Practical and Academic Geotechnical Reflections, 2018

The following article was published in the Florida Engineering Society (FES), July 2018 Journal dedicated annually to the enlightenment and education of Geotechnical Engineering. This article came to my mind as a result of teaching, mentoring, reviewing reports and supervising Geotechnical sites during four decades of my life. I say "Thank You" to my family, colleagues, co-workers and students who have supported me in my passionate pursuit of excellence in this rewarding field. Success of geotechnical projects depend on several coupling factors such as academic preparation, continuing education and professional experience. All of which, when well acquired allow for success and application of what is called “engineering judgment”. All three factors above become more relevant when one considers that geotechnics is not a precise science: rather instead, an art. As the legendary geotechnical engineer and professor, Ralph B. Peck(5) mentioned in one of his last memorable conferences, “geotechnics is an imprecise art”. It is possible that for lack of academic knowledge, poor experiences and even worse, an engineer that has been negligent in their basic duties, the following typically occur: (a) geotechnical exploration is insufficient, (b) application of basic geotechnical concepts are misled, (c) foundation design redundancy is not applied, and (d) instrumentation is not considered or does not have the appropriate scope to fulfill project needs. The goal of this article is to present orderly, important and practical geotechnical aspects (as listed above) to consider when involved in a project design or existing construction project in layman’s terms and without deepening into extended numerical theories. When these aspects are not accounted for properly or focus is missed during project development, generally the project quality and human safety could be compromised causing loss of life and/or loss of property. We are not exonerated from human factors and the geotechnical failures associated with it, but we strive to diminish them.

The following article was published in the Florida Engineering Society (FES), July 2018 Journal dedicated annually to the enlightenment and education of Geotechnical Engineering. This article came to my mind as a result of teaching, mentoring, reviewing reports and supervising Geotechnical sites during four decades of my life. I say "Thank You" to my family, colleagues, co-workers and students who have supported me in my passionate pursuit of excellence in this rewarding field.

Success of geotechnical projects depend on several coupling factors such as academic preparation, continuing education and professional experience. All of which, when well acquired allow for success and application of what is called “engineering judgment”. All three factors above become more relevant when one considers that geotechnics is not a precise science: rather instead, an art. As the legendary geotechnical engineer and professor, Ralph B. Peck(5) mentioned in one of his last memorable conferences, “geotechnics is an imprecise art”.

It is possible that for lack of academic knowledge, poor experiences and even worse, an engineer that has been negligent in their basic duties, the following typically occur: (a) geotechnical exploration is insufficient, (b) application of basic geotechnical concepts are misled, (c) foundation design redundancy is not applied, and (d) instrumentation is not considered or does not have the appropriate scope to fulfill project needs.

The goal of this article is to present orderly, important and practical geotechnical aspects (as listed above) to consider when involved in a project design or existing construction project in layman’s terms and without deepening into extended numerical theories. When these aspects are not accounted for properly or focus is missed during project development, generally the project quality and human safety could be compromised causing loss of life and/or loss of property. We are not exonerated from human factors and the geotechnical failures associated with it, but we strive to diminish them.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

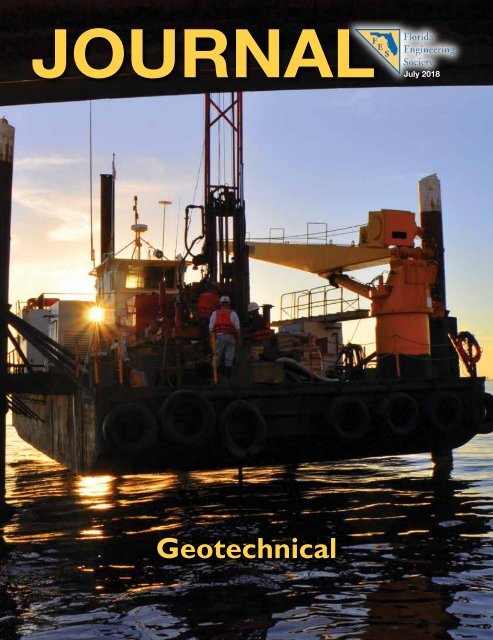

JOURNAL July<br />

<strong>2018</strong><br />

<strong>Geotechnical</strong>

<strong>Practical</strong> <strong>and</strong> <strong>Academic</strong><br />

<strong>Geotechnical</strong> <strong>Reflections</strong><br />

Success of geotechnical projects depends on several coupling<br />

factors such as academic preparation, continuing education <strong>and</strong><br />

