msa_spr18_web_spreads-compressed

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ORIBI<br />

FARMER<br />

GROWS<br />

PEOPLE<br />

FIRST<br />

CULTIVAR<br />

DIVERSITY<br />

A MUST<br />

FOR SA<br />

NUT FUDGE<br />

ROLLS IN THE<br />

“ DOUGH ”<br />

Spring 2018

Contents<br />

PRODUCERS OF GUARANTEED HIGH QUALITY MACADAMIA TREES<br />

GLOBALGAP - SAMAC<br />

4 12<br />

Editor<br />

Gareth Wright<br />

072 223 3498<br />

gareth@blockmedia.co.za<br />

Advertising<br />

Laura Myers<br />

083 271 5243<br />

laura@macadamiasa.co.za<br />

Design & Layout<br />

Elizabeth-Ann Bradley<br />

hello.elizabethann@gmail.com<br />

www.macadamiasa.co.za<br />

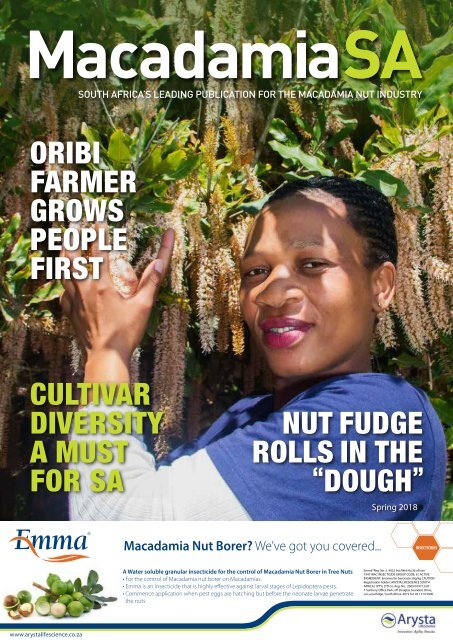

Cover Image<br />

Andiswa Maketa enjoys the<br />

Beaumont flowers in the orchards<br />

at Fairview Farms where she is<br />

the Administration Supervisor.<br />

Image Colleen Dardagan<br />

16<br />

CONTACT MOUNTAINVIEW NURSERY<br />

orders@mountainviewnursery.co.za<br />

Stefan (M) 071 608 9151 (Facsimile) 086 623 2590<br />

5-STAR ACCREDITED<br />

NURSERY<br />

WWW.MOUNTAINVIEWNURSERY.CO.ZA<br />

This publication is<br />

protected by copyright law.<br />

No part of this publication<br />

may be reproduced in any way<br />

without the permission and<br />

acknowledgement of Macadamia<br />

South Africa. Opinions expressed<br />

do not necessarily represent the<br />

views of Macadamia South Africa<br />

or the publishers.<br />

Published By<br />

Block Media<br />

Po Box 1501<br />

Simbithi, Ballito<br />

4390<br />

Printed By<br />

a Novus<br />

Holdings<br />

Company<br />

2 From the Editor<br />

Gareth Wright<br />

4 Oribi Mac Farmers<br />

Grow People First<br />

12 Beaumont<br />

A Tough Nut<br />

To Crack<br />

16 Lowveld Farm<br />

Diversifies<br />

In Mozambique<br />

22 Nut Fudge<br />

Rolls In The ‘Dough’<br />

26 Cultivar Diversity<br />

A Must For<br />

South Africa<br />

30 New App<br />

Makes<br />

Harvesting<br />

A Breeze<br />

34 Beware<br />

The Felted Coccid<br />

38 Industry<br />

Nuts & Bolts

From the<br />

Editor<br />

The shops are filled with Christmas<br />

decorations, festive season celebrations<br />

are under way and Macadamia SA<br />

is celebrating its fourth and final<br />

edition for 2018.<br />

While gathering the stories and doing the research for the<br />

inaugural edition in the first quarter of this year we began<br />

to get an idea of what was in store for us. We have met the<br />

most interesting people, including technical experts, farmers,<br />

processors, workers in the fields and so many more who have<br />

helped us to pack each edition with colour, valuable industry<br />

information and the most inspiring stories of individuals<br />

committed to growing South Africa’s agriculture industry for<br />

the good of all. The macadamia industry is probably one of<br />

the most exciting in South Africa at the moment and this<br />

edition is packed full of the stories of those who make it the<br />

success it is.<br />

We visit Karen and Robert Carlton-Shields who gave up<br />

their high-flying corporate lives in Gauteng to start farming<br />

macadamias in 2011. The couple have brought their extensive<br />

knowledge in staff development to their farming enterprise<br />

which has seen the growth of individuals who previously<br />

could only have dreamed of what they are achieving and the<br />

opportunities that lie ahead for them.<br />

And, as the government works out the complex issue of land<br />

ownership in the country, growers wanting to spread their<br />

risk have branched out into neighbouring countries such<br />

as Mozambique to start growing the crop, but not without<br />

demanding challenges. Some of these include a tangle of red<br />

tape and getting to know the dynamics of a different country<br />

and its people, its climate and growing conditions.<br />

Then there’s our story on Eugene “Dog” Kalafatis, a KwaZulu-<br />

Natal macadamia farmer and one of South Africa’s most<br />

experienced helicopter pilots who is using his expertise to<br />

improve the application of pesticides in orchards by bringing<br />

the very best in technical innovation and development to the<br />

crop spraying sector.<br />

This late in the year, most of the macadamia cultivars in the<br />

country’s orchards have already dropped their nuts, except<br />

of course for the Beaumont variety which is the very last to<br />

deliver on its harvest.<br />

Mayo Macs technical expert Rohan Orford reminds us of the<br />

unique qualities of this original cultivar and why it is still in<br />

demand as a variety in commercial orchards.<br />

From the Macadamia SA team, we wish all our readers,<br />

contributors and advertisers a peace-filled Festive Season and<br />

a prosperous 2019.<br />

Gareth Wright<br />

Colleen Dardagan<br />

Contributing Author<br />

Lindi Botha<br />

Contributing Author<br />

Laura Myers<br />

Advertising<br />

2

Oribi Mac<br />

Farmers<br />

Grow People First<br />

Oribi Flats macadamia farmers believe<br />

transformation is about understanding<br />

the community in which they live,<br />

identifying leaders and then giving them<br />

opportunities for learning while at the<br />

same time creating space where people<br />

are incentivised, respected and promoted.<br />

Article & Images<br />

Colleen Dardagan<br />

Andiswa Maketa was a domestic worker in Johannesburg<br />

before she made the decision in 2011 to move to the<br />

KwaZulu-Natal south coast with her employers Karen<br />

and Robert Carlton-Shields. Maketa knew nothing about<br />

farming and her main reason for making the change was to<br />

live and work closer to her mother who lives in Mthata in<br />

the Eastern Cape. Never in her wildest dreams did she think<br />

she would become a supervisor on her employers’ macadamia<br />

farm. Now her responsibilities include staff management and<br />

the computerised administration of the business. She has also<br />

passed her driver’s and forklift licence tests and bought her<br />

own car. Maketa is central to the day-to-day administration<br />

of the farm, which says Karen, frees her up to focus on other<br />

farm priorities.<br />

Similarly, Pinky Ngcobo, who not so long ago was a picker<br />

in the orchards, has her Professional Driving Permit and was<br />

promoted to Operations Supervisor earlier this year. “When<br />

Karen and Robert first came here, I was a general farm worker,<br />

slashing the grass and spraying the weeds,” said Ngcobo.<br />

“In 2013 I was the first woman to use a brush cutter and<br />

when the new irrigation system was installed, I learned how<br />

to lay the pipes and start the pump. That’s when I learned to<br />

drive, and I now run the entire irrigation system. In 2016 I<br />

was the picker of the year, in 2017, I was the worker of the<br />

