PLC Loggers Voice Spring 2019

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Volume 13 Issue 2 | <strong>Spring</strong> <strong>2019</strong><br />

A Quarterly Publication of the Professional Logging Contractors of Maine

Board of Directors<br />

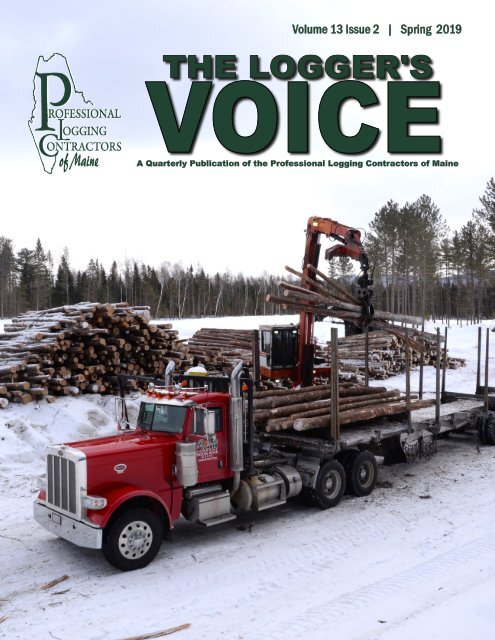

Cover: Jackman Lumber truck loading at a landing in Moose<br />

River in March. Story, p.10.<br />

Jim Nicols, President<br />

Tony Madden, 1 st Vice President<br />

Chuck Ames, 2 nd Vice President<br />

Will Cole, Secretary<br />

Andy Irish, Treasurer<br />

Scott Madden, Past President<br />

Aaron Adams<br />

Kurt Babineau<br />

Donald Cole<br />

A quarterly publication of:<br />

The Professional Logging<br />

Contractors of Maine<br />

William Cole<br />

Tom Cushman<br />

Brent Day<br />

Wes Dube<br />

Steve Hanington<br />

Duane Jordan<br />

Robert Linkletter<br />

Andrew Madden<br />

Ron Ridley<br />

10<br />

110 Sewall St., P.O. Box 1036<br />

Augusta, ME 04332<br />

Phone: 207.688.8195<br />

www.maineloggers.com<br />

Member Showcase<br />

Jackman Lumber<br />

Wayne Tripp<br />

Gary Voisine<br />

<strong>PLC</strong> Staff<br />

Executive Director<br />

Dana Doran ▪ executivedirector@maineloggers.com<br />

Membership Services Coordinator<br />

Jessica Clark ▪ jessica@maineloggers.com<br />

Safety and Training Coordinator<br />

Donald Burr ▪ safety@maineloggers.com<br />

The Logger’s <strong>Voice</strong><br />

Editor and Designer<br />

Jon Humphrey Communications and Photography<br />

▪ jehumphreycommunications@gmail.com<br />

Advertising<br />

Jessica Clark ▪ jessica@maineloggers.com<br />

Email news, notices, and correspondence<br />

▪ jehumphreycommunications@gmail.com<br />

22<br />

Supporting Member Spotlight<br />

Milton CAT<br />

Also Inside<br />

4 Calendar and Updates<br />

6 President’s Report<br />

7 New Members<br />

8 Executive Director’s Report<br />

14 Wage and Employment Study<br />

16 Annual Meeting<br />

18 Trucking<br />

25 MLOP<br />

26 Safety<br />

34 <strong>PLC</strong> News Briefs<br />

36 ALC Updates<br />

39 Master Logger<br />

40 Congressional Updates<br />

This newsletter is printed on FLO Gloss Digital Text paper<br />

produced in Maine and donated by Sappi North America.

Event<br />

Calendar<br />

*Oxford Casino, Oxford<br />

NEW LOCATION!<br />

Cross Insurance Center, Bangor<br />

H.O. Bouchard/Comstock, Hampden<br />

4 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Updates<br />

Do you have news to<br />

share?<br />

The <strong>PLC</strong> is always seeking<br />

news from our Members that<br />

showcases our industry’s<br />

professionalism, generosity, and<br />

ingenuity.<br />

Send ideas to<br />

jonathan@maineloggers.com<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong><br />

5

From the President<br />

By Jim Nicols<br />

Hello everyone,<br />

As I write this, winter is winding down and spring is coming fast. I hope<br />

everyone had a productive and safe winter season. We sure had enough snow in<br />

most parts of the state.<br />

For those of you that weren’t able to attend, we had a great turnout for our<br />

legislative breakfast in late March. We had approximately 100 legislators and <strong>PLC</strong><br />

members attend. Legislators got a chance to listen to some of our needs and<br />

concerns and ask questions of the members. A lot of the discussion that morning<br />

centered around labor, energy and road postings.<br />

There is a lot going on in Augusta right now and Dana is doing a great job<br />

representing <strong>PLC</strong> in the Capital. If you do not receive <strong>PLC</strong>’s weekly updates<br />

through email, call Jess at the office and she will get you on the email list.<br />

I know Donald Burr is working hard on putting the next MLOP training class<br />

together. It is slated to start this summer in Stratton in late June, the first time it has<br />

been in western Maine. We should have a full class, as I believe we have had more<br />

than triple the applicants for this year’s class. However, <strong>PLC</strong> members and their<br />

employees get preferential treatment when making recommendations for applicants<br />

so if you have someone in mind that you would like to send, please let Donald know<br />

as soon as possible.<br />

The dates are now out for the <strong>PLC</strong>’s annual spring safety trainings. If you<br />

haven’t signed up yet, make sure to do so as classes are filling up fast. Last year we<br />

had over 800 people attend these trainings. We are also doing fleet trainings for<br />

truck drivers at various locations throughout the state.<br />

Lastly the <strong>PLC</strong> annual meeting is fast approaching on April 26th. I hope you<br />

will all take the time to attend and support <strong>PLC</strong>. It is an informative and fun day and<br />

evening with a chance to see people you may not have seen throughout the year.<br />

Scott Hanington will once again be the auctioneer for the Log A Load for Kids<br />

auction for the Children’s Miracle Network. We want to try and top last year’s<br />

numbers.<br />

Hope to see you all there and have a good spring.<br />

Thank You<br />

Jimmy<br />

6 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Welcome New Members….…….<br />

Contractor Members<br />

Clayton Pelletier Logging Inc. of Rumford,<br />

ME joined the <strong>PLC</strong> as a new Contractor<br />

Member in March <strong>2019</strong>. The company has a<br />

professional staff of one. For more information<br />

contact Clayton at 446-2724 of<br />

email claypel@yahoo.com.<br />

LAS Logging of Hampden, ME joined the<br />

<strong>PLC</strong> as a new Contractor Member in March<br />

<strong>2019</strong>. The company has a professional staff of<br />

two. For more information call Alphonse at<br />

(207) 862-4614 or email spencer313@tds.net.<br />

Supporting Members<br />

Fabian Oil of Oakland, ME joined the <strong>PLC</strong> as a<br />

new Preferred Supporting Member in January<br />

<strong>2019</strong>. The company is a locally owned and<br />

operated marketer of petroleum products and<br />

has proudly served its many customers for over<br />

30 years. It is a full service company offering all<br />

types of heating and motor fuels and maintains a<br />

full-scale service department for oil, propane<br />

and natural gas. For more information call Ted<br />

Fabian at 465-2000, email<br />

tfabian@fabianoil.com or visit<br />

www.fabianoil.com.<br />

Groundtek Inc. of Fort Kent, ME joined the<br />

<strong>PLC</strong> as a new Forest Contractor Member in<br />

March <strong>2019</strong>. The company has a professional<br />

staff of four. For more information contact<br />

Bruce at (207) 834-5047 or<br />

email GROUNDTEK541@YAHOO.COM.<br />

Pelletier Manufacturing Inc. of<br />

Millinocket, ME joined the <strong>PLC</strong> as a new Forest<br />

Contractor in March <strong>2019</strong>. The company has a<br />

professional staff of 17. For more information<br />

contact Jeff at (207) 723-6500 or<br />

email pelletiermfg@myfairpoint.net.<br />

B. Pelletier Logging Inc. of St. Francis, ME<br />

joined the <strong>PLC</strong> as a new Affiliated Contractor in<br />

March <strong>2019</strong>. The company has a professional<br />

staff of two. For more information contact<br />

Buddy at (207) 316-2831or<br />

email bpelletierlogging@gmail.com.<br />

The Winter <strong>2019</strong> Edition of The Logger’s <strong>Voice</strong><br />

