Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

35 th<br />

SUNDAY SEPT 16th <strong>2018</strong> $5<br />

Austin Healey 100-6<br />

presented by the Toronto Triumph Club www.BritishCarDay.com<br />

<strong>2018</strong> Souvenir Programme<br />

Special<br />

Anniversary Cars<br />

Triumph TR 6<br />

50 Years<br />

60 years<br />

Sponsored by:<br />

Platinum<br />

Morgan Plus 8<br />

50 Years<br />

Gold<br />

Presented by:<br />

Silver<br />

Published By & Including:<br />

Bronze<br />

www.TorontoTriumph.com<br />

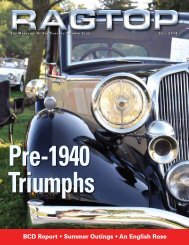

The Magazine Of The Toronto Triumph Club

EXOTIC<br />

MOTORWORKS<br />

65 George Street,<br />

Newmarket, ON, L3Y 4V4.<br />

Tel: 905-806-7127<br />

E-mail:<br />

info@exoticmotorworks.ca<br />

contents<br />

<strong>BCD</strong>8<br />

<strong>BCD</strong>14<br />

<strong>BCD</strong>17<br />

British & European Restoration & Service Specialists<br />

Head Mechanic, Alex<br />

Plestid, formerly of the<br />

hit TV series Restoration<br />

Garage, has over 20<br />

years of experience with<br />

all makes and models<br />

of Classic cars and has<br />

personally restored more<br />

than 150 cars to their<br />

former glory<br />

Our wealth of mechanical and restoration experience includes<br />

Triumph, Jaguar, MG, Austin Healey and Rolls Royce and many<br />

others. When you entrust your special vehicle to Exotic Motorworks,<br />

you can rest assured that we will treat your car like our very own!<br />

Our passion for working on these vehicles and making them better<br />

than new, comes from our love of owning and driving them ourselves.<br />

We would be pleased to answer any questions you might have.<br />

Give us a call for directions to the British Barn or to make an<br />

appointment for a quotation. It will be our pleasure to meet other<br />

vintage car enthusiasts and we look forward to helping you enjoy<br />

your passion for years to come!<br />

www.exoticmotorworks.ca<br />

<strong>BCD</strong>37<br />

<strong>BCD</strong>39<br />

<strong>BCD</strong>20<br />

<strong>BCD</strong>26<br />

<strong>BCD</strong>25<br />

<strong>BCD</strong> Field Map...............<strong>BCD</strong>4/5<br />

Welcome to British Car Day .... <strong>BCD</strong>7<br />

Anniversary Models<br />

The TR6 and TR8 .............. <strong>BCD</strong>8<br />

Aston Martin DB4, 60 Years ... <strong>BCD</strong>14<br />

Austin A40 Farina, 60 Years.... <strong>BCD</strong>17<br />

Morgan Plus-8, 50 Years ...... <strong>BCD</strong>20<br />

Land Rover Series 1, 70 Years.. <strong>BCD</strong>25<br />

Austin America, 50 Years ...... <strong>BCD</strong>26<br />

Austin Healey Sprite 60 Years.... <strong>BCD</strong>29<br />

Jaguar XK 120, 70 Years......... <strong>BCD</strong>33<br />

Jaguar XJ, 50 Years ............ <strong>BCD</strong>37<br />

Ausin Healey 100-6, 60 Years .... <strong>BCD</strong>39<br />

Special Articles<br />

Motor Oils................... <strong>BCD</strong>40<br />

Lighting Upgrades............ <strong>BCD</strong>45<br />

<strong>BCD</strong>29<br />

<strong>BCD</strong>33<br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 3

Sponsor Street<br />

Exotic Motorworks<br />

Crescent Oil<br />

visit Oakville<br />

Autoglym<br />

Lant Insurance<br />

Edward Jones<br />

Hagerty<br />

Toronto Triumph Club<br />

Anniversary Cars<br />

Registration<br />

Awards Presentation Area<br />

Vendor Village<br />

3 Brothers Classic Rover<br />

ALS Canuck<br />

Armchair Motorist<br />

B&G Restoration Inc.<br />

British Auto Sport<br />

Best Quality Oils<br />

British Model Cars<br />

C.S. Trading<br />

CAA Insurance<br />

Chris Hyland<br />

Classic Automotive Repair<br />

Comat Motorsports-Miller oils<br />

Connect Hearing<br />

D-Day wear Attitude Ideas<br />

Digital Moments<br />

European Automotive<br />

Falun dafa Association<br />

Gemstones “N” Silver<br />

Heritage Associates<br />

Hollywood Loser Apparel<br />

Ideal Brake Parts<br />

International Die Cast<br />

J D Auto<br />

KDC Ventures<br />

Leatherique Canada<br />

Lotus (Peninsula Imports)<br />

McArthur Minatures<br />

MacGregor British Cars<br />

Maurice Bramhall<br />

Meguiars<br />

Mini Collectables<br />

Peninsula Import Auto Parts Ltd<br />

Robert J.Morris insurance<br />

Royal Rose Cars<br />

Rudy’s Auto Inc (Mr. Grean)<br />

Soccer Elite and Sports<br />

Transport Books DRB Motors Inc.<br />

UK 2 Canada Pension Transfer<br />

Ultimate Transportation Books<br />

Vintage Auto Insurance<br />

Vintage Car Connection<br />

Vintage Sports Cars<br />

Food Areas<br />

CRESCENT OIL<br />

EXIT<br />

SHOW CARS<br />

NorthWest Beaver Tails<br />

Lisa’s Cookhouse<br />

North East Friends of Bronte Creek Kettle Corn<br />

West British Baked Goods<br />

South Olympic Softee Inc.<br />

South West and East<br />

Lions Club of Oakville<br />

VENDOR<br />

& TRAILER<br />

PARKING<br />

WC<br />

WC<br />

WC<br />

VENDOR<br />

VILLAGE<br />

FLEA<br />

MARKET<br />

NORTHWEST<br />

FOOD AREA<br />

FLEA<br />

MARKET<br />

Platinum Partner<br />

Silver Partner<br />

3.5” x 2.5” | Maximum Font Size: 30 pt<br />

Need directions to your<br />

financial destination?<br />

Marc Nutford<br />

Gold Partners<br />

Financial Advisor<br />

.<br />

2387 Trafalgar Road<br />

Unit E2<br />

Oakville, ON L6H 6K7<br />

905-844-4043<br />

www.edwardjones.com<br />

Member – Canadian Investor Protection Fund<br />

WALKWAY<br />

WALKWAY<br />

Bronze Partners<br />

WEST<br />

FOOD<br />

AREA<br />

B<br />

WALKWAY<br />

A<br />

A<br />

A<br />

B<br />

WALKWAY<br />

SOUTH CHECK POINT<br />

TREES<br />

F<br />

F<br />

C<br />

C<br />

OO<br />

OO<br />

WC<br />

WC<br />

WC<br />

PUBLIC ENTRANCE<br />

ROW 1<br />

ROW 1<br />

ROW 21 ROW 21<br />

G<br />

G<br />

IB<br />

IB<br />

WALKWAY<br />

D<br />

D<br />

H<br />

H<br />

IA<br />

IA<br />

M<br />

M<br />

PP<br />

PP<br />

QQ<br />

QQ<br />

ROW 2<br />

PUBLIC PARKING LOT<br />

H<br />

H<br />

I<br />

I<br />

WALKWAY<br />

M<br />

M<br />

ROAD<br />

RR<br />

RR<br />

SOUTHWEST<br />

FOOD AREA<br />

ROAD<br />

ROW 22 ROW 22<br />

H<br />

H<br />

I<br />

I<br />

M<br />

M<br />

ROW 3<br />

SS<br />

SS<br />

E<br />

E<br />

I<br />

I<br />

N<br />

PUBLIC ENTRANCE<br />

PUBLIC ENTRANCE<br />

MAPNORTHEAST<br />

E<br />

E<br />

I<br />

I<br />

MG CLUB<br />

TENT<br />

DJ<br />

BOOTH<br />

MOTORCYCLES<br />

UU<br />

ROW 33<br />

ROW 34<br />

ROW 35<br />

ROW 36<br />

WC<br />

WC<br />

N N N<br />

TT<br />

TT<br />

NN<br />

NN<br />

MM<br />

XX<br />

LL<br />

LL<br />

NN<br />

N<br />

XX<br />

ROW 4<br />

WW<br />

WW<br />

J<br />

J<br />

K<br />

K<br />

N<br />

WW<br />

ROW 32<br />

WC<br />

WC<br />

J<br />

J<br />

K<br />

K<br />

FF<br />

FF<br />

L<br />

L<br />

WW<br />

ROW 5<br />

ROW 5<br />

ROW 31<br />

WW<br />

LL<br />

LL<br />

R<br />

R<br />

O<br />

O<br />

P<br />

P<br />

SPONSOR STREET<br />

TTC<br />

TENT<br />

R<br />

R<br />

Q<br />

Q<br />

WW<br />

XX<br />

WW<br />

XX<br />

NN<br />

NN<br />

WW<br />

NN<br />

TTC TENT<br />

LOST & FOUND<br />

?<br />

TREES<br />

REGISTRATION<br />

COFFEE<br />

AWARDS<br />

PRESENTATION<br />

S S S<br />

S S S<br />

V W Z<br />

V<br />

Q<br />

Q<br />

WASHROOMS<br />

W<br />

ROW 7<br />

WC<br />

U<br />

U<br />

T<br />

T<br />

Z<br />

FOOD AREA<br />

ROW 8<br />

X<br />

X<br />

Z<br />

Z Z Z<br />

AA<br />

AA<br />

ROAD<br />

VV<br />

BUSES/COMMERCIAL VEHICLES<br />

ROW 9 ROW 9 ROW 9<br />

SHOW CAR<br />

ENTRANCE/EXIT<br />

