WORLD OF INDUSTRIES 2/2020

WORLD OF INDUSTRIES 2/2020

WORLD OF INDUSTRIES 2/2020

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

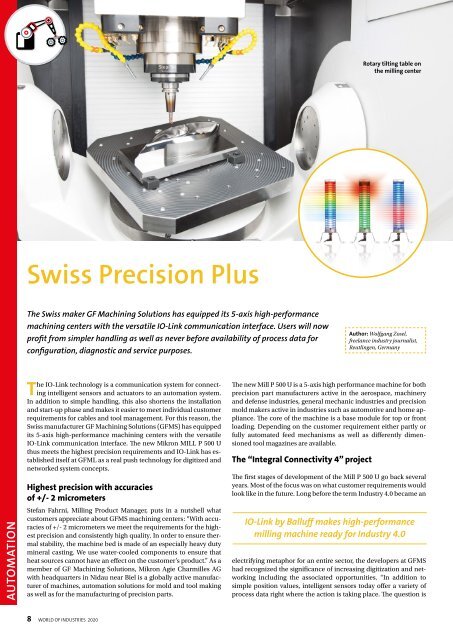

Rotary tilting table on<br />

the milling center<br />

Swiss Precision Plus<br />

The Swiss maker GF Machining Solutions has equipped its 5-axis high-performance<br />

machining centers with the versatile IO-Link communication interface. Users will now<br />

profit from simpler handling as well as never before availability of process data for<br />

configuration, diagnostic and service purposes.<br />

Author: Wolfgang Zosel,<br />

freelance industry journalist,<br />

Reutlingen, Germany<br />

AUTOMATION<br />

The IO-Link technology is a communication system for connecting<br />

intelligent sensors and actuators to an automation system.<br />

In addition to simple handling, this also shortens the installation<br />

and start-up phase and makes it easier to meet individual customer<br />

requirements for cables and tool management. For this reason, the<br />

Swiss manufacturer GF Machining Solutions (GFMS) has equipped<br />

its 5-axis high-performance machining centers with the versatile<br />

IO-Link communication interface. The new Mikron MILL P 500 U<br />

thus meets the highest precision requirements and IO-Link has established<br />

itself at GFML as a real push technology for digitized and<br />

networked system concepts.<br />

Highest precision with accuracies<br />

of +/- 2 micrometers<br />

Stefan Fahrni, Milling Product Manager, puts in a nutshell what<br />

customers appreciate about GFMS machining centers: “With accuracies<br />

of +/- 2 micrometers we meet the requirements for the highest<br />

precision and consistently high quality. In order to ensure thermal<br />

stability, the machine bed is made of an especially heavy duty<br />

mineral casting. We use water-cooled components to ensure that<br />

heat sources cannot have an effect on the customer’s product.” As a<br />

member of GF Machining Solutions, Mikron Agie Charmilles AG<br />

with headquarters in Nidau near Biel is a globally active manufacturer<br />

of machines, automation solutions for mold and tool making<br />

as well as for the manufacturing of precision parts.<br />

The new Mill P 500 U is a 5-axis high performance machine for both<br />

precision part manufacturers active in the aerospace, machinery<br />

and defense industries, general mechanic industries and precision<br />

mold makers active in industries such as automotive and home appliance.<br />

The core of the machine is a base module for top or front<br />

loading. Depending on the customer requirement either partly or<br />

fully automated feed mechanisms as well as differently dimensioned<br />

tool magazines are available.<br />

The “Integral Connectivity 4” project<br />

The first stages of development of the Mill P 500 U go back several<br />

years. Most of the focus was on what customer requirements would<br />

look like in the future. Long before the term Industry 4.0 became an<br />

IO-Link by Balluff makes high-performance<br />

milling machine ready for Industry 4.0<br />

electrifying metaphor for an entire sector, the developers at GFMS<br />

had recognized the significance of increasing digitization and networking<br />

including the associated opportunities. “In addition to<br />

simple position values, intelligent sensors today offer a variety of<br />

process data right where the action is taking place. The question is<br />

8 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> <strong>2020</strong>