incorrectly identified <strong>PLC</strong> Supporting Member<br />

Soleno as a Vermont-based company. Soleno is<br />

based in Canada. We regret the error.<br />

ND Paper, a wholly-owned subsidiary of Nine<br />

Dragons Paper (Holdings) Limited, the largest<br />

containerboard producer in Asia, joined the <strong>PLC</strong><br />

as a new Preferred Supporting Member in<br />

March <strong>2019</strong>. ND Paper is an environmentallyfriendly<br />

company that manufactures various<br />

types of high-quality pulp, paper and paperbased<br />

packaging materials. Its mills in Rumford,<br />

Maine and Biron, Wisconsin are integrated<br />

paper & pulp facilities, and its mill in Fairmont,<br />

West Virginia is one of only three in the world<br />

that produces air-dried, recycled pulp. The<br />

company is working to restart a currently-idled<br />

pulp mill in Old Town, Maine, with expected<br />

commissioning in the summer of <strong>2019</strong>. ND<br />

Paper has 1,100 dedicated employees, who<br />

together produce more than 1.1 million metric<br />

tons of paper annually. ND Paper is<br />

headquartered in Oakbrook Terrace, Ill. For<br />

more information contact Randy Chicoine<br />

at 207) 754-8752 or email<br />

mailto:randy.chicoine@us.ndpaper.com.<br />

Not a member but interested in<br />

joining the <strong>PLC</strong>?<br />

Contact Jessica at (207) 688-8195 or<br />

email jessica@maineloggers.com<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong><br />

7

From the Executive<br />

Director<br />

As this article goes to print, the snow<br />

is melting quickly, the road postings are up<br />

across the state and many winter time<br />

operations are grinding to a halt. While mud<br />

season can be a time of frustration for our<br />

membership as cash flow slows down and the<br />

attention turns to maintenance and catching<br />

up on paperwork, it is also a time to recharge<br />

the batteries after the big winter push before<br />

summer rolls around and wood is moving<br />

again.<br />

<strong>Spring</strong> is also a time to reflect upon<br />

the industry, all that is good, and all that is<br />

bad as well as the opportunities and<br />

challenges. As I talk to our members and get<br />

the lay of the land out there, I have a sense<br />

the challenges are mounting and even though<br />

markets have opened up, there is less and less<br />

optimism about the future.<br />

Back in December, based upon the<br />

instincts of the <strong>PLC</strong> Board and the input of<br />

the membership, the <strong>PLC</strong> conducted a survey<br />

of its members to determine what the<br />

employment needs were at that point in time.<br />

We were hearing that it was getting harder<br />

and harder to find help, that the markets were<br />

wide open, and they could harvest wood<br />

without hesitation, but the workforce could<br />

not fill the need. Rumors were rampant that<br />

mill yards were nearly empty week after<br />

week and there were not enough operators,<br />

truck drivers or mechanics to do the work.<br />

The survey we did was striking as we heard<br />

Future<br />

By Dana Doran<br />

back from a majority of our membership and<br />

the numbers do not lie. As of January, just<br />

among the <strong>PLC</strong> membership, there were<br />

between 750-1,000 job openings and no real<br />

idea how to fill them. This was surprising in<br />

that we knew there were needs, but not at this<br />

size and scale.<br />

At the same time, we also heard from<br />

the membership that competition for labor<br />

was fierce and members were not only having<br />

a challenging time hiring new employees, but<br />

they were losing employees at a rapid pace<br />

because of the opportunity to earn more<br />

money with better benefits and fewer hours<br />

outside of the industry. Some members even<br />

reported that they were losing employees to<br />

local mills that they delivered wood to. This<br />

is a recipe for disaster at exactly the wrong<br />

time as the state has been marketing itself as<br />

having a glut of softwood pulp and biomass<br />

which has motivated new investment in the<br />

state, but now there are real questions about<br />

who is going to do the work. If the contractor<br />

workforce was not really there, could all of<br />

these new investments actually come to<br />

fruition? Would investment continue to occur<br />

if logging and trucking capacity was in<br />

question?<br />

Following the collection of survey<br />

data and the general idea that contractors<br />

could not fulfill the demands they had<br />

presently, not to mention the additional work<br />

they had on the horizon as a result of mill<br />

8 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Nicols Brothers Inc. logging operations underway in Winthrop in March.<br />

