has all the information you need in<br />

one place to help you determine if your workers are<br />

employees or contractors, including:<br />

• the basics – things every business needs to know<br />

• the <strong>com</strong>mon reasons businesses get the employee<br />

or contractor decision wrong<br />

• industry specific information<br />

• an Employee/contractor decision tool which will<br />

give an answer businesses can rely on<br />

• summary of the obligations businesses need to meet<br />

for their employees or contractors.<br />

You are responsible for correctly determining if your<br />

workers are employees or contractors and meeting<br />

the required tax and super obligations. If you get the<br />

decision wrong, you risk having to pay penalties.<br />

For more information visit <strong>www</strong>.ato.gov.<strong>au</strong>/<br />

EmployeeContractorEssentials ●<br />

kitchen according to their proposed plan.<br />

The customer is able to stand in their<br />

kitchen and see what works and what<br />

doesn’t prior to installation. It has been<br />

an amazing success so far in providing<br />

the end user with the reassurance that<br />

their kitchen, once installed, will be a<br />

functional, enjoyable space to work in.”<br />

The facility also has a workshop for<br />

technical product training available by<br />

request through Blum area managers<br />

while Dynamic Space workshops are held<br />

on a regular basis providing research<br />

information and concepts for industry<br />

professionals to utilise in their business. ●<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

16 Industry Leaders speak on<br />

Go to <strong>www</strong>.youtube.<strong>com</strong> now and search empower time tracking software<br />

Greenmount Manufacturing “Substantial increases<br />

in factory productivity” - $10 million annual turnover, 45<br />

staff, in <strong>com</strong>mercial fit outs, kitchens and camper van<br />

fit outs – using Empower for 8 months (Auckland)<br />

Comace Interior Fit Outs “We have achieved well in<br />

excess of 30% increase in factory productivity” – 27<br />

staff business using Empower for 4 years (Adelaide)<br />

Rose and Heather Furniture “100% increase in<br />

factory and staff productivity using Empower Software”<br />

– 20 factory staff and using Empower for 5 years<br />

(Auckland)<br />

Central Joinery “Our goal is for Empower to increase<br />

our factory productivity by 25%” – $10 million annual<br />

turnover, 45 staff, using Empower for 3 years<br />

(Auckland)<br />

RH Page Shop Fitters International Shop Fitter<br />

seriously <strong>com</strong>mitted to lean manufacturing and<br />

Empower Software – 30 factory staff using Empower<br />

for 2 years (Auckland)<br />

Peppertree Furniture 1 “45.25 % increase in factory<br />

productivity - using Empower for 10 weeks” – 20<br />

factory staff (Adelaide)<br />

Peppertree Furniture 2 “86% increase in factory<br />

productivity ¬ using Empower for 6 months” – 20<br />

factory staff (Adelaide)<br />

Montage Kitchens “17% increase in factory<br />

productivity in year 1” – 20 man kitchen shop using<br />

Empower for 8 years (Hamilton)<br />

16 Industry Leading Kitchen, Cabinet, Shop Fitting, Furniture, Window and Joinery Manufacturers throughout Australia and New Zealand<br />

talk about their productivity increases, KPIs, factory secrets and use of Empower Software – live on YouTube NOW. All are short videos a few<br />

minutes each. Factory productivity increases profiled on YouTube range from 17% to 160% - the average increase in factory productivity<br />

across 21 manufacturers is 47.5%.<br />

Go to <strong>www</strong>.youtube.<strong>com</strong> now and search empower time tracking software.<br />

Diary note to view YouTube again in 3 months time: an additional 16 leading manufacturers who use Empower Software will be on YouTube.<br />

Empower Manufacturing Software Modules<br />

• Time Tracking/Labour Management Software (using 2nd hand PCs on the factory floor)<br />

• Job Scheduling Software<br />

• Quoting, Materials, Job Management Software<br />

Phone, e mail or go to our web site - and we will send you a FREE information package including a proposal to implement<br />

Empower Software in your business - manufacturing@xtra.co.nz or <strong>www</strong>.empowersoftware.biz<br />

Sydney (02) 8011 3281, Melbourne (03) 9016 2537, Adelaide (08) 7200 1132, Auckland (09) 307 1115<br />

Modulink Joinery “$6 million annual turnover, 30 staff, in<br />

hotel fit outs, kitchens and office furniture – business and<br />

turnover has grown ten fold in 6 years and Empower has<br />

controlled that growth and profitability over the 6 years”<br />

(Christchurch)<br />

Barrett Joinery “30% increase in Factory Productivity”<br />

18 factory staff using Empower for 5 years (Timaru)<br />

Phoenix Aluminium Windows “160% + increase in factory<br />

productivity. 26 factory staff down to 10 staff and output<br />

increased” - $13 million annual turnover, one of<br />

New Zealand’s most productive and progressive aluminium<br />

window Manufacturers (Auckland)<br />

Vogue Kitchens “Significant increases in factory<br />

productivity within 2 weeks of Empower Software<br />

implementation” – 9 factory staff (New Plymouth)<br />

Total Timba “25% factory productivity increase - and<br />

Empower Software worked from day 1” - 8 factory staff<br />

using Empower for 4 years (Auckland)<br />

PJT Cabinets “We used to use time sheets that our staff<br />

filled in their times on jobs at day end. Empower proved the<br />

time manual sheet times were highly inaccurate. We have<br />

made significant productivity gains in the factory and office<br />

on Empower and I highly re<strong>com</strong>mend it”<br />

MARS Heavy Road Transport “Empower turned our<br />

factory productivity on its ear increasing it by an absolute<br />

minimum 30%, and turned my business around” - 35 man<br />

engineering shop using Empower for 3 years (Riverland, SA)<br />

Home Plus Southland “160% increase in factory<br />

productivity. 9 factory staff reduced down to 5 staff in year<br />

1 – same output. Then 5 factory staff doing twice the<br />

turnover and work load that the 9 staff had been <strong>com</strong>pleting<br />

previously” - using Empower for 5 years (Invercargill)