FAST LANE FAST LANE FAST LANE FAST LANE<br />

CC<br />

CC<br />

BB<br />

BB<br />

Y<br />

Y<br />

TREES<br />

VIP & PRESS<br />

PARKING<br />

DDB<br />

DDB<br />

DDA<br />

DDA<br />

DD<br />

DD<br />

OVER FLOW AREA<br />

ROW 10 ROW 10<br />

ROW 10<br />

PICNIC<br />

Area<br />

PATHWAY<br />

DDB<br />

DDB<br />

GG<br />

GG<br />

EEA<br />

EEA<br />

EE<br />

EE<br />

HH<br />

HH<br />

II<br />

II<br />

ROW 11 ROW 11<br />

EAST<br />

FOOD AREA<br />

Some of the Badges you will see at the show.<br />

JJ<br />

JJ<br />

KK<br />

KK<br />

YY<br />

YY<br />

TREES<br />

TREES<br />

PATHWAY<br />

N<br />

WASHROOMS<br />

Show Vehicle Locations<br />

Make Model/Years Class<br />

AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CC<br />

Ace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CC<br />

Aston Martin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . BB<br />

Austin. ...... Sedans, pre-1960 . . . . . . . . . . . .WW<br />

Austin. ....... Sedans, 1960 on ............ XX<br />

Austin Healey Roadster - 100, 3000 Mk. 1 ....... D<br />

Austin Healey Wind-up window - 3000 etc.. ......C<br />

Austin Healey ..... Sprite. .................. F<br />

Austin Princess ... Coaches. ................ JJ<br />

Bentley .......... Coaches. ................ JJ<br />

Buses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VV<br />

Caterham . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . EE<br />

Cobra . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CC<br />

Commercial Vehicles. . . . . . . . . . . . . . . . . . . . . . . VV<br />

Daimler .......... SP250. ................ HH<br />

Daimler ......... Coaches. ................ JJ<br />

DeLorean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YY<br />

Ford ........ Sedans, pre-1960 . . . . . . . . . . . .WW<br />

Ford ......... Sedans, 1960 on ............ XX<br />

Jaguar . Large Saloons 1995 Onwards ........ LL<br />

Jaguar Large Saloons pre-1968 & 1968 to1995 . MM<br />

Jaguar ....... XK8, XK, F-Type. ............ NN<br />

Jaguar ............ XJS. ................. OO<br />

Jaguar Sports Pre-61 & Sports Saloons Pre-68. ..PP<br />

Jaguar . Sports Saloons 1999 onwards. ...... QQ<br />

Jaguar ... E-Type Series I, 1961-1968 ........ RR<br />

Jaguar ...E-Type Series II, 1968-1971 ........ SS<br />

Jaguar .. E-Type Series III, 1971-1975 .........TT<br />

Jensen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Y<br />

Lanchester ....... Coaches. ................ JJ<br />

Land/Range Rover. 1975 on ................. A<br />

Land/Range Rover Up to 1974 .................B<br />

London Taxis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VV<br />

Lotus ............ Seven. .................EE<br />

Lotus ... Elan, Elan Plus 2, up to 1974 ....... DD<br />

Lotus ...... Elan, 1975 and later .......... DDA<br />

Lotus ........ Elite up to 1974 ............. DD<br />

Lotus ...... Elite, 1975 and later .......... DDA<br />

Lotus ............Europa ................ DD<br />

Lotus ............Cortina ................ DD<br />

Lotus ............ Esprit ................ DDA<br />

Lotus .............Eclat ................ DDA<br />

Lotus ............. Elise ................ DDB<br />

Lotus ............ Exige ................ DDB<br />

Lotus ............ Evora ................ DDB<br />

Lotus ........... Replicas ............... EEA<br />

Marcos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HH<br />

Mayflower ....... Coaches. ................ JJ<br />

McLaren . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CC<br />

MG .............. Midget ................. G<br />

MG ............. T Series .................. J<br />

MGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K<br />

MGB-GT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I<br />

MGC .......... GT/Roadster . . . . . . . . . . . . . . . IA<br />

MGF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IB<br />

MGB ....... Roadster 1962 - 1974. ........... H<br />

MGB ....... Roadster 1975 - 1981. ............E<br />

MG ............. Saloons ................. FF<br />

MG V8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IB<br />

Mini ....Sliding Window (1959 - 1970) ......... L<br />

Mini ...Wind-up Window (1970 - 2000) ....... N<br />

Mini Rover .... (1988 to 2000) .............. N<br />

Mini .......BMW (2001 0nwards) ........... M<br />

Morgan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II<br />

Morris. ...... Sedans, pre-1960 . . . . . . . . . . . .WW<br />

Morris. ....... Sedans, 1960 on ............ XX<br />

Motorcycles ......All British ............... UU<br />

Other Coaches. . . . . . . . . . . . . . . . . . . . . . . . . . . . JJ<br />

Other Sports Cars . . . . . . . . . . . . . . . . . . . . . . . . . CC<br />

Production Sedans Sedans, pre-1960. ........ WW<br />

Production Sedans Sedans, 1960 on .......... XX<br />

Range Rover ..... 1975 on ................. A<br />

Range Rover .... Up to 1974 .................B<br />

Reliant ......... Sports Cars .............. HH<br />

Rolls Royce ..... All models. .............. KK<br />

Rootes Sedans . All Models, pre-1960. ....... WW<br />

Rootes Sedans . All Models, 1960 on ......... XX<br />

Rover ....... Sedans, pre-1960 . . . . . . . . . . . .WW<br />

Rover ........ Sedans, 1960 on ............ XX<br />

Sunbeam ......... Alpine. ................ GG<br />

Sunbeam ..........Tiger ................. GG<br />

Sunbeam ......... Talbot. ................ GG<br />

Triumph ........... GT6. ...................V<br />

Triumph .....Spitfire 1961 - 1973 ............ W<br />

Triumph ....Spitfire 1974 onwards ............Z<br />

Triumph ........... Stag .................. X<br />

Triumph .... TR2, TR3, TR3A, TR3B ........... O<br />

Triumph ....TR4, TR4A, TR5, TR250 . . . . . . . . . . . . Q<br />

Triumph ...... TR6, 1969 - 1973 ..............R<br />

Triumph ...... TR6, 1974 - 1976. ..............S<br />

Triumph ........... TR7. ...................T<br />

Triumph ........... TR8. .................. U<br />

Triumph Other - Roadster, Herald, 2000, Vitesse. ..P<br />

Buses/Trucks/Taxis . . . . . . . . . . . . . . . . . . . . . . . . VV<br />

TVR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .AA<br />

MM<br />

TREES

Welcome to the 35th annual British Car<br />

Day® and the Souvenir Programme issue<br />

of the Toronto Triumph Club’s awardwinning<br />

magazine, Ragtop.<br />

This year we are celebrating eight<br />

anniversary cars on the show field,<br />

ranging from the 1948 introduction of the<br />

Series I Land Rover through to the 1978<br />

introduction of the Triumph TR8 roadster.<br />

As well as highlighting these featured<br />

British car models, we have also reviewed<br />

a number of other British marques and<br />

models with a significant anniversary this<br />

year, examples of which (most but not<br />

all) can be found on the show field today.<br />

This year also marks the 80th anniversary<br />

of the establishment of Sunbeam-Talbot<br />

(1938) under the Rootes Group brand,<br />

although the company had traded<br />

independently from 1902 under the name<br />

of Clément-Talbot Limited; and the 70th<br />

Welcome to British Car Day<br />

Important Information, Times & Events<br />

7:00 am Gates open for Sponsors and Vendors.<br />

8:00 am Gates open for Show Cars and Flea Market vehicles.<br />

9:00 am Vendor Area / Flea Market opens, Park Gates open for spectators.<br />

10:00 am Things to do:<br />

• Please take the time to visit Sponsor Street and see what our terrific sponsors have on<br />

display. Sponsors for this year include Exotic Motorworks, Crescent Oil, visit Oakville,<br />