expansions, the <strong>PLC</strong> Board decided it was<br />

time to get a third party assessment of the<br />

labor and wage picture both now and the<br />

future. How do we stack up against other<br />

industries and is the company by company<br />

picture the same on a larger scale?<br />

In February, the <strong>PLC</strong> reached out to<br />

the Maine Center for Business and Economic<br />

Research at the University of Southern Maine<br />

and asked Dr. Ryan Wallace and his team to<br />

compare logging and trucking against other<br />

similar industries and determine what we are<br />

really up against with respect to wages and<br />

benefits. Is it nearly impossible to hire new<br />

employees or replace old ones if the pool of<br />

people with similar skills are not willing to<br />

work in logging and heavy duty trucking? If<br />

the sense of freedom and autonomy which has<br />

always driven employees to this business,<br />

along with the enjoyment of the outdoors, is<br />

not enough to attract them anymore if the<br />

wages and benefits are not competitive? Is the<br />

labor shortage real and is it attributable to low<br />

wages and long hours and the fact that<br />

contractors can’t afford to pay their<br />

employees more money and still remain<br />

profitable?<br />

What we found was quite astounding<br />

and now we have the data to back it up.<br />

Put simply, Maine is facing a<br />

shortage of loggers and log truckers that will<br />

grow and could hinder the growth of the<br />

forest products industry in the state if wage<br />

growth does not occur. Wages for logging<br />

equipment operators and log truckers in<br />

Maine are lower than those for comparable<br />

jobs in competing industries in the state, and<br />

this combined with a tight labor market and<br />

looming retirement for large numbers of<br />

loggers is not a positive sign.<br />

This analysis simply confirms and<br />

reinforces what many in this industry have<br />

known for a long time. The root of Maine’s<br />

vital forest products economy - the logging<br />

industry - must be able to offer higher wages<br />

to compete for existing workers and attract<br />

new ones at a time when they are desperately<br />

needed to support a resurgent forest products<br />

industry.<br />

The heart of the problem is profit<br />

margins for logging contractors have<br />

dwindled as costs of doing business have<br />

risen, limiting the ability of contractors to<br />

raise pay for workers. With low<br />

unemployment and strong competition for<br />

skilled operators of heavy machinery and<br />

trucks, logging contractors are struggling<br />

simply to keep the workers they have, let<br />

alone attract new ones.<br />

As I mentioned previously, we know<br />

from surveying our own membership, that the<br />

industry is already unable to fill an estimated<br />

750 to 1,000 jobs today. Add to that the<br />

projected loss of upwards of 200 workers per<br />

year over the next 10 years due to retirements,<br />

coupled with the need for more loggers and<br />

truckers to meet rising demand for wood from<br />

expansions that have been announced by mills<br />

in the state recently and you begin to see the<br />

extent of this problem.<br />

In addition to Maine expansions<br />

already announced by mill owners including<br />

Verso, Sappi, Nine Dragons, and Pleasant<br />

River Lumber, the FOR/Maine (Forest<br />

Opportunity Roadmap), a broad coalition that<br />

the <strong>PLC</strong> is working with to diversify the<br />

Doran Continued Page 13<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 9

J<br />

ACKMAN - Russ Griffin was one year old when his<br />

family moved from Levant to the Jackman area, and<br />

he has lived in this Maine border region ever since,<br />

working in the woods from his early teenage years<br />

through decades of major change in the logging industry<br />

and the state.<br />

His father, Reginald, and grandfather came to the<br />

area in the late 1960s when the industry was booming,<br />

trucking with wheelers for several years before getting into<br />

logging themselves in the 1970s. In 1976 his father was<br />

one of the partners who started Moose River Lumber<br />

company.<br />

“So my father went from trucking to logging to<br />

sawmilling,” Russ laughed, “That’s the woods business.”<br />

Reginald got out of the sawmill business in 1981,<br />

going back to logging, and founding Jackman Lumber.<br />

“That’s about when I got into it,” Russ said. “I<br />

started officially when I was about 15, but from 12 years<br />

old that was all I’ve done my whole life. The name<br />

Jackman Lumber came from when we had thoughts that he<br />

Jackman Lumber Co. truck loading in Moose River in early March.<br />

10 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Jackman Lumber<br />

was gonna build his own sawmills again, but it never<br />

happened and it stayed logging and trucking.”<br />

It still is today.<br />

Back in the 1980s when Russ started full time with<br />

the company, Jackman Lumber was running traditional<br />

hand crews and cable skidders in the woods. The first step<br />

in the move to mechanized logging came when the<br />

company added stroke delimbers so the crews could fell the<br />

trees but leave the limbing portion of the work to the<br />

delimbers on the landings. Over time feller bunchers and<br />

grapple skidders were added to make the company fully<br />

mechanized.<br />

“We only cut softwood in the 80s, and then in the<br />

early 90s we worked with ProPac to build the first<br />

hardwood delimbers, we had the prototype and we worked<br />

with them on building that and it went on to be a pretty<br />

successful thing and they’re still making them today,” Russ<br />

said. “So I figure we pioneered the hardwood delimbing<br />

with stroke delimbers, but now I’ve converted to a cut to<br />

length system, we’ve been cut to length for almost 10<br />

years. We’ve moved more to smaller wood, and I think it<br />

works better with the smaller wood.”<br />

The size of the company has changed a lot<br />

over the years. At its peak in the late 1990s the company<br />

had about 50 employees. There were six feller buncher<br />

crews and more than 20 trucks. Like most logging<br />

contractors in Maine, Jackman Lumber met big challenges<br />

in the next two decades with market changes, rising costs,<br />

and closing mills, and in response the company downsized<br />

repeatedly.<br />

Today Jackman Lumber has gone as small as it<br />

can, down to a five-man crew. The crew includes two truck<br />

drivers, himself running a processor, one man in the<br />

garage, and his long-time feller buncher and forwarder<br />

operator and mechanic, Ed Griffin - no relation, “he keeps<br />

our stuff running,” Russ said. Jackman Lumber has three<br />

trucks; a Peterbilt, a Western Star, and an International.<br />

The company does its own low bedding and also hauls for<br />

Jackman Lumber Continued Page 12<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 11

Jackman Lumber Continued from Page 11<br />

other companies in the area. In the woods, Jackman<br />

Lumber operates a CAT 511 processor, A John Deere 753<br />

feller buncher, and a CAT 564 forwarder. It also has an<br />

excavator, dump truck, and three log cranes. The company<br />

once had two chippers, but the chip market has largely<br />

disappeared. The company also<br />

used to travel to more distant jobs,<br />

but these days works primarily<br />

within an hour of Jackman.<br />

“I have a saying, I’ll work<br />

from here to tidewater,” Russ said.<br />

“I’ve worked quite a bit in<br />

Frankfort, Winterport, Levant,<br />

I’ve cut quite a bit on some of our<br />

family land in Levant, and I own a<br />

lot in Frankfort and Liberty, so<br />

I’ve traveled around quite a bit.”<br />

For the past five years,<br />

Jackman Lumber has worked<br />

about half the time on<br />

Weyerhauser lands and the other<br />

half on private lots. Their primary<br />

markets for wood are the Moose<br />

River Lumber mill which is less<br />

than a mile from their shop, and<br />

the Sappi Somerset Mill in<br />

Skowhegan, 75 miles down Route<br />

201.<br />

Reginald Griffin died in 2014<br />

after a long and respected career in the<br />

woods, but Russ’s mother Linda<br />

remains involved with Jackman<br />

Lumber to this day, overseeing the<br />

books and remaining a part owner of<br />

the company.<br />

Linda Griffin built Jackman<br />

Lumber with her husband and both<br />

were leaders in Maine’s forest products<br />

industry over the years. Linda is a Past<br />

President of the Maine Forest Products<br />

Council. Russ said that over time the<br />

Griffins came to feel that loggers<br />

needed their own organization to better<br />

meet their needs and fight for their interests, and so when<br />

the Professional Logging Contractors of Maine (<strong>PLC</strong>) came<br />

along and begin to fill that role, Jackman Lumber joined<br />

the <strong>PLC</strong>. The company is also Master Logger certified.<br />

“I think it’s become a very good thing,” Russ said,<br />

noting the <strong>PLC</strong>’s advocacy for loggers in Augusta, its focus<br />

on safety and professionalism, and its work to inform and<br />

educate the public on the logging industry. “I’ve been<br />

pretty happy with the organization.”<br />

Speaking out for the industry is something Russ is<br />

known for. He has a small but devoted following on<br />

Facebook for his regular “Stump Report” where he offers<br />

blunt commentary on many issues of importance to loggers<br />

Top, Jackman Lumber processor in action.<br />

Bottom, Linda and Russ Griffin.<br />

and other small businesses in Maine’s forest economy.<br />

With some of the viewers including lawmakers in Augusta,<br />

it is not unheard of for an issue or viewpoint Russ shares to<br />

make its way into legislative discussions.<br />

One of the most<br />

important issues to Russ is<br />

preservation of the longstanding<br />

tradition in Maine of keeping<br />

forests open to hunting and<br />

fishing and other recreation by<br />

maintaining their status as<br />

working woodlands - a viewpoint<br />

shared and championed by the<br />

<strong>PLC</strong>.<br />

“The biggest concern I<br />

have is the evaporating land base.<br />

I think over time as loggers we<br />

kind of did our own thing and we<br />

didn’t say much and now I’m<br />

seeing the movement of the<br />

environmental groups buying up<br />

the land bases we depend on and<br />

I’ve become very vocal about it,”<br />

Russ said. “We’re not going to<br />

have a land base to operate on<br />

anymore if we don’t try to combat<br />

this somehow and discourage<br />

landowners from selling to<br />

environmental groups that are basically<br />

locking up land forever. Its dealing a<br />

blow to the people of Maine that don’t<br />

really deserve it.”<br />

For Jackman Lumber, logging<br />

is what pays the bills but Russ has long<br />

enjoyed the trucking side of the<br />

business and sees growth potential for<br />

his company there given the strong<br />

demand for trucking, so he is already<br />

hauling for other companies and hopes<br />

to do more in the future.<br />

“I’m determined to make my<br />

trucking successful,” Russ said. “I think<br />

there’s some future in it because there’s<br />

a need.”<br />

While recent years have been rough ones in<br />

Maine’s logging industry, Russ said he is encouraged by<br />

mills beginning to make a comeback in the state after years<br />

of closings. Overall logging capacity has shrunk as logging<br />

contractors shut down in response to reduced markets, and<br />

now he believes that as demand rises those contractors who<br />

are still standing will be well positioned to capitalize on<br />

that demand.<br />

“Anyone that’s still standing today is a tough son<br />

of a gun,” Russ said. “I do still really enjoy it other than the<br />

winters are starting to be really painful - that’s age I guess,<br />

but I’m gonna stick with what I know to the end.”<br />

12 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Doran Continued from Page 9 16<br />