News<br />

Australian Made wel<strong>com</strong>es<br />

breakthrough for Aussie exports in China<br />

IN a major breakthrough for<br />

Australian exporters, the Australian<br />

Made, Australian Grown (AMAG)<br />

logo has now been formally<br />

trademarked in China.<br />

This means that for the first time ever,<br />

Australian exporters have a symbol<br />

which can be used on their Australianmade<br />

or grown exports into China,<br />

that both establishes their products<br />

as genuinely Australian and is legally<br />

protected under Chinese law.<br />

“Historically, China has been a<br />

challenging environment for the protection<br />

of intellectual property,” Australian Made<br />

Chief Executive, Ian Harrison, said.<br />

“The AMAG logo’s formal registration<br />

in China as a country-of-origin symbol<br />

Timbalac Coatings’ 20th Anniversary<br />

A 20-year milestone for any <strong>com</strong>pany is worth<br />

celebrating.<br />

A celebration where an <strong>au</strong>ditorium is filled with satisfied<br />

customers and business partners is worthy of appl<strong>au</strong>se. Such<br />

was the case on 4 September when at least 90 industry people<br />

gathered at Holmesglen TAFE in Victoria to celebrate 20 years of<br />

Timbalac service to the timber coatings industry.<br />

Director and industry icon, Eric Zeeve was on hand to<br />

wel<strong>com</strong>e his many customers and business associates from<br />

around the country. Special guests included Parliamentary<br />

Secretary for Education, Inga Peulich, master of ceremonies,<br />

Mark Amos from the Master Painters Association, representatives<br />

from Sayerlac (Italy) and Philip Ashley from the furnishing<br />

department at Holmesglen.<br />

Inga Peulich, who sits on the all-party <strong>com</strong>mittee for economic<br />

development and has a 30-year involvement in small business,<br />

said that, over the years, Timbalac has been a <strong>com</strong>pany that has<br />

maintained high standards and that the State Government looked<br />

forward to continue working with <strong>com</strong>panies such as Timbalac to<br />

ensure strong economic development.<br />

Mrs Peulich went on to say that the focus was on capturing<br />

more of the domestic and International markets with increased<br />

<strong>com</strong>petitiveness and that priority markets were China, India and<br />

the Middle East.<br />

Eric spoke about his <strong>com</strong>pany and how it had been able to<br />

weather the ups and downs of the last 20 years and promised<br />

that he would personally be an active partner with industry for<br />

the next 20 years. He thanked his loyal customers, and his major<br />

suppliers, Sayerlac from Italy.<br />

Sayerlac has worked with Timbalac and Australian<br />

manufacturers to develop quality products specifically for the<br />

Australian industry.<br />

Over the years, Eric has always maintained that a quality<br />

product will last longer, provide better coverage and provide<br />

8 | <strong>Supplier</strong>Sept/Oct 2012<br />

for Australia now provides an essential<br />

legal framework which exporters can<br />

rely upon in the event that the logo (or<br />

product carrying it) is copied or used<br />

without proper <strong>au</strong>thority.”<br />

Australian Made <strong>com</strong>menced the<br />

registration process four years ago with<br />

the active and financial support of the<br />

Australian Government.<br />

“Australia has long enjoyed an<br />

invaluable reputation as a reliable<br />

exporter of high-quality goods,” Federal<br />

Trade Minister Dr Craig Emerson said.<br />

“The Government wel<strong>com</strong>es China's<br />

legal recognition of the Australian Made,<br />

Australian Grown symbol and the benefits<br />

our exporters will enjoy from additional<br />

confidence in the Australian brand.”<br />

The work was carried out by<br />

Australian Made Campaign Partner,<br />

EKM Patent and Legal.<br />

The registration covers seven<br />

classes of goods (classes 5, 20 and<br />

29-33). This includes a wide range<br />

of products including furniture. An<br />

application for an eighth class of<br />

goods (class 25, which includes<br />

footwear and clothing) is still pending.<br />

The formal registration of the<br />

AMAG logo in China follows its<br />

registration in the USA. Registration is<br />

also pending in Republic of Korea.<br />

Further information regarding<br />

classes of goods can be found at<br />

http://xeno.ip<strong>au</strong>stralia.gov.<strong>au</strong>/<br />

tmgoods.htm.” ●<br />

Left: Timbalac director and industry icon, Eric Zeeve. Right: Parliamentary Secretary<br />

for Education, Inga Peulich.<br />

the quality finish necessary to <strong>com</strong>bat imported product. He has<br />

often been frustrated with an industry prepared to use product<br />

based on price alone and has seen many of those <strong>com</strong>panies<br />

disappear over the years.<br />

Mr Ashley pointed out that Timbalac was established in 1992<br />

at a time when the Industry made a significant investment with a<br />

joint venture of the furniture training centre in Abbotsford.<br />

Ashley went on to praise Eric’s relationship with the training<br />

sector and said that Eric has always supported training – not<br />

just verbally but with product used in the training program at<br />

Holmesglen. He added that <strong>com</strong>panies such as Timbalac were a<br />

vital element in the training of young Australian trades people.<br />

Ashley quoted industry analyst Phil Ruthven who said that: “It<br />

will be our best owners, managers and enterprises that will take<br />

us into the next golden age of prosperity” and that this age was<br />

“just around the corner.”<br />

With 20 years of service under his belt, there is no doubt that<br />

Eric Zeeve and Timbalac are one of those best enterprises and<br />

will be there to take advantage of any economic upturn.●<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

