48 new materials - Material ConneXion

48 new materials - Material ConneXion

48 new materials - Material ConneXion

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

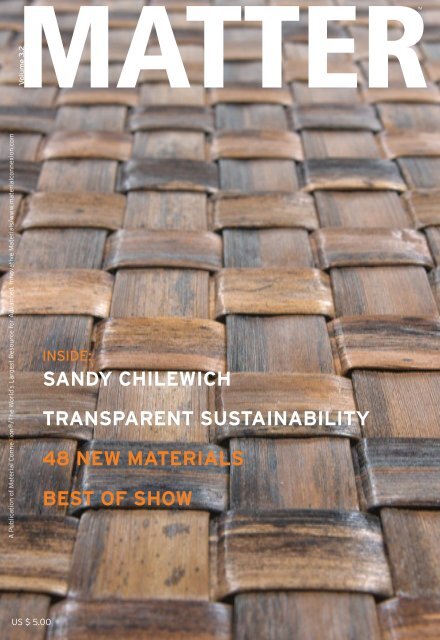

A Publication of <strong>Material</strong> <strong>ConneXion</strong>®/The World’s Largest Resource for Advanced, Innovative <strong>Material</strong>s/www.materialconnexion.com<br />

Volume 3.2<br />

US $ 5.00<br />

INSIDE:<br />

SANDY CHILEWICH<br />

TRANSPARENT SUSTAINABILITY<br />

<strong>48</strong> NEW MATERIALS<br />

BEST OF SHOW

To improve indoor air quality<br />

without raising costs, use<br />

PureBond decorative hardwood<br />

plywood, exclusively from<br />

Columbia Forest Products.<br />

Since it’s formaldehyde-free,<br />

indoor air quality benefits<br />

tremendously. In fact,<br />

PureBond plywood panels<br />

are compliant with the U.S.<br />

Green Building Council’s<br />

LEED standards. Which<br />

means PureBond panels are<br />

smarter for your customers.<br />

And every other life form.<br />

YOU’VE KNOWN SINCE<br />

8TH GRADE BIOLOGY<br />

THAT FORMALDEHYDE<br />

ISN’T REALLY MEANT<br />

FOR LIVING CREATURES.<br />

NOW YOU CAN DO<br />

SOMETHING ABOUT IT.<br />

INTRODUCING PUREBOND, THE COST-COMPETITIVE,<br />

FORMALDEHYDE-FREE HARDWOOD PLYWOOD.<br />

www.columbiaforestproducts.com

<strong>Material</strong> <strong>ConneXion</strong> NEWS<br />

P. 3<br />

P. 4<br />

P. 5<br />

P. 6<br />

<strong>Material</strong> <strong>ConneXion</strong><br />

<strong>Material</strong> <strong>ConneXion</strong> Bangkok<br />

<strong>Material</strong> <strong>ConneXion</strong> Cologne<br />

<strong>Material</strong> <strong>ConneXion</strong> Milano<br />

OF MATERIAL INTEREST<br />

P. 8<br />

P. 11<br />

<strong>Material</strong>s With a Mission<br />

Great design turns abaca into gold<br />

Interview<br />

Sandy Chilewich reminisces about her <strong>materials</strong> career<br />

STATE OF THE ART<br />

P. 17<br />

P. 18<br />

Best of Show<br />

Three extraordinary <strong>new</strong> <strong>materials</strong> selected by our jury<br />

<strong>48</strong> New <strong>Material</strong>s<br />

Recent additions to our library and database<br />

MATERIAL PROFILE<br />

P. 24<br />

P. 26<br />

<strong>Material</strong>s at Extreme Temperatures by Dr. Andrew Dent<br />

Sourcing tips<br />

Smart Fabrics by Dr. Cynthia Tyler<br />

The next generation is genius!<br />

IN THE MATERIAL WORLD<br />

P. 28<br />

P. 30<br />

P. 32<br />

P. 35<br />

Transparent Sustainability by Lindsey Clark<br />

Granola is going, going, gone<br />

This Green House by Alanna Stang<br />

Inspirational and environmentally friendly<br />

Inside the Box by Phil Patton<br />

Shipping containers in art and commerce<br />

Join <strong>Material</strong> <strong>ConneXion</strong><br />

Cover: Quilted Bacbac Panel<br />

Photo: © Colleen Noonan<br />

CONTENTS<br />

1

2<br />

WELCOME Spring is a very exciting season for<br />

<strong>Material</strong> <strong>ConneXion</strong>. We kicked it off with<br />

an appearance at the Salone del Mobile in<br />

Milan and, when this magazine comes off<br />

the press, we will be poised to launch an<br />

ambitious suite of design events to take place<br />

during New York Design Week.<br />

On May 19th, <strong>Material</strong> <strong>ConneXion</strong> is pre-<br />

senting its second annual symposium,<br />

TERRA MATTER: Inspire, Innovate, Sustain.<br />

For those of you who attended Malfatto,<br />

TERRA MATTER will be bigger and even<br />

better. It will feature designers and<br />

intellectuals whom I feel are saying some-<br />

thing relevant, urgent, and unique about<br />

<strong>materials</strong>, design, and sustainability. Some<br />

of these stars I’ve admired for a long time—<br />

Michele Oka Doner, Leslie Hoffman, and Dr. Michael Braungart, for instance—<br />

and some are fresh voices who have caught my ear: Sergio Palleroni, Sami Hayek,<br />

Jill Dumain, and Natalie Chanin, among others.<br />

The program will continue at the International Contemporary Furniture Fair, with<br />

<strong>Material</strong>s Focus Sessions and the unveiling of Transformations, an exhibition of the<br />

building elements and furniture that resulted from a successful partnership with the<br />

Philippine government.<br />

I certainly hope you can join us in May at TERRA MATTER, ICFF, or our<br />

New York office.<br />

George M. Beylerian<br />

Founder and President<br />

<strong>Material</strong> <strong>ConneXion</strong>

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

Headquartered in New York City with locations in Bangkok, Cologne, and Milan,<br />

<strong>Material</strong> <strong>ConneXion</strong> ® has become the definitive resource of cutting-edge <strong>materials</strong> for<br />

architects, artists, and design ers from all disciplines. At our physical libraries, visitors<br />

can reach out and touch the latest inspiring gels, plastics, resins, foams, and laminates.<br />

Complete access to the <strong>Material</strong> <strong>ConneXion</strong> database is also available online.<br />

Following is an update of our initiatives to spread our <strong>materials</strong> expertise worldwide.<br />

Salone del Mobile New Hires<br />

This year’s Salone del Mobile was bigger than<br />

ever. More exhibitors, more buyers, more manufacturers,<br />

and more international press, all<br />

brought together under one dramatic, sweeping,<br />

fiberglass-and-steel canopy designed by architect<br />

Massimiliano Fuksas. Over the course of five days,<br />

they came by the thousands—250,000 by the latest<br />

count—speaking myriad different languages.<br />

Experimental <strong>new</strong> <strong>materials</strong> were a clear trend<br />

throughout the fairgrounds, and visitors obviously<br />

appreciated the relevance of <strong>Material</strong> <strong>ConneXion</strong>’s<br />

message.<br />

The <strong>Material</strong>s Matter exhibition, which the “cream<br />

of the crop” from <strong>Material</strong> <strong>ConneXion</strong> Milan’s permanent<br />

collection, was prominently situated on<br />

the “main street” that connected the various pavilions<br />

housing home furnishings, kitchens, baths,<br />

and lighting show rooms. It was also adjacent to a<br />

bookstore specializing in architecture and design<br />

publications and the crowd naturally spilled over<br />

to request information on <strong>materials</strong>, to meet with<br />

MC representatives, to purchase catalogues, and<br />

to join the <strong>materials</strong> library.<br />

In conjunction with the exhibit at the Fair, MC<br />

showed off its collection of <strong>materials</strong> within the<br />

Milan Triennale, one of the most famous design<br />

museums in the world. The space, designed by<br />

architect Michele de Lucchi, lay on the design pilgrims’<br />

path and enjoyed constant traffic throughout<br />

the five-day event.<br />

Partnership with<br />

Furniture Society<br />

<strong>Material</strong> <strong>ConneXion</strong> is pleased to announce its<br />