state’s wood products businesses, attract capital investments,<br />

and develop greater economic prosperity for communities<br />

impacted by recent mill closures has announced an action<br />

plan to grow Maine’s forest economy from the current $8.5<br />

billion (annual) to $12 billion by 2025. This growth would<br />

position the state to compete in and take advantage of<br />

substantial global market opportunities with much of the<br />

projected 40 percent growth coming from new markets for<br />

the state. Such growth would also require a significant<br />

expansion of the logging and log trucking workforce in<br />

Maine.<br />

Key findings of the employment availability and<br />

wage study include:<br />

· Although capital expenses in the logging industry<br />

have risen across the board, rates for wood harvesting and<br />

trucking have not.<br />

· Recently announced expansions increasing demand<br />

for wood will require an additional 100 jobs in the logging<br />

industry in the immediate future. In addition, occupation<br />

projections suggest upwards of 200 workers per year will need to<br />

be replaced over the next 8-10 years due to an aging logger<br />

workforce.<br />

· Business critical occupations in the logging<br />

industry, including equipment operators and truck drivers<br />

which comprise 2 out of every 3 jobs, currently earn relative<br />

wages well below comparable occupations in other industries,<br />

making it difficult to recruit and attract workers. Logging<br />

equipment operators ranked lowest for wages out of 19<br />

comparable skilled occupations surveyed, while logging truck<br />

drivers ranked second to last for wages out of 14 heavy truck<br />

driving sectors.<br />

· The average earnings for all employment in<br />

Maine’s logging industry have increased by 5% since 2010,<br />

an average increase of just over $2,100 per worker compared<br />

to an average increase of $5,500 in comparative industries,<br />

such as construction, wood manufacturing, and pulp and<br />

paper manufacturing.<br />

· Over 400 workers in the industry are at retirement<br />

age (65+), while an additional 850 workers will be reaching<br />

retirement age within the next 10 years. Attracting younger<br />

generations of workers will be critical in replacing the retiring<br />

workforce.<br />

All of this data and the findings of this report brings<br />

me back to a discussion point I mentioned in my last article in<br />

January and one that needs to be revisited. Contractors own<br />

and operate businesses with the intent to earn a return; they<br />

are not in business to subsidize the financial returns of their<br />

customers. During a time of high prices for lumber markets<br />

and increasing pulp demand, far too many contractors in<br />

Maine are running on borrowed time. Despite some price<br />

creep and increased demand for wood, a majority of<br />

contractors are still reporting much lower profit margins. And<br />

when it comes to cost savings in the supply chain, loggers<br />

have nothing left to give. Any business that does not earn a<br />

return, closes down. It’s that simple.<br />

Back in January, I was reading the blog of a<br />

management company who will remain nameless. In that<br />

article, the author discussed a recent timber sale negotiation<br />

that they conducted with a landowner. The management<br />

company took great pride in the fact that they competed<br />

against a logger to earn the sale and boasted that they could<br />

provide more value to the landowner as a service provider,<br />

could hire a logger to work for them and at the end of the day<br />

would provide a greater financial return to the landowner than<br />

if they contracted directly with the logger. Furthermore, the<br />

logger really wasn’t trustworthy, and it was absolutely<br />

necessary for the landowner to have an intermediary involved<br />

as a result of this trust. Wow!! Not only was I angered to hear<br />

this kind of double talk, but I found this to be exactly what is<br />

wrong with the system that contractors operate in today.<br />

Can you imagine what backlash the logger would<br />

feel if they publicly scrutinized a management company this<br />

way?<br />

I guess all is fair in competitive business, but is this<br />

really the kind of environment we want the landowner<br />

community to be subjected to? Further, this is also exactly<br />

why contractors can barely afford to stay in business. We<br />

have a system in place that encourages the control,<br />

manipulation and degradation of the logger at the logger’s<br />

expense. No wonder loggers cannot hire good people and pay<br />

them a living wage when those who exert control use profit as<br />

a four-letter word and try to use scare tactics against them.<br />

To use an analogy, do architects use these same<br />

tactics when working with property owners? Do they scare<br />

the property owner and tell them they cannot trust their<br />

building contractor? Do engineers use these tactics in similar<br />

circumstances when competing against plumbers and HVAC<br />

professionals? I have a feeling it is a violation of their license<br />

and their professional code of ethics. So, if this is the case in<br />

those professions, shouldn’t it be the same in this business?<br />

I bring up this example because I’m hearing stories<br />

like this more and more as the competition for wood<br />

increases. <strong>Loggers</strong> can compete with anyone, but the playing<br />

field should be equalized and there should be a better level of<br />

respect at this point in time because there isn’t, “just another<br />

logger out there that can take the job.”<br />

We hear all the time that this is a supposed to be a<br />

three-legged stool and the chain is only as strong as its<br />

weakest link. Well, the stool is broken and if it’s going to<br />

stand, it has to stand on its own. If one leg is going to push<br />

the other one down or continues to try to make one leg<br />

stronger than the other, the stool will ultimately fall.<br />

As you start to unwind this spring and look at your<br />

business, please take a look at the study we just released and<br />

see how it compares to your business. If the data is similar<br />

and you don’t see things changing, don’t hesitate to refer to<br />

this in your discussions moving forward. In the end, loggers<br />

are the root of the industry and must speak with one voice.<br />

Now might be the time to use it.<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong><br />

13

Maine Logger and Log Trucker Employment Availability and<br />

Wage Analysis Report Released<br />

AUGUSTA - Maine is facing a shortage of loggers<br />

and log truckers that will grow and could hinder the growth<br />

of the $8.5 billion forest products industry in the state if<br />

wage growth does not occur, an occupational analysis<br />

released in March concludes.<br />

The employment availability and wage analysis<br />

prepared by the Maine Center for Business and Economic<br />

Research at the University of Southern Maine found wages<br />

for logging equipment operators and log truckers in Maine<br />

are lower than those for comparable jobs in competing<br />

industries in the state, and this combined with a tight labor<br />

market and looming retirement for large numbers of loggers<br />

is concerning for Maine’s forest economy.<br />

in Maine, that the industry is already unable to fill an<br />

estimated 750 to 1,000 jobs today,” Doran said. “Add to that<br />

the projected loss of upwards of 200 workers per year over<br />

the next 10 years due to retirements, coupled with the need<br />

for more loggers and truckers to meet rising demand for<br />

wood from expansions that have been announced by mills in<br />

the state recently and you begin to see the extent of this<br />

problem.”<br />

In addition to Maine expansions already announced<br />

by mill owners including Verso, Sappi, Nine Dragons, and<br />

Pleasant River Lumber, the FOR/Maine (Forest Opportunity<br />

Roadmap), a broad coalition working to diversify the state’s<br />

wood products businesses, attract capital investments, and<br />

“profit margins for logging contractors have<br />

dwindled as costs of doing business have<br />

risen, limiting the ability of contractors to<br />

raise pay for workers”<br />

“This analysis simply confirms and reinforces what<br />

many in the industry have known for a long time,” Dana<br />

Doran, Executive Director of the Professional Logging<br />

Contractors of Maine (<strong>PLC</strong>), which commissioned and<br />

partnered with the Center on the study, said. “The root of<br />

Maine’s vital forest products economy - the logging industry<br />

- must be able to offer higher wages to compete for existing<br />

workers and attract new ones at a time when they are<br />

desperately needed to support a resurgent forest products<br />

industry.”<br />

The heart of the problem is profit margins for<br />

logging contractors have dwindled as costs of doing<br />

business have risen, limiting the ability of contractors to<br />

raise pay for workers. With low unemployment and strong<br />

competition for skilled operators of heavy machinery and<br />

trucks, logging contractors are struggling simply to keep the<br />

workers they have, let alone attract new ones, Doran said.<br />

“We know from surveying our own membership,<br />

which cuts approximately 75 percent of all wood harvested<br />

develop greater economic prosperity for communities<br />

impacted by recent mill closures has announced an action<br />

plan to grow Maine’s forest economy from the current $8.5<br />

billion (annual) to $12 billion by 2025. This growth would<br />

position the state to compete in and take advantage of<br />

substantial global market opportunities with much of the<br />

projected 40 percent growth coming from new markets for<br />

the state. Such growth would also require a significant<br />

expansion of the logging and log trucking workforce in<br />

Maine, Doran noted.<br />

▪ The Executive Summary of the study is available at:<br />

http://maineloggers.com/new/wp-content/uploads/<strong>2019</strong>/03/<br />

Professional-Logging-Contractors-of-Maine-Occupational-<br />

Wage-Analysis_final-1.pdf<br />

▪ The Full Report is available here: http://<br />

maineloggers.com/new/wp-content/uploads/<strong>2019</strong>/03/<br />

Professional-Logging-Contractors-of-Maine-Occupational-<br />

Wage-Analysis-Data-Appendix-FINAL.pdf<br />

14 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Legislative Breakfast<br />