News<br />

Impact CNC appoints Positive Camtec<br />

SIGN essentials Pty Ltd, Australian<br />

distributor of Impact CNC routers,<br />

has appointed Positive Camtec Pty<br />

Ltd, based in Silverwater NSW, as its<br />

exclusive NSW/ACT dealer.<br />

Impact CNC routers were l<strong>au</strong>nched<br />

in Australia in mid-2011 and offer an<br />

excellent mix of quality and affordability.<br />

Sign Essentials has already placed<br />

multiple installations in the sign,<br />

aluminium fabrication, woodworking and<br />

educational sectors.<br />

“Our clients love the fact that they<br />

can purchase a fully-featured router at<br />

a great price with expert local training,<br />

service and support,” said Sean Strange,<br />

General Manager of Sign Essentials.<br />

“With that in mind, the obvious partner<br />

for us in NSW and the ACT was Positive<br />

Camtec. Like us, they have over 20<br />

years experience installing, supporting<br />

NZ cabinetmaker turns to casket making<br />

A New Zealand timber<br />

manufacturer is branching out to<br />

weather the tough economic times.<br />

According to Suff.co.nz, Taylormade<br />

Furniture from Masterton, NZ started<br />

making solid pine caskets for funeral<br />

homes two years ago and has seen<br />

production grow steadily.<br />

The <strong>com</strong>pany is now trying to increase<br />

its market share by taking on the dominant<br />

MDF casket manufacturers, offering its<br />

timber models at a similar price.<br />

"It actually started by another casket<br />

maker <strong>com</strong>ing to us for help," said Barry<br />

Taylor. "We spent 12 months working with<br />

10 | <strong>Supplier</strong>Sept/Oct 2012<br />

Sean Strange and Philip Trumble<br />

and servicing CNC routers. We know<br />

they will provide the experience and<br />

expertise purchasers will require.”<br />

“Our sales and technical staff all<br />

agree that Impact CNC offers fantastic<br />

value-for-money,” said Philip Trumble,<br />

Managing Director of Positive Camtec.<br />

“Boasting quality engineering and<br />

a solid build, they are perfect for all<br />

forms of manufacturing. Coupled with<br />

<strong>com</strong>ponents from industry leaders in<br />

Japan and Italy, Impact CNC has put<br />

together an unbeatable value-for-money<br />

offering.”<br />

Adriano Gut, Sales and Marketing<br />

Manager of Positive Camtec said: “In today’s<br />

economic climate, production demands<br />

quality and durability, yet affordability is<br />

crucial. With the Impact CNC range we are<br />

confident we have the right mix of features,<br />

quality and price.” ●<br />

them and when they closed up we took<br />

all that work and put it into production."<br />

Taylormade makes traditional pine<br />

caskets, in a market dominated by MDF,<br />

which accounts for about 90 per cent of<br />

all caskets.<br />

The <strong>com</strong>pany employs four staff, two<br />

fully trained tradesmen and two trainees.<br />

Dean Taylor said their caskets were<br />

made using a <strong>com</strong>puterised router, and<br />

could be left with a natural finish or<br />

stained various colours.<br />

While there were other timber<br />

manufacturers, most were aimed at the<br />

higher end of the market, he said. There<br />

2012 Olympic<br />

Games gets<br />

certification<br />

The entire London 2012<br />

Olympic Park development<br />

achieved dual Project<br />

Certification from the<br />

Programme for the<br />

endorsement of Forest<br />

Certification (PeFC) and the<br />

Forest Stewardship Council<br />

(FSC) schemes for its timber<br />

usage – the first dual Project<br />

Certification in the world.<br />

This groundbreaking<br />

achievement in sustainable<br />

timber procurement has played<br />

a prominent role in helping the<br />

Olympic Delivery Authority (ODA)<br />

achieve its <strong>com</strong>mitment to making<br />

the London 2012 Olympic<br />

Games the greenest games ever<br />

with 100% of wood products<br />

supplied certified as legal and<br />

sustainable.<br />

The development is being<br />

hailed as a major achievement<br />

destined to be a future model<br />

for timber procurement globally.<br />

The scheme also saw a unique<br />

and important partnership role<br />

played by both PEFC and FSC<br />

to make sure that the levels of<br />

legal and sustainable timber<br />

procured by the ODA achieved<br />

the highest possible target. ●<br />

were also environmental benefits with<br />

pine, which made a difference when<br />

used on their caskets.●<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

Eveneer Essentials<br />

Economy range of<br />

reconstructed veneer leaf<br />

available from Elton Group<br />

nationally 1300 133 481<br />

eltongroup.<strong>com</strong>.<strong>au</strong><br />

Available on board from<br />

Associated Panel Products 08 8947 1144<br />

Capital Veneers 02 6299 1557<br />

J H Wilberforce 08 9340 6222 & 03 9793 7099<br />

Legno 02 9645 2137<br />

Plyco 03 9499 4997<br />

Processed Forest Products 02 9771 5155<br />

Revolution Wood Panels 07 3205 9182<br />

Sharp Plywood 07 3271 4511<br />

Specialty Woods 02 9725 2277<br />

Timberwood Panels 03 9769 0177<br />

Veneer Panels 08 8281 3444 & 0414 691 093<br />

Yates Wood Products 02 9618 3499

News<br />

New worldwide timber<br />

legality requirements<br />

It is now clear to traders<br />

and manufacturers of timber<br />

materials, wood products<br />

and many paper products<br />

that governments around<br />

the world are taking an<br />

increasing role in the fight<br />

against illegal logging.<br />

Whatever percentage of<br />

timber harvesting is illegal in<br />

one way or another – and<br />

estimates vary – some key<br />

governments have decided<br />

to stop the undermining of<br />

legitimate operations of<br />

responsible forest products<br />

<strong>com</strong>panies. However, their<br />

approaches differ.<br />

In the United States the<br />

longstanding US Lacey Act,<br />

covering the protection of<br />

endangered wildlife and<br />

wild plants since 1900, has<br />

been amended to include<br />

the protection of trees against<br />

illegal logging by making<br />

any trade found to be illegal<br />

punishable by law.<br />

Now the European Union<br />

has passed legislation, which<br />

takes effect in March 2013,<br />

and will prohibit the placing<br />

of timber harvested illegally<br />

under the rules of the country<br />

of origin, and products<br />

derived from such timber on<br />

the EU market. The Regulation<br />

requires operators to undertake<br />

risk assessment in a process<br />

of Due Diligence, which<br />

must be declared in their<br />

documentation.<br />

The laws of the USA and<br />

the European Union are similar<br />

in intent as they both place a<br />

prohibition within the importing<br />

country on trade in wood<br />

sourced, contrary to laws of<br />

any other country. Meanwhile<br />

the Australian Government<br />

is in the process of enacting<br />

a Bill which still needs to go<br />

12 | <strong>Supplier</strong>Sept/Oct 2012<br />

through Parliament and receive<br />

the official Royal Assent.<br />

Once passed, it will place<br />

requirements on importers<br />

and domestic raw material<br />

suppliers to undertake Due<br />

Diligence to determine the<br />

legality of a list of regulated<br />

products.<br />

Significantly, six countries<br />

had given inputs to the<br />

Australian Government during<br />

a consultation process. The<br />

proposed Bill has been<br />

wel<strong>com</strong>ed by most parties, but<br />

last year an Australian alliance<br />

of wood industry associations<br />

appealed for some changes.<br />

They represent 140 timber and<br />

wood based product importers<br />

and 2,500 businesses in<br />

the merchant and secondary<br />