Hagerty, Lant, Autoglym and Edward Jones.<br />

• Check out our anniversary cars: Land Rover S1 (70 years), Austin A40 Farina, Austin<br />

Healeys 100-6 & Sprite (60 years), Triumph TR6, Morgan Plus 8 and Jaguar XJ6 /<br />

Sovereign (all 50 years).<br />

• Drop by The Friends of Bronte Creek for a coffee.<br />

• Elsewhere on the field Oakville Lions will be selling burgers, hot dogs & pop to help<br />

fund their many charitable endeavours.<br />

• Other food vendors are spread around the field too so you won’t go hungry!<br />

• Visit the Toronto Triumph Club tent to buy a T-shirt, <strong>BCD</strong> Programme or poster.<br />

Annual memberships are $40 p.a.<br />

• Don’t forget to visit Vendor Village where you can shop for your LBC and much more.<br />

• Check out all those wonderful cars and chat with the owners.<br />

• Enjoy the sounds of Brit music brought to you by Jan’s DJ.<br />

1:00 pm Voting closes for Participants’ Choice awards.<br />

• Please submit your completed ballot no later than 1 p.m.<br />

2:00 pm Awards and Charity Presentations<br />

• Charlie Conquergood Award presented by Sandy McCrea.<br />

• Awards presentation for Participants’ Choice judging. You must be present to collect<br />

an award.<br />

• Best of Show Judges’ Award presentation.<br />

3:00 pm Closing comments.<br />

SEE YOU AGAIN NEXT YEAR<br />

Sunday, September 15th, 2019<br />

anniversary of Land Rover and Bond Cars<br />

(1948), with Land Rover being the only<br />

surviving manufacturer today.<br />

British Car Day usually presents a truly<br />

A to Z of former and current British car<br />

models and marques, some from the glory<br />

days prior to the Second World War while<br />

most of the classics you will see today<br />

were manufactured during the 1950s, 60s<br />

and 70s which spanned the recovery years<br />

after the War through to the near demise<br />

of the British car industry during the<br />

1980s, while the more recent models, from<br />

Jaguar, Land Rover, Lotus, Morgan, MINI,<br />

Rolls Royce, Bentley and McLaren, are fine<br />

representatives of the modern revival of<br />

the British motor industry.<br />

Bringing British Car Day to Bronte each<br />

year takes many hundreds of volunteer<br />

hours from the members and immediate<br />

family of the Toronto Triumph Club, as well<br />

as others from some of the participating<br />

British car clubs and from outside friends and<br />

supporters, as well as by the staff of Parks<br />

Ontario. We also gratefully acknowledge the<br />

financial support of our sponsors and the<br />

participation of our vendors.<br />

The Toronto Triumph Club Executive<br />

and the Organising Committee hope you<br />

enjoy this year’s British Car Day. If you<br />

aren’t presently an owner of a classic or<br />

current British vehicle, we hope that the<br />

cars, trucks and motorcycles you see on<br />

display today will inspire you to become<br />

involved in this great hobby.<br />

Have a great day and thank you for<br />

participating at Bronte!<br />

Terence McKillen<br />

Editor Ragtop Magazine<br />

Editor@TorontoTriumph.com<br />

Dave Sims<br />

<strong>BCD</strong> Chairman<br />

President@TorontoTriumph.com<br />

British Car Day Committee<br />

Chairman/Park Liason: Dave Sims<br />

Volunteer Co-ordinator:<br />

Sponsorships:<br />

Advertising Sales:<br />

Vendors:<br />

Event Promotion:<br />

Financials:<br />

Field Layout:<br />

Computer Services:<br />

Programme Editor:<br />

British Car Day Programme<br />

Editor:<br />

Assistant Editor:<br />

Sub Editor:<br />

Art Director:<br />

Advertising Sales:<br />

Ron Etty<br />

Frank Manning<br />

Dave Sims<br />

Frank Manning<br />

Warren Beech<br />

Al Benvenuti<br />

Clive Huizinga<br />

Johan Aaltink<br />

Keith Stewart<br />

Terence McKillen<br />

Terence McKillen<br />

Sean Doherty<br />

Alison Postma<br />

Michael Cleland<br />

Frank Manning<br />

“British Car Day ® ” is the registered trademark of the Toronto Triumph<br />

Club Inc. This programme and its contents may not be reproduced or<br />

distributed by any means without permission of the TTC. Most articles<br />

and photography contained herein have been supplied by various<br />

car clubs and are credited as such, where appropriate. This material<br />

remains their property and reproduction is expressly forbidden, except<br />

by permission from them and the TTC.<br />

Printed by Printwell Offset, Brampton, Ontario.<br />

Copyright © 2017 by the TTC.<br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 7

Triumph<br />

TR6 & TR8<br />

We take a look at the best-selling and last of the traditional Triumph Roadsters celebrating 50 years<br />

and its later iteration, the final Triumph convertible –celebrating 40 years in <strong>2018</strong><br />