professional experience; all of which, when well acquired, allow<br />

for success <strong>and</strong> application of what is called “engineering judgment.”<br />

All three factors become more relevant when one considers that<br />

geotechnics is not a precise science but instead, an art. As the<br />

legendary geotechnical engineer <strong>and</strong> professor, Ralph B. Peck 1 (5)<br />

mentioned in one of his last memorable conferences, “geotechnics is<br />

an imprecise art.”<br />

It is possible that for lack of academic knowledge, poor<br />

experiences <strong>and</strong> even worse, an engineer who has been negligent<br />

in their basic duties, the following typically occur: (a) geotechnical<br />

exploration is insufficient, (b) application of basic geotechnical<br />

concepts is misled, (c) foundation design redundancy is not applied,<br />

<strong>and</strong> (d) instrumentation is not considered or does not have the<br />

appropriate scope to fulfill project needs.<br />

The goal of this article is to present orderly, important <strong>and</strong><br />

practical geotechnical aspects (as listed above) to consider when<br />

involved in a project design or existing construction project in<br />

layman’s terms <strong>and</strong> without deepening into extended numerical<br />

theories. When these aspects are not accounted for properly or focus<br />

is missed during project development, generally the project quality<br />

<strong>and</strong> human safety could be compromised, causing loss of life <strong>and</strong>/<br />

or loss of property. We are not exonerated from human factors <strong>and</strong><br />

the geotechnical failures associated with it, but we strive to diminish<br />

them.<br />

The goal of this article is to<br />

present orderly, important<br />

<strong>and</strong> practical geotechnical<br />

aspects to consider when<br />

involved in a project design<br />

or existing construction<br />

project in layman’s terms<br />

<strong>and</strong> without deepening into<br />

extended numerical theories.<br />

By Jose N. Gomez, PE,<br />

D.GE, F.ASCE<br />

ECS Florida LLC<br />

1<br />

Low numbers in parenthesis refer to references given at the end of the article.<br />

fleng.org JULY <strong>2018</strong> | JOURNAL Florida Engineering Society | 21

<strong>Practical</strong> <strong>and</strong> <strong>Academic</strong> <strong>Geotechnical</strong> <strong>Reflections</strong> continued from page 21<br />