processing sectors.<br />

They accepted the<br />

proposed Bill in principle,<br />

but pointed out a few<br />

changes. What they said<br />

was: “we believe it should<br />

substantially stand as it is,<br />

especially noting that the<br />

Bill matches or exceeds the<br />

requirements of the Lacey<br />

Act and the EU Timber<br />

Regulation (EUTR) in nearly<br />

every case. However, we<br />

have serious concerns<br />

with regards to business<br />

<strong>com</strong>pliance burdens, cost<br />

impacts, impossible time<br />

restraints for <strong>com</strong>pliance and<br />

lack of certainty. To correct<br />

these problems we propose<br />

five amendments, which we<br />

do not think would decrease<br />

regulatory effectiveness, and<br />

may increase it.”<br />

Currently these issues<br />

are under review by the<br />

government and the general<br />

view is that, consequently, the<br />

Bill is unlikely to emerge this<br />

year.<br />

In all these cases the<br />

approaches to solve the<br />

problem of illegal logging are<br />

similar and relate to prohibiting<br />

trade in wood illegally<br />

harvested in contravention<br />

of foreign laws, but the<br />

practicalities are not always<br />

foreseen. Whereas the<br />

Australian timber industry has<br />

anticipated some problems,<br />

in the US a backlash has<br />

emerged bec<strong>au</strong>se of the<br />

consequences of Lacey. A<br />

groundswell movement is<br />

asking Congress to consider<br />

changing the Amendment,<br />

following the celebrated case<br />

of the potential prosecution of<br />

a renowned guitar maker.<br />

In 2009, with a new<br />

administration in power, federal<br />

agents raided the Gibson<br />

<strong>com</strong>pany offices over wood<br />

from Madagascar, which was<br />

suspect, according to the US<br />

Fish and Wildlife Service. The<br />

<strong>com</strong>pany filed a lawsuit in<br />

protest and was raided again<br />

over wood from India. Charges<br />

of wood being imported<br />

illegally were countered by<br />

Gibson's CEO saying that India<br />

has to approve shipments of<br />

wood leaving India.<br />

According to one report:<br />

“SWAT teams were sent to<br />

Gibson Guitar's factories to<br />

confiscate wood and Gibson<br />

cannot ship guitars at the<br />

moment. The US Government<br />

insists that Madagascar law<br />

requires that the work be<br />

<strong>com</strong>pleted on fingerboards in<br />

Madagascar.<br />

So it is with interest that<br />

many wood exporting<br />

countries await some<br />

clarification on the EU<br />

Timber Regulation.<br />

The UK’s Timber Trade<br />

Federation (TTF) l<strong>au</strong>nched<br />

its Responsible Purchasing<br />

Policy, which it offers as a<br />

Due Diligence tool following<br />

members’ vote to make it<br />

a mandatory condition of<br />

membership (see <strong>www</strong>.ttf.<br />

co.uk).<br />

Meanwhile there is no<br />

time to be lost in setting up<br />

corporate procedures by all<br />

importers in the 27 European<br />

Union countries to secure<br />

the necessary information on<br />

sources of legal timber and<br />

wood products; to assess<br />

any risk of dealing in illegal<br />

timber and to mitigate any<br />

risks by requiring additional<br />

information from their<br />

suppliers to satisfy the EUTR<br />

when it goes into effect in<br />

March 2013.<br />

The TTF website has a<br />

countdown clock running<br />

at 259 days at the time of<br />

writing.<br />

Disclaimer: This news brief<br />

has been produced with the<br />

financial assistance of the<br />

European Union. The views<br />

expressed herein can in<br />

no way be taken to reflect<br />

the official opinion of the<br />

European Union. ●<br />

For further press information please<br />

contact Michael Buckley:<br />

Michael@turnstonesingapore.<strong>com</strong><br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

A range of reconstructed timber<br />

veneers, factory finished on a<br />

laminate back, ready for application.<br />

Featuring Moka Oak with Groove<br />

finish, a tactile effect that enhances<br />

the natural depth of the wood texture.<br />

eltongroup.<strong>com</strong><br />

Available from Elton Group nationally 1300 133 481<br />

and the following distributors<br />

ACT Processed Forest Products 02 9771 5155<br />

Timberwood Panels 03 9769 0177<br />

NSW Processed Forest Products 02 9771 5155<br />

NT Associated Panel Products 08 8947 1144<br />

QLD Sharp Plywood 07 3271 4511<br />

SA Veneer Panels 08 8281 3444<br />

TAS Timberwood Panels 03 9769 0177<br />

VIC Plyco 03 9499 4997<br />

Timberwood Panels 03 9769 0177<br />

Veneer Panels 0414 691 093<br />

WA J H Wilberforce 08 9340 6222

Design & Trends<br />

KBDi<br />

Australian Kitchen and<br />

Bathroom Designer Awards<br />

The KBDi awards represent an opportunity for specialist kitchen and bathroom designers<br />

to be judged by their peers.<br />

KBDi is a national organisation<br />

providing kitchen designers and<br />

bathroom designers with professional<br />

certification, professional development<br />

and networking opportunities for<br />

members.<br />

Each year the KBDi Kitchen and<br />

Bathroom Designer Awards attracts<br />

outstanding designers from all over<br />

Australia, from high profile designers<br />

who have been in the industry for<br />

years to those just starting out in<br />

kitchen and bathroom design.<br />

“Judges of this year’s awards<br />

were excited by many of the entries<br />

that were presented to them for<br />

consideration,” said KBDi’s Executive<br />

Director, Alex Milne. “These awards<br />

represent an outstanding opportunity<br />

for specialist kitchen and bathroom<br />

designers to be judged by their peers,<br />

and overall the awards program<br />

continues to lift the bar, facilitating<br />

14 | <strong>Supplier</strong>Sept/Oct 2012<br />

greater excellence in design in the<br />

Australian marketplace.”<br />

Australian Certified Designer of<br />

the Year<br />

Ac<strong>com</strong>plished designer Patricia<br />

La Torre of Outside Inside Building<br />

Elements in Melbourne took out the<br />

coveted KBDi Australian Certified<br />

Designer of the Year for 2012.<br />

Patricia received her award at a<br />

glittering gala event held in Sydney<br />

in July. Patricia’s award was the top<br />

award of the night. She also took<br />

home awards for Designer – Small<br />

Kitchens Victoria/Tasmania and<br />

Designer – Small Kitchens Victoria as<br />

well as Kitchen Designer of the Year –<br />

Victoria/Tasmania.<br />

Patricia’s winning entry had the<br />

hallmarks of design excellence. Her<br />

clients, owners of a be<strong>au</strong>tiful Victorian<br />

period home, sought an open design<br />

for their kitchen that acknowledged<br />

the needs of a young family and<br />

a lifestyle of constant entertaining.<br />

They wanted their kitchen to be<br />

<strong>com</strong>plementary to a new and modern<br />

building addition and to be the hub of<br />

social activity, while not <strong>com</strong>promising<br />

on function.<br />

Inspiration for the design<br />

<strong>com</strong>menced with a prominent oak<br />

tree in full view from the surround<br />

glass of the atrium in the home.<br />

Timber veneer formed part of the<br />

cabinet finishes, matching the oak<br />

tree perfectly, while Grigio Bellisimo<br />

marble further <strong>com</strong>plemented the oak<br />

to be<strong>com</strong>e the conversation piece.<br />

The vast island bench that includes<br />

storage to the front of the island<br />

specifically for the children’s activities<br />

looks out onto the be<strong>au</strong>tiful garden,<br />

family and play areas. The pantry<br />

system allows ease of access and<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