by Terence McKillen • Photographs by Dave Sims & Terence McKillen<br />

Introduced a decade apart, the TR6<br />

was the last of the line of body-on-frame<br />

Triumph Roadsters, a series of models<br />

that began with the TR2 back in 1953 and<br />

reached its final evolution with the 150<br />

bhp fuel injected, in-line, six cylinder TR6<br />

(UK and rest of world markets only). The<br />

TR8, like its smaller engined sibling, the<br />

TR7, were of unibody construction and,<br />

like the TR6, were designed specifically for<br />

the North American market. If Triumph’s<br />

standard model naming protocol had<br />

been followed, the TR8 should have been<br />

named the TR7A or TR7B but with the<br />

availability of the Rover (ex-Buick) small<br />

block V8 engine (3.5 L), the designation<br />

TR8 was too good to pass up. Both cars<br />

were acknowledged, in their day, with<br />

acclamation. The TR6 was dubbed the ‘last<br />

of the hairy-chested British sports cars’<br />

and has been a firm favourite for 50 years<br />

while in 1980, Car & Driver commented<br />

that the TR8 represented, “nothing less<br />

than the reinvention of the sports car.”<br />

The TR6<br />

The Triumph TR6 ranks as one of the<br />

most popular British sports cars ever<br />

made. Introduced in 1968, it was<br />

basically a re-skinned TR5, complete<br />

with fuel-injected (not North American<br />

markets), six-cylinder engine mounted<br />

to an IRS chassis. Long-time Triumph<br />

designer, Giovanni Michelotti, was<br />

unavailable at the time so German firm<br />

Wilhelm Karmann GmbH was retained,<br />

producing a sharp redesign but cleverly<br />

utilising the same body tub. Many saw<br />

the ‘Six’ as the last of a breed of macho<br />

British sports cars, and as such was a<br />

fitting replacement for the likes of the<br />

Austin Healey 3000, which had ceased<br />

production in 1968, just before the<br />

TR6’s release.<br />

In period, more TR6s were<br />

produced than any TR model<br />

before it. The last fuel-injected TR6<br />

was made in February 1975, while<br />

production of the ‘Federal’ car continued<br />

on in carburetted format and with everincreasing<br />

emissions strangulation until<br />

July 1976, although in fairness Triumph<br />

managed to hold on to an output of 104-<br />

106 bhp throughout. When it was finally<br />

replaced by the TR7, 94,619 examples<br />

of the Six had rolled off the Canley<br />

production line. A contemporary road test<br />

noted “the protesting creaks and groans<br />

from a chassis which still does not feel<br />

completely rigid on really rough roads.”<br />

Although the Karman designed<br />

body was different from the preceding<br />

TR5 and 4 models, it cleverly was not<br />

as different as first appearances might<br />

suggest. The TR6 essentially received new<br />

front and rear sections while the centre<br />

section remained as the old TR4/5/250.<br />

The German studio redesigned the TR6<br />

to utilise many of the existing body<br />

pressings. The external boot and bonnet<br />

shapes were changed significantly<br />

resulting in more luggage space, however,<br />

the existing scuttle, doors and inner<br />

panels were retained.<br />

The front and back had a more<br />

squared-off look with a matte-black rear<br />

valance<br />

and with<br />

the headlights<br />

moved out to the wing edges,<br />

resulting in a more aggressive appearance<br />

and finally shedding the rounded design<br />

of the earlier TRs. Triumph retained the<br />

2.5 litre in-line six-cylinder engine and<br />

added a front anti-roll bar and wider (5½<br />

J) wheels, the latter giving the car a lower,<br />

leaner look. The contemporary advertising<br />

by Triumph claimed that the “TR6 beats<br />

any previous TR for road holding, and<br />

that’s really saying something.”<br />

In the cockpit, the facia<br />

and trim followed that of the<br />

TR250 except the ammeter<br />

became a voltmeter and the<br />

instruments changed from<br />

the needle hanging down<br />

to being upright and bezels<br />

went back to being chromed.<br />

The ignition key migrated<br />

from a central position on<br />

the facia to the lower side<br />

of the steering column as<br />

a steering lock was added.<br />

Seating<br />

was improved<br />

with contoured and<br />

adjustable bucket seats<br />

with headrests provided<br />

in the Federal specification<br />

models. For some reason, the fuel tank<br />

got smaller, with only a 43 litre capacity<br />

compared to the 53 litres of the TR4A.<br />

The UK CP series (with PI), produced<br />

from 1969 to 1972, had a nominal 150 bhp<br />

output at 5500 rpm. The corresponding<br />

North American models, the CC series<br />

(twin carb) had a nominal output of 106<br />

bhp at 4900 rpm. The 1973 to 1976 UK<br />

<strong>BCD</strong> 8 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme<br />

Ragtop I Summer I 2013 www.TorontoTriumph.com 9

TRF Wishes You a Great Day<br />

We are hoping you have great weather and a good turnout for British Car Day.<br />

As Jack McGahey has said, “We come together for the cars, but we stay for the<br />

people.” This is something that does not change for us at The Roadster Factory<br />

with regard to national politics. Our relationship with Toronto Triumph Club goes<br />

back a long way, and we hope it will last forever.<br />

Parts Catalogues<br />

Most of The Roadster Factory’s parts<br />

catalogues are found on our web site, but<br />

we are in process of publishing a new “TRF<br />

Shopping Guide.” It is also found on the<br />

web site, but we will send paper copies to<br />

the club when it comes out in September.<br />

Email Newsletters<br />

Our Philosophy<br />

TRF arranges to manufacture as<br />

many parts as possible, actually a<br />

large number for a small company.<br />

It is our goal to make parts that look<br />

like original Triumph parts and<br />

function as well as they did or even<br />

better in some cases. Concours<br />

enthusiasts like our parts because<br />

they look right. Hard drivers like<br />

them because they are always the<br />

best we can offer. We never sell a<br />

part to a customer that we would<br />

not use on our own cars.<br />

TRF transmits two newsletters every week. They offer short and long term<br />

sales and sometimes special shipping. They also promote our hobby generally and<br />

provide various insights and historical perspectives. If you don’t currently receive<br />

the newsletters, please subscribe on our home page. You can easily unsubscribe<br />

later if you wish...<br />

“Thanks to Canada for Continuing to Stand up for<br />

Human Rights Worldwide”<br />

The Roadster Factory, 328 Killen Road, Armagh, PA 15920, U.S.A.<br />

Telephone 800-234-1104 • Fax 814-446-6729<br />

www.the-roadster-factory.com or at www.trfweb.us<br />

models (with PI) had the power output<br />

reduced to 125 bhp at 5000 rpm to meet<br />

European emissions regulations while the<br />

corresponding Federal cars produced 104<br />

bhp at 4500 rpm. To Triumph’s credit, they<br />

attempted to keep the Federal model’s<br />

power output consistent throughout<br />

which they almost achieved despite some<br />

extra weight gain, more complex bumpers<br />

and door inserts and yards of rubber<br />

tubing being added along the way.<br />

Contemporary road test numbers for<br />

the UK TR6 indicated a zero to 60 mph (97<br />

km/h) time of 8.2 seconds and a top speed<br />

of 119 mph (190 km/h), while the federal<br />

cars achieved 0-60 mph in 10.7 seconds<br />

and a top speed of 110 mph (177 km/h).<br />

Some of the progressive changes<br />

made to the TR6 included the change in<br />

1970 of the windscreen frame from body<br />

colour to black, and a change in cooling<br />

hoses from ‘bumble bee’ black-yellow<br />

to green colour as well as the air intake<br />

flap on the cowl being replaced with a<br />

plastic grill. In 1972, the compression<br />

ratio was dropped from 8.5:1 to 7.75:1, in<br />

the UK cars and in 1973, the Union Jack<br />

decal replaced the TR6 logo on the rear<br />

wing of the Federal models. In 1974, new<br />

interior trim included centre door pulls<br />

while in 1975 rubber bumper overiders<br />

were introduced to the Federal models<br />

and the front bumper was raised with<br />

the front indicator lamps moved under<br />

the bumper and an air injection system<br />

introduced.<br />

The TR6 featured a four-speed allsynchromesh<br />

manual transmission<br />

with optional overdrive initially using a<br />

Laycock-de-Normanville A-type which was<br />

replaced by the J-type unit for 1973. The<br />

TR6 also continued with the semi-trailing<br />

arm independent rear suspension, rack<br />

and pinion steering, 15-inch wheels, pile<br />

carpet in both cockpit and trunk which<br />

was now fitted with a courtesy light.<br />

Braking was accomplished by servoassisted<br />

disc brakes at the front and drum<br />

brakes at the rear.<br />

In addition to overdrive, options<br />

included a steel hardtop, vinyl tonneau<br />

cover, AM or AM/FM push-button radio,<br />

wire wheels, cigarette lighter, luggage<br />

rack, driving/fog lamps, rubber floor mats,<br />

walnut gear shift knob, Koni adjustable<br />

shocks, striping kit, and in the U.S., air<br />

conditioning. Michelin 185 SR-15s or<br />

Goodyear G800s were the standard tyres<br />

of the day but most owners now run on<br />

205/70R15 radial tyres.<br />

The TR8<br />

The TR7/8 combination was one of the few<br />

Triumphs that didn’t evolve directly from<br />

an earlier model and shared no DNA with<br />

any of the earlier roadsters. The wedgeshaped,<br />

unibody design was a completely<br />

new departure for a Triumph roadster<br />

and, like the larger Triumph Stag, was<br />

specifically focused on North American<br />

sales. Contemporary Triumph advertising<br />

promoted the TR8 in North America as<br />

the “English Corvette”. The monocoque<br />

body provided welcome rigidity that was<br />

missing in all of the predecessor Triumph<br />

roadster models.<br />

Plans for a V8-engined car were on the<br />

design table from the very beginning of<br />

the TR7 project but labour unrest, engine<br />

availability and other factors delayed its<br />

introduction until 1978. Final styling of<br />

the ‘Wegetarians’ was completed in 1971<br />

under Harris Mann, a stylist working out<br />

of the Austin-Morris design studio rather<br />

than the Triumph division. The front<br />

independent suspension used coil spring<br />

and damper struts and lower single link<br />

at the front, and at the rear was a fourlink<br />

system, again with coil springs. The<br />

suspension was adapted from the Rover<br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 11

