MMEI QUAD-Zilla Brochure.indd

MMEI QUAD-Zilla Brochure.indd

MMEI QUAD-Zilla Brochure.indd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

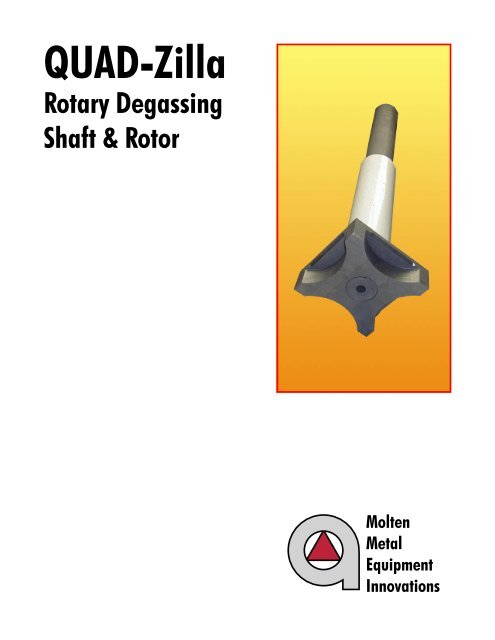

<strong>QUAD</strong>-<strong>Zilla</strong><br />

Rotary Degassing<br />

Shaft & Rotor<br />

Molten<br />

Metal<br />

Equipment<br />

Innovations

Description<br />

Its time to upgrade the performance of your degassing<br />

equipment with the new <strong>QUAD</strong>-<strong>Zilla</strong> Degassing Shaft<br />

and Rotor from <strong>MMEI</strong>!<br />

The <strong>QUAD</strong>-<strong>Zilla</strong> Rotor offers the latest advancements<br />

for superior degassing performance through enhanced<br />

bubble shearing and metal stirring. Unlike many other<br />

rotors in the market, the <strong>QUAD</strong>-<strong>Zilla</strong> increases metal<br />

movement, thereby, ensuring that all the metal in the<br />

ladle is treated. It effectively eliminates dead spots<br />

in the ladle and assures an even bubble dispersion<br />

pattern throughout the ladle. The shearing action of<br />

this rotor is outstanding, the best in the market, shearing<br />

the gas into small bubbles even at low RPM’s. The<br />

benefit to the user is better metal through faster, more<br />

effective degassing while using less gas.<br />

The shaft features our RHINO Sleeve, our newest innovation<br />

for increasing the service life of the shaft.<br />

Positioned on the shaft at the metal line to provide additional<br />

protection for the graphite from oxidation, the<br />

RHINO Sleeve is a refractory material molded directly<br />

onto the graphite for improved bonding. By molding<br />

the RHINO Sleeve directly onto the graphite, we<br />

have achieved a sleeve that has dramatically improved<br />

resistance to thermal shock and cracking. The result<br />

is a sleeve which increases the service life of the shaft<br />

through improved resistance to wear and oxidation.<br />

The <strong>QUAD</strong>-<strong>Zilla</strong> can be provided with most thread connections<br />

for retrofitting to your equipment. If you are<br />

looking for complete degassing equipment, <strong>MMEI</strong> can<br />

provide you with complete ladle degassing stations or<br />

in-line units. Please contact us for more information.<br />

If you are looking to upgrade the performance of your<br />

degassing equipment, the <strong>QUAD</strong>-<strong>Zilla</strong> system is your<br />

first choice. Contact us for more information.<br />

Contact Us for More Information:<br />

Molten<br />

Metal<br />

Equipment<br />

Innovations<br />

16286 Nauvoo Rd, Middlefield, Ohio 44062<br />

Tel: 440.632.9119 Fax: 440.632.9187<br />

e-mail: info@mmei-inc.com<br />

Website: www.mmei-inc.com<br />

<strong>QUAD</strong>-<strong>Zilla</strong> Degassing Rotor and Shaft<br />

Product HighLights<br />

♦ Upgrade the performance of your degassing equipment!<br />

♦ Unique <strong>QUAD</strong>-<strong>Zilla</strong> Rotor offers the following benefits:<br />

• Superior shearing of inert gas bubbles increases<br />

surface reaction area for better metal treatment.<br />

• Pumping action creates subsurface movement of the<br />

metal to eliminate dead spots at the bottom of the<br />

ladle, ensuring complete metal treatment.<br />

• Effectively removes more hydrogen and other impurities<br />

from your metal than other systems.<br />

• Degas your metal faster and better with less gas!<br />

♦ Shaft features our new RHINO Sleeve!<br />

• Positioned at the metal line to provide additional<br />

protection from wear and oxidation.<br />

• Molded onto the shaft for superior adhesion to graphite,<br />

prevents premature cracking and separation.<br />

♦ All graphite components are treated for oxidation resistance<br />

to signifcantly increase service life.<br />

♦ Maximize your productivity by reducing the time it takes to<br />

treat your metal.<br />

♦ Fast, easy assembly.<br />

♦ Self-aligning design eliminates need for an alignment<br />

fixture - simplifies assembly and repair.<br />

♦ Can be provided with most thread connections and in any<br />

shaft length for easy retrofitting to your equipment.<br />

The above picture demonstates the dramatic improvement<br />

in the dispersion of the inert gas bubbles and<br />

metal movement. Metal from the bottom of the ladle is<br />

drawn upward by the rotation of the rotor, eliminating<br />

untreated dead spots.<br />

Form QZ 06/07 Rev. 1