partnership with the Furniture Society, a taxexempt,<br />

nonprofit organization that aims to<br />

advance the art of furniture making.<br />

For more information, go to<br />

www.furnituresociety.org.<br />

Furniture Society members will receive 10% off any<br />

individual or corporate access plan. For more information<br />

on this group, contact Michael LaGreca,<br />

Director of Library Access Programs, at 212-842-<br />

2050 or access@materialconnexion.com.<br />

Steven Wagner joined <strong>Material</strong> Connexion in March<br />

2006 as Director of Marketing and Corporate<br />

Communications. Prior to joining the company he<br />

had been the Senior<br />

Design Editor of House<br />

Beautiful Magazine and<br />

was one of the founding<br />

editors of Metropolitan<br />

Home Magazine. Over<br />

the past ten years he<br />

has worked with the<br />

Hearst Magazine Group<br />

in various roles as editorial<br />

director of the web<br />

component of maga-<br />

Steven Wagner<br />

NEWS<br />

zines such as Town<br />

and Country, Redbook,<br />

Cosmopolitan, Good Housekeeping, Harpers Bazaar,<br />

House Beautiful, and Country Living. He has a long<br />

history of working in the <strong>new</strong> media/internet arena<br />

and will be concentrating on enhancing the <strong>Material</strong><br />

<strong>ConneXion</strong> web site as well as on working with the<br />

national and international press to promote the mission<br />

of <strong>Material</strong> <strong>ConneXion</strong>.<br />

<strong>Material</strong> <strong>ConneXion</strong> also welcomes Stuart Glass to<br />

its sales and marketing team as the Vice President<br />

of Sales and Business Development. In this position,<br />

Mr. Glass will be broadening the reach of the firm’s<br />

consultancy practice, called the Advanced <strong>Material</strong><br />

Solutions Teamsm , which<br />

provides custom <strong>materials</strong><br />

research services<br />

to manufacturers,<br />

designers, architects,<br />

and specifiers in all disciplines.<br />

His attention<br />

will also be given to Innovation<br />

Marketing sm<br />

services and visibility<br />

programs for material<br />

developers. He will build,<br />

oversee, and manage Stuart Glass<br />

the company sales force.<br />

He provided strategic design leadership on<br />

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

both national and New York international · Bangkok · Cologne · Milan high-profile<br />

integrated branding projects as former CEO of<br />

Stuart Glass Design Group and a Design Director of<br />

Landor Associates and Lippincott-Mercer.<br />

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

New York · Bangkok · Cologne · Milan<br />

127 West 25th Street, 2nd Floor<br />

New York, NY 10001<br />

T +1 212 842 2050 / F +1 212 842 1090<br />

E info@materialconnexion.com<br />

MATERIAL CONNEXION<br />

3

MATERIAL CONNEXION BANGKOK<br />

4<br />

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

Bangkok NEWS<br />

This spring, <strong>Material</strong> <strong>ConneXion</strong> Bangkok has<br />

undertaken several successful initiatives to<br />

reach out to its constituency.<br />

In conjunction with the Thailand Creative &<br />

Design Center (TCDC), <strong>Material</strong> <strong>ConneXion</strong><br />

Bangkok exhibited at the Thailand International<br />

Furniture Fair 2006 / Interior Design Asia, from<br />

March 8 – 12, 2006. “Thailand International<br />

Furniture Fair / Interior Design Asia is one of<br />

the premier events of the design, furniture, and<br />

furnishing community in Asia. We are pleased<br />

to be part of this event, which focuses on the<br />

creative forces shaping the future of the industry:<br />

concepts, trends, <strong>materials</strong>, and technologies,”<br />

commented Chaiyong Ratana-ung-goon,<br />

Vice President of <strong>Material</strong> <strong>ConneXion</strong> Bangkok<br />

and Managing Director of TCDC.<br />

At the fair, countless visitors took the opportunity<br />

to explore the showcase, which was designed<br />

to appeal to all five senses. The feedback was<br />

overwhelmingly positive.<br />

The exhibition highlighted tabulae from the first lot<br />

of Thai <strong>materials</strong> juried into <strong>Material</strong> <strong>ConneXion</strong>’s<br />

archive. It attracted tremendous interest from<br />

the local media, architects, engineers, interior<br />

designers, industrial designers, and other<br />

manufacturers. The five featured <strong>materials</strong><br />

from Thailand are Weaving Paper from Daorath<br />

Handicraft Group, Look-Lee Fabric from Daorath<br />

Handicraft Group, Crystaline Mosaics from<br />

N Cubed, Fur Stories from Graph-Tex Studio,<br />

and Fake Fur from Jong Stit. “We strongly believe<br />

that <strong>Material</strong> <strong>ConneXion</strong> Bangkok will<br />

source more and more <strong>new</strong> <strong>materials</strong> and develop<br />

them to meet the needs of designers and<br />

manufacturers locally and worldwide,” said<br />

Chompoonuj Weerakitti, Director of <strong>Material</strong><br />

Library, <strong>Material</strong> <strong>ConneXion</strong> Bangkok.<br />

Apisit Laistrooglai, Managing Director of<br />

<strong>Material</strong> <strong>ConneXion</strong> Bangkok and Director of<br />

the Resources Center, TCDC, added, “Given the<br />

increasing sophistication and consciousness of<br />

today’s consumers, a fitting use of innovative<br />

<strong>materials</strong> is one that considers the following: Is<br />

it stronger and lighter, is it less expensive, is it<br />

environmentally friendly and durable? Designers<br />

must keep an eye on the most recent international<br />

<strong>materials</strong> developments on an international level<br />

and yet, at the same time, also appreciate their<br />

own indigenous natural <strong>materials</strong>.”<br />

On February 17, <strong>Material</strong> <strong>ConneXion</strong> Bangkok, in<br />

cooperation with TCDC, hosted its first subscribers’<br />

party at the Thailand Creative & Design Center.<br />

Mr. Pansak Vinyaratn, chairman of the TCDC,<br />

warmly welcomed the more than 50 attending<br />

subscribers with an inspiring speech. During the<br />

get-together, the crowd was introduced to <strong>new</strong>ly<br />

arrived <strong>materials</strong>.<br />

At the next event, on April 20, George M. Beylerian,<br />

Founder and President of <strong>Material</strong> <strong>ConneXion</strong>,<br />

and Dr. Andrew Dent, Vice President of Library<br />

and <strong>Material</strong>s Research, were on hand to per-<br />

®<br />

sonally <strong>Material</strong> greet subscribers. <strong>ConneXion</strong>After<br />

Bangkok the reception,<br />

Dr. Dent lectured New York on · Bangkok The · Cologne Influence · Milan of <strong>Material</strong>s on<br />

Design Innovation at the TCDC auditorium.<br />

®<br />

<strong>Material</strong> <strong>ConneXion</strong> Bangkok<br />

New York · Bangkok · Cologne · Milan<br />

6th Floor, The Emporium Shopping Complex<br />

622 Sukhumvit 24<br />

Bangkok 10110 Thailand<br />

T +66 0 2 664 84<strong>48</strong><br />

F +66 0 664 8459<br />

E infothailand@materialconnexion.com

Photo: Survey<br />

inc?<br />

capitals?<br />

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

Cologne NEWS<br />

Good <strong>new</strong>s! According to IFO, the institute for<br />

economic research, the motor of Germany’s<br />

economy has fired up. Experts calculate a 1.5%<br />

economic growth for 2006. And with high export<br />

figures and an increase in domestic investment,<br />

manufacturing industry is right at the forefront<br />

of this development. German companies, among<br />

the worldwide technological elite, are once<br />

again making healthy profits. In recognition of<br />

this fact, the stock market has reached record<br />

levels.<br />

The German branch of <strong>Material</strong> <strong>ConneXion</strong>, established<br />

in March 2005 in Cologne’s design<br />

center, is already profiting from this trend and<br />

has registered an increase in demand. The consultancy<br />

service in particular is showing satisfying<br />

growth. Internationally renowned companies<br />

from a wide variety of industries all figure in<br />

<strong>Material</strong> <strong>ConneXion</strong> Cologne’s customer listing<br />

and avail themselves of the library’s extensive<br />

range of <strong>materials</strong> and services. These include<br />

German automobile manufacturers, internationally<br />

recognized fashion labels and textile<br />

companies, producers of consumer goods, and<br />

telecommunications suppliers, as well as many<br />

companies and independent designers involved<br />

in interior design.<br />

Alongside the big names from business, many<br />

small- and medium-sized suppliers are also<br />

subscribers to Cologne’s library. Often these<br />

are the real innovators, because today it is the<br />

suppliers’ development teams who completely<br />

manufacture the pre-assembly products used<br />

in automobiles, furniture, consumer goods, etc.<br />

Designers are developing <strong>new</strong> ideas on a daily<br />

The <strong>Material</strong> <strong>ConneXion</strong> Cologne Team (left to right): Niki Vogiantzi, Anne Farken,<br />