year and in January this year I was promoted to Operations<br />

Supervisor,” she said.<br />

Above Karen and Robert Carlton-Shields who say creating<br />

opportunities for others to develop to their full potential gives them<br />

the greatest joy in the new life they have chosen for themselves.<br />

And Zama Mbele - the newly promoted Maintenance Leader<br />

- says from picking the nuts to where he is today has given<br />

him motivation to keep on learning and to see himself<br />

growing and shining both at work and in his community.<br />

All three, the Carlton-Shields say, are integral to the successful<br />

running of the 101ha macadamia orchards on the Oribi Flats<br />

inland from Port Shepstone. “We see our staff as the backbone<br />

of our business - the very centre of its success - we are only<br />

as successful as the people who work for us. Because of our<br />

corporate background, and the training and development we<br />

received there we bring a very different mindset as to how we<br />

want to develop our people here,” they said.<br />

The farm is over 200ha with the portions not under<br />

macadamias left as natural grassland, which the couple say is<br />

important for the promotion and protection of the natural<br />

environment. Karen and Robert have a very remarkable<br />

story to tell but they pointedly keep diverting attention<br />

away from their decision to leave the corporate sector in<br />

Johannesburg and become macadamia farmers. They say this<br />

is because the achievements of their staff are what they want<br />

highlighted. To them those are the stories of true courage<br />

and determination. “Karen and I were in high level corporate<br />

jobs in Johannesburg,” said Robert. “My area of expertise<br />

is the management of hazardous and toxic chemicals, while<br />

Karen is a qualified health and safety professional.<br />

Karen saw her dad work his whole life in the corporate<br />

sector. She just knew she didn’t want to live her whole life<br />

in the same way. Her dream was to farm coffee in Kenya,”<br />

Robert said. He told her they could farm, but just not coffee<br />

in Kenya!<br />

Above Bongi Ngcobo and Phelile Zulu take a break from their task of<br />

4 knocking the ripe macadamia nuts from the late-harvesting Beaumont trees. MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

5

Above Winnie Mzotho holds up the macadamia nuts ready for sorting and processing at Fairview Farms.<br />

Below Administrative supervisor, Andiswa Maketa takes a break from her office work to sort the newly picked nuts.<br />

Top Pinky Ngcobo, the Operations Supervisor at Fairview Farms<br />

returns from checking the irrigation systems in the orchards.<br />

Above Newly promoted maintenance supervisor, Zama Mbele<br />

cleans air filters in the farm workshop.<br />

Left Sibonelo Mbutho harvests the late bearing Beaumont<br />

macadamia variety. She says the work is important to her<br />

and her family who live in a neighbouring community.<br />

6<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

7

Right Sibongiseni<br />

Shazi, left and<br />

Mlamuli Mbutho<br />

sort the newly<br />

harvested nuts<br />

as they arrive<br />

onto the conveyor<br />

belt in the farm’s<br />

sorting facility.<br />

Above Nokwanda Gumede gives the macadamia trees a good<br />

shaking to encourage the nuts to drop for easier harvesting.<br />

Above Learning the ropes, new to macadamia<br />

picking, Phelile Zulu in the Fairview orchard.<br />

Right Manelise Cele who is the dehusker supervisor is<br />

one of the up and coming leaders at Fairview Farm.<br />

It took four years and a tremendous<br />

amount of research and “homework”<br />

before the couple finally bought<br />

Fairview Farm. Robert is in charge<br />

of the farm’s strategic planning while<br />

Karen runs the day-to-day operations.<br />

which include staff management. “We<br />

arrived here on June 1, 2011. And we<br />

hit the ground running. Yes, we had<br />

done our homework, but the reality<br />

of the farm was way different from<br />

the theory. We didn’t have time to<br />

think, we just had to get on and do it,”<br />

he said.<br />

Fairview Farm has about 26 000<br />

macadamia trees, some of which are<br />

irrigated and some dryland. Most of<br />

the trees on the farm are Beaumont<br />

cultivars. “The climate is very different<br />

from that on the coastline so we<br />

typically have multiple flowerings and<br />

our harvesting is late. This presents<br />

challenges for us as well as for the<br />

local nut processors we supply. Our<br />

pickers who have such an arduous<br />

task are amazing, even after months of<br />

harvesting they are still cheerful and<br />

committed. Fortunately, our processors<br />

are understanding of the challenges as<br />

well and they have been very supportive<br />

over the years,” the couple said.<br />

Once settled on the farm and as soon as they managed to<br />

catch their breath both Robert and Karen started identifying<br />

the people who they believed could be leaders, or as they say:<br />

“to step up and take over from us”.<br />

“For us transformation is about the small steps rather than<br />

the big tokens which come to nothing,” said Karen. “The<br />

first step though was to change our mindset. We had been<br />

used to working with people who had degrees with serious<br />

corporate responsibilities. Here we found ourselves working<br />

with people who had experienced tremendous challenges<br />

such as little or no education which had resulted in limited<br />

cognitive and lateral thinking skills.”<br />

The couple engaged the services of an industrial psychologist<br />

to assess the potential of their staff before putting together<br />

a practical plan on how to change thinking and learned<br />

behaviour. Those who were identified as leaders were then<br />

sent on a formal training session which was hosted at a hotel<br />

in Margate. “This in itself took most of the group out of their<br />

comfort zones,” they said. “None of them had ever stayed in<br />

a hotel or had sat through formal training sessions before.<br />

We made sure the sessions were very visual and interactive<br />

as a result. They included training on personal development,<br />

conflict management, how to motivate people and work as a<br />

team. Our staff are beginning to realise their value and their<br />

role in the business. They have grown in confidence as they<br />

are seeing how their input is valuable and how important<br />

their contributions are to the decision-making processes on<br />

the farm. For us to see their yearning for knowledge and a<br />

Above Administrative supervisor, Andiswa Maketa teaches Elizabeth Duvenage<br />

to work the farm computer as she prepares to take maternity leave in December.<br />

