SNN December 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

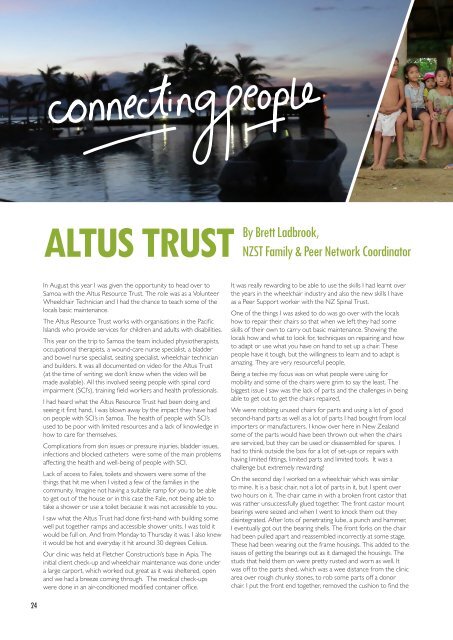

ALTUS TRUST<br />

By Brett Ladbrook,<br />

NZST Family & Peer Network Coordinator<br />

In August this year I was given the opportunity to head over to<br />

Samoa with the Altus Resource Trust. The role was as a Volunteer<br />

Wheelchair Technician and I had the chance to teach some of the<br />

locals basic maintenance.<br />

The Altus Resource Trust works with organisations in the Pacific<br />

Islands who provide services for children and adults with disabilities.<br />

This year on the trip to Samoa the team included physiotherapists,<br />

occupational therapists, a wound-care nurse specialist, a bladder<br />

and bowel nurse specialist, seating specialist, wheelchair technician<br />

and builders. It was all documented on video for the Altus Trust<br />

(at the time of writing; we don’t know when the video will be<br />

made available). All this involved seeing people with spinal cord<br />

impairment (SCI’s), training field workers and health professionals.<br />

I had heard what the Altus Resource Trust had been doing and<br />

seeing it first hand, I was blown away by the impact they have had<br />

on people with SCI’s in Samoa. The health of people with SCI’s<br />

used to be poor with limited resources and a lack of knowledge in<br />

how to care for themselves.<br />

Complications from skin issues or pressure injuries, bladder issues,<br />

infections and blocked catheters were some of the main problems<br />

affecting the health and well-being of people with SCI.<br />

Lack of access to Fales, toilets and showers were some of the<br />

things that hit me when I visited a few of the families in the<br />

community. Imagine not having a suitable ramp for you to be able<br />

to get out of the house or in this case the Fale, not being able to<br />

take a shower or use a toilet because it was not accessible to you.<br />

I saw what the Altus Trust had done first-hand with building some<br />

well put together ramps and accessible shower units. I was told it<br />

would be full on. And from Monday to Thursday it was. I also knew<br />

it would be hot and everyday it hit around 30 degrees Celsius.<br />

Our clinic was held at Fletcher Construction’s base in Apia. The<br />

initial client check-up and wheelchair maintenance was done under<br />

a large carport, which worked out great as it was sheltered, open<br />

and we had a breeze coming through. The medical check-ups<br />

were done in an air-conditioned modified container office.<br />

It was really rewarding to be able to use the skills I had learnt over<br />

the years in the wheelchair industry and also the new skills I have<br />

as a Peer Support worker with the NZ Spinal Trust.<br />

One of the things I was asked to do was go over with the locals<br />

how to repair their chairs so that when we left they had some<br />

skills of their own to carry out basic maintenance. Showing the<br />

locals how and what to look for, techniques on repairing and how<br />

to adapt or use what you have on hand to set up a chair. These<br />

people have it tough, but the willingness to learn and to adapt is<br />

amazing. They are very resourceful people.<br />

Being a techie my focus was on what people were using for<br />

mobility and some of the chairs were grim to say the least. The<br />

biggest issue I saw was the lack of parts and the challenges in being<br />

able to get out to get the chairs repaired.<br />

We were robbing unused chairs for parts and using a lot of good<br />

second-hand parts as well as a lot of parts I had bought from local<br />

importers or manufacturers. I know over here in New Zealand<br />

some of the parts would have been thrown out when the chairs<br />

are serviced, but they can be used or disassembled for spares. I<br />

had to think outside the box for a lot of set-ups or repairs with<br />

having limited fittings, limited parts and limited tools. It was a<br />

challenge but extremely rewarding!<br />

On the second day I worked on a wheelchair which was similar<br />

to mine. It is a basic chair, not a lot of parts in it, but I spent over<br />

two hours on it. The chair came in with a broken front castor that<br />

was rather unsuccessfully glued together. The front castor mount<br />

bearings were seized and when I went to knock them out they<br />

disintegrated. After lots of penetrating lube, a punch and hammer,<br />

I eventually got out the bearing shells. The front forks on the chair<br />

had been pulled apart and reassembled incorrectly at some stage.<br />

These had been wearing out the frame housings. This added to the<br />

issues of getting the bearings out as it damaged the housings. The<br />

studs that held them on were pretty rusted and worn as well. It<br />

was off to the parts shed, which was a wee distance from the clinic<br />

area over rough chunky stones, to rob some parts off a donor<br />

chair. I put the front end together, removed the cushion to find the<br />

24