Karsten Bleymehl, Rolf Warda, Carsta Schauff and Sandra Wichtrup.<br />

basis, experimenting with <strong>new</strong> <strong>materials</strong> and selecting<br />

and combining these according to their<br />

visual, haptic, and functional qualities. <strong>Material</strong><br />

<strong>ConneXion</strong> offers them a one-stop platform where<br />

they can quickly find information that might otherwise<br />

require hours of time-consuming research<br />

on their part to obtain.<br />

In response to the increase in demand, the team<br />

at <strong>Material</strong> <strong>ConneXion</strong> Cologne has grown significantly<br />

over the past year. In addition to Manager<br />

Rolf Warda, five colleagues are employed in Cologne:<br />

Karsten Bleymehl and Anne Farken (research),<br />

Niki Vogiantzi (sales), Sandra Wichtrup<br />

(management), and Carsta Schauff (office). Their<br />

range of duties includes participation at industry<br />

shows—from exhibition stand design through customer<br />

care. In 2006 alone, <strong>Material</strong> <strong>ConneXion</strong><br />

Cologne attended six trade fairs including the biggest<br />

industrial show in the world, the Hannover<br />

Messe. At this and other such shows, the MCC<br />

team has the chance to track down innovative <strong>materials</strong><br />

and processing methods and to introduce<br />

itself to manufacturers. After all, at the end of the<br />

day, the library is built on what it gives its customers:<br />

a pool of innovative, cutting-edge <strong>materials</strong>.<br />

Lichtstr. 43 G<br />

50825 Cologne, Germany<br />

T +49 221 99 22 28 0<br />

F +49 221 99 22 28 11<br />

E infogermany@materialconnexion.com<br />

MATERIAL CONNEXION C OLOGNE<br />

5

Formed by Nature, Crafted by Man<br />

Known as one of the most technically innovative companies in the wood<br />

industry, The G.R. Plume Company brings distinctive solutions to the clients of<br />

<strong>Material</strong> <strong>ConneXion</strong>, opening up <strong>new</strong> and unexpected uses of organic wood<br />

products such as RFKD timber. Radio frequency kiln dried freshly sawn timber<br />

maintains the classic motif of true wood timber without the frustration of<br />

performance problems during and after incorporation, making it one of<br />

the most solid, stable and purest <strong>materials</strong>.<br />

MC # 5361<br />

G.R. Plume Company 1373 West Smith Road Suite A-1 Ferndale, WA 982<strong>48</strong> Tel: 360-384-2800 Fax: 360-384-0335 www.grplume.com

inc?<br />

capitals?<br />

<strong>Material</strong> <strong>ConneXion</strong> ®<br />

The 45th Salone Internazionale del Mobile<br />

and associated events took place from April 5<br />

to 10 inside Milan’s brand <strong>new</strong> fairgrounds situated<br />

in the city’s northern suburb, Rho-Pero.<br />

The space was immediately sold out to 2,549<br />

exhibitors anxious to display the best of their<br />

home and office furniture production.<br />

The exhibited designs, characterized by warm,<br />

enveloping environments furnished with colorful<br />

and comfortable pieces, reflected the<br />

Italian home and life style. The <strong>new</strong> home<br />

concept turns its back on absolute minimalism<br />

and welcomes a wide range of textures,<br />

decorations, and colors.<br />

Combinations of styles and furnishings create<br />

environments conceived for wellbeing. This is<br />

especially apparent in bathroom and kitchen;<br />

however, there was also obvious attention<br />

paid to making working areas more comfortable,<br />

functional, and ergonomic: the office as<br />

second home.<br />

<strong>Material</strong> <strong>ConneXion</strong> exhibited a selection of<br />

cutting-edge <strong>materials</strong> from three interesting<br />

areas of material development:<br />

• New polymer forms<br />

• Alternative natural <strong>materials</strong><br />

• Metal processing<br />

New polymer forms<br />

The development of good quality expanded<br />

foams from plastics such as polypropylene<br />

and polyethylene has broadened the application<br />

field for these molded, lightweight rigid<br />

forms. Easily colorable and shaped to complex<br />

geometries, they can also be molded onto textiles,<br />

incorporate metallic objects, and have<br />

texture. The organic-looking, convoluted ligaments<br />

of soil erosion matting also buck the<br />

assumption that molded polymers need to<br />

have synthetic-looking regular forms.<br />

Alternative natural <strong>materials</strong><br />

Creative use of bark, wheat, and paper <strong>materials</strong><br />

has given us <strong>new</strong> ways of looking at natural<br />

Via Davanzati n. 33<br />

20158 Milano, Italy<br />

T +39 02 39 32 55 85<br />

F +39 02 39 32 12 39<br />

E infoitalia@materialconnexion.com<br />

Milano NEWS<br />

surfaces. Although produced using techniques<br />

thousands of years old, the re-purposing of<br />

bark cloth has added a unique textural surface<br />

to both flexible cloth sheet and also rigid laminate.<br />

Foamed paper forms for packaging give<br />

us more sustainable packaging alternatives<br />

to current plastics, and pressed, rigid wheat<br />

waste has been used to decorative advantage<br />

in particleboard alternatives.<br />

Metal processing<br />

The continued lure of metals and metallic surfaces<br />

has led to a number of developments<br />

in alternative ways of recreating the solidity<br />

and surface effect of this class of <strong>materials</strong>.<br />

Multilayering of dissimilar metals can create<br />

<strong>new</strong> color combinations when the metals are<br />

bent and polished. The use of pressure to deform<br />

welded steel results in almost soft looking<br />

creases and folds. Plating plastics with hard,<br />

wear- and corrosion-resistant metal has also<br />

become a more viable alternative to solid metal,<br />

creating the feel of titanium, stainless steel,<br />

and other high-performance <strong>materials</strong> without<br />

the attendant processing and cost issues.<br />

c/o La Triennale di Milano<br />

Viale Alemagna 6<br />

20121 Milano, Italy<br />

T +39 02 72 43 42 55<br />

F +39 02 39 32 12 39<br />

E triennale@materialconnexion.com<br />

MATERIAL CONNEXION MILANO<br />

7

OF MATERIAL INTEREST<br />

108<br />

MATERIALS WITH A MISSION<br />

by Lilas Harley<br />

The more than 7,000 volcanically formed<br />

islands that compose the Philippines encompass<br />

spectacular forests, wetlands,<br />

and beaches. It is no secret that, in contrast<br />

to this natural abundance, many of the<br />

nation’s nearly 88 million inhabitants live<br />

in poverty. Traditionally, skilled craftsmen<br />

made a living fashioning decorative household<br />

items, gifts, and accessories out of the<br />

plants, shells, and rocks that surrounded<br />

them. However, strenuous competition from<br />

China—which can make such products for<br />

less—has seriously threatened this income<br />

source.<br />

In conjunction with the Philippine Department<br />

of Trade and Industry and the Center<br />

for International Trade Expositions and<br />

Missions (CITEM), <strong>Material</strong> <strong>ConneXion</strong> has<br />

successfully completed the unique project<br />

Transformations: Nature & Beyond, which<br />

explores <strong>new</strong> applications of indigenous<br />

<strong>materials</strong> in an effort to breathe <strong>new</strong> life<br />

into the Philippine economy. Individually,<br />

the furniture, interior, and architectural<br />

elements that resulted from the endeavor<br />

exemplify outstanding design; collectively,<br />

they represent a bold plan to accelerate the<br />

economy of developing nations.<br />

CITEM approached George M. Beylerian,<br />

founder of <strong>Material</strong> <strong>ConneXion</strong>, because of<br />

