ZRP Catalog 2019

ZRP Racing Parts Official Catalog 2019

ZRP Racing Parts Official Catalog 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

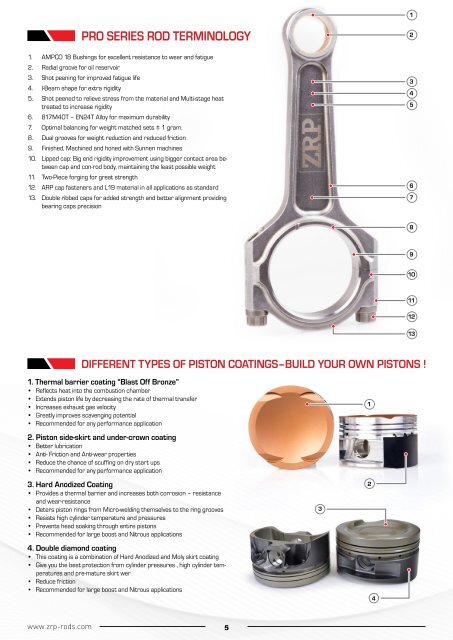

1. AMPCO 18 Bushings for excellent resistance to wear and fatigue<br />

2. Radial groove for oil reservoir<br />

3. Shot peening for improved fatigue life<br />

4. I-Beam shape for extra rigidity<br />

Pro Series Rod Terminology<br />

5. Shot peened to relieve stress from the material and Multi-stage heat<br />

treated to increase rigidity<br />

6. 817M40T – EN24T Alloy for maximum durability<br />

7. Optimal balancing for weight matched sets ± 1 gram.<br />

8. Dual grooves for weight reduction and reduced friction<br />

9. Finished, Machined and honed with Sunnen machines<br />

10. Lipped cap: Big end rigidity improvement using bigger contact area between<br />

cap and con-rod body, maintaining the least possible weight<br />

11. Two-Piece forging for great strength<br />

12. ARP cap fasteners and L19 material in all applications as standard<br />

13. Double ribbed caps for added strength and better alignment providing<br />

bearing caps precision<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

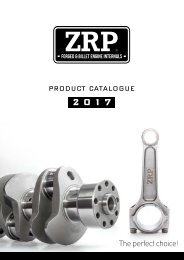

Different Types of Piston Coatings–Build your own Pistons !<br />

1. Thermal barrier coating “Blast Off Bronze”<br />

• Reflects heat into the combustion chamber<br />

• Extends piston life by decreasing the rate of thermal transfer<br />

• Increases exhaust gas velocity<br />

• Greatly improves scavenging potential<br />

• Recommended for any performance application<br />

1<br />

2. Piston side-skirt and under-crown coating<br />

• Better lubrication<br />

• Anti- Friction and Anti-wear properties<br />

• Reduce the chance of scuffing on dry start ups<br />

• Recommended for any performance application<br />

3. Hard Anodized Coating<br />

• Provides a thermal barrier and increases both corrosion – resistance<br />

and wear-resistance<br />

• Deters piston rings from Micro-welding themselves to the ring grooves<br />

• Resists high cylinder temperature and pressures<br />

• Prevents head soaking through entire pistons<br />

• Recommended for large boost and Nitrous applications<br />

3<br />

2<br />

4. Double diamond coating<br />

• This coating is a combination of Hard Anodized and Moly skirt coating<br />

• Give you the best protection from cylinder pressures , high cylinder temperatures<br />

and pre-mature skirt wer<br />

• Reduce friction<br />

• Recommended for large boost and Nitrous applications<br />

4<br />

www.zrp-rods.com 5