MB Oil Services Non-man Entry Oil Tank Cleaning - Manway Cannon System

The Manway Cannon System is part of the range of Non-man Entry Oil Tank Cleaning Systems offered by MB Oil Services.

The Manway Cannon System is part of the range of Non-man Entry Oil Tank Cleaning Systems offered by MB Oil Services.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MANWAY CANNON SYSTEM<br />

Product Information Sheet<br />

J<br />

2

<strong>Non</strong>-<strong>man</strong> <strong>Entry</strong> Versus<br />

Manned-<strong>Entry</strong> <strong>Tank</strong> <strong>Cleaning</strong><br />

There are distinct disadvantages when undertaking Manned-<strong>Entry</strong> tank cleaning<br />

when compared with innovative <strong>Non</strong>-<strong>man</strong> <strong>Entry</strong> <strong>System</strong>s that are available to<br />

<strong>MB</strong> <strong>Oil</strong> <strong>Services</strong>' clients.<br />

<strong>Oil</strong> Storage <strong>Tank</strong> <strong>Cleaning</strong> requirements<br />

All refineries have ongoing requirements to clean<br />

their oil storage tanks.<br />

The main reasons for a cleaning program<br />

include:<br />

• Periodic inspection and certification to API<br />

Standards;<br />

• Requirement for repair or modification to be<br />

undertaken;<br />

• Product grade change;<br />

• Sludge removal, recovery of hydrocarbon<br />

from sludge and optimisation of storage<br />

volume;<br />

• Sludge blocks pumps and pipework and<br />

interferes with the operation of floating roof<br />

systems - potentially costing millions of<br />

dollars.<br />

Traditionally, <strong>man</strong>ned-entry cleaning methods<br />

have been employed to clean tanks with<br />

personnel being required to wear breathing<br />

apparatus and protective clothing in order<br />

to clean the tanks. In addition, all personnel<br />

require to be trained in confined space access<br />

techniques to perform the tasks which include<br />

removing the contaminants and residues from<br />

the tank floor, shell and the underside of the<br />

roof.<br />

There are distinct disadvantages when undertaking<br />

<strong>man</strong>ned-entry tank cleaning when compared with<br />

the innovative <strong>Non</strong>-<strong>man</strong> <strong>Entry</strong> <strong>System</strong>s that are<br />

available to <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong>’ clients. Productivity is<br />

also drastically reduced when compared to <strong>Non</strong><strong>man</strong><br />

entry cleaning. However, it should be noted that<br />

when cleaning a tank to hotwork standards e.g. for a<br />

tank floor inpection, the final cleaning stage of the<br />

operation is required to be carried out using Manned-<br />

<strong>Entry</strong> Techniques, but by the time that this procedure<br />

is required the bulk of the hazardous material inside<br />

the tank will already have been removed.<br />

2 <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong> www.mb-oilservices.com

Disadvantages of Manned-<strong>Entry</strong> <strong>Cleaning</strong><br />

The disadvantages of Manned-<strong>Entry</strong> <strong>Cleaning</strong> include:<br />

Extended exposure to:<br />

• Mercury;<br />

• Lead Compounds TEL/TML;<br />

• Benzene;<br />

• Polyaromatic Hydrocarbons (PAH);<br />

• Hydrogen Sulphide;<br />

• Pyrothoric FeS;<br />

• Explosive Atmosphere;<br />

• The <strong>man</strong>ways are required to be opened for<br />

ventilation prior to <strong>man</strong>ned entry;<br />

• Lighter hydrocarbons are continually released<br />

during the de-sludging operation and this creates<br />

an explosive atmosphere prior to venting to<br />

atmosphere;<br />

• Large volumes of hazardous waste are removed<br />

from the tank into the open and are an<br />

environmental liability;<br />

• The process overall is a lot slower resulting in a<br />

significant loss through downtime. An 80-110m<br />

diameter tank will typically take months to clean.<br />

<strong>Manway</strong> <strong>Cannon</strong> <strong>System</strong><br />

3

Our <strong>Tank</strong> <strong>Cleaning</strong><br />

Advantages<br />

<strong>MB</strong> <strong>Oil</strong> <strong>Services</strong> <strong>Non</strong>-<strong>man</strong> <strong>Entry</strong><br />

<strong>System</strong>s provide advantages in QHSE,<br />

time and cost for the tank cleanig<br />

operation including:<br />

• Exposure to hazardous materials<br />

and environments is minimised<br />

almost to the point of elimination;<br />

• Overruns in cost and time are<br />

avoided due to system efficiency;<br />

• Cleans the tank to a gas free<br />

environment as per API<br />

requirements in the safest and<br />

most practical <strong>man</strong>ner;<br />

• Minimises the requirement for<br />

maintenance workers to enter a<br />

haardous environment to perform<br />

their duties;<br />

• Reduces the cost of residual<br />

disposal and off-site<br />

transportation costs.<br />

Design<br />

All of our <strong>Non</strong>-Man <strong>Entry</strong> <strong>System</strong>s<br />

have been designed in accordance<br />

with current safety legislation<br />

in mind while still providing a<br />

highly efficient system of work<br />

that reduces tank downtime and<br />

increases revenue steams.<br />

Development<br />

The systems have evolved to their<br />

current specifications over <strong>man</strong>y<br />

years. Our engineers have taken<br />

feedback from the site teams<br />

and acted on the feedback and<br />

reccomendations. This process of<br />

development is ongoing.<br />

Maintenance<br />

The equipment items are<br />

well engineered but they still<br />

undergo routine and planned<br />

and preventative maintenance in<br />

accordance with <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong>’<br />

