Refurb Projects September 2018

Refurb Projects launched in 1987 to cater for the expanding Repair, Maintenance, Improvement and Refurb sectors of the UK Building Industry. This represents a massive market, with refurbishment in the Health, Leisure, Education and Social Housing sectors a mainstay of the industry. Sustainability and the protection of the built environment are essential ingredients of the refurbishment market, and Refurb Projects Journal is a leader in reporting and promoting these ideals.

Refurb Projects launched in 1987 to cater for the expanding Repair, Maintenance, Improvement and Refurb sectors of the UK Building Industry.

This represents a massive market, with refurbishment in the Health, Leisure, Education and Social Housing sectors a mainstay of the industry.

Sustainability and the protection of the built environment are essential ingredients of the refurbishment market, and Refurb Projects Journal is a leader in reporting and promoting these ideals.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

INSULATION<br />

Flat Out performance<br />

by Adrian Pargeter, Head of Technical and Product Development, Kingspan Insulation Limited<br />

As we head into the wetter<br />

winter months, the nation’s<br />

roofs are once again set to be<br />

put to the test. This can<br />

prove to be a particularly challenging<br />

time for buildings with flat roofs, with<br />

water ponding occurring either<br />

because the existing surface has<br />

become damaged or an insufficient<br />

fall was introduced when the building<br />

was first constructed. When<br />

refurbishing these surfaces,<br />

contractors should not only look to<br />

address drainage issues but also to<br />

consider whether improvements can<br />

be made to the thermal performance<br />

of the element. One of the simplest<br />

ways to achieve both of these aims is<br />

by installing a tapered insulation<br />

system. The latest systems now<br />

incorporate phenolic insulation,<br />

allowing the desired U-value to be<br />

met with a slimmer build-up.<br />

<strong>Refurb</strong>ishment Requirements<br />

Flat roofs are defined in BS 6229:<br />

2003 as “having a pitch less than 10o<br />

to the horizontal”, although some<br />

within the industry extend this<br />

definition to pitches of up to 15o.<br />

The British Standard recommends<br />

that flat roofs should have a design<br />

fall of 1:40 and a minimum “as-built”<br />

fall of 1:80. These falls are crucial as<br />

failure to effectively channel<br />

rainwater run-off can result in water<br />

ponding. If untreated, this can lead to<br />

a number of further issues including<br />

alkaline formation and mould growth.<br />

The additional roof loading can cause<br />

further deflection, aggravating the<br />

issue and potentially reducing the<br />

design life of the roof.<br />

Poorly insulated flat roofs can also<br />

act as a significant source of heat loss<br />

from a property, so it makes sense to<br />

raise the thermal performance of<br />

these surfaces as part of any work.<br />

Typically, this can<br />

either be achieved<br />

with a warm roof<br />

construction,<br />

where the<br />

insulation layer is<br />

installed above the<br />

deck, or a cold<br />

roof construction,<br />

where insulation is<br />

installed between<br />

and below the roof<br />

rafters with a<br />

minimum air gap<br />

of 50mm between<br />

the insulation and<br />

the deck.<br />

Recently, a<br />

trend has emerged<br />

where installers fit<br />

a hybrid solution<br />

with a thin layer<br />

of insulation above<br />

the deck and the<br />

rest below. Whilst<br />

in principle this may seem like a<br />

sensible way to reduce the above-deck<br />

construction depth whilst eliminating<br />

the need for a below deck ventilation<br />

gap, it can lead to significant longterm<br />

issues.<br />

In a warm roof, condensation is<br />

prevented by keeping the deck at a<br />

warm temperature, therefore there is<br />

no cold surface for the condensation<br />

to form on. In a cold roof,<br />