A great success!<br />

The <strong>PLC</strong>'s Annual Legislative Breakfast<br />

was a great success March 14th, drawing<br />

a crowd of more than 100 to the<br />

Governor's Hill Mansion in Augusta to<br />

hear directly from our Members about<br />

the challenges in Maine's logging<br />

industry and the importance of the<br />

Legislature to our efforts to sustain and<br />

improve that industry.<br />

Thanks to the many lawmakers who<br />

attended, including Senate President<br />

Troy Jackson of Allagash and Speaker of<br />

the House Sara Gideon of Freeport.<br />

Thanks also to our <strong>PLC</strong> Board Members<br />

who did such a great job standing up to<br />

speak about issues that were highlighted<br />

during the event including worker<br />

shortages and the need for higher wages<br />

for logging operators and log truckers.<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 15

The <strong>PLC</strong> of Maine 24th Annual<br />

Meeting<br />

April 26, <strong>2019</strong> - Oxford Casino & Event Center, Oxford, ME<br />

An Invitation,<br />

Please join us for our 24th<br />

Annual Meeting to learn and network<br />

with other professional loggers as we<br />

look toward the future.<br />

24TH<br />

ANNUAL<br />

MEETING<br />

Highlights<br />

-Nine Dragons<br />

-Commissioner of Agriculture,<br />

Conservation & Forestry<br />

-Legislative Leadership<br />

-Children's Miracle Network Children<br />

-Log A Load Auction<br />

-<strong>PLC</strong> Annual Awards<br />

The Morning Session is only for <strong>PLC</strong> Contractor<br />

Members. During this time, we will: Conduct a<br />

general membership meeting, hold Board elections<br />

and review our legislative agenda. Acadia Insurance<br />

will let us know how the dividend program<br />

performed in 2018, hear from the new<br />

Commissioner of the Department of Agriculture,<br />

Conservation and Forestry and Nine Dragons to learn<br />

about their expansion plans in Rumford and Old<br />

Town.<br />

During our Luncheon, which is open to all <strong>PLC</strong><br />

Contractor Members, Supporting Members and<br />

invited guests, we will hear from the President of the<br />

Senate , Troy Jackson and Speaker of the House, Sara<br />

Gideon about policies to ensure profitability for<br />

Maine <strong>Loggers</strong>.<br />

We reconvene at 4:00 pm for our social hour and<br />

time to preview the Log A Load Auction items, open<br />

to all <strong>PLC</strong> Contractor Members, Supporting<br />

Members and invited guests.<br />

To help the Children’s Miracle Network raise<br />

money, our Log A Load Auction will be kicked<br />

off by a Miracle Network Children.<br />

Can we exceed the $46,000 we raised in 2018?<br />

Dinner will include a welcome and remarks from<br />

<strong>PLC</strong> President, Jim Nicols and remarks from<br />

Congressman Jared Golden, 2nd District (Invited).<br />

The Master Logger Certificate Ceremony will<br />

follow and the night will conclude with the <strong>PLC</strong>’s<br />

annual awards presentation.<br />

Dinner Guests — Join us for a buffet dinner and the honor<br />

of meeting a couple of the many children helped by the<br />

Children’s Miracle Network (CMN), Hazel and Edgar are<br />

wonderful children who would like to share their story!<br />

Meet the amazing people that our fundraising is impacting<br />

and feel the difference that we are making!<br />

In 2018 the <strong>PLC</strong> of Maine raised over $122,000 to<br />

support local Maine children!<br />

Creating Real Miracles by Raising Funds for Local Hospitals<br />

Since 1983, Children’s Miracle Network (CMN) Hospitals<br />

have raised more than $5 billion for 170 children’s<br />

hospitals across the United States and Canada. The <strong>PLC</strong> of<br />

Maine and Eastern Maine Healthcare Systems (EMHS)<br />

Foundation have raised over $1,129,000 since 1996 for<br />

children in Maine. These donations have gone to support<br />

research and training, purchase equipment, and pay for<br />

uncompensated care, all in support of the mission to save<br />

and improve the lives of as many children as possible. Some<br />

are battling cancer, some are suffering from a traumatic<br />

injury, and others require constant care because they were<br />

born too early, or with a genetic disease.<br />

14 Professional Logging April Contractors 26, <strong>2019</strong> - Oxford of Maine Casino & Event Center, <strong>Loggers</strong> Oxford, Serving ME <strong>Loggers</strong> Since 1995

Meeting Agenda:<br />

24TH<br />

ANNUAL<br />

MEETING<br />

REGISTER NOW!<br />

WE NEED AUCTION ITEMS FOR LOG A LOAD!<br />

Morning Session<br />

<strong>PLC</strong> Contractor Members Only<br />

7:30 AM Registration<br />

(Coffee & Continental Breakfast)<br />

8:00 AM Full Board and General Membership Meeting,<br />

Board Elections, Legislative Update and Acadia<br />

Dividend Program Update.<br />

10:00 AM Amanda Beal, Commissioner of Agriculture,<br />

Conservation and Forestry<br />

Director of the Maine Forest Service<br />

11:00 AM Randy Chicoine, Mill Manager, Nine Dragons<br />

- expansion plans in Rumford and Old<br />

Town<br />

Afternoon Session<br />

<strong>PLC</strong> Contractor Members, Supporting Members<br />

& Invited Guests<br />

12:00 PM Lunch Buffet<br />

Children’s Miracle Network Auction<br />

Would you like to donate an item or cash?<br />

Contact Jessica at jessica@maineloggers.com<br />

12:30 PM Luncheon Speakers:<br />

<strong>2019</strong> Maine Legislature – Policies to<br />

Ensure Profitability for Maine <strong>Loggers</strong>.<br />

- President of the Senate, Troy Jackson<br />

- Speaker of the House, Sara Gideon<br />

2:00-4:00 PM Afternoon Break<br />

Evening session<br />

<strong>PLC</strong> Contractor Members, Supporting Members, Invited Guests<br />

4:00 PM Social Hour—Auction Items Preview<br />

5:00 PM Children’s Miracle Network Children & Log A Load for Kids—Special Guest Auctioneer—Scott Hanington<br />

6:00 PM Dinner Buffet<br />

6:45 PM <strong>PLC</strong> President’s Welcome & Congressman Jared Golden, 2nd District (Invited)<br />

7:00 PM Presentation of Master Logger Supporter Award & Presentation of Certificates to 2018 Cohort of Certified<br />

Master Logger Companies<br />

7:30 PM Awards Presentation: <strong>PLC</strong> Logger of the Year, Acadia Insurance Safety Award, <strong>PLC</strong> Impact Award,<br />

<strong>PLC</strong> Community Service Award, Supporting Member Award & <strong>PLC</strong> President’s Award<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 15 17

Photos<br />

Top: Groundtek Inc.<br />

low-bedding<br />

equipment.<br />

OWNERS: Bruce and Meagan Plourde<br />

YEAR FOUNDED: April 2009<br />

ADDRESS: South Perley Brook Road, Fort Kent, Maine.<br />

Below: Bruce<br />

Plourde.<br />

Opposite: Groundtek<br />

Inc. Western Star.<br />

PHONE NUMBER: (207) 316-3006<br />

EMPLOYEES: 6<br />

TRUCKS: 2 Western Star 4900 heavy haul trucks, 1 Western<br />

Star 4900 dump truck, 1 International 9370 eagle dump truck<br />

AREA OF OPERATION: Aroostook County<br />

SERVICES PROVIDED: Construction, excavation, concrete<br />

work, sewer systems, retainer walls, heavy equipment<br />

transportation up to 55 tons, on and off road hauling<br />

<strong>PLC</strong> FOREST CONTRACTOR SINCE: January <strong>2019</strong><br />

18 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

WHY DID THE COMPANY JOIN <strong>PLC</strong>: “<strong>PLC</strong> is a wonderful group with a voice. They work for the<br />

people and give us the opportunity to be heard at different levels of the state. They provide great<br />

trainings and accommodate all areas of the forest industry.”<br />

WHAT ARE THE BIGGEST ISSUES THE COMPANY WOULD LIKE <strong>PLC</strong> TO WORK ON:<br />

“Currently <strong>PLC</strong> is assisting us with the process of lowbed transportation permitting, rules and<br />

regulations.”<br />

Trucking section Continued Page 20<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 19