appliances easily slip away when not<br />

in use.<br />

The opportunity to break away and<br />

create a unique ambience, specific to<br />

the surrounding environment is displayed<br />

in the glass splashback motif, which<br />

echoes the oak tree: the copper colour<br />

of the large leaf splayed across the<br />

glass connects to the copper and gold<br />

veins in the magnificent marble.<br />

The award judges said that this was<br />

a well-conceived award entry of a<br />

technically high standard. The design<br />

showed a simple but bold use of colour,<br />

effectively demonstrating that ‘less<br />

is more’. The kitchen sits well in the<br />

surrounding space and the light panel<br />

adds a little ‘rock and roll’ that reflects<br />

This page: Patricia La Torre<br />

of Outside Inside Building<br />

Elements took out the coveted<br />

KBDi Australian Certified<br />

Designer of the Year for 2012.<br />

Opposite: Eileen Middleton<br />

Interiors won the KBDi<br />

Australian Kitchen Designer of<br />

the Year for 2012.<br />

the interests of the client. Overall,<br />

the judges said the client brief was<br />

interpreted very well.<br />

Australian Kitchen Designer<br />

of the Year<br />

Eileen Middleton (Eileen Middleton<br />

Interiors) was awarded the KBDi<br />

Australian Kitchen Designer of the Year<br />

for 2012.<br />

Presented by Tamara Buchanan<br />

of SMEG Australia, this award<br />

acknowledges excellence in kitchen<br />

design and innovation.<br />

A spacious, open plan kitchen<br />

designed for entertaining with<br />

style and that reflects a mix of<br />

contemporary and eastern design<br />

elements was required by Eileen<br />

Middleton’s clients.<br />

The judges said that Eileen Middleton<br />

had successfully created a space that is<br />

sleek but casual – a real home with a<br />

real kitchen. Interesting and practical,<br />

all principles of kitchen design were<br />

incorporated: timber detailing adds<br />

texture and interest; clever use of lattice<br />

screens creates privacy and adds a<br />

graphic element; the splashback shows<br />

a different interpretation; and use of line<br />

in the island <strong>com</strong>plements the floor.<br />

Eileen Middleton also received<br />

awards for Designer – Large Kitchens,<br />

Queensland 2012, Kitchen Designer of<br />

the Year – Queensland and Designer –<br />

Large Bathrooms, Queensland. 16

Design & Trends<br />

15<br />

Australian Bathroom<br />

Designer of the Year<br />

Sam Robinson, of Royston Wilson<br />

Design, was awarded the KBDi<br />

Australian Bathroom Designer of the<br />

Year for 2012.<br />

Presented by Julie Shaw, Executive<br />

Officer of Designer Training which<br />

specialises in delivering nationally<br />

recognised training to the Australian<br />

kitchen and bathroom industry, this<br />

award acknowledges excellence in<br />

bathroom design and innovation.<br />

Sam Robinson’s clients especially<br />

wanted more light and a modern<br />

space, bec<strong>au</strong>se the existing bathroom<br />

was cramped and dreary. A large<br />

window was added for natural light,<br />

and extensive use of strategically placed<br />

mirrors and a mirror ball over the bath<br />

provide more light and reflection.<br />

The vanity unit appears to float and<br />

the bench top protrudes through the<br />

shower screen to be<strong>com</strong>e a shower<br />

shelf. The drop-in bath has strong simple<br />

lines and all surfaces are seam free. A<br />

simple angled blade of glass delineates<br />

the shower area, with the shower head<br />

mounted flush to the ceiling.<br />

16 | <strong>Supplier</strong>Sept/Oct 2012<br />

Earlier in the night, Sam Robinson<br />

also took home the awards for Designer<br />

– Small Bathrooms Victoria/Tasmania<br />

2012 and Bathroom Designer of the<br />

Year – Victoria/Tasmania.<br />

Australian Unique Project of the<br />

Year – joint winners<br />

This year joint winners for the coveted<br />

KBDi Australian Unique Project of the<br />

Year were announced.<br />

Due to the entries being so diverse,<br />

the judges found it difficult to choose<br />

a single winner and impossible to<br />

separate two of the finalists.<br />

Therefore this year’s joint winners<br />

were Royston Wilson were Robert<br />

Bayly. Trophies and certificates to<br />

Royston and Robert were presented<br />

by the award sponsor, Kitchen and<br />

Bathrooms Quarterly.<br />

“This special award celebrates<br />

those projects that sit outside of<br />

kitchen or bathroom categories,” said<br />

KBDi, Alex Milne. “Our designers are<br />

creative, professional and versatile<br />

so it makes sense to showcase the<br />

special projects they undertake. And,<br />

on this occasion, it was impossible<br />

for the judges to separate the two<br />

winners whose projects were in<br />

domestic and <strong>com</strong>mercial settings<br />

respectively,” he said.<br />

Royston Wilson’s Toorak custom<br />

designed and built entertainment<br />

and display unit is located in a<br />

large family room that adjoins a<br />

kitchen and informal meals area.<br />

The clients sought an exciting,<br />

unique and modern unit with plenty<br />

of storage and display areas.<br />

Design challenges, like the heat<br />

given off from the fireplace and<br />

TV, had to be solved. The final<br />

effect speaks for itself: a unique,<br />

interesting and practical piece.<br />

Robert Bayly’s brief was to design<br />

a new concept showroom for SMEG<br />

highlighting its branding. A number<br />

of requirements were specified<br />

including the provision of a working<br />

kitchen and flexible open spaces for<br />

functions and cooking sessions.<br />

The design solution was based<br />

on zoning Smeg’s appliance groups<br />

and orientating them to room size<br />

constraints, invisible lines of traffic<br />

flow and street view.<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

Above: Joint winners for the KBDi<br />

Australian Unique Project of the Year<br />

were (from top) Royston Wilson and<br />

Robert Bayly.<br />

Opposite: Sam Robinson, of Royston<br />

Wilson Design, was awarded the<br />

KBDi Australian Bathroom Designer<br />

of the Year for 2012.<br />

The 2012 winners<br />

Australian Certified Designer of<br />

the Year<br />

Patricia La Torre, Outside Inside<br />

Building Elements<br />

Australian Kitchen Designer of the<br />

Year<br />

Eileen Middleton, Eileen Middleton<br />

Interiors<br />

Australian Bathroom Designer of<br />

the Year<br />

Sam Robinson, Royston Wilson Design<br />

Australian Unique Project of the<br />

Year – joint winners<br />

Royston Wilson, Royston Wilson<br />

Design and Robert Bayly, RB Design<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong><br />