22 | JOURNAL Florida Engineering Society | JULY <strong>2018</strong><br />

<strong>Geotechnical</strong> Exploration. This is<br />

perhaps one of the most needed activities<br />

in practical geotechnics. Quite often the<br />

geotechnical engineer is pressured by<br />

projects’ incumbents to reduce the scope of<br />

an exploration plan, alleging that budgets<br />

are too low. You may be forced to reduce the<br />

number of borings or test pits <strong>and</strong>/or their<br />

depths without any valid technical support or<br />

geotechnical judgment. As such, a complete<br />

soil profile (the “x-ray” of subsoil) with basic<br />

properties to develop appropriate designs<br />

might not be accomplished, thus leaving<br />

gaps that will affect a foundations’ design.<br />

Professor R. Peck (5)<br />

, a disciple of K. Terzaghi<br />

(known as the father of Soil Mechanics)<br />

also emphasized the need to know <strong>and</strong><br />

differentiate the types of soils to reach<br />

interpretations according to existing subsoil<br />

conditions.<br />

It isn’t a secret for any member of an<br />

engineering team that during the construction<br />

of a project, there can be a negative impact<br />

associated with poor subsoil exploration<br />

scope. As a result, one is exposed to more<br />

contingencies, which can generate significant<br />

changes in the project cost <strong>and</strong> schedule.<br />

Sufficiently complete geotechnical<br />

exploration campaigns <strong>and</strong> soil laboratory<br />

tests supported by traditional practices of<br />

the Soil Mechanics should be attained under<br />

all circumstance to meet project needs.<br />

Exploration scopes may also be extended,<br />

if applicable, during the construction stage<br />

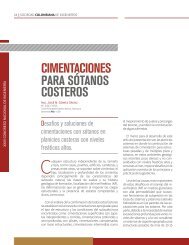

Figure 1. Fine soils: typical shear strength envelopes.<br />

Figure 1. Fine soils: typical shear strength envelopes<br />

of the project by recommending additional<br />

field explorations <strong>and</strong> laboratory tests to be<br />

able to adjust the designs by observational<br />

engineering.<br />

Basic <strong>Geotechnical</strong> Concepts. There are<br />

cases when review of geotechnical studies<br />

are needed due to slope failures, unexpected<br />

foundation behaviors, or concerns generated<br />

by owners who have some experience in the<br />

field. These concerns usually are generated<br />

because the projects are somehow over—<br />

or under—designed. The typical issues<br />

here are the strength properties assigned<br />

to fine soils such as clays, based on their<br />

classification from the point of view of<br />

formation. Normally consolidated clays (NC)<br />

are usually saturated <strong>and</strong> soft, while preconsolidated<br />

clays (PC) <strong>and</strong>/or residual soils<br />

are partially saturated <strong>and</strong> stiff. The strength<br />

of these clays are very sensitive to moisture<br />

conditions <strong>and</strong> to the rate of application of<br />

the foundation load, which consequently<br />

affects the dissipation of pore pressure (water<br />

in the soil structure). The point here is that<br />

the same fine-grained soil, depending on the<br />

initial moisture <strong>and</strong> loading conditions, will<br />

have differing strength responses.<br />

Deficiencies in the underst<strong>and</strong>ing of clay<br />

strength are sometimes noticed in young<br />

engineers, which then become inappropriate<br />

habits. This arises due to lack of support<br />

<strong>and</strong> guidance from more experienced<br />

engineers who do not share the need for (a)<br />

identification of either NC or PC clay type, or<br />

(b) the determination of strength properties.<br />

There have been cases of working under<br />

unconsolidated undrained conditions (UU)<br />

in partially saturated PC clays that greatly<br />

underestimate its shear strength. As shown<br />

in Figure 1, the designer was most likely<br />

working on the “safe” or “conservative” side.<br />

What really happened was that this concept<br />

did not apply or wasn’t correct; especially if<br />

one has data to prove otherwise. The result<br />

of this erroneous assignment of the strength<br />

to a fine soil could lead in practice to having<br />

a more expensive foundation solution,<br />

e.g., piles instead of a shallow foundation<br />

with footings. The actual ultimate bearing<br />

fleng.org

Figure 1. Fine soils: typical shear strength envelopes<br />

Figure 2. Concrete diaphragm wall, slope failure; misled selection of LEP<br />

capacity (qult) of a PC clay using the<br />

general bearing capacity developed by<br />

Terzaghi <strong>and</strong> Meyerhof can be of the<br />

order of 75 tn/m² (Ø = 21˚, c = 3.5 tn/<br />

m², B=1.5m), whereas if the criteria of<br />

an NC clay is wrongly used under the<br />

UU condition (cu = qu/2 = 2.0 tn/m²),<br />

qult could be less than 15 tn/m² (80%<br />

less or more).<br />

Estimation of lateral earth<br />

pressures (LEP) distribution on a<br />

temporary bracing structure also<br />

deserves attention. Retaining walls<br />

(rigid structures) support triangular<br />

Rankine or Coulomb LEPs, whereas<br />

temporary bracing-shoring structures<br />

are flexible <strong>and</strong> support different<br />

LEP distribution shapes based on<br />

empirical analyses. It turns out that<br />

the latter develops LEPs from the<br />

ground surface, unlike the former.<br />

Within empirical formulas, it is also<br />

necessary to differentiate between<br />

continued on next page<br />

Figure 2. Concrete diaphragm wall, slope failure; misled selection of LEP.<br />

fleng.org JULY <strong>2018</strong> | JOURNAL Florida Engineering Society | 23

<strong>Practical</strong> <strong>and</strong> <strong>Academic</strong> <strong>Geotechnical</strong> <strong>Reflections</strong> continued from page 23<br />

