Automotive Component Holdings, LLC (ACH ... - Hilco Trading

Automotive Component Holdings, LLC (ACH ... - Hilco Trading

Automotive Component Holdings, LLC (ACH ... - Hilco Trading

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

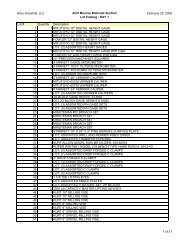

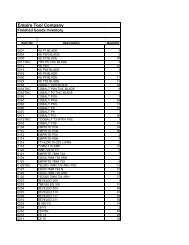

273 1 TECNO WASINO A12<br />

274 1 TECNO WASINO A12<br />

275 1 MORI SEIKI ZT 1500Y<br />

276 1 FMB TURBO 3-36/5300/A/D<br />

277 1 MORI SEIKI ZL 150S<br />

278 1 IEMCA TS 560F<br />

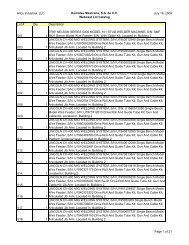

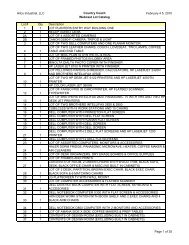

<strong>Automotive</strong> <strong>Component</strong> <strong>Holdings</strong>, <strong>LLC</strong> (<strong>ACH</strong>) Indianapolis Onsite Auction with Webcast<br />

Wednesday Thursday, June 27 28, 2012<br />

Beginning at 9:00 AM ET Each Day<br />

CNC TURNING/MILLING CENTER; S/N 442 (2002); Fanuc Series 18i-T CNC<br />

Control; Nominal Work piece 2" x 2" x 3 1/8"; Standard Bar Capacity 2" Diameter;<br />

Travels: X-145 mm (5.71"); Y-100 mm (3.94"); Z-350 mm (13.78"); C-Axis least<br />

Setting .001 Deg; Work Spindle Nose A2 No 6; Work Spindle Bore 54 mm (2.13");<br />

Max Work Spindle 4,000 RPM; S-Robo Auto Arm Space Saving Robot; Work<br />

Stocker WRS-1 10 Station Rotary Worktable; LM Magnetic Chip Conveyor; BT<br />

807222 (Loc. D-14) 1 Indianapolis, IN<br />

CNC TURNING/MILLING CENTER; S/N 369 (2000); Fanuc Series 18i-T CNC<br />

Control; Nominal Work piece 2" x 2" x 3 1/8"; Standard Bar Capacity 2" Diameter;<br />

Travels: X-145 mm (5.71"); Y-100 mm (3.94"); Z-350 mm (13.78"); C-Axis least<br />

Setting .001 Deg; Work Spindle Nose A2 No 6; Work Spindle Bore 54 mm (2.13");<br />

Max Work Spindle 4,000 RPM; S-Robo Auto Arm Space Saving Robot; Work<br />

Stocker WRS-1 10 Station Rotary Worktable; LM Magnetic Chip Conveyor; BT<br />

807180 (Loc. D-14) 1 Indianapolis, IN<br />

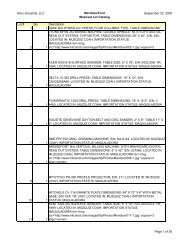

CNC TWIN SPINDLE TURNING CENTER; S/N ZT151FH0271 (2006); Spindle Through‐<br />

Hole 2.44" Dia; Chuck Through‐Hole 2" Dia; Bed Length 19.68" (500 mm); Max<br />

Cutting Dia. 12.8"; Max Turn Length 4.7"; MAPP III / MSX‐501 III CNC Control;<br />

Spindle Drive 22 KW/18.5 KW; Milling / Y‐Axis (6,000 RPM); Spindle Speeds 6,000<br />

RPM; Rigid Tap; Two (2) 12‐Position Turrets; Linear Ways; Economoto Chip<br />

Conveyor S/N E19234; Chip Blaster Model JV10 High Pressure/High Volume<br />

Coolant System; Parts Catcher; BT 807473 (Loc. D‐5) 1 Indianapolis, IN<br />

BAR FEED; S/N 16-260 294/R:502.913; EDGE TECHNOLOGIES DEBUNDLER -<br />

Approx. Length 210"; (Running with Mori Seiki BT 807473); (Loc D-5) 1 Indianapolis, IN<br />

CNC TURNING CENTER; S/N ZL150BE0266 (2002); Main Spindle Through‐Hole 2.2"<br />

Dia; Sub Spindle Through‐Hole 1.69" Dia; Bed Length 19.68" (500 mm); MSC‐501<br />

CNC Control; Swing over Bed 26.7"; Swing over Cross Slide 20"; Max Turning Length<br />

18.5"; Spindle 1 ‐ Rigid Tap; Spindle RPM 5,000; Twin 12 Station Tool Turrets;<br />

Kitigawa Model B205A521 Chuck; Spindle 1 ‐ 11 KW/7.5 KW; Spindle 2 ‐ 7.5 KW /<br />

5.5 KW; Tsubaki/Mayfran Chip Conveyor; S/N MF20250432; Chip Blaster Model JV8‐<br />

1000 Coolant System; Chip Conveyor; BT 807174 (Loc. C‐5) 1 Indianapolis, IN<br />

BAR FEED; S/N 0200224001; Type 43L & DEBUNDLER (Running with Mori Seiki<br />

BT 807174); (Loc. C-5) 1 Indianapolis, IN<br />

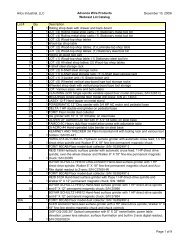

279 1 MORI SEIKI ZL-153<br />

CNC TURNING CENTER; S/NZL150CA0289 (2003); Spindle Through‐Hole 2.2" Dia<br />

Chuck Through‐Hole 1.7" Dia; MSC‐501 / MAPPS I CNC Control; Bed Length 19.68"<br />

