Preliminary status note: Thermal biomass conversion technologies ...

Preliminary status note: Thermal biomass conversion technologies ...

Preliminary status note: Thermal biomass conversion technologies ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.4. Fast Pyrolysis Technology<br />

2.4.1 Short description of technology<br />

10<br />

By pyrolysis of <strong>biomass</strong> in the absence of oxygen a large fraction of the <strong>biomass</strong> can be converted to bio-‐<br />

oil, and smaller amounts of char and gas. Biomass such as wood, agricultural residues and waste products<br />

can be used as feedstock for fast pyrolysis processes. A maximum oil yield is in most cases obtained at<br />

reactor temperatures between 450 and 600°C with a high feedstock heating rate and a short gas residence<br />

time. The bio-‐oil mass yield obtained from various <strong>biomass</strong> sources are in the range of 30 – 75 %wt. Wood<br />

having a low ash content and a high cellulose content is often found to provide a high bio-‐oil yield of 70 –<br />

75 %wt. The generated bio-‐oil has high oxygen content, cannot be distillated and may in some cases have a<br />

limited storage stability. The oil can be utilized as a heavy fuel oil in boilers, while it in most cases needs<br />

some upgrading by hydrogenation if the oil shall be used in diesel engines or gas turbines. Two classes of<br />

reactor types that can obtain high <strong>biomass</strong> feedstock heating rates have mainly been developed for flash<br />

pyrolysis plants, ablative reactors and fluid bed reactors. In an ablative reactor high heating rates is<br />

obtained by pressing the fuel particles towards a hot metal surface, while the high heating rate in a fluid<br />

bed reactor is obtained by a fast mixing of hot inert bed material and the fuel. Recently it has been<br />

proposed, that the char from the pyrolysis process can be used as bio-‐char that is distributed on<br />

agricultural fields, and thereby act as a method to sequestrate carbon (Bruun et al. 2011).<br />

2.4.2 Global <strong>status</strong> of technology development<br />

The most active research community regarding fast <strong>biomass</strong> pyrolysis is at Aston University in the UK, and<br />

the research group is headed by A. V. Bridgwater (Bridgwater 2012).<br />

The construction of commercial and pilot pyrolysis plants has gradually increased the last 10 years and<br />

initially most plants were constructed in Canada. Today both pilot and commercial plants are constructed in<br />

several countries as seen in Table 1. The largest planed pyrolysis plant is the construction of a 400 tpd plant<br />

that has been announced by Alberta placed Tolko industries LTD using the Ensyn developed CFB<br />

technology.<br />

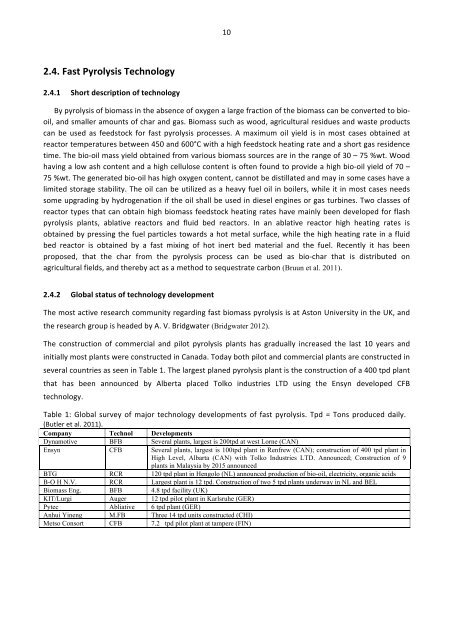

Table 1: Global survey of major technology developments of fast pyrolysis. Tpd = Tons produced daily.<br />

(Butler et al. 2011).<br />

Company Technol Developments<br />

Dynamotive BFB Several plants, largest is 200tpd at west Lorne (CAN)<br />

Ensyn CFB Several plants, largest is 100tpd plant in Renfrew (CAN); construction of 400 tpd plant in<br />

High Level, Albarta (CAN) with Tolko Industries LTD. Announced; Construction of 9<br />

plants in Malaysia by 2015 announced<br />

BTG RCR 120 tpd plant in Hengolo (NL) announced production of bio-oil, electricity, organic acids<br />

B-O H N.V. RCR Largest plant is 12 tpd. Construction of two 5 tpd plants underway in NL and BEL<br />

Biomass Eng. BFB 4.8 tpd facility (UK)<br />

KIT/Lurgi Auger 12 tpd pilot plant in Karlsruhe (GER)<br />

Pytec Abliative 6 tpd plant (GER)<br />

Anhui Yineng M.FB Three 14 tpd units constructed (CHI)<br />

Metso Consort CFB 7.2 tpd pilot plant at tampere (FIN)