burning desire to learn more and more has been a humbling<br />

experience.” But it is listening to the hopes and dreams of the<br />

three staff members that the full impact of the journey thus<br />

far becomes clear.<br />

Maketa, who is about to go off on maternity leave, has had to<br />

train her replacement on how to manage the administration<br />

of the farm. For Ngcobo each day is about learning more<br />

new things, while for Mbele it’s constantly growing his<br />

skills as a leader. “What I have learned here is that it is not<br />

a disgrace to say you don’t know something and then to<br />

ask questions on how to do that task right,” Ngcobo said.<br />

“There have been challenges in my new role, but the training<br />

we received gave me tools to use to be able to cope with<br />

them. As supervisors on the farm, we also work together to<br />

solve our problems before we go to Karen and Robert,” the<br />

three said. And for Robert and Karen, their unique incentive<br />

scheme and staff management model is aimed at continuing<br />

the development and growth already started in their people.<br />

“We work in an environment of mutual trust and respect.<br />

And if one of them gets a better opportunity or head-hunted<br />

in the industry we support that because then they can grow<br />

themselves elsewhere. Through our succession plan we<br />

will be able to find someone to step up into their place,”<br />

Robert said.<br />

“Our whole aim is to see people elevated and to<br />

see them achieve the very best of their potential.”<br />

- Robert Carlton-Shields<br />

8<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

9

A 3-part series on the history of Beaumont in South Africa.<br />

ADVERTORIAL<br />

Part<br />

3<br />

Above & Left: Amorentia Beaumont trees ranging<br />

from 3 to 4.5 years old in the Letsitele Valley, Limpopo.<br />

The 4 year olds produced 2.6 tons per Ha WIS.<br />

It is true that not all cultivars root well on their own<br />

rootstocks in which case either a seedling or a clonal<br />

rootstock is required for grafting.<br />

Amorentia customers give consistent feedback confirming<br />

what is already known at Amorentia – their Beaumont<br />

VPs are of excellent quality and show evidence of high<br />

yield early because they are well rooted and because their<br />

genetic material is superior.<br />

Macadamia growers (especially those who are new to<br />

Macadamia farming) often question the differences<br />

between the root systems of vegetative clonal rootedcuttings<br />

(VPs) versus seedling rootstocks. The answer<br />

is simple; VPs will produce a more even orchard due to<br />

the consistency of genetics and they offer a superior<br />

root-system when propagated by superior nurseries<br />

with experience.<br />

High yielding nursery trees come from excellent mothermaterial.<br />

Through its Plant-Improvement Scheme, the<br />

Amorentia Macadamia Nursery Beaumont mother-trees,<br />

(as well as all other cultivars) were monitored for high<br />

performance over a 15 year period. This exercise ensured<br />

that only high yielding trees remain in the mother-blocks.<br />

This was achieved by weighing the nuts from each mothertree<br />

and removing all poor performing trees. It means<br />

that the genetic material used for all propagation at<br />

Amorentia offers growers a high-yield potential from day 1.<br />

It also means that the Nursery has 100% control over their<br />

propagation procedures.<br />

For more information on Amorentia Estate and Nurseries,<br />

visit their <strong>web</strong>site www.amorentia.co.za or contact them<br />

directly: admin@amorentia.co.za<br />

Proving the science behind our Beaumont cultivar yield success.<br />

www.amorentia.co.za

Beaumont<br />

A Tough Nut To Crack<br />

Beaumonts, affectionately known as<br />

‘695’, are currently and historically the<br />

most popular cultivar in South Africa,<br />

which we estimate to represent at least<br />

35 % of the total trees in the ground.<br />

Article Rohan Orford<br />

Images Colleen Dardagan<br />

It is a hybrid of M. integrifolia and M. Tetraphyla and<br />

characterised by its iconic crimson flush, prolific rich<br />

smelling pink bloom and slightly knobbly husk. The leaves<br />

are also notoriously spiky, making picking and pruning an<br />

uncomfortable affair.<br />

Its primary popularity stems from its precociousness and<br />

hardy reputation which is especially attractive to farmers in<br />

South Africa who seek the blend of a high yielding tree that is<br />

tough at the same time. Further, they can with care produce<br />

their first crop in the third year after planting which is earlier<br />

than later maturing varieties such as the ‘816’ which tend to<br />

produce in year 4-5. This is very attractive to new farmers<br />

where early cash-flow is hugely appreciated.<br />

Lastly Beaumont are the foundation cultivar for root-stocks<br />

in the macadamia nursery industry. Other characteristics<br />

include it being late (Aug-Sept) flowering variety, with its<br />

harvest ready in September to October. This is an advantage<br />

in that the kernel develops when the season has warmed up<br />

allowing for better kernel growth but also has its risks in<br />

that the winds in KZN and heat in Nelspruit can wreck the<br />

flowering and early nut set. It requires heavy pruning due to<br />

its vigorous growth and dense canopy. Canopy density and<br />

flowering in a more humid time of the year also makes it<br />

susceptible to blossom blight, which is a fungal disease that<br />

also destroys the flowers.<br />

In management terms it has the unfavourable nature of<br />

not dropping its nuts, but tolerates the use of ethylene to<br />

drop the nuts making it a more popular variety as spraying<br />

ethylene speeds up harvest and helps reboot the trees for the<br />

next season.<br />

12<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

13

With the higher altitudes of Mpumalanga being the original<br />

hub of Macadamia farming, Beaumonts also fared rather<br />

well from a kernel recovery and style of kernel characteristics<br />

relative to other historically popular varieties such as the<br />

‘788’ and ‘344’.<br />

With the advent of the macadamia farming boom in KZN,<br />

it became abundantly clear that the Beaumont quality was<br />

far poorer than the other cultivars. Mayo Macs carried out<br />

some further analysis on all the elements that dictate price<br />

such as kernel recovery, style spread and yield and related<br />

this to altitude of our mapped farms and interestingly the<br />

Beaumonts do not seem to tolerate the conditions within<br />

100 meters above sea level which we assume is due to the sea<br />

aerosols. What is also becoming clear is that Beaumont only<br />

performs well when irrigated but tends to suffer severe yield<br />

declines of up to 50% with drought.<br />

However, with all things considered the Beaumont is<br />

considered one of the best earning varieties available. This is<br />

probably one of those rare cases where in hindsight the older<br />

“mac” farmers were right! They planted a variety that, despite<br />

all the new cultivars and new information on hand today,<br />

still turns out to be a really great nut bearing tree.<br />

Above & Below Left Beaumont macadamia trees, or 695 in full flower on the KwaZulu-Natal south coast.<br />

COASTALS<br />

PRODUCT AND SERVICE OFFERING<br />

A few of our lines include:<br />

Fertilizer, pesticides, fuel, lubes, overalls,<br />

gumboots, cleaning detergents, dog food,<br />

fencing…in summary anything from A – Z<br />

2 FLANDERS DRIVE<br />

MOUNT EDGECOMBE<br />

info@coastals.co.za<br />

031 508 8000<br />

HEAD OFFICE<br />

www.coastals.co.za<br />

Twitter: @CoastalFarmers<br />

Facebook: Coastal Farmers<br />

Co-operative Limited<br />

14<br />

Above Rohan Orford, Senior Technical Advisor, Mayo Macs.<br />

MACADAMIA SOUTH AFRICA<br />

Everything you need from A - Z

The uncertainty of farm tenure in Zimbabwe in the early 2000s and the unfolding land reform process in<br />

South Africa prompted a group of South Africans to spread their risk by investing in a macadamia farm in<br />

Northern Mozambique. And the challenge, they say, has proven that persistence and innovation does pay off,<br />

although tackling the unknown in a foreign country meant management had to be hands on from the start.<br />

Above The farm has micro irrigation, but often the trees do not get adequate water in the dry months due to a lack of power.<br />

Lowveld Farm<br />

Diversifies<br />

in Mozambique<br />

Establishing a macadamia farm in Mozambique has proved a steep<br />

learning curve for a group of South African farmers. But higher<br />

efficiencies and vast supplies of land and water have resulted in a<br />

profitable operation that offers a favourable option for diversification.<br />

Article & Images<br />

Lindi Botha<br />

Duncan Macgregor (above) who is one of the six<br />

shareholders in the business named Tenga Limitada said<br />

there were always surprises popping up that the group could<br />

never have bargained on. The business is made up of 250ha<br />

of macadamia orchards in Niassa province which is 120km<br />

east of Lichinga and about 200km south of Tanzania in the<br />

upper lefthand corner of the East African country.<br />

VIRGIN TERRITORY<br />

After identifying a suitable piece of land, the administrative<br />

process to secure a land lease or duat as it is known in<br />

Mozambique, was set in motion, says Macgregor. Initially<br />

the Mozambican government granted the South African’s a<br />

two-year lease. “This allows time for lessees to do community<br />

consultations and prove that you are actually going to do<br />

something with the land. After that you can apply to have<br />

it converted to a definitive duat of 49 years and then after<br />

that for another 49 years, bringing it to the maximum 99-<br />

year lease that is allowed in Mozambique,” he said. But the<br />

process can be drawn-out which meant it came with its own<br />

challenges, for example, to get through all the bureaucracy<br />

and to find the right channels of communication was not<br />

only challenging, but time consuming. Further, Macgregor<br />

said, the system there is based on Portuguese law, not British<br />

or Roman law as they were accustomed to in South Africa.<br />

“There are very different interpretations and the language<br />

barrier is problematic. For example, a farmer might get the<br />

land at a nominal rental, but what they end up paying for in<br />

compliance, is far more than their investment in the land.”<br />

“The idea of cheap land in Mozambique<br />

does not exist as the cost of doing business in<br />

Mozambique is high,” - Duncan Macgregor<br />

The South Africans established the farm from scratch on<br />

virgin land. First, they planted 10ha to various cultivars to<br />

see which ones did well. The farm is still without electricity<br />

and a mix of solar panels, generators and gasifiers are used to<br />

power the operation which creates its own challenges. Since<br />

the farm is in an isolated area the shareholders wanted to<br />

develop the surrounding community and create an enabling<br />

environment for economic activity. At the time Mozambique<br />

was receiving foreign aid from NGO’s and several were<br />

approached by Tenga to assist with putting up infrastructure<br />

in the nearby town. “One NGO required us to rapidly expand<br />

our hectares so that they could see we were there to stay. We<br />

ended up taking many short cuts to get the orchards going to<br />

meet the NGO’s requirements. But then the funding never<br />

materialised and we had orchards where the land preparation<br />

was not done thoroughly. “That was one of our biggest errors<br />

as it has affected yields and pushed us further away from the<br />

break-even point as we are constantly trying to rectify the<br />

soils. Now we rip the soil and do proper lime and phosphate<br />

applications before planting, as would be standard practice<br />

in South Africa,” said Macgregor.<br />

With continuous expansion the farm will eventually have<br />

350ha planted to macadamias in a few years. The 816<br />

and Beaumont varieties in particular have done well with<br />

crackouts around 38% sound kernel recovery.<br />

16<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

17

Above The layout of the farm is such that the straight rows can extend up to 3km.<br />