Outstanding Student of the Year<br />

Helen B<strong>au</strong>mann<br />

Kitchen Designer of the Year<br />

NSW – Erika Forster, White Door<br />

Design<br />

QLD – Eileen Middleton, Eileen<br />

Middleton Interiors<br />

VIC/TAS – Patricia La Torre, Outside<br />

Inside Building Elements<br />

SA – Tony Warren, TMA Kitchen<br />

Design<br />

WA – Maggie Milligan, Town &<br />

Country Kitchens<br />

Bathroom Designer of the Year<br />

NSW – Gavin Hepper, Concepts by<br />

Gavin<br />

QLD – Eileen Middleton, Eileen<br />

Middleton Interiors<br />

VIC/TAS – Sam Robinson, Royston<br />

Wilson Design<br />

SA/WA – Janine Izzo, Brilliant SA<br />

Designer - Small Kitchens<br />

NSW – David Bartlett, Art of Kitchens<br />

VIC/TAS – Patricia La Torre, Outside<br />

Inside Building Elements<br />

SA/WA – Maggie Milligan, Town &<br />

Country Kitchens<br />

Designer - Medium Kitchens<br />

NSW – Erika Forster, White Door<br />

Design<br />

QLD – Kim Duffin, Sublime<br />

Architectural Interiors<br />

VIC/TAS – Lindsay Williams, Mint<br />

Kitchens by Lifestyle<br />

SA/WA – Haris Bahtiyarov, Alby<br />

Turner & Sons Kitchens<br />

Designer - Large Kitchens<br />

NSW – Gavin Hepper, Concepts by<br />

Gavin<br />

QLD – Eileen Middleton, Eileen<br />

Middleton Interiors (Highly<br />

Commended, Lee Hardcastle, Enigma<br />

Interiors)<br />

VIC/TAS – Patricia La Torre, Outside<br />

Inside Building Elements<br />

SA – Tony Warren, TMA Kitchen<br />

Design<br />

WA – Maggie Milligan, Town &<br />

Country Kitchens<br />

Designer - Small Bathrooms<br />

VIC/TAS – Sam Robinson, Royston<br />

Wilson Design<br />

QLD – Helene Newson, The Brisbane<br />

Bathroom Co.<br />

SA/WA – Janine Izzo, Brilliant SA<br />

NSW – Elizabeth Luke, Luke Interiors<br />

Designer - Large Bathrooms<br />

SA/WA – Janine Izzo, Brilliant SA<br />

NSW – Gavin Hepper, Concepts by<br />

Gavin<br />

VIC/TAS – Katrina Luxton, Royston<br />

Wilson Design<br />

QLD – Eileen Middleton, Eileen<br />

Middleton Interiors ●<br />

<strong>Supplier</strong>Sept/Oct 2012 | 17

Tel: 03 9590 0706

Design & Trends<br />

Nikpol – helping to ensure<br />

a healthy environment<br />

Nikpol is <strong>com</strong>mitted to managing its business in a responsible manner including<br />

environmentally responsible procurement of wood-based products to help ensure a<br />