"Keep‘em On The Road"®<br />

3500. Front and rear anti-roll bars were<br />

fitted and the car was provided with front<br />

disc brakes and drums at the rear.<br />

The Rover V8 engine began<br />

life as the Buick 215, an<br />

all-aluminium engine<br />

introduced in 1960.<br />

The compact engine was<br />

light, at just 144 kg (318 lb), and<br />

capable of high power outputs. Rover<br />

purchased the rights to the engine in<br />

1964 and following further in-house<br />

development, introduced the 3,528 cc<br />

engine for the Rover 3500 (P6), the Rover<br />

SD1 and various Land/Range Rover<br />

models. Shifting the Triumph-built five<br />

speed transmission is easy, once warmed<br />

up. When cold, the box has a somewhat<br />

difficult 1-2 shift. Careful lubricant<br />

selection has alleviated this, as the factory<br />

specified too heavy an oil for the built in<br />

pump to circulate. The 3.08:1 differential<br />

ratio makes highway cruising comfortable.<br />

In 1980, two Stromberg carburettors<br />

were standard but Bosch fuel injection<br />

was later required for the California<br />

market. By 1981, all TR8 cars being<br />

delivered to the U.S. market had a<br />

Bosch L-Jetronic fuel injection system<br />

with a specially designed Lucas fuel<br />

injection computer. Instrumentation is<br />

comprehensive and can be seen clearly<br />

through the top part of the small padded<br />

steering wheel. Switches and controls are<br />

easy to locate and use.<br />

The TR8 came well equipped with<br />

extras and options. Power steering was<br />

standard. The heating/cooling system<br />

was outstanding in comparison to most<br />

British cars of its day, being able to keep<br />

the car comfortable in both summer and<br />

winter conditions.<br />

The TR7/TR8 model production had<br />

a very chequered production history.<br />

There were three factories involved in the<br />

production run from 1975 to 1981, initially<br />

at Speke, then Canley and finally at the<br />

Rover plant in Solihull. On occasion, cars<br />

were being assembled in two factories at<br />

the same time, resulting in better quality<br />

build control at one over the other. It is<br />

reported that cars assembled at Speke<br />

suffered from significantly more problems<br />

than cars produced at Canley or Solihull.<br />

Our TR8 was provided by Brad<br />

Reynolds of the Toronto Triumph Club.<br />

Brad’s car is a 1981 example in metallic<br />

green over tan with five-speed manual<br />

transmission. Goodyear G800s were the<br />

factory supplied tires, on 13 x 5.5 inch<br />

vented cast alloy rims but most owners<br />

now run on 185/70R13 radial tyres.<br />

The car feels very solid especially<br />

compared to the TR6 and earlier<br />

roadster models because of the unibody<br />

construction. Brad’s engine bay and<br />

bodywork are in good shape, having<br />

been repainted in 2010. The instruments<br />

on the dash panel are easy to read but<br />

gone are the wooden panels fitted on<br />

Triumph’s earlier roadsters. The unibody<br />

construction and the shortest wheelbase<br />

of any TR roadster, provides the TR8 with<br />

great agility. The Rover V8 emits a great<br />

sound under acceleration and has good<br />

low-end torque and the car is a joy to<br />

power around corners. Everything seems<br />

to come together providing for a great<br />

deal of fun.<br />

The original fuel injection has been<br />

swapped out of Brad’s car in favour of a<br />

4-barrel Holley carburettor with a very<br />

neat Edelbrock pancake air canister. Brad’s<br />

car is pretty much stock excepting the<br />

Holley carburettor, and he has added an<br />

Offenhauser 4-barrel, dual port intake<br />

manifold and Bilstein adjustable struts.<br />

The power output varies depending<br />

upon the source of the data but it seems<br />

that the TR8 in standard Federal trim<br />

developed around 137 bhp at 5,000 rpm,<br />

sufficient to achieve a top speed of 120<br />

mph (190km/h) and acceleration from<br />

0-60 mph (100km/h) of about 9 seconds<br />

which is comparable to the V8 Triumph<br />

Stag and significantly better than a<br />

normally aspirated Federal TR6. At 60 mph<br />

(100km/h) in fourth gear the tachometer<br />

is reading 2,700 rpm and in fifth it drops to<br />

2,300 rpm for very comfortable highway<br />

cruising. Fuel consumption is a relatively<br />

thirsty 21-22 mpg.<br />

TR8 Coupé<br />

It is a not a particularly well known fact<br />

that the Triumph factory produced 145<br />

pre-production LHD TR8 coupés for<br />

evaluation in the United States, powered<br />

by the Rover V8 engine, prior to making<br />

the commitment to go ahead with the TR8<br />

convertible. The cars were well received<br />

by U.S. dealers and Triumph subsequently<br />

decided to put the TR8 into production.<br />

A further number of production coupés<br />

(somewhere around 100 to 120 units)<br />

were shipped to the U.S. in 1979 and 1980,<br />

immediately prior to the introduction of<br />

the TR8 convertible. Currently, these TR8<br />

coupés are as rare as hen’s teeth.<br />

Conclusion<br />

Both these cars are brilliant classic models<br />

and a reflection of the great design and<br />

engineering thought that was emanating<br />

from Triumph in late 1960 into the 1970s<br />

despite the deteriorating business world<br />

in which the development and production<br />

teams were operating. Both cars deserved<br />

to succeed in their targeted market<br />

segments, and the TR6 certainly did, but<br />

what a great pity the “reinvention of the<br />

sports car” hit the proverbial brick wall<br />

before it could reach a wider market. Only<br />

an estimated 2,750 TR8s were built over the<br />

three year production run. <strong>BCD</strong><br />

Parts and Accessories for<br />

TR2, TR3, TR4, TR4A, TR250, TR6, TR7, TR8, GT6, Spitfire<br />

VictoriaBritish.com (800) 255-0088<br />

©2016 Long Motor Corp.<br />

<strong>BCD</strong> 12 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme

Aston Martin<br />

DB4<br />

-60 Years<br />

Auto<br />

Hibernation<br />

The DB4 was the fourth grand<br />

tourer produced by Aston Martin,<br />

under the ownership of David Brown,<br />

from 1958 until 1963. Technically, it<br />

was a development of the DB Mark III it<br />

replaced, but with a completely new body.<br />

The DB4’s design formed the basis for later<br />

Aston Martin classics, such as the DB4 GT<br />

Zagato and the Lagonda Rapide 4-door<br />

saloon. It was eventually replaced by the<br />

Aston Martin DB5.<br />

Brown had made his fortune in farm<br />

tractors and transmissions and proceeded<br />

to build a well-known line of Aston Martin<br />

sports cars, starting with the Aston DB1<br />

(1948-50). However, the DB1 was just a<br />

low-volume interim car, and Brown began<br />

producing really serious sports cars with<br />

the faster, sleeker DB2 model (1950-53). It<br />

was a race winner trimmed like a Rolls-<br />

Royce, as were subsequent Astons. Aston<br />

Martins were expensive cars built mainly<br />

for gentlemen, although a young rock star<br />

called Mick Jagger owned one in the 1960s.<br />

It was the subsequent model, a<br />

1964-65 Aston Martin DB5 driven by<br />

James Bond in the first Bond movies,<br />

that introduced the Aston Martin brand<br />

to most North Americans. Aston Martin’s<br />

history actually dates back to 1917, but<br />

auto racing enthusiast Brown bought<br />

the financially troubled Aston Martin<br />

company to have, as he lightheartedly<br />

put it, “a lot o’ fun.” The first prototype<br />

Aston Martin was partly developed by<br />

Lionel Martin, and the Aston part of the<br />

company’s name was derived from Aston<br />

Clinton, Buckinghamshire, which used to<br />

host a hillclimb event (now known as the<br />

Chiltern Hills Vintage Vehicle Rally).<br />

About 1,204 DB4s were produced<br />

over its five-year production run. The<br />

lightweight superleggera (tube-frame)<br />

body was designed by Frederico Formenti<br />

of Carrozzeria Touring in Milan, and it<br />

caused quite a sensation at the 1958<br />

London Motor Show. Although the design<br />

and construction techniques were Italian,<br />

the DB4 was the first Aston to be built at<br />

the company’s Newport Pagnell works in<br />

Buckinghamshire. Every major part of the<br />

DB4 was new, with a new frame designed<br />

in six weeks which went on to be used<br />

through the 1960s and 1970s.<br />

The 3.7 litre engine was designed by<br />

Tadek Marek, a Polish engineer, who had<br />

studied at Berlin’s Technische Universität<br />

before joining Fiat in Poland and also for<br />

General Motors. He moved to England<br />

in 1940 to join the Polish Army in exile<br />

and in 1949 joined the Austin Motor<br />

Company, eventually joining Aston<br />

Martin in 1954. There he designed three<br />

engines – developing an alloy straight<br />

six-cylinder for the Aston Martin DBR2<br />

racing car (1956), later refined for the DB4;<br />

redesigning the company’s venerable<br />

straight six-cylinder Lagonda (1957); and<br />

developing the Aston Martin V8 (1968).<br />

The DB4’s engine was prone to<br />

overheating initially, but the 240 hp<br />

produced by the twin-SU carburetor<br />

version made buyers forgive this<br />

unfortunate trait. Servo-assisted disc<br />

brakes were fitted all-round. The<br />

independent front suspension used<br />

ball-jointed wishbones, coil springs and<br />

rack-and-pinion steering. The live rear axle<br />

also used coil springs and was located by<br />

a Watt’s linkage.<br />

A car tested by The Motor magazine in<br />

1960 had a top speed of 139.3 mph (224.2<br />

km/h) and could accelerate from 0-60<br />

mph (97 km/h) in 9.3 seconds. The test car<br />

cost £3,967 including taxes. The DB4 could<br />

do 0-100 mph and stop in 27 seconds -<br />