Above New trees are constantly being added to the farm to expand the orchards.<br />

Once harvested the nuts are dried on the farm and shipped<br />

as nut-in-shell to China. Those nuts that don’t fit the grade<br />

are sent to South Africa to be cracked. Macgregor said there<br />

were no problems transporting the nuts across the border<br />

and as far as possible they tried to share loads with other<br />

inputs coming to the farm on the return trip. Macgregor<br />

said unfortunately yields were not optimal and didn’t always<br />

reach the industry average of 4 tons/ha. He said this was<br />

largely as a result of the ongoing irrigation problems caused<br />

by power supply challenges. “The climate in Mozambique<br />

is favourable for macadamia production, however the very<br />

definitive rainy and dry season causes problems if there is not<br />

adequate irrigation. Just before the rains start in December,<br />

it’s extremely hot and dry and affects nut development.<br />

The gasifiers we use to power the irrigation system often<br />

breakdown, which means we can only irrigate a few blocks<br />

at a time. In those hot months the demand for water is high<br />

and if the trees don’t get what they need, it reduces the yield<br />

and crackouts,” he said.<br />

Macgregor said the water supply was abundant with various<br />

large rivers in the area and they were about to build a dam<br />

on a small stream, which would allow most of the orchards<br />

to be gravity fed. There is also the possibility of setting up a<br />

hydro power plant on one of the bigger rivers. Such projects<br />

which had benefits for the neighbouring communities were<br />

key when doing business in Africa, he said.<br />

“As South African farmers we have to have a different mindset.<br />

It can’t be ‘us and them’. The growth must be inclusive<br />

in those areas and you can’t fence yourself off and progress<br />

on your own without any benefit to the community. If the<br />

hydro power gets off the ground, we will be able to assist the<br />

local village with some electricity for their school and clinic.<br />

There is a possibility of assisting the local community with a<br />

drip irrigation scheme from the dam that supplies the farm<br />

with water. They will be able to plant vegetable gardens or<br />

whatever other crops they choose to plant.”<br />

He said during the expansion phase having the budget to<br />

help surrounding communities was not always possible.<br />

“It is important to balance the cash flow for the business with<br />

the requirements from the community. If our business fails<br />

the whole community is affected. We supply employment to<br />

around 130 people and we need to ensure they can keep their<br />

jobs,” he said.<br />

CHALLENGES AND OPPORTUNITIES<br />

Farming at a distance with at least 1 700km between the<br />

farm and the nearest shareholder required a certain degree of<br />

micro management to make sure the operation remained on<br />

track. Macgregor said a large part of the farm’s success was<br />

attributable to the six shareholders having taken ownership of<br />

their specific portfolios. They were each actively involved in<br />

the day to day running of the farm and each was committed<br />

to making the trip to the farm twice a year. Management,<br />

he said was a serious challenge because the farm was so<br />

isolated. While middle management positions were taken<br />

up by locals, senior managers were sourced from elsewhere.<br />

“It takes a special kind of person to work there; it is isolated<br />

with little social interaction and there are no schools for the<br />

children. We have had some hits and misses, but currently<br />

have a good manager in place. There is a weekly reporting<br />

system on a very detailed level that I don’t even get on my<br />

own farm in South Africa,” he said.<br />

Despite being far from any other macadamia farms, insects<br />

from other crops have made their way into the orchards.<br />

“We have picked up insects that we have never seen in South<br />

Africa. There is a mosquito bug that emerged a few weeks<br />

ago that originates in tea and cashew plantations. There is<br />

no registered pesticide against it but we have found that<br />

chemicals used for stinkbug control works for the mosquito<br />

bug as well,” Macgregor said. The challenges created by the<br />

lack of power on the farm were vastly underestimated and<br />

much of the cash flow was used to get these basics right.<br />

“You are suddenly faced with things that would never be<br />

an issue in South Africa. Even buying a tractor becomes a<br />

problem beyond just getting it from Maputo to the farm. If<br />

it breaks there are no mechanics around so you have to risk<br />

fixing it yourself and losing the warranty,” he said. Planning<br />

was also extremely important to make sure inputs reached<br />

the farm in a timely manner. “The cost of inputs is only<br />

slightly more expensive due to the distance the loads must<br />

travel, but labour is significantly cheaper. We run an efficient<br />

operation and benefit from economies of scale. The land is<br />

flat and vast so we plant 9ha blocks at a time. The farm layout<br />

allows rows to reach up to 3km long. We have adequate water<br />

and a great climate.<br />

Challenges aside - it is well worth the<br />

investment,” - Duncan Macgregor<br />

18<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

19

ADVERTORIAL<br />

SELECTING<br />

VARIETIES<br />

For Commercial<br />

Macadamia Orchards<br />

Because there are so many cultivars to choose from and their yield performance differs from region to<br />

region, selecting macadamia varieties to plant in commercial orchards is complex. Managing Director of<br />

Red Sun Hortitech, Mark Hassenkamp says often comparisons between varieties are based on nut in shell<br />

(NIS) yields per tree, but this was in general a poor measure of tree performance. “A variety may have a<br />

high yield per tree, but if trees have a low spacing and are excessively large they may still perform poorly<br />

when assessed on a per hectare basis. Equally, small trees planted on a wide spacing will also not achieve<br />

acceptable yields per hectare,” Hassenkamp said.<br />

HASSENKAMP SUGGESTS THE FOLLOWING WHEN CHOOSING CULTIVARS FOR AN ORCHARD:<br />

THINK IN TERMS OF FIRST<br />

GRADE KERNEL PER HECTARE<br />

When making decisions about new orchards,<br />

all factors must be considered such as yield,<br />

benchmarks, climate, management capacity,<br />

equipment, and then most importantly; yield,<br />

income, cost and profit.<br />

DECIDE ON PLANTING DENSITY<br />

Hassenkamp said the planting density of a new<br />

orchard was the deciding factor on the selection<br />

of varieties to plant. “It is unlikely that a semidwarfing,<br />

small, compact, upright tree such as<br />

A16 will fill the orchard at low densities, leaving<br />

a large area of the orchard unproductive with<br />

lower returns per hectare. By the same token,<br />

planting a larger precocious variety such as<br />

695, 842 and 849 at high densities would mean<br />

intensive management would be required to<br />

keep the orchard under control in later years.”<br />

IMPORTANCE OF VARIOUS TRAITS<br />

Hassenkamp advised growers to take all the different traits of each variety into account, rather than<br />

concentrating on one or two, although he agreed the ultimate decision was subjective and would<br />

depend on various external factors such as climate. Many growers, he said, considered it desirable<br />

to have all varieties ready for harvest at the same time, to achieve a short harvest window. Other<br />

growers prefer to spread the harvest out to reduce stress risk and minimised the need for large capital<br />

equipment to handle the harvest. “Another important aspect to consider is to select varieties that are<br />

more less the same tree size across the orchards,” he said. There are some debates at the moment on<br />

the preferred size of the kernels, but processors generally prefer large kernels, because they are less<br />

costly to handle,” he said.<br />

DESIGN AND PLANT THE ORCHARD ACCORDING TO POLLENISER COMPATIBILITY<br />

While Hassenkamp advises growers to select at least three varieties to reduce risk, flowering periods<br />

should also remain top of mind. “We recommend that farmers plant solid blocks of selected varieties<br />

rather than mixing the varieties in the row. This might slightly effect pollination, but it makes the<br />

orchards easier to manage,” he said. Red Sun currently has two experimental varieties on controlled<br />

release namely A203 which has a medium to large uneven sized nut with white kernels which drop<br />

mid-season. The variety is hardy and may suit more marginal areas and A268, a medium to large tree<br />

with an open spreading canopy, a mid-season nut drop and very large, good quality nuts which have<br />

creamy, white kernels.<br />

Red Sun Hortitech is approved by CitroGold to propagate and distribute Australian Hidden Valley macadamia varieties to southern<br />

African growers in addition to having dedicated clonal mother blocks for propagation of all commercial South African varieties.