healthy environment for now and future generations.<br />

In an effort to simplify the process<br />

of finding and specifying products<br />

that meet high environmental and<br />

sustainable standards, Nikpol has<br />

created the ARC product collection.<br />

This collection was l<strong>au</strong>nched to<br />

the industry on FSC Friday, 28<br />

September, a day when people are<br />

invited to consider the wood and<br />

paper products they buy and to<br />

look for the FSC logo, the mark of<br />

responsible forestry.<br />

“The ARC collection represents<br />

another positive step towards simpler<br />

sourcing of sustainable certified<br />

products and Nikpol’s <strong>com</strong>mitment<br />

to significantly expand the range<br />

of FSC certified materials available<br />

in Australia,” explained Nikpol’s<br />

Managing Director, Spiro Nikolakakis.<br />

“Timber is one of the world’s most<br />

environmentally friendly building<br />

products and we are fully behind the<br />

FSC certification system as the world’s<br />

best forestry practice. Our role is to<br />

take the lead in the strategic direction<br />

of market procurement and activity.”<br />

All products that appear under the<br />

ARC banner are guaranteed to meet<br />

the following third party certification<br />

standards:<br />

• FSC Chain of Custody;<br />

• 0.3mg/l (Super E0) or lower in<br />

accordance to the relating AS/<br />

NZS product standards;<br />

• low or no volatile organic<br />

<strong>com</strong>pounds (VOC).<br />

The ARC range includes melamine,<br />

reconstructed veneers and plywood,<br />

20 | <strong>Supplier</strong>Sept/Oct 2012<br />

all of which are sustainable,<br />

formaldehyde free and Green Star<br />

<strong>com</strong>pliant.<br />

Melamine – Nikpol has sourced<br />

some of best decor colour and finishes<br />

available on the world market. In<br />

doing so, Nikpol has been able to<br />

match this with an FSC 0.3mg/l<br />

(Super E0) formaldehyde low VOC<br />

MR particleboard substrate. The<br />

product also contains 25% of post<br />

consumer wood product that allows for<br />

a sustainable product in the market.<br />

Reconstructed veneers – constructed<br />

using veneers that are dyed to<br />

achieve rich colours. The production<br />

process allows unlimited scope for<br />

producing colours and grains with<br />

dimensional, flowing characteristics.<br />

Reconstructed veneers over<strong>com</strong>e the<br />

limitations of natural logs, are easy to<br />

manufacture and are environmentally<br />

friendly. Made from poplar timber,<br />

the veneers are selected from FSC<br />

managed, sustainable forests.<br />

Due to the sourcing of the raw<br />

material veneer material through Slice<br />

Veneers, Nikpol has the opportunity<br />

to lay the veneer on a FSC 0.3mg/<br />

l(Super E0) formaldehyde low VOC<br />

MR particleboard, as well as a FSC<br />

Rock Maple Purebond soy based glue<br />

line with no formaldehyde or VOCs.<br />

Plywood – Rock Maple PureBond<br />

plywood <strong>com</strong>es in sheet size of<br />

2440 x 1220mm and 3050 x<br />

1220mm and ranges in thickness<br />

from six to 30mm. It is manufactured<br />

using PureBond technology utilising<br />

formaldehyde-free, soy-based<br />

adhesive. The hardwood plywood<br />

panels have no added urea<br />

formaldehyde <strong>com</strong>ponents and are<br />

assembled with no added urea<br />

formaldehyde adhesives.<br />

PureBond veneer-core panels are<br />

made in the US and Canada and are<br />

cost-<strong>com</strong>petitive.<br />

Green Star – The ARC range by<br />

Nikpol range give the maximum<br />

contribution to the Green Star Office<br />

Interiors V1.1 rating system – IEQ 12:<br />

Formaldehyde minimisation.<br />

Nikpol’s <strong>com</strong>mitment to sound and<br />

sustainable environmental practice<br />

has seen the <strong>com</strong>pany adopt rigorous<br />

standards to ensure they provide a<br />

transparent and verifiable sourcing of<br />

all wood based products.<br />

With full FSC chain of custody<br />

certification, Nikpol offers its clients<br />

the assurance of FSC certified<br />

materials that meet the stringent<br />

demands of FSC for environmentally<br />

appropriate, socially beneficial and<br />

economically viable management of<br />

forests.<br />

Nikpol’s <strong>com</strong>mitment to FSC and<br />

sound environmental management<br />

extends into every aspect of the<br />

business – from the products sold to<br />

the <strong>com</strong>pany’s own office environment<br />

and materials. Its expertise and<br />

implementation of FSC standards puts<br />

the <strong>com</strong>pany at the forefront in interior<br />

materials supply and a valuable<br />

asset to design, construction and<br />

architectural firms across Australia. ●<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

The premier collection of<br />

certifi ed and sustainable<br />

interior décors.<br />

<strong>www</strong>.nikpol.<strong>com</strong>.<strong>au</strong>/fsc

Strangford design<br />

Tel: 03 9590 0347 Mob: 0414 370 200<br />

email: info@strangford.<strong>com</strong>.<strong>au</strong><br />

<strong>www</strong>.strangford.<strong>com</strong>.<strong>au</strong>

Interior<br />

Design Service<br />

No need for any more expensive <strong>com</strong>plicated hard to learn design software.<br />

Strangford design can help bring your visions and ideas into reality, with the aid of the latest 3D visualisation<br />

software. Our 3D designers can turn your clients vision into a 3D coloured render giving your client a realistic<br />

image with accurate measurements and the colours and textures of the proposed kitchen, bathroom or any<br />

interior layout . Our service allows your clients to understand every aspect of the proposed design and layout<br />

before <strong>com</strong>mencement of the manufacturing.<br />

Whether your clients home lends itself to a traditional, contemporary or modern style our design team can<br />

provide on even the smallest of details.<br />

We offer a two tier service, draw only where we you provide all measurements and a sketch of the interior<br />

required or our full design service were we fully design and draw to suit your specification.<br />

Our turnaround time from receiving your order is within 3 working days and delivered direct to your email<br />

inbox.<br />

Strangford design provide drawings and plans Australia wide to quality designers and manufacturers but always<br />

within the strictest of confidence.<br />

We will provide 5 3D angle shots and one floor plan<br />

Your logo and your customers name on each drawing and plan.

