Cnc-metal working machines - Aircraft

Cnc-metal working machines - Aircraft

Cnc-metal working machines - Aircraft

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

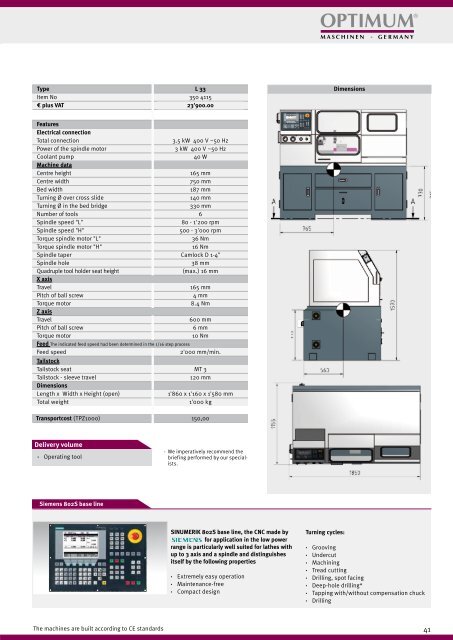

Type L 33<br />

Item No 350 4115<br />

€ plus VAT 23'900.00<br />

Features<br />

Electrical connection<br />

Total connection 3.5 kW 400 V ~50 Hz<br />

Power of the spindle motor 3 kW 400 V ~50 Hz<br />

Coolant pump<br />

Machine data<br />

40 W<br />

Centre height 165 mm<br />

Centre width 750 mm<br />

Bed width 187 mm<br />

Turning Ø over cross slide 140 mm<br />

Turning Ø in the bed bridge 330 mm<br />

Number of tools 6<br />

Spindle speed "L" 80 - 1'200 rpm<br />

Spindle speed "H" 500 - 3'000 rpm<br />

Torque spindle motor "L" 36 Nm<br />

Torque spindle motor "H" 16 Nm<br />

Spindle taper Camlock D 1-4"<br />

Spindle hole 38 mm<br />

Quadruple tool holder seat height<br />

X axis<br />

(max.) 16 mm<br />

Travel 165 mm<br />

Pitch of ball screw 4 mm<br />

Torque motor<br />

Z axis<br />

8.4 Nm<br />

Travel 600 mm<br />

Pitch of ball screw 6 mm<br />

Torque motor 10 Nm<br />

Feed The indicated feed speed had been determined in the 1/16 step process<br />

Feed speed<br />

Tailstock<br />

2'000 mm/min.<br />

Tailstock seat MT 3<br />

Tailstock - sleeve travel<br />

Dimensions<br />

120 mm<br />

Length x Width x Height (open) 1'860 x 1'160 x 1'580 mm<br />

Total weight 1'000 kg<br />

Transportcost (TPZ1000) 150,00<br />

Delivery volume<br />

· Operating tool<br />

Siemens 802S base line<br />

- We imperatively recommend the<br />

briefing performed by our specialists.<br />

SINUMERIK 802S base line, the CNC made by<br />

for application in the low power<br />

range is particularly well suited for lathes with<br />

up to 3 axis and a spindle and distinguishes<br />

itself by the following properties<br />

· Extremely easy operation<br />

· Maintenance-free<br />

· Compact design<br />

Turning cycles:<br />

Dimensions<br />

· Grooving<br />

· Undercut<br />

· Machining<br />

· Tread cutting<br />

· Drilling, spot facing<br />

· Deep-hole drilling*<br />

· Tapping with/without compensation chuck<br />

· Drilling<br />

The <strong>machines</strong> are built according to CE standards 41