Nut Fudge<br />

Rolls In The ‘Dough’<br />

A beautiful view and a love for all things sweet has<br />

turned the growing domestic consumer demand for<br />

macadamia nuts into a profitable agri-processing business<br />

for Nelspruit farmer, Jaco van der Merwe.<br />

Article & Images<br />

Lindi Botha<br />

Above Jaco van der Merwe<br />

plans on using the five<br />

hectares of land he has<br />

planted to macadamia nut<br />

orchards to build an agriprocessing<br />

business able to<br />

create a thriving domestic<br />

market for the nuts in<br />

the Lowveld.<br />

Left Husband and wife<br />

team Lizl and Jaco<br />

van der Merwe.<br />

Making delicious fudge from macadamia nuts was the last<br />

thing on Jaco van der Merwe’s mind when he set out to build<br />

his dream home in the magnificent countryside of South<br />

Africa’s Lowveld in the Mpumalanga Province.<br />

Instead of buying just one hectare to build his home in<br />

Nelspruit, van der Merwe landed up buying a farm and<br />

planting an orchard of macadamia trees. “I went from<br />

wanting a one hectare stand to building a home to eventually<br />

buying a 16ha farm,” he laughed. “I had the land and the<br />

water so planting macadamia trees was the next obvious step.<br />

I figured it would eventually help me pay for the cost of the<br />

property and the house.” But, it was his sweet tooth that<br />

saw the farmer starting to play around with various fudge<br />

recipes until he found the one he liked the best. And while<br />

the enterprise was never meant to go commercial, when<br />

toying around with a plan to add value to his crop, the idea<br />

of producing fudge for sale was born. In fact, van der Merwe<br />

admits to originally not having a particular liking for the<br />

taste of the macadamia nuts until he tasted those destined<br />

for export to markets around the world. “The quality of nuts<br />

available to the public in South Africa is not up to standard<br />

because all the good stuff is sent abroad. This creates a<br />

negative perception of macadamia nuts and consequently<br />

limits the market growth here.”<br />

Van der Merwe said he wanted to see the macadamia nut<br />

market developed in the Lowveld. “We are the biggest<br />

producing region globally but there are no products for<br />

the public to buy here. In Australia they have massively<br />

developed the market to nut milks, nut butters, and huge<br />

ranges of nut flavours from honey to wasabi.<br />

In South Africa we are lucky if we can find anything other<br />

than salted nuts, and even then, the quality is poor. We have<br />

to start developing our own market with quality products,”<br />

he said.<br />

After giving up some space used by his beer brewery in the<br />

garage for the fudge, van der Merwe started on his “Toxic<br />

Fudge” project, which he said, was way more rewarding than<br />

making beer. “My wife gave me a beer brewing kit as a gift.<br />

I spent all my time brewing beer only to end up with too<br />

much to consume and no market. It was a natural choice to<br />

give that space up for something that actually had a market,”<br />

he laughed.<br />

First, he sourced cream for the fudge from a nearby dairy and<br />

used a portion to make the butter for the fudge. “The price<br />

of the cream is more consistent at the dairy (than the price of<br />

butter) and the added bonus is that we are supporting a local<br />

business. We also get more consistency in the colour of the<br />

fudge because we make the butter ourselves,” he said.<br />

The family produce about 50kg to 60kg of fudge a week<br />

and the variety of flavours is growing with the addition of<br />

salted caramel and dark and white chocolate. Van der Merwe<br />

said the recipe hadn’t been adapted for mass production and<br />

would never be. “The whole idea is to make small batches<br />

and to keep it as artisanal fudge. That means it is more of a<br />

gourmet or adult fudge, not something aimed at children. A<br />

big batch for us is 10kg. If we were ever to put up a factory I<br />

would rather do a few smaller production lines than one big<br />

line so that we can maintain the integrity of our product,”<br />

he said.<br />

22 MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

23

ADVERTORIAL<br />

FENCING SOLUTIONS FOR A SECURE CROP<br />

In November of 2005, husband and wife team,<br />

Colin and Hesté Outram, started Drakensberg<br />

Gate & Fence along with Jors McDonald.<br />

Drakensberg Gate & Fence currently have<br />

about twenty-five permanent employees. An<br />

office manager, technicians, welders, fencers<br />

and drivers make up our enthusiastic team.<br />

While farmer’s markets never featured high on van der<br />

Merwe’s priority list as an avenue for sales, much to his<br />

surprise, they have proven to be the most lucrative for the<br />

marketing of the product. “You really have to be a super<br />

extrovert to spend your weekends selling fudge and interacting<br />

with so many people,” he said. But, with the demand for the<br />

fudge increasing and its high visibility at the markets, various<br />

other lucrative opportunities have opened up.<br />

Toxic Fudge now features each evening on the crisp turneddown<br />

sheets in the guest bedrooms of many upmarket<br />

accommodation lodges in the Lowveld, according to van<br />

der Merwe. “At this stage the farmer’s markets are our prime<br />

marketing tool. While we sell quite a bit on the day of the<br />

market, we pick up so many connections to supply to other<br />

outlets.”<br />

The versatility of the fudge has also meant the family has the<br />

scope to explore further partnerships with other farmers in<br />

the area to create products unique to the Lowveld.<br />

Toxic Fudge now comes as an orange fudge thanks to a<br />

partnership with citrus producers, Joubert & Seuns that is<br />

sold at a farm stall in the Schoemanskloof. A coffee fudge<br />

Above Gallan van der Merwe helps his parents on the farm and with running the market stalls.<br />