Business<br />

Times are tough:<br />

who can afford<br />

an ad agency?<br />

When many marketers<br />

think of advertising<br />

they think of consumer<br />

advertising... typically on<br />

TV – big businesses like<br />

Kellogg, Unilever and Nestle<br />

advertising to end-users/<br />

consumers. This is called<br />

Business to Consumer<br />

advertising or B2C.<br />

B2C advertising can be<br />

very effective but requires big<br />

spending, often in the millions.<br />

The vast majority of<br />

businesses in Australia,<br />

however, are actually Small<br />

to Medium Enterprises or<br />

SMEs which deal principally<br />

with other SMEs; in other<br />

words, businesses advertising<br />

to businesses. This is<br />

called Business to Business<br />

Advertising or B2B.<br />

B2B advertising is very<br />

important, not just to those<br />

businesses but to the entire<br />

economy and, while it follows<br />

some of the same principles<br />

as B2C advertising, it is on a<br />

different scale and usually uses<br />

different <strong>com</strong>munication tools.<br />

The budgets are lower and<br />

arguably have to work even<br />

harder to generate a return on<br />

investment.<br />

There are advertising<br />

agencies who specialise in<br />

B2B <strong>com</strong>munication and who<br />

have experience, expertise,<br />

tools and, very importantly,<br />

cost structures that are geared<br />

to the needs of SMEs.<br />

Business decisions in SME<br />

B2B advertising are still based<br />

on human emotions but tend to<br />

be more fact-based and detail-<br />

24 | <strong>Supplier</strong>Sept/Oct 2012<br />

oriented. The <strong>com</strong>munication<br />

tools used reflect this and<br />

often involve print and digital<br />

<strong>com</strong>munications, which have<br />

a lower cost of entry and are<br />

capable of carrying detail<br />

and flexible in that different<br />

messages can be tailored to<br />

discrete markets.<br />

Many B2B advertisers have<br />

very effective advertising<br />

programs targeting their<br />

business customers with<br />

budgets in the tens of<br />

thousands of dollars rather<br />

than millions.<br />

OK, you say, but that’s still<br />

money that is hard to find<br />

in this environment…,and it<br />

probably is – but when it is<br />

tough for everybody then this<br />

is the time when it is often<br />

most effective to promote your<br />

business… when everyone<br />

else has pulled their horns in.<br />

After all the difference in<br />

a boom market and a tough<br />

one is often a few percentage<br />

points. Markets don’t usually<br />

disappear they just shrink a bit<br />

and the marketers who fight<br />

for market share are not just<br />

the survivors but are brilliantly<br />

placed to grow spectacularly<br />

when the market recovers.<br />

So, how will an advertising<br />

agency help?<br />

<strong>Supplier</strong> Magazine<br />

talked to Chris Boseley<br />

of Beyond Advertising, a<br />

<strong>com</strong>pany specialising in B2B<br />

advertising for SMEs, usually<br />

through digital and print<br />

<strong>com</strong>munications, to expand<br />

on what they could contribute.<br />

Chris said: “Manufacturers<br />

and marketers often think of<br />

their business 99.9% of the<br />

time but they are lucky if they<br />

can get their customers to think<br />

of their business 0.1% of the<br />

time. Much B2B advertising<br />

reflects the advertiser’s needs<br />

through the advertiser’s point<br />

of view. The right advertising<br />

agency will help you see your<br />

business through the eyes of<br />

your customer so that you<br />

can work together to position<br />

and promote your <strong>com</strong>pany<br />

or brand with <strong>com</strong>munication<br />

that talks to your customer’s<br />

needs”.<br />

For example, The Solution<br />

Specialists, who were<br />

licensed distributors in the<br />

CAD and CAM kitchen and<br />

bathroom fabrication software<br />

business, called themselves<br />

Solspec and marketed a<br />

range of brands – Alphacam,<br />

Cabnetware, CabinetVision,<br />

Radan and Planit all delivering<br />

similar products through other<br />

sub-branded distributors in<br />

different states.<br />

Solspec retained Beyond<br />

Advertising.<br />

Chris Boseley said that<br />

Beyond helped Solspec look<br />

past their <strong>com</strong>plex branding<br />

and distribution system and<br />

see the market from their<br />

Left: BEFORE - When<br />

Solspec first approached<br />

Beyond Advertising,<br />

they were marketing a<br />

plethora of brands and<br />

promises.<br />

AFTER – Planit became<br />

single minded in its<br />

direction – resulting<br />

in more concise<br />

and powerful<br />

<strong>com</strong>munications.<br />

customer’s eyes. After a<br />

full market <strong>au</strong>dit, Beyond<br />

persuaded Solspec to clarify<br />

and concentrate their offering<br />

into one core brand – Planit.<br />

This allowed Planit to have<br />

a clear identity with all the<br />

<strong>com</strong>munication (and budget)<br />

focussed on one clear brand<br />

positioning and promise. This<br />

happened in the same tough<br />

market we are all operating<br />

in today. The marketing and<br />

advertising program cost<br />

no more than Solspec were<br />

spending on their previous<br />

multi-brand strategy but laid<br />

the foundations that helped<br />

double the size of the business<br />

in two years.<br />

“If your business turns over<br />

$2+million then you can<br />

afford the professional advice<br />

of an advertising agency<br />

and you probably need that<br />

advice,” said Chris. “There<br />

are advertising agencies<br />

like Beyond who have the<br />

expertise to really help your<br />

business grow with affordable<br />

cost structures.<br />

“We are an SME too.<br />

We also operate in a B2B<br />

environment. We know the<br />

value of a dollar and how<br />

to make every cent work<br />

effectively for our clients.” ●<br />

<strong>www</strong>.supplier<strong>magazine</strong>.<strong>com</strong>.<strong>au</strong>

��������������������������������������<br />

�<br />

�������������������������������������������������������������������������������<br />

����������������������������������������������������������������������������<br />

��������<br />

�<br />

�������������������������������������������������������������������������<br />

��������������������������������������������������������������������������<br />

�<br />

����������������������������������������<br />

�<br />

����������� � ������������������������<br />

������������ ��������������������������������������<br />

������������� ������������������������������������<br />

� � � ������������������������������������<br />

� � � ����������������������������������<br />

�<br />

��������������������������������������������������������������<br />

�<br />

��������������������������<br />

����������������������������������������<br />

���������������������������������������������������������<br />

�<br />

�� ����������������������������������������������������<br />

�� ��������������������������������������������������<br />

�� ��������������������������������������������<br />

�� ����������������������������������������<br />

�� ���������������������������������������<br />

�<br />

�������������������������������������������������������������������������<br />

��������������������<br />

������������<br />

���������������������������<br />

�������������<br />

������������������������<br />

������������������������������������������������������<br />

�<br />

����������������������������������������������������������������������������������������������������������������<br />

��������������������������������������������������������������������������������� � � ��������������������<br />

�<br />

����������������������������������������<br />

�����������������������

Business<br />

Is your business<br />

running you?<br />

“To get ahead you need to work on your<br />

business rather than in it”.<br />

By Jurgen Mennel<br />

We have all heard this<br />

before. Why is it, then, that<br />

many small business owners<br />

are getting consumed by the<br />

hands-on operation of their<br />

business and end up feeling<br />

overwhelmed, stressed and<br />

frustrated?<br />

Why is it that people so<br />

passionate about their craft<br />

are often struggling to run a<br />

successful business?<br />

Business operators get<br />

c<strong>au</strong>ght up in the day-to-day<br />

tasks and, before too long,<br />

start to think that the purpose<br />

of their life is to serve the<br />

business. The main point of<br />

any business, however, is to<br />

serve the owner.<br />

So what can be done?<br />

Well, any business should<br />

be built so that it can run even<br />

if the owner is not there.<br />

26 | <strong>Supplier</strong>Sept/Oct 2012<br />

With the right mindset and<br />

business skills it is easier than<br />

you may think. Building a<br />

business that way requires<br />

planning and of course a bit<br />

of work. Depending on the<br />

current situation it may also<br />

require a substantial amount<br />

of change but it will be well<br />

worth the effort. Imagine you<br />

get your business to the stage<br />

where it can run without you.<br />

A good way to get started<br />

is to imagine that you are<br />

building a prototype business<br />

for a franchise – a business<br />

you can replicate many<br />

times over. One of the keys<br />

to making this happen is<br />

to implement systems that<br />

everyone can follow. Once in<br />

place, these systems will allow<br />

your staff to create consistent<br />

results with minimal effort.<br />

Rather than relying on highly<br />

skilled staff or your own hard<br />

work, relatively low skilled<br />

personnel can <strong>com</strong>plete the<br />

job.<br />

Getting systems in place<br />

and teaching your staff how<br />

to run the systems will allow<br />

you to pass on tasks, which<br />

previously only you could do.<br />

This is certainly not a new<br />

concept and many business<br />

owners have <strong>com</strong>e across this<br />

before. They have great plans<br />

but still find themselves getting<br />

c<strong>au</strong>ght up in the day-to-day<br />

operation. Consequently they<br />

never develop their business<br />

to it’s full potential. In other<br />

words, they fall back into<br />

the “working in the business”<br />

mindset.<br />

The real breakthrough will<br />

<strong>com</strong>e if trade and business<br />

skills are <strong>com</strong>bined with the<br />

right mindset. Combining all<br />

three elements is the secret to<br />

business success.<br />

The right mindset will keep<br />

you focused and working<br />

on the business side of<br />

the equation. Habits and<br />