Trucking Industry News...<br />

FMCSA Updates SMS Website...<br />

FMCSA has updated the CSA SMS Website with<br />

the February 22, <strong>2019</strong> results.<br />

Motor carriers participating in FMCSA’s Crash<br />

Preventability Demonstration Program will continue to<br />

see the Agency’s final determinations on SMS for crashes<br />

reviewed as part of the program. Logged-in carriers and<br />

enforcement users with crashes determined to be Not<br />

Preventable as part of the program can view measures and<br />

percentiles calculated with and without those crashes.<br />

View the site here: https://maineloggers.us10.listmanage.com/track/click?<br />

u=50356bc32e7c1ced15b258bf6&id=7bae694128&e=114d<br />

18f9f8<br />

FMCSA Launches Drug and Alcohol Clearinghouse<br />

Website...<br />

FMCSA has launched a new website with<br />

information about the Commercial Driver’s License Drug<br />

and Alcohol Clearinghouse. Visit https://<br />

clearinghouse.fmcsa.dot.gov to learn more about how<br />

CDL drivers and their employers will be required to use the<br />

Clearinghouse beginning January 6, 2020. You will be able<br />

to sign up for email updates.<br />

Canadian Revenue Agency Notice of Fuel Charge<br />

and Registration Requirements...<br />

A new fuel charge, administered by the Canada<br />

Revenue Agency (CRA), was introduced as part of the<br />

Greenhouse Gas Pollution Pricing Act.<br />

The fuel charge is expected to be effective April 1,<br />

<strong>2019</strong> for the provinces of Manitoba, New Brunswick,<br />

Ontario and Saskatchewan and July 1, <strong>2019</strong> for the<br />

territories of Nunavut and Yukon.<br />

The attached informational bulletin, provided by<br />

the CRA, details the fuel charge plan. IFTA, Inc. is<br />

forwarding this bulletin to provide jurisdictions with<br />

20 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

information to assist their carriers. It will also be posted on<br />

the IFTA Inc. website.<br />

The registration materials are available at:<br />

https://www.canada.ca/en/revenue-agency/services/tax/<br />

excise-taxes-duties-levies/fuel-charge.html<br />

Unified Carrier Registration Online Service…<br />

This service allows Maine based individuals and<br />

companies that operate commercial motor vehicles in<br />

interstate or international commerce to register their<br />

business and pay the annual UCR fee based on the size of<br />

their fleet. Brokers, freight forwarders, and leasing<br />

companies are also required to register and pay a fee equal<br />

to the lowest fee tier. Companies providing both motor<br />

carrier services as well as broker, freight forwarder or<br />

leasing services are required to pay the fee level set at the<br />

motor carrier level.<br />

Roadside enforcement period will begin April 1,<br />

<strong>2019</strong>. You can access the payment portal at Maine<br />

BMV here: https://maineloggers.us10.list-manage.com/<br />

track/click?<br />

u=50356bc32e7c1ced15b258bf6&id=d4a06e1c92&e=114d<br />

18f9f8<br />

Open Seats for Class A CDL Program…<br />

Eastern Maine Community College's January 14th<br />

CDL class was postponed and the college is seeking to add<br />

a few more participants, like you! Class will run from noon<br />

to 6 p.m. for the first few weeks. Driving and range times<br />

will be scheduled during class to accommodate your<br />

schedule.<br />

The next classes are scheduled to start:<br />

June 3.<br />

Learn more at: https://www.emcc.edu/workforcedevelopment/non-credit-classes/commercial-drivers-license<br />

-cdl-training-center/<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 21

<strong>PLC</strong> Supporting Member Spotlight<br />

B<br />

REWER - There are few companies as deeply<br />

embedded in Maine’s logging industry today as<br />

Milton CAT.<br />

Milton CAT heavy equipment can be<br />

found working in Maine forests from Fort Kent to Kittery,<br />

and the state’s loggers have been reliable and solid<br />

customers for the company for decades. Now, though the<br />

company is changing some of its approach to the forest<br />

equipment market, its commitment to the Maine logging<br />

industry remains as strong as ever.<br />

“For us, Maine is a big piece of the pie,” Peter<br />

Collins, Forest Industry Manager for Milton CAT said<br />

recently during a discussion at the company’s Brewer<br />

location, the distribution center for all forestry parts for<br />

Milton CAT. “Maine is historically about half the<br />

opportunity in terms of forestry machine sales for the<br />

entire territory.”<br />

Those equipment sales are critical to the<br />

company, and so is the Maine logging industry, Collins<br />

said.<br />

From its start in a dirt floor garage in Concord,<br />

New Hampshire, Milton CAT has grown to 12 locations,<br />

spanning a six-state territory. Two of those locations are in<br />

Maine; Brewer and Scarborough.<br />

Milton CAT has over 1,000 employees, many with<br />

twenty, thirty or even forty years of service at the<br />

company, and it's widely recognized by Caterpillar as<br />

being one of its top performing dealerships worldwide.<br />

Milton CAT still runs on the same philosophy that<br />

made the company successful in its early years. The<br />

company's growth and reputation have been a result of<br />

experience, continuity of purpose, empowering employees,<br />

and a longstanding partnership with Caterpillar.<br />

A privately-held company, Milton CAT is owned<br />

by the Milton family. Dealer principal and Chief Executive<br />

Officer Chris Milton, is the third-generation Milton to be<br />

at the helm of a Caterpillar dealership. Chris Milton's<br />

father, Jack, learned the ropes under his father, Milt<br />

Milton, at former Massachusetts CAT dealership Perkins-<br />

Milton. In 1960, Jack Milton and partner Bill Jordan<br />

founded Jordan-Milton Machinery and represented<br />

Caterpillar equipment and engines in New Hampshire and<br />

Vermont, expanding into Maine with the acquisition of<br />

Arnold Machinery Company in 1982. In 1991, Jordan-<br />

Milton acquired Southworth Machinery and the company<br />

name became Southworth-Milton. That name was changed<br />

to Milton CAT shortly after the company expanded its<br />

territory into western New York with the acquisition of<br />

bordering CAT dealership Syracuse Supply Company in<br />

2004.<br />

Today, the company's products and technology<br />

can be found in logging camps and nuclear facilities; dairy<br />

farms, U.S. Army Defense installations, hospitals, lobster<br />

boats and underground salt mines; solid waste landfills,<br />

data centers, paving projects and ferries; commuter rail<br />

trains, quarries, school buses and on job sites of all sizes.<br />

22 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Peter Collins has been with the company for 36<br />