using espresso beans is under development for Sabie Valley<br />

Coffee with the next on the menu, a fudge made with local<br />

rum produced in Malelane. All the products are co-branded<br />

with the Toxic Fudge logo and that of the collaborating<br />

company to give profile to both businesses. “I don’t just want<br />

to sell fudge, I want to build a brand,” said van der Merwe.<br />

Collaboration had played a significant role in their marketing<br />

strategy. “Some of this has come about through happy coincidences.<br />

For example, at the markets when we realised<br />

how well our salted caramel fudge paired with champagne<br />

or gin. There is just so much scope for expansion and further<br />

collaboration here in the Lowveld,” he said.<br />

The van der Merwe family has also launched the Farm Nut<br />

Roastery which they say will produce a wide range of good<br />

quality macadamia nut products such as nut milk, nut<br />

butter and flavoured nuts. While small in size, the value-add<br />

projects are making the small macadamia business a worthy<br />

investment.<br />

“I can’t take five hectares of nuts to the processor and then<br />

sit back and wait for my money. I believe in adding value,<br />

whether I have 5ha or 100ha. There is always a niche to tap<br />

into,” he added.<br />

Drakensberg Gate & Fence provide security<br />

fencing solutions across a wide range of areas<br />

including industrial and residential estates,<br />

agriculture premises, education institutions,<br />

game farms and other associated facilities.<br />

We specialise in electrified fencing but<br />

are equally competent in the supply and<br />

erection of all types of wire mesh fencing,<br />

steel palisade fencing, razor security fencing,<br />

concrete fencing and steel gates. All gates are<br />

custom made to suit all orders.<br />

As Drakensberg Gate & Fence is a family<br />

owned business, we pay attention to every<br />

detail and especially in building a lasting<br />

relationship with our clients, we endeavour to<br />

erect a fence that suits each client’s individual<br />

needs. By word of mouth, we have reached a<br />

wide client basis throughout South Africa. We<br />

stay up to date with all the latest developments<br />

in the security and fencing industry.<br />

We have our own pecan nut orchard and are<br />

aware of theft involved in the industry. We are<br />

ready to assist in providing you with a quote<br />

on all your fencing requirements and would<br />

especially like to assist nut, flowers, vegetable<br />

and fruit growers in finding a practical fencing<br />

solution for your specific needs.<br />

”Since their inception, Drakensberg Gate &<br />

Fence have been retailers and installers of<br />

the Stafix and JVA Ranges of electric fencing<br />

systems. During this period of association,<br />

we have seen them provide outstanding<br />

service and quality workmanship to their<br />

customer base. Although based in Winterton,<br />

Drakensberg Gate & Fence have successfully<br />

erected fences and serviced customers<br />

within the Free State, KZN and Mpumalanga.<br />

Their friendly and helpful staff has been a<br />

pleasure to be associated with and we take<br />

pleasure in confidently recommending their<br />

service and workmanship.”<br />

- Maurice Williamson<br />

(C.E.O. Stafix Electric Fence and Security Centres)<br />

24<br />

MACADAMIA SOUTH AFRICA

Cultivar<br />

Diversity<br />

A Must For South Africa<br />

To meet the change in demand for<br />

macadamias across the globe and<br />

the expected downward pressure on<br />

exports of nut-in-shell to China, South<br />

Africa’s growers are urged to plant a<br />

variety of cultivars for a crop able to<br />

cater for consumer diversity.<br />

Article & Images<br />

Lindi Botha<br />

Right Alex Whyte, General Manager<br />

of Green Farms Nut Company.<br />

While South Africa’s macadamia industry is hard at work<br />

growing international markets to create increased demand<br />

for the domestic supply, farmers are warned to keep an eye<br />

on changing consumer demand when deciding on what<br />

varieties to plant in the orchards.<br />

Industry expert and general manager at the Mpumalangabased<br />

Green Farms Nut Company, Alex Whyte says consumer<br />

demand for the style and grade of the nuts they wanted to<br />

buy was changing fast which meant farmers must stay abreast<br />

of these shifts to make sure they were well placed to serve a<br />

broad spectrum of markets. Whyte said what had worked<br />

in the past would probably not work in the future and with<br />

different cultivars suited to the nut-in-shell (NIS) market<br />

and others to kernel, choosing the right variety to plant was<br />

now crucial to make sure the country’s industry remained<br />

sustainable into the future. “It would be remiss of us as an<br />

industry to assume that what got us here today is going to<br />

get us to where we need to be in 10 or even 20 years. Market<br />

demand has fundamentally shifted and there are significant<br />

changes in what customers, from the United States, Europe<br />

and China want on the horizon.” He said it was good news<br />

that different markets wanted different cultivars and styles<br />

of nuts, but it required a fine balancing act between what<br />

was planted and how the nuts were ultimately processed and<br />

marketed.<br />

Of concern though, is that at present 50% of South Africa’s<br />

trees are the Beaumont cultivar, which is more suited to<br />

the nut-in-shell market demanded by China. Around 56%<br />

of South Africa’s crop is exported to the east but the region<br />

represented just 27% of global tree nut consumption.<br />

Whyte said while the macadamia industry was in a unique<br />

and prosperous position with both supply and demand on<br />

the up, he cautioned that more work was needed to secure<br />

long term kernel contracts in the west to diversify export<br />

markets. “This is largely attributable to growing populations<br />

and momentous changes in healthy and ethical eating.”<br />

Additionally, for a variety of reasons, Asia is increasingly<br />

demanding larger nuts and the requirement within the<br />

ingredient sector for diced product is on the rise globally.<br />

Macadamia tree cultivars each yield different nut sizes, sound<br />

kernel recovery (SKR) and volumes depending on a number<br />

of factors from region to region. This becomes significant<br />

through the lens of South Africa’s current export market<br />

mapped to meet global consumption.<br />

Mark Hassenkamp, director of the Red Sun Hortitech<br />

nursery said since global tree nut consumption had increased<br />

by 24% over the last ten years, this, alongside the astonishing<br />

473% increase in their value over the same period of time<br />

made it understandable focus had been on the here and<br />

now. “However, as the market continues to mature and crop<br />

volumes grow, specific demands for quality and nut grade<br />

is going to have a consequential impact,” Hassenkamp said.<br />

He said an estimated 50% of macadamia trees planted in<br />

South Africa were the Beaumont variety. “They are popular<br />

because they are relatively easy to cultivate, are fast growing<br />

with typically large yields, tend to produce a smaller nut and<br />

are more difficult to crack due to their lower sound kernel<br />

ratios (SKR). Around 20% of trees going into the ground<br />

(now) are the A4 variety, which usually deliver good SKR<br />

and larger nuts. Another 20% are the 816 variety and the<br />

remaining 10% a mix of 849, 814, 842 and others,” he said.<br />

What is concerning, however, is reports out of China show<br />

their domestic crop is set to grow exponentially over the<br />

next few years which means they will serve a large portion<br />

of domestic demand from their own crop. However, Whyte<br />

said he believed the Chinese market would stabilise in the<br />

future due to aggressive demand. “And as part of this process<br />

2018 has again faced some uncertainty in that region.<br />

Chinese buyers have not been as proactive as in the past<br />

in procuring product and have little interest in small NIS<br />

nuts. Increasingly this market is becoming more discerning<br />

resulting in demand shifts,” he said.<br />

26<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

27

OPPORTUNITIES<br />

FOR MACADAMIA<br />

PRODUCT<br />

EXPANSION<br />

WERE HIGHLIGHTED IN<br />