sensational for the late 1950s and early<br />

1960s. No American car, regardless of<br />

power rating, could match that feat, which<br />

Aston proudly advertised.<br />

There were five “series” of DB4. The<br />

most visible changes were the addition<br />

of window frames in Series II and the<br />

adoption of a barred grille in Series IV.<br />

The Series III cars differed from the earlier<br />

ones in having taillights consisting of<br />

three small lamps mounted on a chrome<br />

backing plate. Earlier cars have singlepiece<br />

units and the last Series V cars of<br />

September 1962 have similar taillights<br />

but recessed. The Series V also has a taller<br />

and longer body to provide more interior<br />

space, though the diameter of the wheels<br />

was reduced to keep the overall height<br />

the same. The front of the Series V usually<br />

was more aerodynamic as already used<br />

on the Vantage and GT models, a style<br />

that was later carried over to the DB5<br />

cars. A convertible was introduced in<br />

October 1961. <strong>BCD</strong><br />

By<br />

Parkfield Motor Cars Ltd. est. 1974<br />

Fully Insured, Free Standing 22,000 sq. ft.<br />

Building with No Columns or Posts<br />

• CCTV-Monitored 24/7 Security at Discreet Location<br />

• Spotless, Vermin and Climate Controlled<br />

• Seasonal Complimentary Chauffeured<br />

Livery Service Available<br />

Closer Than You Think!<br />

Contact Chris Sas at 416-720-4133 or 905-833-4336<br />

email: chris@saspark.com<br />

www.autohibernation.ca<br />

<strong>BCD</strong> 14 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme

Austin<br />

A40 Farina<br />

-60 Years<br />

by John McLaine<br />

The Austin A40 Farina was a midsized<br />

family car introduced by Austin in<br />

saloon format at the 1958 London Motor<br />

Show and in the Countryman (estate)<br />

version the following year. Although<br />

usually referred to as the A40 Farina,<br />

to distinguish it from previous models<br />

bearing the A40 name, it was badged<br />

simply as the Austin A40. It was also<br />

produced in and for other markets, mainly<br />

exports to Commonwealth countries<br />

in CKD format but also built in Italy by<br />

Innocenti, who contemporaneously and<br />

subsequently built Minis and Allegros<br />

under licence. The A40 was introduced at<br />

a time of growing prosperity in the UK,<br />

when families were acquiring a car for the<br />

first time or acquiring a second family car<br />

for mom and the older teenagers to share.<br />

Although it is often overlooked in the<br />

history of BMC, the Austin A40 was an<br />

important model. It marked a transition<br />

or turning point in the evolution and<br />

direction of BMC’s automotive designs. It<br />

was the first post-WWII Austin to be styled<br />

without input from Ricardo ‘Dick’ Burzi,<br />

the Argentinian designer who had moved<br />

over to Austin’s design team from Lancia<br />

in 1929. More importantly, it presaged the<br />

fashion in Britain for employing Italian<br />

design houses to style regular family<br />

cars rather than just exotic models; in<br />

the case of the A40, Battista Farina of the<br />

Pininfarina Studio was employed while<br />

Triumph engaged Giovanni Michelotti<br />

for the contemporary Herald models.<br />

It also was the last rear-wheel drive<br />

small car introduced by BMC before the<br />

introduction of the front-wheel drive<br />

Austin<br />

and<br />

Morris Minis a<br />

year later, in 1959.<br />

Initially<br />

conceived to<br />

replace the ageing<br />

A35, the A40<br />

emerged as a cleanstyled<br />

two-door, two-box design. Under<br />

the bodywork, the same A-series engine<br />

that powered the A35 and the Morris<br />

Minor was used, and the running gear<br />

was absolutely conventional, despite<br />

the innovative styling. It used the A35’s<br />

underpinnings, including the dubious<br />

hydro-mechanical brakes.<br />

The Countryman hatchback appeared<br />

a year later in October 1959, and differed<br />

from the saloon in that the rear window<br />

was now a horizontally-split tailgate<br />

having a top-hinged upper door and<br />

bottom-hinged lower door – actually a<br />

small estate car. Individual seats were<br />

fitted in the front, with a bench at the<br />

rear that could fold down to increase<br />

luggage capacity. Options included a<br />

heater, radio, and windscreen washers.<br />

The gearshift was floor-mounted and<br />

the handbrake positioned between<br />

the seats. The door windows were not<br />

opened by conventional winders, but<br />

pulled up and down using finger grips.<br />

The Countryman design presaged the<br />

advent of hatchbacks that would become<br />

dominant in the industry 15 or more years<br />

later. In Italy, Innocenti went a step further<br />

and added a single-piece tailgate, calling<br />

it the Combinata. (I have fond memories of<br />

setting off on camping and canoeing trips<br />

with friends in a new 1962 A40 Countryman.<br />

The car was quite capable of hauling all<br />

the necessary paraphernalia for a weekend<br />

under canvas together with a couple of<br />

kayaks strapped to a roof rack – Ed.)<br />

An A40 Farina Mark II was introduced<br />

in 1961. It had a 3.5 in. longer wheelbase<br />

which served to increase the passenger<br />

area in the back and the front grille and<br />

dashboard were redesigned. The Mark<br />

II had more power (37 hp) and an SU<br />

replaced the previous Zenith carburettor<br />

but was otherwise similar mechanically.<br />

An anti-roll bar was fitted at the front.<br />

The 948cc engine was replaced in the<br />

late 1962 by a larger 1,098cc version with<br />

an output of 48 bhp. The A40 shared<br />

this engine with the Morris Minor. An<br />

improved gearbox was fitted to the A40<br />

at the same time although still sans<br />

synchromesh on first gear.<br />

Further changes were minimal. However,<br />

in 1964 a new fascia with imitation wood<br />

veneer covering was fitted. This version of<br />

the model remained in production until<br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 17

Creative Commons<br />

1967. The brakes<br />

also became fully<br />

hydraulic, replacing<br />

the semi cableoperated<br />

rear system<br />

that the Mark I had<br />

inherited from the<br />

A35. Nevertheless,<br />

the introduction at<br />

the end of 1962 of<br />

the similarly sized<br />

Morris 1100, followed<br />

by an Austin-badged<br />

counterpart a year<br />

later, left the A40<br />

looking cramped on<br />

the inside and outclassed in terms of road<br />

holding and ride.<br />

A deluxe version tested by The Motor in<br />

1958 had a top speed of 66.8 mph (107.5<br />

km/h) and could accelerate from 0–50<br />

mph (80 km/h) in 19.5 seconds. A fuel<br />

consumption of 38 miles per gallon (7.4<br />

L/100 km) was recorded. The test car cost<br />

£689 including taxes.<br />

Believe it or not, the<br />

A40 Farina played a<br />

very significant role in<br />

British saloon car racing<br />

over the years, starting<br />

most notably when<br />

Doc Shepherd secured<br />

the British Saloon Car<br />

Championship in 1960.<br />

Race-prepared cars<br />

frequently achieved<br />

more than 70 bhp<br />

from the A-Series<br />

engine.<br />

The production run ended in<br />

November 1967 after approximately<br />

342,000 had been built in the UK (plus<br />

67,207 in Italy as the Innocenti A40). As<br />

the BMC 1100/1300 range established<br />

itself as the UK’s top seller, the newer<br />

more space-efficient ADO16 took sales<br />

away from the A40. In its last year, only<br />

12,000 A40s were built. The last of the A40<br />

The Austin Motor Company was one of<br />

England’s earliest car manufacturers, founded by<br />

Herbert Austin in 1905 with its factory at<br />

Longbridge near Birimingham, and merging with<br />

Morris Motors Ltd in 1952 to form the British<br />

Motor Corporation. The A40 ‘Farina’ was actually<br />

one of the last Austin-badged cars; other<br />

Longbridge models wore differing marque badges<br />

denoting their levels of equipment and trim.<br />

The new “baby Austin” was in development between 1955–58 and was designed<br />

by the Italian stylist Battista Pininfarina. It was launched on 18th September 1958<br />

and the standard model (heater and extra trim not included!) cost £676 7s 0d. The<br />

Mk 1 was propelled by the wonderfully compact 948 cc A-series engine (which<br />

grew from a design originated in the late 1940s by Eric Bareham). It returned an<br />

average of 45 mpg, did 0–60 in 35.6 seconds (!) and could reach 73 mph.<br />

A ‘Countryman’ version of the saloon (with top-hinged rear window – arguably<br />

one of the first “hatch-backs” in UK mass-production) was announced in<br />

September 1959 and, two years later, the Mk 1 models were restyled into the Mk 2<br />

which (later to have 1098cc engines) continued in production until 20th November<br />

1967, by which time a grand total of 342,180 A40 Farinas had been built.<br />

Today the A40 Farina Club Ltd estimates that less than six hundred of the little<br />

cars now exist but they still represent economical classic motoring. The Club was<br />

founded in 1979 and has almost 400 members around the world. Annual subscription<br />

is just £17.50 and technical advice is always available, plus the Club has a thriving<br />

spares supply service combining top-quality components with sensibly low prices,<br />

while steadily expanding their list of remanufactured obsolete items unavailable<br />

elsewhere.<br />

Farina News, a 42-page A5 full-colour magazine is published quarterly, while<br />

several friendly meetings are organised during the year. Many members attend various<br />

car shows while others are enthusiastic race or rally participants (specially-prepared<br />