Beylerian’s formidable reputation as one of<br />

design’s savviest businessmen, with a special<br />

sensitivity for <strong>materials</strong>. With CITEM<br />

overseeing the manufacturing facilities,<br />

Beylerian brought in big designer names<br />

from Europe and the United States. A veteran<br />

of the furniture industry, Beylerian k<strong>new</strong><br />

that these exceptional talents, “could create<br />

something with cachet that could be sold to<br />

architects and interior designers whose clients<br />

will pay a higher price for a substantial,<br />

enduring object.” He is confident that the<br />

ad valorum strategy will allow the Philippines<br />

to find a profitable market niche for themselves<br />

because, while he admits that others<br />

could copy these pieces, “there is less<br />

incentive in that market because it is so exclusive.”<br />

After visiting the Philippines and inspecting<br />

the manufacturing facilities there, Beylerian<br />

invited celebrity designers Gijs Bakker,<br />

Gregory and Judith Beylerian, Ed and Lor<br />

Calma, Clodagh, Tom Dixon, Doug Fitch, Paul<br />

and Barbara Haigh, Tom Hardy, Arik Lexy,<br />

Michele Oka Doner, Satyendra Pakhale,<br />

Karim Rashid, Shigeru Uchida, and Kevin<br />

Bamboo

Woven bamboo and foam by Satyendra Pakhalé<br />

Walz to participate in the project by designing<br />

modular building and decorative elements.<br />

Each designer received a kit containing<br />

such <strong>materials</strong> as abaca fiber, bamboo,<br />

saguing (banana plant fiber), coconut shell,<br />

lahar (pumice), and nito (a supple fern) and<br />

was asked to select at least one material to<br />

transform into something precious—hence<br />

the exhibition’s title.<br />

Clodagh has gained a reputaion for using<br />

sustainable <strong>materials</strong>, modern technology,<br />

and ancient techniques to create almost<br />

spiritually beautiful environments. She<br />

chose to work with abaca fiber, which is obtained<br />

from the leaf of a banana-like plant,<br />

for its exceptional strength, flexibility, and<br />

lustrous color palette. In her wall and ceiling<br />

panels, she capitalizes on the material’s<br />

naturally uneven fiber concentration to<br />

achieve different levels of transparency. For<br />

this designer, part of the excitement of being<br />

involved in the Transformations project<br />

was the hope that her product would be “a<br />

true commodity and create a work source to<br />

increase the prosperity of the Philippines.”<br />

Kevin Walz Clodagh David Rockwell<br />

Photo: © Jonathan Levine<br />

OF MATERIAL INTEREST<br />

9

OF MATERIAL INTEREST<br />

10<br />

Photo: © J. Alex Halderman<br />

Quilted banana fiber by Tony Gonzales<br />

Insert: The raw material

Photos: © Colleen Noonan<br />

Woven nito chair by Shigeru Uchida Woven seagrass chair by Karim Rashid<br />

Superstar interior designer Kevin Walz freely<br />

admits that he hadn’t paid much attention<br />

to bamboo until he chose to work with it for<br />

Transformations. Conventional treatments,<br />

he had found, tended to disguise or homogenize<br />

its natural properties, thus stripping<br />

it of its “vibrancy and life.” In his own three<br />

building products, he sought to preserve<br />

these qualities. Walz predicts great things<br />

for bamboo: “[It] will certainly outperform<br />

cedar as a siding material. Bamboo will take<br />

on a silvery richness once the sun hits it,<br />

which will bring a warm, rustic quality to the<br />

[building’s] surface.”<br />

Although intrigued by all the <strong>materials</strong> presented<br />

to them, the Rockwell Group settled<br />

on coconut shell, a material not usually associated<br />

with the design or architecture<br />

fields. Rockwell’s design, a coconut-chip<br />

screen, embraces variance and encourages<br />

variants. The Group can see altering<br />

the chips’ size, shape, and color, “while the<br />

curtain itself could appear in any length or<br />

width desired.” Moreover, a bamboo frame<br />

could quickly take the concept from curtain<br />

to cabinet.<br />

Most of the furniture items, floor and ceiling<br />

tiles, and screens developed through the initiative<br />

are still at the prototype stage, with<br />

testing needed to determine both levels of<br />

stability and environmental ratings (due to<br />

some of the resins used). However, having<br />

come this far, Beylerian is confident that<br />

testing and any necessary improvements<br />

can be made quickly: “Basically, our role<br />

thus far has been one of consulting and developing<br />

projects and we would now be happy<br />

to take the next step.” The exhibition’s<br />

reception at ICFF will inform the participating<br />

parties about the best ways to market<br />

and distribute the items. One line of furniture—benches,<br />

tables and stools designed<br />

by Karim Rashid—is already installed in the<br />

Semiramis Hotel, Athens, the location for<br />

which they were exclusively designed.<br />

From May 20 to 23, <strong>Material</strong> <strong>ConneXion</strong> will<br />

preview Transformations: Nature & Beyond<br />

at the International Contemporary Furniture<br />

Fair, NYC. By highlighting the sophistication<br />

of natural <strong>materials</strong>, the Transformations<br />

exhibit will undoubtedly generate interest in<br />

the Philippine marketplace. It is also expected<br />

to inform other <strong>materials</strong>-rich countries<br />

about <strong>Material</strong> <strong>ConneXion</strong>’s ability to open<br />

up <strong>new</strong> and vital markets globally.<br />

OF MATERIAL INTEREST<br />

11

OF MATERIAL INTEREST<br />

12<br />

INTERVIEW<br />

Sandy Chilewich and George Beylerian are both entrepreneurs who are<br />

driven by a love of <strong>materials</strong>. They met at <strong>Material</strong> <strong>ConneXion</strong> to talk<br />

about how they turn creative inspiration into business success.<br />

GB: Before you had Chilewich, you had already<br />

gained a name and reputation with the hosiery<br />

company, HUE. But first you were trained as a<br />

jewelry designer?<br />

SC: I wasn’t trained at anything.<br />

GB: Just like me! I know nothing about <strong>materials</strong>.<br />

SC: I know nothing about <strong>materials</strong> either!<br />

[laughter]<br />

GB: How did you get into textiles, then?<br />

SC: You know, I thought I was an artist. I never<br />

graduated from college. I was very confused,<br />

but I always did artwork.<br />

GB: You created things.<br />

SC: Yes. I remember going into one gallery and<br />

the guy—in the nicest way—said, “You know,<br />

I think your stuff is very commercial.” At the<br />

time, I thought that was the biggest insult. I<br />

cried! He didn’t mean it as a criticism, but I<br />

thought all right, that’s the end of that career.<br />

GB: What were you showing him?<br />

SC: Collages. I was also doing sculpture with<br />

Plexiglas, and there were these beaded things<br />

going on in there. So I started to design jewelry—again,<br />

I had no background so there was<br />

beading but no soldering. But I started to sell at<br />

Bendel’s and Bloomingdale’s.<br />

I lived in Noho at that time (1976). There was<br />

another woman [in my building] who was an<br />

art teacher. You know those black canvas<br />

Mary Jane Chinese slippers? They had them<br />

only available in black at that point. We had just<br />

been drinking wine and we thought, wouldn’t it<br />

be great to make them in color? And she had<br />

some bleach and some Tintex, and we were<br />

drunk and we bleached the shoes out and we<br />

died them. We thought, “Oh this looks pretty<br />

cool!” (It was, like, fuchsia.) So we did a bunch<br />

of them, and at the next building meeting every<br />

girl who walked in said “Oh my God, where did<br />

you get these?”<br />

So I had an appointment with Vogue to show my<br />

jewelry. I went in with the shoes and the jewelry.<br />

They punted the jewelry and then they said “Oh<br />

my God!” and they go into Grace Mirabella’s office<br />

and she comes out herself and says, “Oh my<br />

God, we’re doing a shoot in Sardinia and we need<br />

these colors in size ten. We’re leaving on Monday<br />

morning can you do it?” This was on a Friday.<br />

And we say, “Yeah, yeah, yeah, yeah.” But these<br />

shoes are all teeny because they come from<br />

China town. To find size ten in China town, we<br />

had to get cartons of forty and throw away three<br />

quarters of it for the eights, nines, and tens, and<br />

then we had to duplicate the colors that we did<br />

like soups: eggplant, mustard…. We gave them up<br />

wet on Monday and off they went. We didn’t know<br />

what the hell we were doing.<br />

When they came back they said, “These look fabulous.<br />

We’re doing a full-page spread. What’s the<br />

name of your company and who do you sell to?”<br />

We had no idea what they meant, that we had to<br />

sell to somebody. We were really naïve. We went<br />

to Bergdorf’s and said, “We’re going to get this<br />

two-page spread in Vogue do you want to buy<br />

some of these? And the name of the company is<br />

Shoes by Kathy and Sandy.” It was phenomenal.<br />

We had washing machines going day and night.<br />

All we’d done was we took a commodity that was<br />

only available in one color and we offered it in<br />

many colors.<br />

Chilewich<br />

of<br />

GB: That’s like my success story with plastics.<br />

Courtesy<br />

In those days plastics were red, blue, yellow,<br />

green…and then people got tired of that. One Photos:

of my sales reps in Chicago told me “You know<br />

George, I think people are getting tired of these<br />

colors.” (He was very sophisticated.) “What<br />

about something like dusty rose?” he said.<br />

Dusty rose was an exotic color to use. We all<br />

looked at him and laughed. And I said “What<br />

about periwinkle!” So we had periwinkle and<br />

then we had another color, jade green. Before<br />

you know it, we had a <strong>new</strong> product.<br />

SC: That was right when color was just beginning,<br />

when t-shirts were first being offered in<br />

25 colors.<br />

GB: How did the transition go from shoes to<br />

tights?<br />

SC: Well the editors kept asking us “What other<br />

things do you do?” And so we thought about<br />

what else we could offer a lot of colors in. One<br />

of the things we bought were cotton nurse’s<br />

stockings. They got a great reaction, and we<br />

were asked whether we could do the same for<br />

tights. So we went down South and we really<br />

started to play on the machines. At that point,<br />

there was really only one other company that<br />

was doing anything even remotely interesting<br />

and they were taking bulky socks and making<br />

them colorful. We were doing something more<br />

feminine, and we were the first people to make<br />

a cotton core-spun so that it would stretch.<br />

From just a business perspective we realized<br />

that we couldn’t do everything; so we dropped<br />

the shoes. There was such a big market for legwear.<br />

GB: Organizing that was such a big job, from nowhere<br />

to become a major, influential company!<br />

SC: Yeah, but you know I owned HUE for 16<br />

years, so that was a long process to build it up<br />

to the established brand that it still is. I think I<br />

kind of stumbled on that process. I didn’t start<br />

out thinking that I wanted to become a hosiery<br />

designer. I went jewelry to shoes to hosiery.<br />

Once I sold HUE, sales were grossing $40 million.<br />

Then I had this concept for making the textile<br />

baskets, the Ray Bowls. I did have that idea<br />

in my head of making the basket and of using<br />

the hosiery material, the stretch mesh. Once<br />

that was made, I had another idea and that’s<br />

why I came to <strong>Material</strong> <strong>ConneXion</strong>. I wanted to<br />

take solid vinyls and weave them, sort of like in<br />

50s junky chairs.<br />

I didn’t know where to look to find this vinyl. But<br />

you guys had just opened. When I came here I<br />

found Phifer and it was way more interesting as<br />

a product than what I had expected, which was<br />

OF MATERIAL INTEREST<br />

13

OF MATERIAL INTEREST<br />

14<br />

just solid vinyl. So I started pursuing them.<br />

GB: What was Phifer’s reaction when you came<br />

to them?<br />

SC: You know, it was amazing. I went down and<br />

was just buying off of their line. From their line<br />

I was making placemats and bags and I backed<br />

it in this rudimentary way as floor mats, and I’d<br />

already started selling a little bit. I brought it all<br />

down there and It was great and we really bonded.<br />

Not that I was making them much money at<br />

that stage in the game, but I think they were<br />

flattered that I could take their <strong>materials</strong> and do<br />

something with it.<br />

GB: That’s the difference between big-time industrialists<br />

who have mono-vision and someone<br />

like you. You are the perfect entrepreneurial person.<br />

Your entrepreneurship is based on <strong>materials</strong><br />

and development.<br />

SC: The artistic end is vital to me; nevertheless,<br />

the commercial viability is equally critical. When<br />

I first introduced the Ray Bowl, I was in the store<br />

counting how many they’d sold on a daily basis<br />

because I k<strong>new</strong> that if it didn’t come across in retail,<br />

it wasn’t going to work. I don’t consider myself<br />

an artist but I am artistic and I like to make<br />

as few design compromises as possible, but<br />

if it doesn’t work with the consumer then I am<br />

not a businessperson. It ultimately has to make<br />

money. That’s not everybody’s cup of tea. But if<br />

you’re going to go that route, then you have to<br />

test your product.<br />

GB: I think what’s important here is the sense of<br />

<strong>materials</strong> as a key source of inspiration. It’s the<br />

material that drives you to do things rather than<br />

the other way round.<br />

SC: Yes, I look at <strong>materials</strong> and ask myself, “What<br />

else could this material be?”

BEST OF SHOW<br />

Once a month, an interdisciplinary team of experts from a variety of design related<br />

fields come together to select <strong>new</strong> <strong>materials</strong> for the library. Out of the forty <strong>materials</strong>,<br />

juried monthly, one is chosen as the Best of Show. According to Dr. Andrew Dent, our<br />

Vice President of Library and <strong>Material</strong> Research, who moderates the jury sessions, a model material<br />

is innovative, eco-friendly, technologically advanced, and has many possible applications.<br />

Here, we have highlighted three of the most recent Best of Show <strong>materials</strong>.<br />

Contact information for the manufacturers of the <strong>materials</strong> on these pages is available in<br />

<strong>Material</strong> <strong>ConneXion</strong>’s online library database www.materialconnexion.com. Refer to the MC#.<br />

For information on how to become a subscriber e-mail us at access@materialconnexion.com.<br />