THE RESEARCH AS FOLLOWS:<br />

Both Whyte and Hassenkamp say in percentage terms the<br />

spread of global nut consumption is unlikely to change.<br />

However actual consumption is projected to remain on the<br />

rise. “From a marketing perspective, we would be wise to<br />

cultivate relationships, market access and scope in the US and<br />

Europe,” said Whyte. His advice to farmers is to plant a wellbalanced<br />

spread of cultivars based on careful benchmarking<br />

of the region in which they farm and then on farm specific<br />

analysis to ensure they’re well hedged for future demand.<br />

“It’s not just about what’s profitable now - it is about what<br />

is sustainable and expected from markets in 10 years from<br />

now. A combination of volume and value is paramount, as<br />

is a spread of varieties delivering good crackout and SKR<br />

percentages,” he said.<br />

MARKET HOTSPOTS<br />

Research out of Australia is showing how macadamia nuts<br />

are ideal to meet global snacking trends and points to the<br />

importance of developing value-add products. These products<br />

should be aimed at increasing the demand for the nuts by<br />

consumers, and especially to counter the expected slowdown<br />

in demand for nut-in-shell from China. The respondents in<br />

the research project were consumers and food “influencers”<br />

in China, Japan, South Korea, America and Australia. The<br />

results highlighted “innovation hotspots” for macadamia<br />

nuts converted into snacks.<br />

Lynne Ziehlke, market development manager for Australian<br />

Macadamias, said the research revealed a number of drivers<br />

and ways that today’s consumers snack. “Snacking can be a<br />

proactive, functional and mindful choice to manage hunger<br />

during a busy day. It can also be a mindless activity, driven<br />

by boredom or the need to feel better,” Ziehlke said. Further,<br />

regardless of the way consumers snacked, she said, they were<br />

essentially pursuing a common outcome: to regulate their<br />

mood and the rhythm of their day. “This is fertile ground<br />

for new product development. As a premium, great tasting<br />

and nutritious ingredient, macadamias are an ideal fit for<br />

this increasingly important snacking space,” Ziehlke said.<br />

The research showed that time and energy management was<br />

as relevant as ever in the demand for snacks, this Ziehlke<br />

said was driven largely by the busy and transient nature of<br />

modern life particularly in Asian and western markets.<br />

-<br />

-<br />

-<br />

Indulgence and size: As an inherently indulgent<br />

and nutrient-dense ingredient, even a small<br />

quantity of macadamias can deliver a big impact<br />

on taste, quality and premium quality.<br />

Health additions: While all nuts are known for<br />

their broad health benefits, there is an untapped<br />

opportunity in the snack category to build greater<br />

awareness around the specific health benefits<br />

of macadamias. Research aimed at providing<br />

evidence to support the role of macadamias in a<br />

healthy diet is now underway and aimed at laying<br />

the foundations for macadamias to take a more<br />

assertive place in this space in the years ahead.<br />

Taste: Macadamias’ versatile taste and unique<br />

texture give them broad appeal. As a good flavour<br />

carrier, they offer substantial opportunity for<br />

flavour innovation in snack products.<br />

For marketers and product innovators, this offers up a list<br />

of possibilities, which include the development of sweet<br />

flavoured macadamias (vanilla or caramel), macadamia white<br />

hot chocolate, powders for smoothies and energy bars for<br />

the Asian market. Products such as macadamia raw bars and<br />

balls, granola, protein bars, indulgent nut and trail mixes,<br />

and macadamia crunch popcorn were also ideal for the<br />

western market. Ziehlke said when making snack purchase<br />

decisions, consumers felt the burden of balancing a series of<br />

opposing needs. “They desire satiety, without being weighed<br />

down. They want high nutritional quality as well as great<br />

taste, and they’re looking for small portions that deliver a big<br />

payoff. Macadamias in a snack can resolve all these tensions,<br />

paving the way for a more effortless purchase decision,”<br />

she said.<br />

Top International trends<br />

in consumer demand for<br />

macadamias has resulted<br />

in a call for farmers to<br />

plant a variety of cultivars<br />

to meet the evolving<br />

marketing strategies.<br />

Left Flavoured macadamia<br />

nuts will play a big role in<br />

increasing demand for the nut<br />

in the coming years according<br />

to research findings.<br />

Why do the biggest avocado, macadamia and<br />

citrus growers and exporters, among others, use<br />

Heli-Tractor?<br />

Visit our <strong>web</strong>site<br />

or contact<br />

Eugene for<br />

more information<br />

Ask yourself ...<br />

The answer is simple: Using<br />

precision laser-guided applications,<br />

chemicals are blasted like a mist blower into highdensity<br />

crops from above (vertically downwards), providing<br />

unsurpassed crop penetration. Better chemical coverage and<br />

efficacy means increased yields for sales and export.<br />

Heli-Tractor is now the ONLY operator in Africa to use the latest<br />

South American electrostatic spraying system technology in our<br />

helicopter.<br />

Heli-Tractor<br />

guarantees better droplet deposition<br />

TRACTOR ELECTROSTATIC SPRAYING<br />

Convert your mist blower to an electrostatic sprayer with our bolt-on<br />

kits. No need to purchase a complete stand alone electrostatic mist<br />

blower and more powerful tractor, when our kit uses what you have<br />

and gives you the most powerful electrostatic charge<br />

so you get the best droplet deposition and coverage<br />

at lower costs. We have multiple kits to fit axial<br />

and cannon mist blowers, as well as high boys and<br />

boom sprayers. Visit our <strong>web</strong>site and see why the top<br />

farmers in the mac, avo and citrus industries have<br />

changed to our electrostatic spraying systems.<br />

28<br />

MACADAMIA SOUTH AFRICA<br />

Cell<br />

082 652 6705<br />

E-Mail<br />

helitractor@vodamail.co.za<br />

Website<br />

www.helitractor.co.za<br />

The only operator in<br />

Africa to use laser<br />

guidance technologies

While the macadamia harvesting season is over, farmers are being encouraged to download the app and get acquainted<br />

with it before next season and report any glitches or problems with the system so that they may be ironed out.<br />

New App<br />

Makes Harvesting A Breeze<br />

A new smartphone application<br />

has been developed to help farmers<br />

better manage and keep track of<br />

their macadamia harvesting season.<br />

Article & Images<br />

Lindi Botha<br />

The Harvest App aims to assist growers with yield data and<br />

optimise workers’ performance by efficiently measuring<br />

worker productivity, tracking the foremen on the farm,<br />

recording information and data, and displaying the necessary<br />

information on the farmer’s smartphone or desktop. In<br />

short, it replaces the old-fashioned clipboard with a real<br />

time monitoring and data collection system that farmers can<br />

manage from afar.<br />

The app was developed by a group of students at the University<br />

of Pretoria, in collaboration with the macadamia industry<br />

and is available on both Android and iOS platforms. It can<br />

also be downloaded onto your desktop for easier viewing and<br />

management. The app is simple to use and any staff member<br />

with a smartphone will be able to enter data into the app<br />

as the nuts are being harvested. This includes the amounts<br />

of nuts brought in by each worker and the total harvest<br />

for each block.<br />

THE APP IS AVAILABLE FREE OF CHARGE ON THE PLAY STORE OR AT THESE LINKS:<br />

iOS Application - https://itunes.apple.com/us/app/harvest-app/id1434929167?ls=1&mt=8<br />

Android Application - https://play.google.com/store/apps/details?id=za.org.samac.harvest<br />

Go to www.harvestapp.co.za to download the programme onto your desktop.<br />

HARVEST GIVES FARMERS ALL THE<br />

INFORMATION THEY WOULD GET<br />

FROM MONITORING EACH WORKER’S<br />

YIELD COLLECTION ON A CLIPBOARD.<br />

THESE INCLUDE:<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Graphs of worker performance throughout the day<br />