Figure 3. Base failure; wrong excavation sequence.<br />

Figure 3. Base failure; wrong excavation sequence (EITHER WORKS or BOTH)<br />

fine soils (clays) <strong>and</strong> coarse or granular soils,<br />

since the differences in magnitude <strong>and</strong> the<br />

shape of the LEP distributions are important.<br />

Figure 2 shows the case of a l<strong>and</strong>slide (2)<br />

where the LEP in the lower part of the<br />

excavation was considered for a granular soil<br />

rather than a clayey soil that was encountered<br />

afterwards… thus generating a LEP up<br />

to four times larger than those that were<br />

considered. Obviously, the system collapsed.<br />

Designs concepts must not be changed<br />

without knowledge or technical support,<br />

even if requests come from high management<br />

levels. Some examples are: reducing safety<br />

factors; ignoring events such as earthquakes,<br />

floods, hurricanes; reducing excavation<br />

support elements; among others (redundancy,<br />

see below). Modifying excavation methods<br />

from sections to continuous modalities<br />

under the pretext of speeding up the work<br />

(see Figure 3) could end in failure. In short,<br />

several examples could be given that often<br />

lead to generating serious problems in<br />

projects.<br />

Lack of Redundancy. The classic<br />

article of professor J. Osterberg (4)<br />

deepens the<br />

philosophy of redundancy in geotechnical<br />

engineering. This concept is often forgotten<br />

when designing (e.g.) key <strong>and</strong> repetitive<br />

elements, on which the stability of a work<br />

depends. This is the case for systems<br />

involving tiebacks, piles, pumping systems,<br />

among others, where if “a single element”<br />

which is an integral part of several fails, the<br />

Figure 4. Excavation slide due to tiebacks failure (see Figure 2)<br />

entire system could collapse. The l<strong>and</strong>slide<br />

that occurred on Calle 72(2), where, due<br />

to the failure of one or two 25-ton tiebacks<br />

out of many caused an entire 17-meter deep<br />

excavation to collapse (Figures 2 <strong>and</strong> 4) is an<br />

example. As a recommendation, one should<br />

habitually ask oneself, “what happens if an<br />

element fails within a well mathematically<br />

calculated <strong>and</strong> stable system” <strong>and</strong> “what<br />

measures can be anticipated to insure the<br />

stability of a work?” This is what is now<br />

called Plan B. A simple <strong>and</strong> illustrative<br />

example is the case of a foundation with<br />

piles when the calculation result indicates<br />

that only one pile per foundation support<br />

element is required. It is better to decrease<br />

(e.g.) the diameter of the pile a little <strong>and</strong> to<br />

contemplate two or three smaller diameter<br />

piles in each support rather than depending<br />

on a single element for stability.<br />

Lack of Instrumentation. It is necessary<br />

to insist on designing <strong>and</strong> implementing<br />

instrumentation programs in projects,<br />

regardless of the “magnitude or size” of the<br />

project. Both the “large” <strong>and</strong> “small” projects<br />

will require it. As Professor R. Marsal<br />

said when it came to teaching, “there is no<br />

difference between small or large projects;<br />

all of them need studies <strong>and</strong> solutions to be<br />

thoroughly analyzed.” (3)<br />

Instrumentation<br />

is the only tool that is available to verify<br />

the project design considerations <strong>and</strong> to<br />