Polymer: D30<br />

MC# 5536-01<br />

Moldable resin that stiffens<br />

on impact. The technology<br />

harnesses dilatancy, the property<br />

ascribed to a substance<br />

that flows when moved slowly<br />

but that stiffens when moved<br />

quickly (similar to cornstarch<br />

in water). The resin is molded<br />

into flexible, elastic sheets<br />

that are designed predominantly<br />

as protective padding<br />

in sportswear.<br />

Natural: Particle Board<br />

from Natural Waste<br />

MC# 5496-01<br />

Resin-impregnated, natural fiber<br />

sheet that utilizes waste<br />

<strong>materials</strong>. The rigid panels incorporate<br />

Vetiver grass, rice<br />

husk, wood chips, lemon grass,<br />

or orange skin in an 8% polymeric<br />

dipheylmethane diisocyanate<br />

adhesive (PDMI) matrix.<br />

The sheets comply with standard<br />

particleboard in strength,<br />

screw pullout, water resistance<br />

and surface roughness.<br />

Process: Polymer Chain Mail<br />

MC# 539001<br />

Automated injection-molding<br />

process that manufactures<br />

seamless, interlinked<br />

elements. This mesh may<br />

be manufactured from most<br />

thermoplastic <strong>materials</strong> including<br />

polypropylene (PP),<br />

polyethylene (PE), and polycarbonate<br />

(PC). Potential<br />

applications include exterior<br />

facades, drapes, seating, or<br />

lampshades.<br />

STATE OF THE ART<br />

15

16<br />

<strong>48</strong> NEW MATERIALS<br />

MC# 0027-03<br />

MC# 4207-02<br />

MC# 5510-01<br />

MC# 5514-01<br />

MC# 5517-01<br />

MC# 5519-01<br />

Highly transparent polymer<br />

sound barrier for exterior<br />

use. 100% acrylic (PMMA)<br />

is cast into clear sheets that<br />

incorporate polyamide threads<br />

to guard against explosive<br />

shattering. Comes with a<br />

10-year weathering guarantee.<br />

For exterior sound abatement<br />

along transport lines.<br />

Cast resin sheet with a “double<br />

layer” effect. This 100% acrylic<br />

(PMMA) sheet is cast as one<br />

piece, with the two dissimilar<br />

sections formed at the same<br />

time, thus eliminating any<br />

chance of delamination. Available<br />

in sheets of 8 x 4 ft (2.44<br />

x 1.22 m) and in six colors.<br />

Sublimation process that<br />

combines digital printing<br />

with high-temperature<br />

image transfer to print high<br />

resolution graphics onto<br />

a wide variety of surfaces,<br />

from glass and concrete<br />

to high-pressure laminate.<br />

Appropriate for promotional<br />

displays, interior design, and<br />

architecture.<br />

Cellulosic matrix impregnated<br />

with polyester resin<br />

for cost-effective cooling and<br />

humidification. When hot,<br />

dry air passes at a relatively<br />

low speed through the wet<br />

matrix, it is cooled and humidified.<br />

Applications include<br />

greenhouses and open air<br />

structures.<br />

Durable, crocodile-textured<br />

linoleum. The flexible sheets<br />

are made of natural <strong>materials</strong><br />

calendared onto jute<br />

or paper backing. Class B1<br />

according to DIN 4102. Appropriate<br />

for commercial and<br />

residential settings.<br />

Rigidized metal sheet.<br />

Hydroforming imparts regular<br />

square forms or other shapes<br />

onto metal sheets. These<br />

sheets are staggered and<br />

glued together back to back to<br />

create one highly stiff sheet.<br />

Applications include dividing<br />

panels, work surfaces, and<br />

electromagnetic shielding.<br />

MC# 0091-15<br />

MC# 5508-01<br />

MC# 5513-01<br />

MC# 5516-01<br />

MC# 5518-01<br />

MC# 5520-01<br />

High-pressure laminates<br />

(HPL’s) with a textured<br />

surface. Decorative paper<br />

impregnated with melamine<br />

is pressed with kraft paper<br />

impregnated with phenolic<br />

resin at high pressure to<br />

produce laminates with high<br />

hardnesses.<br />

Rigid textured aluminum<br />

tiles for interior flooring. The<br />

tiles are anodized to impart<br />

a durable UV resistant color.<br />

The textured top surface may<br />

receive a clear coating to<br />

ensure good slip and scratch<br />

resistance. Custom sizes, thicknesses,<br />

colors and finishes are<br />

available on request.<br />

Faux stone surface that<br />

can be worked like wood.<br />

Mineral particulates in a<br />

resin binder are adhered<br />

to a rigid substrate that<br />

may be MDF, aluminum,<br />

Alucobond, particleboard or<br />

other construction material<br />

substrates. Applications are<br />

wall surfaces, event design<br />

elements, and furniture.<br />

A process for generating<br />

highly detailed decorative<br />

and functional surface structures<br />

using 3-D rendering<br />

software and rapid prototyping.<br />

This software improves<br />

upon the existing capabilities<br />

of shaders, making it possible<br />

to impart a highly detailed<br />

surface texture.<br />

Solid surfacing from 100%<br />

post consumer recycled<br />

paper. Waste paper pulp is<br />

mixed with a non-petroleum<br />

phenolic resin to produce a<br />

rigid, hard, durable solid surfacing<br />

sheet. The slabs come<br />

up to 60 in x 12 ft (1.524 x<br />

3.66 m) with thicknesses of<br />

1/4 to 2 in (6.35 to 51 mm).<br />

Tactile decorative wall covering.<br />

These wallcoverings use<br />

a special effect fleece surface<br />

on a non-woven backing.<br />

They are dimensionally<br />

stable, Class B1 according to<br />

DIN 4102 (Class 1 according<br />

to ASTM E-84). For use in<br />

commercial interior applications.

Contact information for the manufacturers of the <strong>materials</strong> on these pages is available in <strong>Material</strong> <strong>ConneXion</strong>’s<br />

online library database www.materialconnexion.com. Refer to the MC#. For information on how to become<br />