condensation is prevented as the<br />

ventilation current takes away the<br />

moisture vapour before it can form as<br />

condensation.<br />

With the hybrid solution, however,<br />

the above-deck insulation layer often<br />

offers insufficient performance to<br />

keep the deck warm and as the<br />

ventilation void is absent there is no<br />

way to remove the moisture before it<br />

forms condensation. This construction<br />

should only be considered if a full<br />

condensation risk analysis is carried<br />

out and even then, it will rely on an<br />

almost perfect level of workmanship.<br />

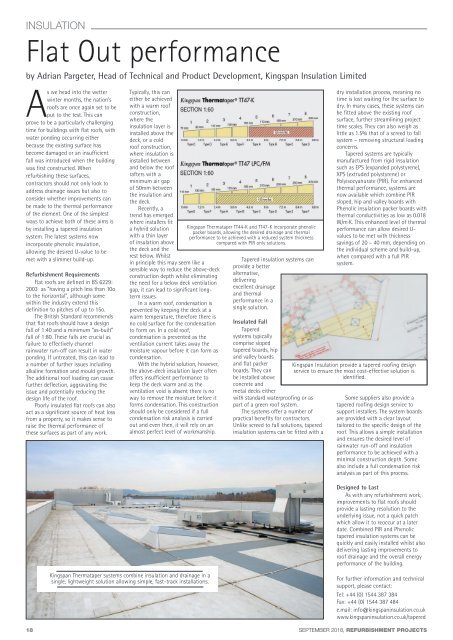

Kingspan Thermataper TT44-K and TT47-K incorporate phenolic<br />

packer boards, allowing the desired drainage and thermal<br />

performance to be achieved with a reduced system thickness<br />

compared with PIR only solutions.<br />

Tapered insulation systems can<br />

provide a better<br />

alternative,<br />

delivering<br />

excellent drainage<br />

and thermal<br />

performance in a<br />

single solution.<br />

Insulated Fall<br />

Tapered<br />

systems typically<br />

comprise sloped<br />

tapered boards, hip<br />

and valley boards<br />

and flat packer<br />

boards. They can<br />

be installed above<br />

concrete and<br />

metal decks either<br />

with standard waterproofing or as<br />

part of a green roof system.<br />

The systems offer a number of<br />

practical benefits for contractors.<br />

Unlike screed to fall solutions, tapered<br />

insulation systems can be fitted with a<br />

dry installation process, meaning no<br />

time is lost waiting for the surface to<br />

dry. In many cases, these systems can<br />

be fitted above the existing roof<br />

surface, further streamlining project<br />

time scales. They can also weigh as<br />

little as 1.5% that of a screed to fall<br />

system – removing structural loading<br />

concerns.<br />

Tapered systems are typically<br />

manufactured from rigid insulation<br />

such as EPS (expanded polystyrene),<br />

XPS (extruded polystyrene) or<br />

Polyisocyanurate (PIR). For enhanced<br />

thermal performance, systems are<br />

now available which combine PIR<br />

sloped, hip and valley boards with<br />

Phenolic insulation packer boards with<br />

thermal conductivities as low as 0.018<br />

W/m·K. This enhanced level of thermal<br />

performance can allow desired U-<br />

values to be met with thickness<br />

savings of 20 – 40 mm, depending on<br />

the individual scheme and build-up,<br />

when compared with a full PIR<br />

system.<br />

Kingspan Insulation provide a tapered roofing design<br />

service to ensure the most cost-effective solution is<br />

identified.<br />

Some suppliers also provide a<br />

tapered roofing design service to<br />

support installers. The system boards<br />

are provided with a clear layout<br />

tailored to the specific design of the<br />

roof. This allows a simple installation<br />

and ensures the desired level of<br />

rainwater run-off and insulation<br />

performance to be achieved with a<br />

minimal construction depth. Some<br />

also include a full condensation risk<br />

analysis as part of this process.<br />

Designed to Last<br />

As with any refurbishment work,<br />

improvements to flat roofs should<br />

provide a lasting resolution to the<br />

underlying issue, not a quick patch<br />

which allow it to reoccur at a later<br />

date. Combined PIR and Phenolic<br />

tapered insulation systems can be<br />

quickly and easily installed whilst also<br />

delivering lasting improvements to<br />

roof drainage and the overall energy<br />

performance of the building.<br />

Kingspan Thermataper systems combine insulation and drainage in a<br />

single, lightweight solution allowing simple, fast-track installations.<br />

For further information and technical<br />

support, please contact:<br />

Tel: +44 (0) 1544 387 384<br />

Fax: +44 (0) 1544 387 484<br />

e.mail: info@kingspaninsulation.co.uk<br />

www.kingspaninsulation.co.uk/tapered<br />

18 SEPTEMBER <strong>2018</strong>, REFURBISHMENT PROJECTS