know the timely behavior of the works<br />

during <strong>and</strong> after construction. This is an<br />

24 | JOURNAL Florida Engineering Society | JULY <strong>2018</strong><br />

fleng.org

activity that can usually be classified as<br />

“Cinderella” in engineering projects; its cost<br />

is insignificant compared to the total value<br />

of the project, but its benefits are priceless<br />

if it prevents a project from collapsing<br />

(with the consequences worse than can be<br />

imagined). With the implementation of a<br />

good instrumentation program, we can safely<br />

sleep in peace.<br />

Conclusions. The author wanted to<br />

highlight <strong>and</strong> alert some aspects of the<br />

general practice of applied geotechnics,<br />

which when not considered or omitted, could<br />

lead to geotechnical situations difficult to<br />

manage <strong>and</strong> control. Damage <strong>and</strong> even loss<br />

of human life can occur easily when these<br />

concepts are not put into focus on every<br />

project. Finally, let’s not forget the eminent<br />

Professor G. Sowers (6)<br />

(author’s professor<br />

1982-83), who emphasized the human factors<br />

<strong>and</strong> the geotechnical failures with these<br />

words: “we do not exonerate ourselves from<br />

failures, but surely, we can reduce them;<br />

by training us, updating our knowledge<br />

frequently <strong>and</strong> controlling our emotions, we<br />

practice safer engineering.”<br />

References<br />

(1) Focht, (1994) “Lessons Learned from<br />

Missed Prediction;” 29th Terzaghi Lecture,<br />

Journal of <strong>Geotechnical</strong> Engineering, Vol<br />

120 No. 10, ASCE, October.<br />

(2) Gómez S., Jose N., (1999), “Analysis<br />

<strong>and</strong> Solution of Stabilization of a L<strong>and</strong>slide<br />

with Reinforced L<strong>and</strong>fill,” XI Panamerican<br />

Conference on Soil Mechanics <strong>and</strong><br />

<strong>Geotechnical</strong> Engineering, Fox do Iguassu,<br />

Brazil.<br />

(3) Marsal, Raúl J. (1986). “Teaching <strong>and</strong><br />

Exercise of Civil Engineering,” Conference<br />

Fern<strong>and</strong>o Espinosa, Edited by the Federal<br />

Electricity Commission <strong>and</strong> the College of<br />

Civil Engineers of Mexico.<br />

(4) Osterberg Jorj O. (1989). “Necessary<br />

Redundancy in <strong>Geotechnical</strong> Engineering;”<br />

2nd Terzaghi Lecture, Journal of<br />

<strong>Geotechnical</strong> Engineering, Vol 115. No. 11,<br />

ASCE, pp. 1511 - 1531, November.<br />

Figure 4. Excavation slide due to tiebacks failure (see Figure 2).<br />

(5) Peck, Ralph B. (1997). “Gaining<br />

Ground,” Civil Engineering Magazine,<br />

ASCE, pp. 54-56; December.<br />

(6) Sowers, George F. (1993). “Human<br />

Figure 4. Excavation slide due to tiebacks fail<br />

Factors in Civil <strong>and</strong> <strong>Geotechnical</strong><br />

Engineering Failures;” Journal of<br />

<strong>Geotechnical</strong> Engineering. Vol. 119, No. 2,<br />

ASCE, pp. 238-256, February.<br />

About the Author:<br />

Jose N. Gómez, PE, D.GE, F.ASCE,<br />

is Vice President <strong>and</strong> Senior Principal<br />

<strong>Geotechnical</strong> Engineer with ECS Florida<br />

LLC. He has worked as a consulting<br />

geotechnical engineer for over 38 years<br />

<strong>and</strong> as adjunct professor for 25 years. He<br />

is the incoming vice-chair of the GMEC<br />

<strong>and</strong> current president of FES Palm Beach<br />

chapter.<br />

fleng.org JULY <strong>2018</strong> | JOURNAL Florida Engineering Society | 25