You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Methods of Manufacture<br />

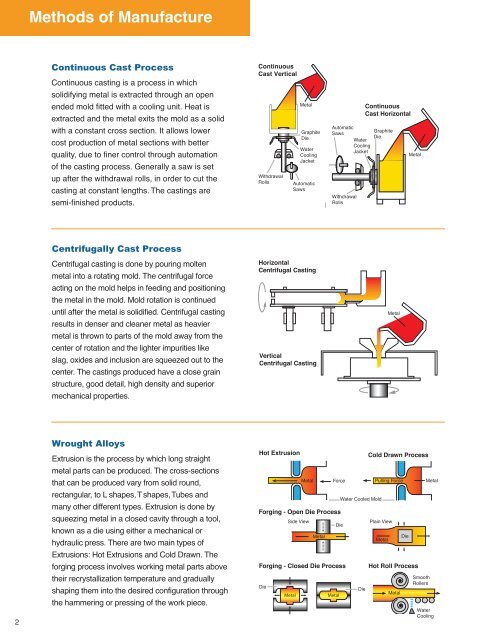

Continuous Cast Process<br />

Continuous casting is a process in which<br />

solidifying metal is extracted through an open<br />

ended mold fitted with a cooling unit. Heat is<br />

extracted and the metal exits the mold as a solid<br />

with a constant cross section. It allows lower<br />

cost production of metal sections with better<br />

quality, due to finer control through automation<br />

of the casting process. Generally a saw is set<br />

up after the withdrawal rolls, in order to cut the<br />

casting at constant lengths. The castings are<br />

semi-finished products.<br />

Continuous<br />

Cast Vertical<br />

Withdrawal<br />

Rolls<br />

Metal<br />

Graphite<br />

Die<br />

Water<br />

Cooling<br />

Jacket<br />

Automatic<br />

Saws<br />

Automatic<br />

Saws<br />

Withdrawal<br />

Rolls<br />

Water<br />

Cooling<br />

Jacket<br />

Continuous<br />

Cast Horizontal<br />

Graphite<br />

Die<br />

Metal<br />

Centrifugally Cast Process<br />

Centrifugal casting is done by pouring molten<br />

metal into a rotating mold. The centrifugal force<br />

acting on the mold helps in feeding and positioning<br />

the metal in the mold. Mold rotation is continued<br />

until after the metal is solidified. Centrifugal casting<br />

results in denser and cleaner metal as heavier<br />

metal is thrown to parts of the mold away from the<br />

center of rotation and the lighter impurities like<br />

slag, oxides and inclusion are squeezed out to the<br />

center. The castings produced have a close grain<br />

structure, good detail, high density and superior<br />

mechanical properties.<br />

Horizontal<br />

Centrifugal Casting<br />

Vertical<br />

Centrifugal Casting<br />

Metal<br />

2<br />

Wrought Alloys<br />

Extrusion is the process by which long straight<br />

metal parts can be produced. The cross-sections<br />

that can be produced vary from solid round,<br />

rectangular, to L shapes,Tshapes,Tubes and<br />

many other different types. Extrusion is done by<br />

squeezing metal in a closed cavity through a tool,<br />

known as a die using either a mechanical or<br />

hydraulic press. There are two main types of<br />

Extrusions: Hot Extrusions and Cold Drawn. The<br />

forging process involves working metal parts above<br />

their recrystallization temperature and gradually<br />

shaping them into the desired configuration through<br />

the hammering or pressing of the work piece.<br />

Hot Extrusion<br />

Forging - Open Die Process<br />

Forging - Closed Die Process<br />

Die<br />

Metal<br />

Metal<br />

Side View<br />

Metal<br />

Force Pulling Force Metal<br />

Metal<br />

Die<br />

Water Cooled Mold<br />

Die<br />

Cold Drawn Process<br />

Plain View<br />

Metal<br />

Hot Roll Process<br />

Metal<br />

Die<br />

Smooth<br />

Rollers<br />

Water<br />

Cooling