or for any given time period;<br />

Real-time location tracking of the person (typically<br />

a foreman) using the app;<br />

Historic locations of where the phone or tablet<br />

travelled and where data points were captured<br />

while using the app;<br />

Heat maps to show differences in yield within<br />

an orchard, farm or area, which can also be used<br />

to semi-quantitatively measure theft or other<br />

problems in specific areas on the farm. The heat<br />

maps also assist in viewing the hot spots of where<br />

work is being done. Farmers will be able to see the<br />

critical areas of where workers, foremen, orchards<br />

or farms are best or underperforming;<br />

Comparisons in yield between orchards. Compare<br />

and contrast the performance of workers, orchards,<br />

foremen and farms over periods of time. This is<br />

done through predictive graphs that are shown<br />

using prior performance history to give an estimate<br />

of what might be expected in the future.<br />

“It all starts in the nursery”<br />

Any plant’s success starts in the nursery, propagating high<br />

quality trees ensures a good start to a new orchard.<br />

Our nursery consists of 2 lath-houses and 1 seedbed all<br />

amounting to 2 500m². We Produce 50 000 trees per annum.<br />

Established in 2014, Brondal Kwekery have grown to a<br />

reputable supplier and grower of Macadamia trees. Situated just<br />

9km outside White River, with easy access from main routes, it<br />

allows the nursery quick collection and delivery ways. Co-owned<br />

and managed by Arve Grindstad & Ziaan Barnard, the nursery is<br />

run with a team of well trained and enthusiastic Ground Staff.<br />

Contact Us<br />

30<br />

MACADAMIA SOUTH AFRICA<br />

SPRING 2018<br />

Ziaan Barnard 083 555 4988<br />

brondalkwekery@gmail.com / www.brondalkwekery.co.za

Introducing helicopter crop spraying<br />

in South Africa was in itself a bold and<br />

dynamic move but compared with his<br />

latest innovation that was just “small<br />

change” for one of South Africa’s most<br />

respected helicopter pilots.<br />

ADVERTORIAL<br />

Eugene Kalafatis - better known as “Dog”<br />

to his friends - was the first to start<br />

flying a helicopter for commercial aerial<br />

crop spraying and sugarcane ripening<br />

in the country. That was back in the<br />

late 1990s when he and an old South<br />

African Airforce friend converted a spray<br />

rig destined to spray mosquitoes in<br />

Ghana for an Enstrom F28C helicopter.<br />

“That’s how Heli-Tractor – my business -<br />

started,” Kalafatis said. Now the Midlands<br />

macadamia farmer of Greek heritage<br />

has upped the ante with dramatic effect<br />

for South Africa’s crop farmers. “I also<br />

have crop spraying businesses in South<br />

America. I tell you the Brazilians know<br />

about technology in agriculture! That’s<br />

where I first saw the use of electrostatic<br />

spraying for pest control. I decided to<br />

introduce it in South Africa. It’s a game<br />

changer,” he said. In September 2017,<br />

Kalafatis took his Bell Jet Ranger to the<br />

air for the first time fitted with<br />

electrostatic spray gear and from the<br />

video evidence the efficacy of the system<br />

is beyond dispute.<br />

SPECTACULAR RESULTS<br />

At about the same time Kalafatis also<br />

fitted the electrostatic system (ES) onto a<br />

Jacto tractor mist blower for macadamia<br />

tree spraying. The results are spectacular.<br />

There are now 11 Jacto ES-fitted systems<br />

operating in Levubu, Tzaneen and in<br />

KwaZulu-Natal, with more in the pipeline.<br />

Previously these farmers used about<br />

2000l to 3000l of product per hectare,<br />

since the ES systems were fitted to the<br />

blowers, that has reduced to just 600l<br />

a hectare. “We have also reduced the<br />

carbon footprint of the orchard threefold.<br />

And the diesel costs for the tractors<br />

have come down by 30%,” Kalafatis said.<br />

The ES system was first used in the<br />

automotive industry for spraying cars in<br />

the 1970s. The spray paint is atomised in<br />

a static field which is formed at the end of<br />

a electrostatic spray gun. Just before the<br />

fog of paint leaves the nozzle, it is given<br />

a positive charge. The negatively charged<br />

and earthed metal of the car then<br />

attracts the positively charged liquid to<br />

its surface very much like a magnet. For<br />

crop spraying the same principle applies.<br />

And because the trees are “earthed” into<br />

the soil they become a magnet for the<br />

“positively charged” pesticide.<br />

SUPERCHARGED<br />

“SKY TRACTOR”<br />

UPS THE ANTE<br />

ON AERIAL PEST<br />

CONTROL<br />

Flying low and slow over the fields of<br />

South Africa’s crop farms, a helicopter<br />

pilot is busy changing the country’s<br />

aerial crop spraying landscape with<br />

technology and innovation geared for<br />

efficacy and precision.<br />

Eugene “Dog” Kalafatis shows the arm of<br />

nozzles on the Bell Jet Ranger spray gear<br />

all “wired” for electrostatic crop spraying.<br />

He describes this methodology of aerial<br />

pest control as a “game changer” for<br />

environmental best practice and crop<br />

cost efficacies in the country.<br />

PULLED EARTHWARDS<br />

PRECISELY ON TARGET<br />

Turning to his laptop screen, Kalafatis<br />

shows a video of his helicopter in action<br />

over an avocado orchard in the Limpopo<br />

province. The first clip is of conventional<br />

spraying and the product is mixed as<br />

the chemical manufacturers prescribe.<br />

The bird flies low over the rows of trees,<br />

releases its load of pesticide and despite<br />

the evidence of very little breeze, most<br />

of the white fog drifts away from the<br />

orchard and into a neighbouring timber<br />

plantation. The second clip is the same<br />

orchard, the same conditions and on the<br />

same day. But this time the helicopter is<br />

fitted with the electrostatic gear. Again,<br />

the Bell Jet Ranger comes in low and slow,<br />

as it reaches the tree line the chemical is<br />

released from the polymer spray nozzles.<br />

The white fog is visibly pulled earthwards,<br />

within the blink of an eye it disappears<br />

into the orchard canopy precisely on<br />

target and without any drift.<br />

Kalafatis is visibly pleased. “Did you see<br />

that? Same conditions, same helicopter,<br />

same orchards, completely different<br />

effect!” He said the efficacy of the system<br />

was being measured using computerised<br />

data downloaded from the helicopter’s<br />

on-board systems. “We also include a<br />

fluorescent dye in the products we spray.<br />

Then we use an ultra-violet light at night<br />

to measure the droplet distribution on<br />

the trees. The electrostatic method has<br />

seen an increase of droplet deposition<br />

on the leaves and fruit from 30 to 40<br />

250-micron droplets per cm³ to 80 to100<br />

100-micron droplets per cm³.<br />

Previously you were lucky if product<br />

coverage on the trees was at 75%<br />

maximum, now it’s more like 95%. We<br />

have also reduced the need for farmers<br />

to overspray. Over spraying can result in<br />

the toxification of the soil as the pesticide<br />

drips off the leaves on to the ground. We<br />

have also reduced the chemical load per<br />

hectare by up to 30%,” he said. Once<br />

applied the efficacy of the pesticides<br />

was also now extended because of the<br />

precision of the droplet distribution and<br />

the more effective cover of the product<br />

on the trees. “Previously we were lucky<br />

if the product gave four weeks cover, we<br />

are still measuring this, but initial results<br />

are showing it is working past six weeks,”<br />

he said.<br />

WORLD FIRSTS<br />

Now waiting for the delivery of a spanking<br />

new Bell Huey UH1H, Kalafatis is visibly<br />

proud of his company’s achievements.<br />

“The Heli-tractor spray system we still use<br />

to this day was a first on the continent.<br />

The Bell Huey Uh-1H spray system and<br />

fire attack all-in-one system was a world<br />

first. We were the first to use the New<br />

Zealand designed Trac-Mac GPS systems<br />

on our helicopters. We were also the<br />

first to use an aerial fertilising bucket<br />

for sugarcane, maize and in the forestry<br />

sector. We were also the first in the<br />

world to use a laser guided system in a<br />

helicopter,” he said.<br />

Pulling at the collar of his crisp cotton<br />

shirt, Kalafatis who says all his life he has<br />

preferred a toolbox to a pencil box, is<br />

emphatic about his business ethics.<br />

Contact Heli-Tractor on 082 652 6705 or Email helitractor@vodamail.co.za<br />

Website: www.helitractor.co.za<br />

“WE PRIDE OURSELVES IN DOING EVERYTHING WE DO WITH PRECISION<br />

AND TO THE VERY BEST AND HIGHEST STANDARDS.” - KALAFATIS

Beware<br />

The Felted Coccid<br />

A new pest has made its way from<br />

Australia to macadamia orchards<br />

in Mpumalanga, causing tree dieback<br />

and reduced yields.<br />

Article & Images<br />

Lindi Botha<br />

Known as the Macadamia Felted Coccid, the pest has had a major detrimental<br />

effect on orchards in Australia where it originated, and on macadamia plantations<br />

in Hawaii. Dense infestations cause leaf die-back and flower drop, with subsequent<br />

reductions in nut set. In extreme cases trees will die-off completely.<br />

Now for the first time the coccid has been found and identified on several farms in<br />

the Lowveld here in South Africa. Although it was initially thought the infestation<br />

was contained in Barberton where the pest was first found, it spread within a<br />

month to White River, presumably through infested plant material.<br />

Dr Schalk Schoeman (above), a senior researcher at the Agricultural Research<br />

Council, said little was known as to how the coccid reached South Africa and<br />

how it was being spread. “My suspicion is it was somehow brought over in plant<br />

material from Australia. I would advise anyone that has recently bought trees from<br />

the Barberton area to carefully inspect the tree for the coccid,” Schoeman said.<br />

The coccids can be identified by their elongated shape. They are covered with a<br />

felted like sac and are whitish in colour and form thick encrustations in leaves,<br />

twigs and even the main stem. The adult female is about 1.5 mm long, dirty white<br />

or pale yellow in colour, with a raised circular opening at the posterior end. The<br />

scale cover of the male is white and is smaller, about 1 mm long. In some instances<br />

infested trees can be detected by a dull bronze colour in the foliage. “According<br />

to the research once the coccids are in the orchard, spread is relatively slow and<br />

they tend to stay in the same tree. But observations in White River contradict this<br />

as there was considerable spread to adjoining trees. These trees were young and<br />

although the planting density was high, the trees were not touching which leads<br />

me to believe that they are probably dispersed by wind,” said Schoeman. He said<br />

the main focus now should be on awareness so that everyone became informed<br />

about the presence of the pest in the country. “Following on from that, we should<br />

focus on containment. I have noticed branch die back in White River and from<br />

photos in Hawaii this can get quite bad and it will affect nearly the entire tree, with<br />

obvious detrimental effects on yields. On bearing trees, nut yields are reduced and<br />

a delay is caused in the fall of mature nuts,” Schoeman said.<br />

Currently there are no registered<br />

chemicals to combat the coccid. A<br />

sprayable oil mixed with Movento as<br />

well as an insect growth regulator such<br />

as Buprofezin can be used. The method<br />

of treating the coccid is somewhat<br />

different from that of stinkbugs. The<br />

oil and Movento is directed at adults<br />

and the Buprofezin is directed as a<br />

second spray against the crawlers.<br />

Schoeman said stink bug spraying<br />

should offer some form of protection<br />

but would not give adequate control<br />

and could increase the development of<br />