a Library User e-mail us at access@materialconnexion.com.<br />

MC# 5522-01<br />

Perforated rubber sheet for<br />

fashion and interior design<br />

applications. Thin, durable,<br />

black rubber sheet is perforated<br />

in a range of patterns<br />

to create a flexible, durable,<br />

elastic, and tear-resistant<br />

sheet. Currently available<br />

only in black. For apparel<br />

and interiors.<br />

MC# 5528-01<br />

3D graphics that can be applied<br />

to various substrates.<br />

This printing technique<br />

goes beyond lenticulars by<br />

allowing the placement of<br />

flat graphics over kinetic<br />

3D graphics to further create<br />

the illusion of depth.<br />

MC# 5532-01<br />

Ceramic tiles that incorporate<br />

unique textured surfaces<br />

for decorative effect.<br />

Nine distinct topographical<br />

surfaces are created on<br />

glazed ceramic tiles for<br />

interior applications. The<br />

tiles come in matte, glossy,<br />

and extra glossy finishes.<br />

MC# 5535-01<br />

Electroluminescent polymer<br />

sheet that offers greater<br />

flexibility than existing types,<br />

due to the usage of printable<br />

polyurethane in conjunction<br />

with other inks. These sheets<br />

may be used as backlighting<br />

for cell phones, as safety<br />

lighting in backpacks and<br />

wearables, and in novelty<br />

gear.<br />

MC# 5537-01 MC# 1949-07 MC# 5358-02 MC# 5<strong>48</strong>5-01<br />

A process for powder coating<br />

plastics that offers an<br />

alternative to liquid painting<br />

or inherent coloring.<br />

It works by applying dry,<br />

pigmented powder onto<br />

a substrate via a charged<br />

particle stream and<br />

charged substrate. The part<br />

is then baked in an oven.<br />

MC# 5491-01<br />

Laminated glass sheet<br />

that converts electricity to<br />

radiant heat. Two sheets of<br />

glass sandwich a consuctive<br />

polymer film to creat<br />

a clear panel. Its maximum<br />

service heat is approximately<br />

70°C (158°F).<br />

A high-definition printing<br />

process for coloring carpet.<br />

Using a proprietary technique,<br />

pattern is created<br />

through selective bleaching<br />

of the color. The modular<br />

tile is tufted, textured, loop<br />

pile nylon 6,6 and backed<br />

with a PVC-free cushion.<br />

For interior contract<br />

flooring.<br />

MC# 5492-01<br />

Custom perforated metal<br />

sheets for a wide range of<br />

applications. Aluminum,<br />

plain carbon and stainless<br />

steel, titanium zinc or brass<br />

sheets are perforated with<br />

round or square holes in<br />

any pattern or size.<br />

A process for custom<br />

manufacturing woven<br />

security mesh for containers<br />

and bags. Copper wire is<br />

sheathed in 100% polyvinyl<br />

chloride (PVC) and knit into<br />

1200 mm (47.2 in) wide textiles.<br />

The mesh is connected<br />

to a continuous current<br />

circuit so that if one section<br />

of the wire is cut, the circuit<br />

shorts and an alarm sounds.<br />

MC# 5477-01<br />

Leather produced using<br />

organic farming, handling,<br />

and tanning techniques.<br />

The hides are tanned using<br />

vegetable dyes and kept<br />

separate from any nonorganic<br />

hides. The company<br />

produces a range of qualities<br />

and thicknesses as well<br />

as suede and Nubuck.<br />

House insulation made<br />

from dried sea grass that<br />

has been harvested as<br />

bio-waste. This insulation<br />

is durable, does not attract<br />

parasites, has good absorption,<br />

and acts as a humidity<br />

buffer. It is supplied in bags<br />

and complies with B2 fire<br />

retardance according to<br />

DIN 4102-2.<br />

MC# 5<strong>48</strong>7-01<br />

Structural sheet steel that<br />

incorporates fine spacer filaments<br />

to achieve strength<br />

with lightness. This stainless<br />

steel sheet comprises two<br />

outer thin sheets that are<br />

separated with a regular array<br />

of thin wires orthogonal<br />

to the sheet orientation.<br />

Applications include aircraft,<br />

electronics, and sports<br />

equipment.<br />

17

18<br />

<strong>48</strong> NEW MATERIALS<br />

MC# 5474-01<br />

Flooring made from<br />

recycled bicycle inner tubes.<br />

This handmade, handloomed<br />

100% recycled rubber<br />

rug is made by looping<br />

recycled bicycle tubes and<br />

weaving them into 100%<br />

wool backing. The pile<br />

height is 35 mm (1.4 in) and<br />

the rug is 170 x 240 cm (67<br />

x 94.5 in).<br />

MC# 5472-01<br />

Removable vinyl wall decals<br />

for interior and exterior<br />

applications. These die-cut,<br />

100% polyvinyl chloride<br />

(PVC) decals incorporate<br />

a removable adhesive that<br />

will affix to any smooth,<br />

flat surface. The decals are<br />

available in more than 50<br />

colors and 35 patterns.<br />

MC# 5359-05<br />

Rigid melamine sheets that<br />

incorporate a decorative<br />

layer. These low-cost, formaldehyde-free<br />

panels are<br />

manufactured from 55%<br />

melamine resin, 40% cellulose,<br />

and 5% cloth. The<br />

melamine paper surface<br />

has a hand-painted design.<br />

MC# 5497-02<br />

Metal sheet that has been<br />

slit and expanded to create<br />

a mesh of uniformly spaced<br />

openings. These hot-dip<br />

galvanized or chromiumplated<br />

milled steel forms<br />

are rigid, though they may<br />

be curved and bent according<br />

to needs.<br />

MC# 5<strong>48</strong>6-01<br />

This stainless steel “chainmail”<br />

has been developed<br />

with a ring diameter of 12.0<br />

mm (0.472 in) with a wire<br />

gauge of 1.10 mm (0.043<br />

in). Applications are for<br />

safety fences, blast protection<br />

for buildings, interior<br />

drapery, and other interior<br />

and exterior architectural<br />

accents.<br />

MC# 5436-01<br />

Insulating tubing that<br />

shrinks when heated. Polyvinyl<br />

chloride (PVC) tubing<br />

shrinks when heated,<br />

proving a protective and insulating<br />

coating for objects<br />

of various shapes. Applications<br />

include insulation for<br />

wiring as well as protective,<br />

waterproof coatings for any<br />

object.<br />

MC# 5498-01<br />

Decorative glass sheet that<br />

incorporates an interlayer<br />

of resin and textile. Textiles<br />

are laminated between<br />

the glass sheets using a<br />

polyvinyl butyral (PVB)<br />

layer. Customization of the<br />

decorative layer is possible.<br />

The sheets may be curved.<br />

Natural fiber rug that has<br />

a deep pile height. These<br />

100% New Zealand wool<br />

rugs are woven using felted<br />

wool loops in ten patterns<br />

with a pile height of up to<br />

2 3/4 in (70 mm). They are<br />

backed with a woven jute<br />

and cotton mat. They are<br />

woven 12 ft (3.66 m) wide.<br />

MC# 5503-01<br />

MC# 4791-03 MC# 5091-04<br />

MC# 5438-01<br />

Non-stick enamel coating<br />

that offers higher temperature<br />

resistance than<br />

existing non-stick surfaces.<br />

Porcelain and PTFE enamel<br />

that is bonded to metal.<br />

The coatings are typically<br />

used as an ultimate-quality,<br />

highly durable, and sanitary<br />

finish on appliances.<br />

Sheets of decorative glass<br />

tiles secured by a polymer<br />

grid. These mosaics are<br />

created by cutting squares<br />

of clear float glass and<br />

coating one surface with<br />

a colored layer of paint.<br />

They are then adhered to a<br />

flexible backing of PVB that<br />

holds them perpendicular<br />

to and equidistant from<br />

each other.<br />

Structural building panels<br />

that utilize a formaldehydefree,<br />

soy-based binder.<br />

These building panels are<br />

comprised of one of four<br />

core <strong>materials</strong>, faced in veneer.<br />

The wheat straw fiber<br />

is annually re<strong>new</strong>able and<br />

was historically considered<br />

to be agricultural waste.<br />

MC# 5441-01<br />

Additives to paints, inks,<br />

resins, and coatings that<br />

“tag” the material with<br />

a unique code. These<br />

microtaggants are a unique<br />

numeric code sequence<br />

in a multiple colored layer<br />

format. Applications are<br />

for security tagging of<br />

packaging, products, and<br />

written data.

Contact information for the manufacturers of the <strong>materials</strong> on these pages is available in <strong>Material</strong> <strong>ConneXion</strong>’s<br />

online library database www.materialconnexion.com. Refer to the MC#. For information on how to become<br />

a Library User e-mail us at access@materialconnexion.com.<br />

MC# 5442-01<br />

MC# 5444-01<br />

MC# 5446-01<br />

MC# 5453-01<br />

MC# 5463-01<br />

MC# 5462-02<br />

A two-step sublimation<br />

printing process in which a<br />

substrate is printed with sublimation<br />

dyes. Then dry heat<br />

and pressure are applied to<br />

the paper so that the image<br />

is dyed into the substrate<br />

surface. For printing onto any<br />

hard solid surfacing material.<br />

Coating that contains an iron<br />

filler for wood and woodbased<br />

surfaces. This flameretardant<br />

filler composed of<br />

ferro-magnetic particulates<br />

and a bonding agent can<br />

be applied to wood or wood<br />

composite surfaces.<br />

Pultruded composites that<br />

use carbon fiber roving<br />

for strength. These rigid<br />

profiles are produced using<br />

unidirectional fiber roving,<br />

which provides longitudinal<br />

strength. Applications<br />

include aerospace structural<br />

profiles, racing car profiles, in<br />

bridge construction, and for<br />

molded parts.<br />

Wool textiles with various<br />

3-dimensional patterns.<br />

These textiles are handmade<br />

from 100% wool felt and<br />

woven. Patterns are created<br />

by twisting and/or stitching<br />

different pieces of fabric<br />

together. The textiles are sold<br />

by the square meter and are<br />

available in a standard range<br />

of colors and textures.<br />

Polymer mosaic squares<br />

and discs for interior wall<br />

and counter surfaces. These<br />

100% polyester (PET) colored<br />

chips are an alternative<br />

to glass or ceramic and are<br />

offered in 80 basic and 26<br />

marble colors.<br />

Woven fabric that incorporates<br />

cotton fiber and<br />

yarn for decorative effect.<br />

Bunches of cotton fibers are<br />

woven in parallel lines into<br />

un-colored cotton to create<br />

fabric that is 500, 600,<br />

700, 800, or 900 cm (19.68,<br />

23.62, 27.56 31.5 or 35.4<br />

in) wide.<br />

MC# 5443-01<br />

MC# 4108-02<br />

MC# 5452-01<br />

MC# 5462-01<br />

MC# 5464-01<br />

MC# 5467-01<br />

Concrete-like composite material<br />

that incorporates sand<br />

and household waste plastic.<br />

75% silica sand and 25%<br />

mixed polymer regrind from<br />

recycling plants are bonded<br />

together using heat (300°C;<br />

572°F) and pressure. Any<br />

extruded or molded shape is<br />

possible.<br />

A rapid prototyping process<br />

for creating thermoplastic<br />

three-dimensional models. A<br />

software program (generating<br />

an .stl file) first “slices”<br />

the object into thin layers.<br />

Then a computer-aided<br />

design (CAD) file controls the<br />

laying down of thermoplastic<br />

material in thin layers according<br />

to the .stl file.<br />

Electrically conductive,<br />

low-weight, high-strength,<br />

flexible Zylon® (polyphenylene<br />

bisoxazole, PBO)/metal<br />

hybrid yarn. Applications<br />

include EMI shielding,<br />

aerospace, computing, and<br />

electronic textiles.<br />

Woven decorative textile<br />

that incorporates an herb<br />

for fragrance. The woven<br />

paper is 90% herb (warp)<br />

and 10% cotton (weft), with<br />

widths 500, 600, and 700<br />

mm (19.68, 23.62, and 27.56<br />

in). No chemicals are used to<br />

create the fragrance.<br />

Handmade floor and wall<br />

covering that uses rope-like<br />

tendrils to create a thick<br />

pile. This 20% sisal, 80%<br />

cotton woven rug is glued<br />

to a mesh backing to ensure<br />

solidity. The rugs may be<br />

waterproofed.<br />

Pile fabrics that mimic fur.<br />

These 100% acrylic or 100%<br />

polyester textiles are available<br />

jacquard or loop knit;<br />

yarn, drop, or fiber dyed, and<br />

with a pile length of 5-100<br />

mm (0.2 – 3.94 in). Available<br />

in flame-retardant, waterrepellent,<br />

anti-bacterial, and<br />

anti-odor versions and in a<br />

wide range of colors.<br />

19

you make the choice.<br />

Zambaiti<br />

PCF Natural Living line<br />

NatureWorks ® PLA glasses<br />

Heimtextil Creative Gallery<br />

ADVERTISEMENT<br />

NatureWorks LLC, the first company to offer a family of commercially<br />

available polymers derived from 100% annually re<strong>new</strong>able<br />

resources (marketed under the NatureWorks ® PLA brand for<br />

packaging applications and Ingeo fibers for textile products),<br />

is proud to participate in <strong>Material</strong> <strong>ConneXion</strong>’s Terra Matter<br />

