Case study: TerraGen - Retrofitting aging wind turbines (USA)

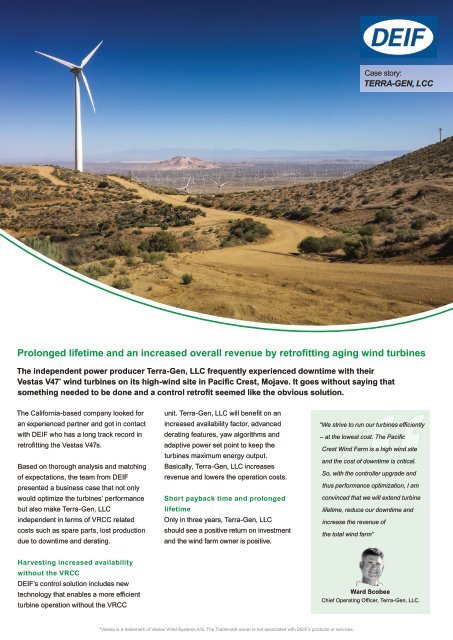

The independent power producer Terra-Gen, LLC frequently experienced downtime with their Vestas V47* wind turbines on its high-wind site in Pacific Crest, Mojave. It goes without saying that something needed to be done and a control retrofit seemed like the obvious solution.

The independent power producer Terra-Gen, LLC frequently experienced downtime with their Vestas V47* wind turbines on its high-wind site in Pacific Crest, Mojave. It goes without saying that something needed to be done and a control retrofit seemed like the obvious solution.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Case</strong> story:<br />

TERRA-GEN, LCC<br />

Prolonged lifetime and an increased overall revenue by retrofitting <strong>aging</strong> <strong>wind</strong> <strong>turbines</strong><br />

The independent power producer Terra-Gen, LLC frequently experienced downtime with their<br />

Vestas V47 * <strong>wind</strong> <strong>turbines</strong> on its high-<strong>wind</strong> site in Pacific Crest, Mojave. It goes without saying that<br />

something needed to be done and a control retrofit seemed like the obvious solution.<br />

The California-based company looked for<br />

an experienced partner and got in contact<br />

with DEIF who has a long track record in<br />

retrofitting the Vestas V47s.<br />

Based on thorough analysis and matching<br />

of expectations, the team from DEIF<br />

presented a business case that not only<br />

would optimize the <strong>turbines</strong>’ performance<br />

but also make Terra-Gen, LLC<br />

independent in terms of VRCC related<br />

costs such as spare parts, lost production<br />

due to downtime and derating.<br />

unit. Terra-Gen, LLC will benefit on an<br />

increased availability factor, advanced<br />

derating features, yaw algorithms and<br />

adaptive power set point to keep the<br />

<strong>turbines</strong> maximum energy output.<br />

Basically, Terra-Gen, LLC increases<br />

revenue and lowers the operation costs.<br />

Short payback time and prolonged<br />

lifetime<br />

Only in three years, Terra-Gen, LLC<br />

should see a positive return on investment<br />

and the <strong>wind</strong> farm owner is positive.<br />

“We strive to run our <strong>turbines</strong> efficiently<br />

– at the lowest cost. The Pacific<br />

Crest Wind Farm is a high <strong>wind</strong> site<br />

and the cost of downtime is critical.<br />

So, with the controller upgrade and<br />

thus performance optimization, I am<br />

convinced that we will extend turbine<br />

lifetime, reduce our downtime and<br />

increase the revenue of<br />

the total <strong>wind</strong> farm”<br />

Harvesting increased availability<br />

without the VRCC<br />

DEIF’s control solution includes new<br />

technology that enables a more efficient<br />

turbine operation without the VRCC<br />

Ward Scobee<br />

Chief Operating Officer, Terra-Gen, LLC.<br />

*Vestas is a trademark of Vestas Wind Systems A/S. The Trademark owner is not associated with DEIF’s products or services.

Full data access<br />

Besides having extended the lifetime of their <strong>wind</strong> <strong>turbines</strong>, tttv<br />

also have free access to all available data enabling them to<br />

continuously optimize their business.<br />

Performance optimization & lifetime extension<br />

The increased demand for competitive power production and<br />

the rapid development in the <strong>wind</strong> industry necessitates that<br />

older turbine models such as the Vestas V47 are equipped to<br />

meet today’s performance standards. DEIF’s control retrofit<br />

solution extends the turbine lifetime and optimizes the turbine<br />

performance in terms of variable speed concepts, extended<br />

cut-out and adaptive power set point.<br />

“We believe that our customers should have free access to all<br />

collected data - after all it is their <strong>wind</strong> <strong>turbines</strong>. Data access<br />

enables owners and service crew to analyze the health of the<br />

equipment and troubleshoot faster.”<br />

Jean S. Felber<br />

Sales and Business Development Manager<br />

DEIF<br />

DEIF A/S • Frisenborgvej 33, 7800 Skive, Denmark • Tel. +45 9614 9614 • www.deif.com