years and his long-time customers include many founding<br />

members of the Professional Logging Contractors of Maine<br />

(<strong>PLC</strong>). He has worked with multiple generations of many<br />

well-known Maine logging families.<br />

Milton CAT’s relationship with the <strong>PLC</strong> began<br />

long before the organization offered Supporting<br />

Memberships (Milton CAT is an Enhanced Supporting<br />

Member). The company has been a strong supporter of<br />

<strong>PLC</strong>’s Log A Load for<br />

Maine Kids annual<br />

fund raising efforts<br />

and other initiatives<br />

over the years.<br />

Among the<br />

most noteworthy of<br />

Milton CAT’s more<br />

recent contributions to<br />

the <strong>PLC</strong>’s efforts has<br />

been the company’s support for the Mechanized Logging<br />

Operation Program (MLOP), launched three years ago to<br />

provide entry level training for mechanized logging<br />

operators. The program was created thanks to a partnership<br />

between three Maine community colleges, the <strong>PLC</strong>, and<br />

industry partners including Milton CAT and Nortrax.<br />

The program gives students a broad overview of<br />

the most common mechanical systems found in modern<br />

timber harvesting equipment, an understanding of the<br />

variables of timber growth, tree species, and markets, and a<br />

strong emphasis on safety. It also includes hands-on<br />

training in mechanized logging equipment, and Milton<br />

CAT has provided half the equipment for the training<br />

program since its start. On the Milton CAT website, a<br />

video promoting MLOP is prominently displayed in the<br />

forestry section.<br />

Like most companies involved in Maine’s logging<br />

industry, Milton CAT realizes there is a skilled worker<br />

shortage in the state’s forest economy, particularly for<br />

mechanized logging operators and truck drivers, Collins<br />

said.<br />

“I think the training program is a good thing as we<br />

try to deal with the situation, and I think Milton CAT has<br />

put some money and<br />

some emphasis on that<br />

because you’ve got to<br />

try and do something<br />

about it,” Collins said.<br />

Milton CAT<br />

has served Maine<br />

loggers through major<br />

changes and challenges<br />

in the industry, and is committed to maintaining the health<br />

of that industry.<br />

In August 2018 Caterpillar Inc. announced a major<br />

change for the industry itself - Caterpillar had entered into<br />

a preliminary agreement with Weiler, Inc. to sell its<br />

forestry product business, which includes Wheel Skidders,<br />

Track Feller Bunchers, Wheel Feller Bunchers and<br />

Knuckleboom Loaders. As part of the sale, Weiler is taking<br />

ownership of the Caterpillar manufacturing plant in<br />

LaGrange, Georgia, the training center in Auburn,<br />

Alabama and the parts distribution center in Smithfield,<br />

North Carolina.<br />

For Milton CAT the announcement is bringing<br />

change, but not drastic change. Milton CAT already had a<br />

long-standing relationship with Weiler in the paving<br />

Milton CAT has been a strong supporter of the<br />

Mechanized Logging Operations Program since it<br />

began three years ago. Opposite: Graduates of the<br />

most recent class pose with a grapple skidder donated<br />

by Milton CAT for their use in the summer of 2018.<br />

Milton CAT Continued Page 24<br />

Alex Labonville, Sales Manager<br />

Cell: 207-233-4801<br />

www.labonville.com<br />

Ask about special <strong>PLC</strong> of<br />

Maine member only discounts!<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 23

Milton CAT Continued from Page 23<br />

business, and Weiler will be manufacturing track feller<br />

bunchers, skidders, rubber tired feller bunchers, and<br />

knuckle booms. The machines to mount delimbers on will<br />

still be manufactured by CAT.<br />

Milton CAT will remain the source for sales, parts<br />

and service on CAT forestry products as well as Weiler<br />

forestry products and will remain the source for parts and<br />

service on Prentice product as part of the deal as well.<br />

This spring Milton CAT is continuing to sell<br />

Milton CAT forestry equipment but it is anticipated that<br />

Weiler product will be available this year. Milton CAT is<br />

also selling Logset forwarders and processors, so the<br />

product lineup for the company is diversifying, but<br />

customers so far seem comfortable with the changes,<br />

Collins said.<br />

For Milton CAT the relationship with the <strong>PLC</strong> and<br />

with Maine’s loggers is a natural one that is mutually<br />

beneficial, and that is not going to change, Collins said.<br />

“The membership needs to know how important<br />

their business is to our business, it’s not just an<br />

afterthought, Collins said. “Long term we’re committed to<br />

this and we’ve got a lot of different products that we’re<br />

working with now and Milton CAT’s still going to be in<br />

the forestry business, we’re not going anywhere.”<br />

Photos, top: MLOP students with CAT delimber in 2017.<br />

Bottom: A CAT log loader in action.<br />

24 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Mechanized Logging Operations Program Recruiting<br />

Students for Summer <strong>2019</strong><br />

STRATTON - Recruiting is now underway for<br />

students in the Mechanized Logging Operations Program<br />

(MLOP), which is beginning its next class June 24 in the<br />

woods of Western Maine.<br />

Students enrolled in the post-secondary training<br />

program will spend weeks harvesting timber using<br />

sophisticated state-of-the-art machines like those they will<br />

encounter in the logging industry. The hands-on experience<br />

students gain operating equipment is<br />

something unavailable anywhere else<br />

in Maine and neighboring states.<br />

This summer’s class will be<br />

the third since the program launched in<br />

2017. Graduation for the class will be<br />

held on Sept. 19.<br />

“I would encourage any<br />

individual with an interest in a goodpaying,<br />

exciting career in the Maine<br />

woods to take a look at the MLOP<br />

program,” Dana Doran, Executive Director of the<br />

Professional Logging Contractors of Maine (<strong>PLC</strong>), said.<br />

“There is literally no better or more efficient way to gain the<br />

experience and knowledge you need to become an<br />

equipment operator in the logging industry.”<br />

The Mechanized Logging Operations Program was<br />

created thanks to a partnership between three Maine<br />

community colleges, the <strong>PLC</strong>, and industry partners<br />

including Milton CAT and Nortrax.<br />

The program gives students a broad overview of the<br />

most common mechanical systems found in modern timber<br />

harvesting equipment, and an understanding of the variables<br />

of timber growth, tree species, and markets. It also includes<br />

a strong emphasis on safety.<br />

Students who are accepted into<br />

the program pay no tuition, but are<br />

responsible for transportation, housing,<br />

and food costs. Personal Protective<br />

Equipment (PPE) is provided by the<br />

program.<br />

A 2014 study by the <strong>PLC</strong><br />

found the average annual salary for<br />

workers employed by logging firms in<br />

Maine was $42,795. Mechanized<br />

logging operators are among the<br />

highest paid members of the logging workforce.<br />

Anyone with an interest in the program should<br />

contact Leah Buck at Northern Maine Community College<br />

at 207-768-2768. Information and application instructions<br />

may be found online at https://www.nmcc.edu/industrycustomized-training/mechanized-forest-operations/<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 25

SAFETY<br />

STARTS<br />

WITH ME<br />

<strong>2019</strong> Safety Training<br />

Presented by:<br />

SAFETY<br />

STARTS<br />

WITH ME<br />

<strong>PLC</strong>’s Safety Committee is committed to offering tools to help keep our members safe! The goal of this FREE, for <strong>PLC</strong><br />

Contractor members and Maine Master <strong>Loggers</strong>, training is to provide practical, hands-on instruction to improve<br />

individual & company safety. Still time to register for remaining classes! Go to http://maineloggers.com/safety/<br />

<strong>2019</strong> Logger Safety Training: 7:30 AM—3:30 PM<br />

Safety training is designed for all company employees and employees may attend one or both spring trainings.<br />

Topics: STOP The Bleed | Hydraulic Hazards | Road & Job Site Communication<br />

Accident Review - Report, Not Repeat | Falling Safely - I’ve Fallen & I can get up! | Driving Simulator<br />

Training locations:<br />

1S. Friday, April 5 th Denmark— John Khiel III Logging & Chipping, Inc.<br />

2S. Thursday, April 11 th Rumford—Nicols Bros.<br />

3S. Friday, April 12 th Waltham — Elliott Jordan & Son, Inc.<br />

4S. Friday, April 19 th Passadumkeag — Madden Timberlands, Inc.<br />

5S. Friday , May 3rd Stratton—Pepin Lumber<br />

6S. Thursday, May 9 th Millinocket— Gerald Pelletier, Inc.<br />

7S. Monday, May 13 th Lincoln — Treeline, Inc.<br />

8S. Wednesday, May 22 nd Fort Kent—TNT Road Company, Inc.<br />

9S. Friday, May 31 st Jackman—E.J. Carrier<br />

<strong>2019</strong> Fleet Training: 7:30 AM—3:30 PM<br />

Fleet Training is specifically designed for drivers, mechanics and loader operators. Employees may attend one or<br />

both spring trainings.<br />

Topics: Legal Liability—You said what?<br />

Troop-K: Practical Pre-Trip<br />

| Not your Daddy’s Diesel<br />

Ditch Diving & Digging Out | Trailer Tech. & Techniques | Driving Simulator<br />

Training locations:<br />

10F. Thursday, April 4 th Denmark— John Khiel III Logging & Chipping, Inc.<br />

11F. Thursday, April 18 th Milford—Randall Madden Trucking<br />

12F. Thursday, May 2 nd Stratton—Pepin Lumber<br />

13F. Tuesday, May 21 st Fort Kent— TNT Road Company, Inc.<br />

NEW FOR <strong>2019</strong> – During Fleet Trainings there are optional, alternative training classes:<br />

• CPR & First Aid certification— $35 a person (Company options available—see registration)<br />

• Maine Driving Dynamics Course—3 point credit on driving record - $10 a person<br />

26 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

The <strong>PLC</strong> would like to thank sponsors of the <strong>2019</strong> Safety<br />