(500 mm); Swing over Bed 26.77"; Swing over Cross Slide 20.08"; Max Turning<br />

Length 18.54"; Bar Capacity 1.77"; Sub Spindle; C‐Axis Milling (3,000 RPM); Spindle<br />

1 ‐ 7.5 KW / 5.5 KW ‐ 5,000 RPM; Spindle 2 ‐ High Output 11 KW / 7.5 KW; Twin 12<br />

Station Tool Turrets; Kitigawa Model B205A521 Chuck; Chip Blaster Model JV8‐<br />

1000 Coolant System; Mayfran Chip Conveyor; BT 807210 (Loc. C‐5)<br />

BAR FEED; S/N 0200245001; Type 53L & DEBUNDLER (Running with Mori Seiki<br />

1 Indianapolis, IN<br />

280 1 IEMCA TS 560F BT 807210); (Loc. C-5)<br />

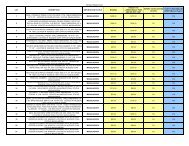

CNC TURNING CENTER; S/NZL150CA0288 (2003); Spindle Through‐Hole 2.2" Dia;<br />

Chuck Through‐Hole 1.7" Dia; MSC‐501 CNC Control ‐ MAPPS II; Bed Length Max<br />

Turning Length 18.54"; Bar Capacity 1.77"; Sub Spindle; C‐Axis Milling (3,000 RPM);<br />

Spindle 1 ‐ 7.5 KW/5.5 KW; Spindle 2 ‐ High Output 11 KW/7.5 KW; Twin 12 Station<br />

Tool Turrets; Kitigawa Model B205A521 Chuck; Chip Blaster Model JV8‐1000<br />

1 Indianapolis, IN<br />

281 1 MORI SEIKI ZL-153 Coolant System; Mayfran Chip Conveyor; BT 807259 (Loc. C‐5) 1 Indianapolis, IN<br />

282 1 IEMCA TS 560/53/F BAR FEED; S/N 1999 45003 (Running with Mori Seiki BT 807259); (Loc. C-5) 1 Indianapolis, IN<br />

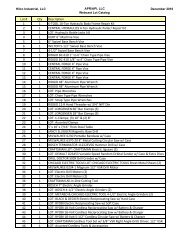

283 1 HARDINGE<br />

CONQUEST<br />

TWIN TURN 65<br />

284 1 IEMCA TS 560F<br />

285 1 HARDINGE<br />

CONQUEST<br />

TWIN TURN 65<br />

286 1 IEMCA TS 560F<br />

287 1 HARDINGE<br />

CONQUEST<br />

T42<br />

288 1 IEMCA TS560 / 43F<br />

289 1 HARDINGE<br />

CONQUEST<br />

T42<br />

290 1 IEMCA TS560 / 43F<br />

291 1 HARDINGE<br />

CONQUEST<br />

T42<br />

292 1 IEMCA TS560 / 43F<br />

CNC TWIN SPINDLE TURNING CENTER; S/N TT-145 (2000); GE Fanuc Series 18i-<br />

T CNC Control; Two (2) 10 Station Turrets; Coolant System; Turbo Model 6475-9859<br />

Chip Conveyor; S/N 348447; BT 808915 (Loc. C-5) 1 Indianapolis, IN<br />

BAR FEED; S/N 199948002; Capacity 5-65 mm (.196" - 2.56") & DEBUNDLER -<br />

Approx. Length 20' (Running w/Hardinge BT 808915); (Loc. C-5) 1 Indianapolis, IN<br />

CNC TWIN SPINDLE TURNING CENTER; S/N TT-144 (2000); GE Fanuc Series 18i-<br />

T CNC Control; Two (2) 10 Station Turrets; Coolant System; Turbo Model 6475-8959<br />

Chip Conveyor; S/N 348446; BT 808838 (Loc. D-5) 1 Indianapolis, IN<br />

BAR FEED; S/N 199948001; Capacity 5-65 mm (.196" - 2.56") & DEBUNDLER -<br />

Approx. Length 20' (Running w/Hardinge BT 808838); (Loc. D-5) 1 Indianapolis, IN<br />

CNC TURNING CENTER; S/N SG-524 (1995); GE Fanuc Series 18-T Control;<br />

00699 Hours; 12-Position Turret; Sub Spindle; Chip Conveyor; BT-805665; (Loc. A-<br />

6) 1 Indianapolis, IN<br />

BAR FEED & DEBUNDLER; S/N 95020108 (Running with Hardinge BT 805665);<br />

(Loc. A-6) 1 Indianapolis, IN<br />

CNC TURNING CENTER; S/N SG-525 (1995); GE Fanuc Series 18-T Control;<br />

80594 Hours; 12-Position Turret; Sub Spindle; Chip Conveyor; BT-805666; (Loc. A-<br />

6) 1 Indianapolis, IN<br />

BAR FEED & DEBUNDLER; S/N 95020109 (Running with Hardinge BT 805666);<br />

(Loc. A-6) 1 Indianapolis, IN<br />

CNC TURNING CENTER; S/N SG-553 (1995); GE Fanuc Series 18-T Control;<br />

85892 Hours; 12-Position Turret; Sub Spindle; Chip Conveyor; BT-805668; (Loc. A-<br />

6) 1 Indianapolis, IN<br />

BAR FEED & DEBUNDLER; S/N 95032614 (Running with Hardinge BT 805668);<br />

(Loc. A-6) 1 Indianapolis, IN