Automation's Next Step

This edition of The Journal considers automation of container terminals and how the industry is delivering the next steps towards full and semi-automation. With the inclusion of over 30 technical papers The Journal also explores terminal planning in the age of automation, environmental sustainability for ports, the impact of mega ships and other topics. Automation continues to drive innovation across several industries, and there is no greater example of this than maritime. However, implementation, technology and best practices continue to be a constant source of debate and analysis across the sector, as is shown in this edition of the PTI Journal. The automation debate is not new, but it remains a booming market and a source of growth for the wider container terminal industry. One thing is for certain, automation is here to stay.

This edition of The Journal considers automation of container terminals and how the industry is delivering the next steps towards full and semi-automation.

With the inclusion of over 30 technical papers The Journal also explores terminal planning in the age of automation, environmental sustainability for ports, the impact of mega ships and other topics.

Automation continues to drive innovation across several industries, and there is no greater example of this than maritime.

However, implementation, technology and best practices continue to be a constant source of debate and analysis across the sector, as is shown in this edition of the PTI Journal.

The automation debate is not new, but it remains a booming market and a source of growth for the wider container terminal industry.

One thing is for certain, automation is here to stay.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

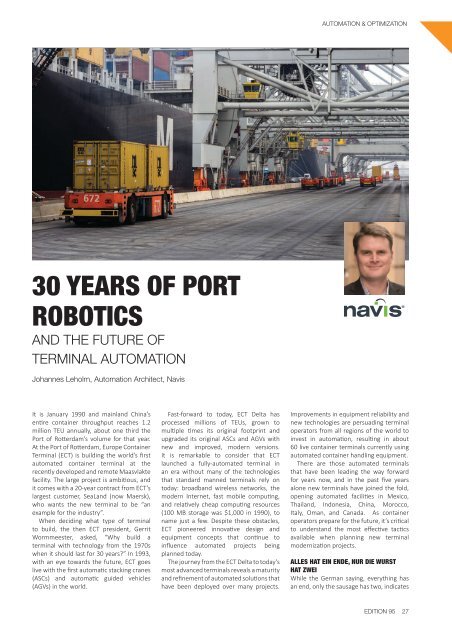

AUTOMATION & OPTIMIZATION<br />

30 YEARS OF PORT<br />

ROBOTICS<br />

AND THE FUTURE OF<br />

TERMINAL AUTOMATION<br />

Johannes Leholm, Automation Architect, Navis<br />

It is January 1990 and mainland China’s<br />

entire container throughput reaches 1.2<br />

million TEU annually, about one third the<br />

Port of Rotterdam’s volume for that year.<br />

At the Port of Rotterdam, Europe Container<br />

Terminal (ECT) is building the world’s first<br />

automated container terminal at the<br />

recently developed and remote Maasvlakte<br />

facility. The large project is ambitious, and<br />

it comes with a 20-year contract from ECT’s<br />

largest customer, SeaLand (now Maersk),<br />

who wants the new terminal to be “an<br />

example for the industry”.<br />

When deciding what type of terminal<br />

to build, the then ECT president, Gerrit<br />

Wormmeester, asked, “Why build a<br />

terminal with technology from the 1970s<br />

when it should last for 30 years?” In 1993,<br />

with an eye towards the future, ECT goes<br />

live with the first automatic stacking cranes<br />

(ASCs) and automatic guided vehicles<br />

(AGVs) in the world.<br />

Fast-forward to today, ECT Delta has<br />

processed millions of TEUs, grown to<br />

multiple times its original footprint and<br />

upgraded its original ASCs and AGVs with<br />

new and improved, modern versions.<br />

It is remarkable to consider that ECT<br />

launched a fully-automated terminal in<br />

an era without many of the technologies<br />

that standard manned terminals rely on<br />

today: broadband wireless networks, the<br />

modern Internet, fast mobile computing,<br />

and relatively cheap computing resources<br />

(100 MB storage was $1,000 in 1990), to<br />

name just a few. Despite these obstacles,<br />

ECT pioneered innovative design and<br />

equipment concepts that continue to<br />

influence automated projects being<br />

planned today.<br />

The journey from the ECT Delta to today’s<br />

most advanced terminals reveals a maturity<br />

and refinement of automated solutions that<br />

have been deployed over many projects.<br />

Improvements in equipment reliability and<br />

new technologies are persuading terminal<br />

operators from all regions of the world to<br />

invest in automation, resulting in about<br />

60 live container terminals currently using<br />

automated container handling equipment.<br />

There are those automated terminals<br />

that have been leading the way forward<br />

for years now, and in the past five years<br />

alone new terminals have joined the fold,<br />

opening automated facilities in Mexico,<br />

Thailand, Indonesia, China, Morocco,<br />

Italy, Oman, and Canada. As container<br />

operators prepare for the future, it’s critical<br />

to understand the most effective tactics<br />

available when planning new terminal<br />

modernization projects.<br />

ALLES HAT EIN ENDE, NUR DIE WURST<br />

HAT ZWEI<br />

While the German saying, everything has<br />

an end, only the sausage has two, indicates<br />

EDITION 95 27