A40s can be very, very quick!)<br />

For further details do please contact us either by post to 36 Wood End, Banbury<br />

OX16 9ST, e-mail us to info@A40FarinaClub.co.uk or else feel free to visit our<br />

website at www.A40FarinaClub.co.uk or find our official club page on facebook.<br />

thanks for your interest<br />

production<br />

run enjoyed a final burst of<br />

publicity as Unit Beat ‘Panda’ cars for<br />

Birmingham City Police. The UK based<br />

A40 Farina Club now estimates that less<br />

than four hundred of these unique little<br />

cars exist world-wide (a one-tenth of one<br />

percent survival rate). <strong>BCD</strong><br />

Pssst!<br />

Want Some Great Advice?<br />

1565 Hwy 5 West, RR#1<br />

Troy, Ontario, L0R 2B0<br />

Toll Free 1-888-485-2277<br />

Local: 905-627-9995<br />

24hr Fax: 416-410-6479<br />

E-mail: britishautosport@bellnet.ca<br />

You could search big catalogues for the best price<br />

You could buy parts from various suppliers<br />

You could pay huge shipping and crazy broker fees<br />

You could be returning the parts<br />

You could...<br />

...but why would you?<br />

We are your local source for quality parts and only stock<br />

the best. When you consider the benefits of friendly local<br />

service, no quibble exchanges, next day delivery or same<br />

day pick-up, plus great advice and customer service, British<br />

Auto Sport is hard to beat.<br />

Try us for your next project!<br />

<strong>BCD</strong> 18 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme<br />

British Auto Sport<br />

Toll Free 1-888-485-2277

Morgan<br />

Plus-8<br />

– 50 Years<br />

by Norm Hendrycks<br />

The history of the Morgan Plus-8<br />

using the Rover 3.5L V8 engine is well<br />

documented in the book titled “Morgan<br />

- First and Last of the Real Sports Cars”<br />

by Gregory Houston Bowden. The first<br />

Morgan Plus-8 had chassis number R7000<br />

and the last was chassis number R13233.<br />

The total Plus-8 chassis numbers allocated<br />

was 6,233 but 31 were never built. There<br />

were five duplicate chassis numbers<br />

leaving the total number of Plus-8 (Rover)<br />

manufactured from 1968 to 2004 at 6,207.<br />

The concept of the Morgan Plus-8<br />

began in May of 1966 and in 1967 Morgan<br />

was ready to fit the Rover V8 engine into<br />

the chassis of the Plus-4. The first Morgan<br />

Plus-8 was produced in October 1968 and<br />

the last one was in May 2004.<br />

The body of the first production run<br />

had to be widened by two inches to<br />

accommodate the wider tires used on<br />

the Plus-8. This was accomplished by<br />

widening the wings by one inch on either<br />

side. The body was also lengthened by<br />

two inches<br />

From 1968 to 1972 the Plus-8 had the<br />

Rover 3.5L V8 with<br />

a 10.5:1 CR,<br />

184 BHP at 5200rpm, and used the Moss<br />

gearbox 4-speed manual transmission<br />

with synchromesh on 2nd,3rd,and 4th.<br />

The carburettors were twin SU type HS6.<br />

From 1972 to 1977 the Plus-8 Rover V8<br />

engine was reduced to 9.25:1 CR and used<br />

the Rover 3500s 4-speed all-synchromesh<br />

manual transmission, which required a<br />

modification of the chassis to accept the<br />

new transmission.<br />

From 1974 to 1992 all imported Morgan<br />

Plus-8s to the United States were converted<br />

to propane by independent dealers in<br />

order to pass the U.S. emissions regulations.<br />

From 1977 to 1995 the Plus-8 Rover<br />

V8 compression ratio was raised to 9.35:1<br />

and used the Rover LT77 5-speed allsynchromesh<br />

manual transmission which<br />

required a further widening of the body<br />

in order to fit the new transmission and<br />

changes in tyre size.<br />

In 1981 the engine’s twin carburettors<br />

were changed to Stromberg CD175.<br />

In 1990 the 3.9L<br />

version of the<br />

Rover engine was fitted with Lucas fuel<br />

injection.<br />

In 1995 the Rover R380 - speed allsynchromesh<br />

manual transmission was<br />

introduced which was used until 2004.<br />

In 1996 the Rover 4.6L engine became<br />

an option.<br />

In May of 2004 production of the Morgan<br />

Plus-8 using the Rover engine stopped with<br />

the last chassis number R13233.<br />

In all, the Morgan Plus-8 grew from<br />

57.5 inches in 1968 to 67 inches in width<br />

by 2004 and the Rover engine size<br />

increasing from 3.5L to 3.9L to 4.6L.<br />

In 2012 a new Morgan Plus- 8 was<br />

introduced powered by a 4.8L BMW V8.<br />

In 2014 Morgan announced a Limited<br />

Edition run of 60 Plus-8s.<br />

My 1969 Morgan Plus-8 Chassis # R7077<br />

My Morgan Plus-8 was purchased from<br />

the factory in Malvern, Worcestershire<br />

on December 23, 1968. It came off the<br />

assembly line and was test driven on the<br />

19th of May 1969 by Charlie Curtis. It left<br />

the factory on 23rd June 1969. I received it<br />

on July 26, 1969, delivered through Metro<br />

Motors in Windsor, Ontario. I ordered<br />

my Plus-8 in black with red interior, but<br />

received it in gray primer with black<br />

interior. I was informed that I could have it<br />

painted the colour of my choice.<br />

The standard 1968 finishes for<br />

Morgans was Westminster Green,<br />

Crimson, Indigo Blue, Orange Chrome or<br />

Broken White. WOW! Alternative colours<br />

were at an extra charge of £15. A rear<br />

bumper was an extra £5, seatbelts - lap<br />

and diagonal, an extra £9.1s.<br />

There was an interesting statement<br />

in the original brochure which read,<br />

“Powerful yet docile, you can sing up<br />

Peninsula<br />

Imports<br />

LOTUS OF OAKVILLE<br />

EST<br />

82<br />

MOTOR VEHICLE GROUP<br />

Special introductory offers including financing & flexible lease<br />

terms from 3.9% Inviting current Lotus owners to trade-up<br />

2412 South Service Rd. West<br />

Oakville ON L6L 5M9<br />

905-847-0838<br />

sales@peninsulaimports.com<br />

Browse our parts catalogues online<br />

www.peninsulaimports.com<br />

CANADA'S<br />

BRITISH<br />

MOTOR<br />

HERITAGE<br />

SUPPLIER<br />

<strong>BCD</strong> 20 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme<br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 21