Planned Maintenace <strong>System</strong>.<br />

4 <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong> www.mb-oilservices.com

Our Equipment<br />

Our wide range of <strong>Non</strong>-Man <strong>Entry</strong> <strong>Tank</strong><br />

<strong>Cleaning</strong> Equipment ensures that we<br />

will always provide the correct solution<br />

for our clients.<br />

We are constantly striving to<br />

provide the safest, most cost<br />

effective methods of tank<br />

cleaning for our clients.<br />

Efficiency<br />

In addition to being safer than<br />

Manned-<strong>Entry</strong> operations the<br />

systems are much quicker. This<br />

results in less downtime, quicker<br />

return to service times and the<br />

ability for the client to implement<br />

secondary tasks e.g. inspection.<br />

Environment<br />

If the SpinTech <strong>Oil</strong> Recovery <strong>System</strong><br />

is an integral part of the <strong>Non</strong>-<br />

Man <strong>Entry</strong> <strong>System</strong> e.g. <strong>Tank</strong> Sweep<br />

<strong>System</strong>, then the process is highly<br />

environmentally friendly with<br />

residual waste for off-site disposal<br />

or incineration greatly reduced.<br />

Increased Revenues<br />

It is easy to see that the use of<br />

highly technical and efficient<br />

equipment in place of <strong>man</strong>ual<br />

labour and increased project<br />

completion times results in<br />

increased revenues for the<br />

client.<br />

<strong>Manway</strong> <strong>Cannon</strong> <strong>System</strong><br />

5

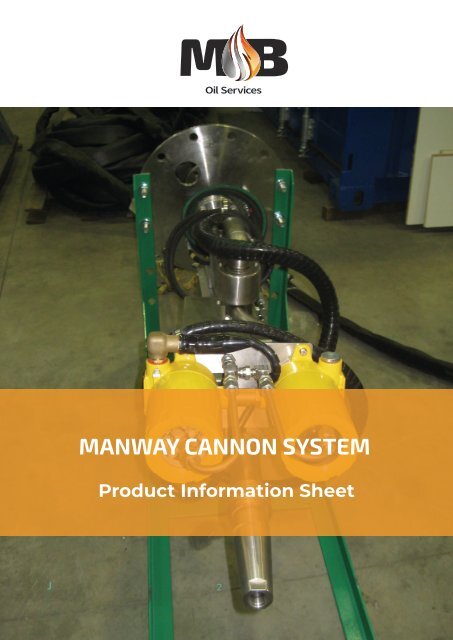

<strong>Manway</strong> <strong>Cannon</strong><br />

The latest generation of <strong>Manway</strong> <strong>Cannon</strong> <strong>System</strong>s used by <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong><br />

come completely installed inside a modified ISO 20’ container, divided into two<br />

compartments. The first compartment serves as the control unit with the second<br />

compartment designated as the power and equipment room.<br />

<strong>Cannon</strong> in Transport Position <strong>Manway</strong> <strong>Cannon</strong> Equipment Compartment<br />

The container is fully insulated and<br />

air conditioned and the control<br />

unit contains all the necessary<br />

joysticks, buttons and switches that<br />

are used to control the system.<br />

Three or four screens display<br />

camera feedback as well as the<br />

computer software display. The<br />

whole cleaning operation can be<br />

recorded to HDD Recorder.<br />

The second compartment contains<br />

an electro-hydraulic power unit<br />

and reels for umbilical storage. A<br />

pressure washer is also included<br />

for the cleaning of equipment.<br />

Real-time graphical simulation of the<br />

cannon allows the operator to clean with<br />

a fully automated system from outside<br />

the tank.”<br />

6 <strong>MB</strong> <strong>Oil</strong> <strong>Services</strong> www.mb-oilservices.com

Increased Safety and Efficiency<br />

The <strong>Manway</strong> <strong>Cannon</strong> <strong>System</strong> offers numerous<br />

advantages over traditional <strong>man</strong>ned-<strong>Entry</strong> <strong>Tank</strong><br />

<strong>Cleaning</strong> Techniques.<br />

The mounting flange for the cannon contains gas<br />

detection equipment that is electrically tied into the<br />

control system. If rising gas levels or other safety<br />

issues arise then the equipment automatically shuts<br />

down.<br />

The whole operation is highly efficient, and another<br />

added benefit of using this cleaning method is that<br />

if the tank incurs a temperature inversion then the<br />

operation can still continue, this would not be possible<br />

with Manned-<strong>Entry</strong> working. In this regard, we could<br />

not offer a more efficient service where increased<br />

safety also equates to more productivity and also the<br />

continuation of work.<br />

The efficiency of the system contributes greatly to<br />

ensuring that we avoid overruns in both cost and time<br />

on our tank cleaning projects.<br />

Quality Built Zone ll Rated Equipment<br />

For a full <strong>Manway</strong> <strong>Cannon</strong> Product Information Sheet contact:<br />

enquiries@mb-oilservices.com<br />

<strong>Manway</strong> <strong>Cannon</strong> <strong>System</strong><br />

7

YOUR ENVIRONMENTAL SOLUTIONS PROVIDER<br />

<br />

www.mb-oilservices.com<br />

enquiries@mb-oilservices.com