Trainings<br />

Presenting Sponsor<br />

Presenting & Prize Sponsor<br />

Fleet Lunch Sponsor<br />

Lunch Sponsor<br />

Fleet Lunch Sponsor<br />

Break Sponsor<br />

Breakfast Sponsor<br />

Break Sponsor<br />

Knowledge Check & Prize Sponsor<br />

Safety Prize Sponsor<br />

Safety Prize Sponsor<br />

Safety Prize Sponsor<br />

There is still time to register for<br />

Safety and Fleet trainings! Visit<br />

http://maineloggers.com/safety/<br />

to learn more!<br />

The Logger’s <strong>Voice</strong> ▪ <strong>Spring</strong> <strong>2019</strong> 27

Wearing the right<br />

Safety Sunglasses<br />

By Donald Burr<br />

<strong>PLC</strong> Safety & Training Coordinator<br />

Today we are going to talk safety sunglasses. One<br />

of the standards that I apply to writing articles is can the<br />

everyday logger use this information to be safer and spend<br />

less money? In today’s topic I think the answer is yes.<br />

Buying the right safety sunglasses you get<br />

protection and you don’t have to spend a lot to get it. The<br />

average price for safety sunglasses is well under $20.00 (I<br />

saw some that meet the ANSI standard for $1.50 each), but<br />

you can spend hundreds if you want but you don’t get any<br />

better protection by spending the big money. Picking the<br />

right sunglasses is one of the most important things you<br />

should consider first before starting your day, every day.<br />

We are entering into longer days with brighter sun with<br />

snow & water bouncing the light around us into our eyes.<br />

You need to protect your eyes from the harmful UV rays.<br />

There are three different types of UV rays that we<br />

need to protect from: UVA, UVB and UVC, and it is<br />

important that your sunglasses protect you from UVA & B<br />

and here’s why.<br />

UVA rays affect the inner eye and can cause eye<br />

damage. These rays have a longer wavelength and can<br />

easily pass through glass.<br />

UVB rays also affect the inner and outer eye and<br />

most people have felt the effects of snow blindness and this<br />

is caused by UVB rays.<br />

The last is UVC, the good news here is that this is<br />

blocked by the earth’s upper atmosphere so we don’t have<br />

to worry about this type.<br />

All UV light is cut down by the earth’s<br />

atmosphere. This is not important to you unless you work<br />

in high altitudes areas or you’re a pilot, then you need to<br />

take extra precautions. The pilots wear those cool<br />

sunglasses not just for looks, they are functional too.<br />

Now whether or not you know the names of these<br />

rays or care it is important that you take steps to avoid<br />

exposure to these rays with sun glasses. Look for the<br />

amount of UV protection. Make sure it reads 99 - 100%.<br />

With UV protection settle for nothing less, and you<br />

shouldn’t because full protection does not have to cost a lot<br />

of money.<br />

Get sunglasses that wrap around your face because<br />

light can come in from the sides also and with your eyes<br />

dilated because you are looking through dark glasses you<br />

are letting in more harmful light from the sides. This goes<br />

for sunglasses that don’t have uv protection or have poor<br />

protection also.<br />

Sunglasses should take out most of the visible light<br />

(75% - 90%). This refers to how dark they are and if you<br />

look in a mirror and can see your eyes they are not dark<br />

enough.<br />

Make sure you get glasses that have good quality<br />

lenses. Take them off and look through them an arm length<br />

away and notice if the image stays consistent when moving<br />

over a straight line like a corner of a door or wall. If the<br />

straight line wobbles any these sunglasses are not good<br />

quality.<br />

Here are some special options that you can<br />

consider:<br />

Polarized: Cuts down the glare. Fishermen, river<br />

guides and skiers like these because of the high glare<br />

environment that they are operating in. Be aware that these<br />

will sometimes change your perception of color. A long<br />

time ago we sent a coworker to bring a group of people to<br />

the blue bus. He was wearing polarized sun glasses and the<br />

blue bus turned green. The funny thing was that it did not<br />

change the color of the other buses in line that happened to<br />

be green. So he looked and he looked and came back and<br />

said that there were no blue buses only green. I told him to<br />

take off his sunglasses and then tell us what he found.<br />

Bingo!<br />

Mirrored sunglasses: This is more than just a look.<br />

They are popular in high glare environments and with law<br />

enforcement and they tend to be good at filtering UV rays<br />

but not always. The one caution about these is that you can<br />

sunburn your nose and cheeks easily and then that leads to<br />

skin issues so remember to wear sun screen and reapply<br />

often.<br />

Impact resistant: Look for Z87 stamped on the<br />

frame somewhere. This is a reference to the ANSI high<br />

velocity impact resistant standard. Don’t buy safety<br />

sunglasses without it.<br />

I will leave you with this: put on your safety<br />

sunglasses and Hum a few bars of ZZ Top’s classic song<br />

“Cheap Sun Glasses”<br />

28 Professional Logging Contractors of Maine <strong>Loggers</strong> Serving <strong>Loggers</strong> Since 1995

Ted Clark, CLCS, Loss Control Consultant, Acadia Insurance<br />

Year after year, falls continue to be one of the<br />

leading causes of death and serious injury in the workplace.<br />

Did you know that many of these falls actually occur on the<br />

same level or from a relatively low surface? In fact, recent<br />

studies show that one of the leading sources of falls is<br />

actually from ladders. Luckily, many of these falls are<br />

preventable with only minor changes in your approach. In<br />

this safety meeting we will discuss a few points that will help<br />

reduce your exposure to falls when utilizing a step ladder. In<br />

addition to the following points, it is important to also refer<br />

to manufacturer requirements.<br />

1. Proper ladder selection: Ladder selection is the first of<br />

several critical steps to working safely at height.<br />

A. Many people don’t realize that step ladders<br />

are designed only to be worked off and are<br />

not designed for accessing higher or lower<br />

levels.<br />

B. The ladder also needs to be tall enough to do<br />

the job. Most step ladder manufacturers<br />

clearly state that the ladder is not designed<br />

for the user to stand on the top or the second<br />

-to-top rungs. If you need to step on the top<br />

two rungs, your ladder should be replaced<br />

with a longer ladder.<br />

C. Is the ladder rated for the user’s weight?<br />

Unless it is a heavy duty step ladder, it may<br />

not be rated for more than someone<br />

weighing 200 pounds. Verify the weight<br />

load limits of the ladder by referring to the<br />

stickers on the ladder’s rails.<br />

2. Ladder inspection: One of the most critical but often<br />

overlooked steps is to thoroughly inspect your ladder<br />

before each use.<br />

A. Steps: Steps should be intact, with no dents,<br />

clean, and free of oil and grease. The<br />

manufacturer generally prohibits<br />

modification or repair of the steps.<br />

B. Rails: Rails should be in good condition, with<br />

fiberglass in good shape without divots or<br />

dents. Aluminum should be free of dents<br />

and cracks. Pay special attention to the areas<br />

where the steps are mounted to the rails.<br />

Look closely for cracks in the fiberglass.<br />

The manufacturer labels should be legible<br />

and, therefore, should be protected from<br />

damage when the ladder is new.<br />

C. Feet: Feet should have the manufacturer<br />

mounted slip free pads in place. The pads<br />

should be clear of debris, oil, and grease.<br />

D. Spreaders: These are critical to the stability<br />

of the ladder and proper setup. Therefore,<br />

they must both be on the ladder and must be<br />

intact without any bends or dents.<br />

Quarterly Safety Meeting: Ladders<br />

3. Ladder Setup:<br />

A. Inspect the ground prior to setting up the<br />

ladder. Look for uneven surfaces that will<br />

cause the ladder to rock while working on it.<br />

Look for slippery substances such as oil and<br />

grease and avoid setting the ladder up in<br />

those areas.<br />

B. Avoid setting up in front of closed doors. If<br />

you must leave the door closed, clearly label<br />

it and/or lock it, to avoid someone coming<br />

through and knocking your ladder over.<br />

C. The ladder should NEVER be leaned against<br />

a wall or machine and climbed.<br />

Manufacturers require that the ladder, in<br />

order to work properly, be opened<br />

completely. Not completely opening and<br />

locking the step ladder can result in the<br />

ladder toppling over.<br />

4. Step Ladder Use:<br />

A. When climbing and descending the ladder,<br />

three points of contact is critical. Don’t<br />

carry tools or equipment in your hands.<br />