to seventy mph in 7.5 seconds or start<br />

from standstill in top gear, as a test of<br />

strength”. It has been stated that the<br />

suspension was so stiff that if you drive<br />

over a Canadian quarter you could tell if<br />

it was heads or tails.<br />

After a short pre-delivery discussion<br />

with Doug Ellis of Metro Motors, we were<br />

on our way home. Keep in mind that<br />

when driving a Morgan there is always an<br />

adventure associated with it. I was having<br />

an exciting time driving while my friend<br />

George was reading the Owner’s Manual<br />

giving me details as we travelled along. No<br />

more than 40 miles or so from Windsor we<br />

heard some funny noises; a grinding noise<br />

from the rear axle every time we turned<br />

a corner. “George, what was that?” I asked<br />

“I don’t know,” was George’s reply, “There<br />

is nothing in the manual about that.”<br />

We stopped and called Metro Motors.<br />

We were reassured that it was only the<br />

Salisbury Limited Slip differential breaking<br />

in and there would be no problem. We<br />

set off again somewhat assured that<br />

there would be no more surprises. We<br />

were on our way again, top down, wind<br />

in our hair, George still reading the<br />

Owner’s Manual. Just past London we saw<br />

potential rain clouds so we stopped under<br />

an overpass to put the top up and install<br />

the side curtains. The Manual refers to<br />

the convertible top as “The Hood”. On our<br />

way again, we were greeted with a steady<br />

rainfall and we soon realize that there<br />

is limited protection in the car with the<br />

“Hood” up. Wet outside and wet inside and<br />

no defroster. The defrosters were installed<br />

in later years. We used whatever we had<br />

on hand to keep the windshield inside<br />

clear and with not a lot of dry clothes<br />

available it was difficult. However, after a<br />

lot of laughs we made it home.<br />

I decided that the Morgan Plus-8 was<br />

to be painted “Smokey Gray” to match<br />

the colour of the Owner’s Manual. Not a<br />

good colour for dawn and dusk driving,<br />

as I soon discovered. Some years later<br />

the car was repainted with a red body<br />

and black wings. It was at this time that<br />

I detected some wood deterioration<br />

caused by retained water in the padding<br />

material under the vinyl interior covering.<br />

I purchased some Belgian Ash and made<br />

new wood chassis parts to replace the<br />

deteriorated wood. I decided to leave<br />

the new wood exposed so it could dry<br />

when it got wet. I like it better, no more<br />

moisture problems. The mechanical fuel<br />

pump was replaced with a Carter P4070<br />

electric fuel pump.<br />

With having three children, I had to<br />

store the car for a few years but now the<br />

Morgan is back on the road.<br />

It is an interesting car with an<br />

interesting history made by a familyowned<br />

business in a small English town.<br />

It has maintained the “Morgan Shape”<br />

with little to no change in the body shape,<br />

which was introduced in 1935 when the<br />

first 4-wheel car was produced. <strong>BCD</strong><br />

Moss Triumph parts<br />

at the best prices<br />

in Canada<br />

Sunday 10:15am. YO U , THAT PE R FECT FIN ISH AND T HE O PEN R O A D.<br />

I N D U L G E I N T H E G L O RY.<br />

A large<br />

selection of<br />

TRs for sale!<br />

Always more<br />

arriving.<br />

Attacking the twists and bends with the sun shimmering on pristine bodywork and supple leather – it makes that bit of effort worthwhile. Don’t<br />

worry, you’re not alone, we share your passion for detail. For us it’s an obsession that started over 40 years ago and continues to drive us today.<br />

That’s why our products work beautifully, are quick and easy to use and more durable than ever. It also means you and your car get to look<br />

good for longer. That’s the Autoglym way. Always has been.<br />

www.autoglym.com<br />

PA SSI O N for P E R F E CTI O N<br />

Now exclusively available at Canadian Tire and PartSource<br />

Drakes’ British Motors Inc.<br />

(250)763-0883 Ph., (250)861-8051 Fax, email lendrake@shaw.ca<br />

2286 K.L.O. Road, Kelowna, B.C., V1W 3Z7<br />

<strong>BCD</strong> 22 www.BritishCarDay.com September 16, <strong>2018</strong> • British Car Day Programme<br />

AutoGlym.00.indd 1<br />

13-08-30 5:30 PM<br />

British Car Day Programme • September WWW.DRAKESBRITISHMOTORS.COM<br />

16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 23

Land Rover<br />

Series 1 (LR 1) – 70 Years<br />

Staff Report<br />

I’m not an expert on the Land Rover<br />

marque but even the most basic research<br />

would not dispute that the brand and<br />

early model is regarded as an enduring<br />

British icon. You have probably seen<br />

images of the Queen, in her wellies<br />

and headscarf, piloting her Land Rover<br />

across the countryside at Balmoral or<br />

Sandringham. Indeed, the Land Rover was<br />

granted a royal warrant by King George VI<br />

in 1951, only three years after the vehicle<br />

was first launched. In preparing this<br />

revue I have drawn heavily on input from<br />

Wikipedia and the Ifixit and Land Rover<br />

FAQ websites.<br />

The initial design was scratched out on a<br />

Welsh beach in 1947 by Maurice Wilks who<br />

at the time was chief designer at the Rover<br />

Company. He collaborated with his brother<br />

Spencer, Rover’s managing director, on<br />

the project. Maurice had been using a<br />

Willys Jeep for light utility on his farm in<br />

Newborough, Anglesey and was pleased<br />

with the Jeep’s usefulness but found that<br />

parts were very difficult to acquire and only<br />

available in bulk from military surplus. He<br />

thought there would be a market niche<br />

that Rover could step into with a similar<br />

vehicle, so he and Spencer set about<br />

building a prototype. The project was<br />

simply called Land Rover (the terms “Series”<br />

and “Defender” are retroactive and only<br />

introduced in the 1990s). The prototype,<br />

later nicknamed Centre Steer, was built<br />

on the Jeep chassis and axles coupled to a<br />

Rover car engine.<br />

In April 1948, the Land Rover was<br />

officially launched, at the Amsterdam<br />

Motor Show to a positive reception.<br />

Three thousand production models were<br />

produced for 1948 and approximately<br />

182,000 vehicles were produced until the<br />

introduction of Series II in 1958. The early<br />

choice of colour was determined by a<br />

surplus of military aircraft cockpit paint,<br />

so vehicles only came in various shades of<br />

light green; all models until<br />

recently feature sturdy<br />

box section<br />

ladder-frame<br />

chassis. The<br />

use of<br />

simple<br />

body panels<br />

made from<br />

light alloy<br />

and a chassis fabricated from<br />

off-cuts avoided the use of rationed steel<br />

and the need for complex and expensive<br />

press tools. Early vehicles were field-tested<br />

at Long Bennington and designed to be<br />

field-serviced. Fourty-eight prototypes were<br />

produced during development at Rover’s<br />

Solihull facility that first year.<br />

Rover quickly realised that this ‘stop<br />

gap’ product was set to outsell its other<br />

vehicles – and by the end of 1948 was<br />

exporting the Land Rover to nearly 70<br />

countries. The U.S. received their first Land<br />

Rovers the following year.<br />

During the life of the Land Rover many<br />

different engines have been fitted. The<br />

inlet-over-exhaust petrol engines (“semi<br />

side-valve”), in both four- and six-cylinder<br />

variants, which were used for the Series I<br />

Land Rovers, and which had their origins<br />

in pre-war Rover cars had a displacement<br />

of 1,600 cc. In 1951, Land Rovers received<br />

2.0L motors to replace the 1.6L powerplant.<br />

The 1,997 cc Petrol, inlet-over-exhaust<br />

Series I engine, carried over for the first few<br />

months of Series II production.<br />

In 1950, changes were made to the<br />

original Land Rover design, which included<br />

larger and more powerful headlamps that<br />

shone through apertures in the grill, and<br />

a hard-top. The four-wheel system was<br />

modified to shift dynamically, with drive to<br />

the front axle in high range being activated<br />

by pressing down on one lever, while low<br />

range was selected by pulling another lever<br />

rearward. In selecting low range, four-wheel<br />

drive was automatically engaged.<br />

Then, in 1953, to increase the<br />

load space area, the wheelbase<br />

of the Land Rover<br />

was extended to<br />

86 inches. A new<br />

long-wheelbase<br />

pickup version and<br />

a Station Wagon were<br />

introduced and well<br />

received.<br />

1956 saw more tweaks to the size of<br />

the platforms with the introduction of<br />

a 10-seater, 107-inch wheelbase Station<br />

Wagon. Other wheelbases were extended<br />

to 88 and 109 inches to make room for a<br />

new diesel engine under development.<br />

One of the last major improvements to<br />

the “LR1” came in 1957 with the introduction<br />

of the 2.0L overhead valve diesel engine.<br />

This engine has endured and evolved over<br />

the years to become the 300 TDi turbodiesel,<br />

which remains in production today for some<br />

international markets. In 1965 Rover acquired<br />

from General Motors an alloy 3.5 L V-8 engine<br />

which after further design changes in Solihull,<br />

went on to power many subsequent Rover,<br />

Land Rover and Range Rover models as well<br />

as the Triumph TR8 and Morgan +8.<br />

Various Land Rover models have been<br />

used in a military capacity, most notably<br />

by the Australian Army and British Army<br />

which purchased a trial batch of Series<br />

I Land Rovers in 1949. The earliest Land<br />

Rovers were found to complement the<br />

Austin Champ very well. The Land Rover<br />

was cheaper, lighter, consumed less fuel,<br />

and was ideal for behind-the-lines transport<br />

duties. However, the Champ was better<br />

suited as a front-line combat vehicle.<br />

Military modifications may have included<br />

“blackout” lights, heavy-duty suspension,<br />

uprated brakes, 24 volt electrics, convoy<br />

lights, electronic suppression of the ignition<br />

system, blackout curtains and mounts for<br />

special equipment and small arms. <strong>BCD</strong><br />

British Car Day Programme • September 16, <strong>2018</strong> www.BritishCarDay.com <strong>BCD</strong> 25

416.871.2358<br />

9 Forster Park Drive<br />

Oakville, Ontario Canada L6K 1Y5<br />

info@winslowdelaney.com<br />

www.winslowdelaney.com<br />

Austin<br />

America<br />

– 50 Years By Mark Margetts<br />

Todd Miller of the Austin America<br />

Club has kindly authorized the publication<br />

of this short history of the Austin America.<br />

The Austin America was a special version<br />

of the two-door Austin 1300 (ADO 16).<br />