program, a key event coinciding with Ingeo Earth Month.<br />

A revolutionary biopolymer,<br />

NatureWorks ® PLA is the world’s<br />

first greenhouse gas neutral<br />

polymer 1 . It is the base resin<br />

used to create a <strong>new</strong> breed of<br />

compostable packaging solutions<br />

such as service trays, cutlery, and<br />

water bottles. It is also the basis for<br />

Ingeo fiber, from which a range of<br />

<strong>new</strong>, high-performance alternatives<br />

to both wovens and nonwovens<br />

for apparel and home is made.<br />

Our partners are committed<br />

to nurturing and developing<br />

responsible and innovative<br />

products that are beautiful to touch<br />

and wear and that often outperform<br />

the competition. Together with<br />

NatureWorksLLC, they are<br />

participating in Ingeo Earth Month<br />

2006.<br />

April 22 nd is United Nations Earth<br />

Day, a time when we can all<br />

reflect on global environmental<br />

issues. It marks the launch<br />

of Ingeo Earth Month,<br />

Armani Collezioni shirt<br />

which will continue until May<br />

31 st . During this period, our retail<br />

and brand partners will take the<br />

opportunity to showcase their very<br />

best Ingeo fiber products and to<br />

demonstrate their commitment to<br />

the message and motivation behind<br />

Ingeo Earth Month. In 2006, 54<br />

brands will participating by selling<br />

a wide variety of products for the<br />

home, the wardrobe, and even for<br />

personal care in at least 650 stores<br />

worldwide.<br />

For more details on what is<br />

happening, or on products,<br />

partners, and point of sale, visit<br />

www.ingeofibers.com.<br />

One key event that we are involved<br />

with during Ingeo Earth Month is<br />

<strong>Material</strong> <strong>ConneXion</strong>’s symposium,<br />

Terra Matter: Inspire, Innovate,<br />

Sustain, which promotes a<br />

message of responsible innovation.<br />

It will be presented May 19 th at the<br />

Equitable Center and May 20 th at<br />

the International Contemporary<br />

1 Based on the purchase of re<strong>new</strong>able energycertificates by NatureWorksLLC<br />

*Compostable in industrial composting facilities where available

enjoy the difference.<br />

Univisio duvets Roda cushion<br />

NaturAll Baby Wipes by W.I.P.<br />

Aquavibe bio-energetic living water<br />

how it’s made<br />

“Ingeo” means ingredients from<br />

the earth, and is derived entirely<br />

from more sustainable agricultural<br />

resources like corn. In other words,<br />

it begins with an abundant, natural<br />

raw material that can be easily and<br />

efficiently produced year after year.<br />

The extracted starch is put through<br />

a simple process to make plant<br />

sugars. The sugars are fermented in<br />

a process similar to making yogurt.<br />

Then the fermentation products are<br />

transformed into a high-performance<br />

polymer called polylactide, which<br />

is branded NatureWorks® PLA.<br />

Ingeo fiber is extruded from this<br />

polymer.<br />

ADVERTISEMENT<br />

Furniture Fair, both in New York City.<br />

At Terra Matter, Natureworks LLC will<br />

present its mission for sustainability<br />

and invite selected partners to share<br />

their own experiences. The central<br />

expression of the project will be an<br />

exhibition titled Live the dream, the<br />

future of sustainable living, where<br />

attendees will be able to experience<br />

eco-friendly products for themselves.<br />

Ingeo fiber will be featured in the<br />

exhibition through the presentation<br />

of the Ingeo Creative Gallery, a<br />

showcase demonstrating the diversity<br />

of commercially available applications,<br />

with cutting edge fashion from<br />

Boudicca, Linda Loudermilk, Armani,<br />

Moral Fervour and naturevsfuture®.<br />

For the home, try pillows from Pacific<br />

Coast Feather, blankets from Zambaiti<br />

and Univisio, and also the <strong>new</strong><br />

generation of diposable nonwovens<br />

from HealthQuest’s “Earth friendly<br />

baby ® ” wipes, and diapers from W.I.P.,<br />

as well as the first official Ingeo Earth<br />

Month water from Aquavibe in a <strong>new</strong><br />

bottle created from NatureWorks ® PLA<br />

and much more.<br />

This exhibition will be held at the<br />

<strong>Material</strong> <strong>ConneXion</strong> headquarters in<br />

New York City, running from April 27th<br />

through August 1st 2006.<br />

Ingeo, the only fiber made from 100% natural, annually re<strong>new</strong>able agricultural resources. Not oil.<br />

Ingeo, the Ingeo logo and NatureWorks are registered trademarks of NatureWorks LLC<br />

Boudicca<br />

Linda Loudermilk<br />

naturevsfuture ®

MATERIAL PROFILE<br />

22<br />

16<br />

MATERIALS AT EXTREME TEMPERATURES<br />

by Dr. Andrew Dent<br />

Broken completely in half, this Liberty Ship was subject to catastrophic<br />

brittle fracture in the cold waters off the shores of Maine, New England.<br />

Objects generally appear still and coherent,<br />

but the molecules they’re made of vibrate. At<br />

hotter temperatures they vibrate like crazy,<br />

and might even move about; at colder temperatures,<br />

they vibrate hardly at all. For all <strong>materials</strong>,<br />

transitioning from solid to liquid state<br />

(changing phase) just means that the molecules<br />

vibrate enough to break the bonds that<br />

hold them together; transitioning the other<br />

way means that the molecules slow their vibrating<br />

enough to form bonds. This is true for<br />

the molecules in polar-expedition lip balm as<br />

for those in the hot section of a jet engine.<br />

Simple as this seems, scientists have devoted<br />

careers to figuring out in detail how <strong>materials</strong><br />

behave at different temperatures. (To<br />

be precise, scientists are really interested<br />

not in temperature per se, but rather in the<br />

kinetic energy of a material, or how fast the<br />

molecules are vibrating.) This is because all<br />

<strong>materials</strong> react uniquely to energy.<br />

When trying to gauge which material is best<br />

for a certain temperature-sensitive application,<br />

we can rely on some rather intuitive rules<br />

of thumb—up to a point. For instance, when<br />

specifying <strong>materials</strong> for hot applications, use<br />

metals. (Caveat: The useable temperature<br />

for metals varies widely!) Even better are<br />

engineering ceramics, for which the maximum<br />

service temperature is more than 1800ºF. For<br />

temperatures below freezing, polymers are often<br />

a good choice, not least because they have<br />

low thermal conductivity: you can touch your<br />

tongue to a plastic pipe in winter and pull it<br />

away unscathed.<br />

However, if performance at a particular temperature<br />

is key to your <strong>materials</strong> problem, perhaps<br />

you will find the information below helpful.<br />

Glass Transition Temperature (T g )<br />

Roughly defined, a plastic’s glass transition<br />

temperature (T g ) is the temperature at which<br />

its chemical structure goes from crystalline to<br />

amorphous. When plastics experience temperatures<br />

below their T g , they become rigid and can<br />

crack and shatter, like glass. Polystyrenes and<br />

acrylic are typically used below their T g , thus<br />

they are hard and brittle. Elastomers and polyolefins,<br />

on the other hand, are used above their<br />

T g , thus they are softer and more flexible. T g is a<br />

very important property when specifying composites,<br />

predominantly because the polymer<br />

binder is relied upon for flexibility.<br />

Ductile to Brittle Transition Temperature (DBTT)<br />

In metals, a similar property, the ductile to brittle<br />

transition temperature (DBTT), appertains

to certain structures of metals. At this temperature,<br />

which is often the lowest temperature at<br />

which a structural engineering material can be<br />

considered useful, a metal will fail in a brittle<br />

manner rather than in a ductile manner. That<br />

is, it will shatter rather than bend before giving<br />

way. The DBTT is very sensitive to alloy composition<br />

and processing. This makes it a useful<br />

criterion for quality control.<br />

The notorious catastrophe that befell the World<br />

War II Liberty ships illustrates the importance<br />

of considering DBTT. When launched in cold,<br />

northern waters, the steel hulls of the Liberty<br />

ships split in half. Evidently a hapless engineer<br />

had forgotten that the DBTT of some steel<br />

roughly coincides with the freezing point of water.<br />

Of course, one person’s catastrophe is another<br />

person’s good fortune. Aristotle Onassis<br />

purchased these ships for a pittance and, with<br />

them, created a shipping empire. He k<strong>new</strong> that<br />

in warmer, equatorial waters, they were completely<br />

safe.<br />

<strong>Material</strong>s at elevated temperatures<br />

It is important to remember that the description<br />

“solid” is a relatively general term that<br />

Brittle fracture in steel. This micrograph of the fracture<br />

surface shows the cleavage along crystal planes that<br />

absorbs little energy.<br />

refers to a range of material behaviors. On<br />

their way to becoming liquids, some solid<br />

<strong>materials</strong> transition through a viscous,<br />

gooey state (e.g. molten magma). However,<br />

long before this solid to liquid transition<br />

happens, the material loses its mechanical<br />

performance. Aluminum melts at around<br />

1220ºF but is of little use in any structural<br />

application above 360ºF. Polymers behave<br />

similarly, with the softening point typically<br />

falling at 70% of their melting point. Exceptionally,<br />

the upper limits of ceramics’<br />

operating temperatures are much closer to<br />

their melting points.<br />

<strong>Material</strong>s at low temperatures<br />

Absolute zero (0 Kelvin [0K], -273.15ºC,<br />

-459.7ºF) is as cold as anything can get. At this<br />

temperature the molecules in an object cease<br />

to move. It is actually impossible to reach this<br />

temperature, though we’ve got within a few<br />

millionths of a degree. The coldest naturally occurring<br />

place we know of is deep space, a very<br />

chilly 3K. In fact, this slight temperature elevation<br />

above 0K is the best evidence we have that<br />

the Big Bang actually occurred.<br />

The most significant change in material properties<br />

at below-ambient (or below-room) temperatures<br />

is the increasing brittleness of the<br />

material, but there are also other properties<br />

that manifest very close to 0K.<br />