seg royal-diamond, sa miscellaneous articles

seg royal-diamond, sa miscellaneous articles

seg royal-diamond, sa miscellaneous articles

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

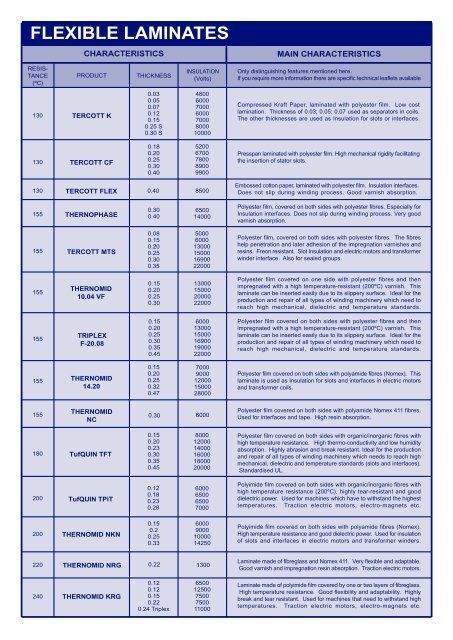

FLEXIBLE LAMINATES<br />

RESIS-<br />

TANCE<br />

(ºC)<br />

130 TERCOTT K<br />

130 TERCOTT CF<br />

130 TERCOTT FLEX 0.40 8500<br />

155 THERNOPHASE<br />

155 TERCOTT MTS<br />

155<br />

155<br />

155<br />

155<br />

TRIPLEX<br />

F-20.08<br />

THERNOMID<br />

14.20<br />

180 TufQUIN TFT<br />

200 TufQUIN TPiT<br />

200 THERNOMID NKN<br />

220 THERNOMID NRG 0.22 1300<br />

240 THERNOMID KRG<br />

CHARACTERISTICS MAIN CHARACTERISTICS<br />

PRODUCT THICKNESS<br />

THERNOMID<br />

10.04 VF<br />

THERNOMID<br />

NC<br />

0.03<br />

0.05<br />

0.07<br />

0.12<br />

0.15<br />

0.25 S<br />

0.30 S<br />

0.18<br />

0.20<br />

0.25<br />

0.30<br />

0.40<br />

0.30<br />

0.40<br />

0.08<br />

0.15<br />

0.20<br />

0.25<br />

0.30<br />

0.35<br />

0.15<br />

0.20<br />

0.25<br />

0.30<br />

0.15<br />

0.20<br />

0.25<br />

0.30<br />

0.35<br />

0.45<br />

0.15<br />

0.20<br />

0.25<br />

0.32<br />

0.47<br />

0.15<br />

0.20<br />

0.23<br />

0.30<br />

0.35<br />

0.45<br />

0.12<br />

0.18<br />

0.23<br />

0.28<br />

0.15<br />

0.2<br />

0.25<br />

0.33<br />

0.12<br />

0.12<br />

0.15<br />

0.22<br />

0.24 Triplex<br />

INSULATION<br />

(Volts)<br />

4800<br />

6000<br />

7000<br />

6000<br />

7000<br />

8000<br />

10000<br />

5200<br />

6700<br />

7800<br />

8900<br />

9900<br />

6500<br />

14000<br />

5000<br />

6000<br />

13000<br />

15000<br />

16900<br />

22000<br />

13000<br />

15000<br />

20000<br />

22000<br />

6000<br />

13000<br />

15000<br />

16900<br />

19000<br />

22000<br />

7000<br />

9000<br />

12000<br />

15000<br />

28000<br />

0.30 6000<br />

8000<br />

12000<br />

14000<br />

16000<br />

18000<br />

20000<br />

6000<br />

6500<br />

6500<br />

7000<br />

6000<br />

9000<br />

10000<br />

14250<br />

6500<br />

12500<br />

7500<br />

7500<br />

11000<br />

Only distinguishing features mentioned here.<br />

If you require more information there are specific technical leaflets available<br />

Compressed Kraft Paper, laminated with polyester film. Low cost<br />

lamination. Thickness of 0.03; 0.05; 0.07 used as separators in coils.<br />

The other thicknesses are used as Insulation for slots or interfaces.<br />

Presspan laminated with polyester film. High mechanical rigidity facilitating<br />

the insertion of stator slots.<br />

Embossed cotton paper, laminated with polyester film. Insulation interfaces.<br />

Does not slip during winding process. Good varnish absorption.<br />

Polyester film, covered on both sides with polyester fibres. Especially for<br />

Insulation interfaces. Does not slip during winding process. Very good<br />

varnish absorption.<br />

Polyester film, covered on both sides with polyester fibres. The fibres<br />

help penetration and later adhesion of the impregnation varnishes and<br />

resins. Freon resistant. Slot Insulation and electric motors and transformer<br />

winder interface. Also for sealed groups.<br />

Polyester film covered on one side with polyester fibres and then<br />

impregnated with a high temperature-resistant (200ºC) varnish. This<br />

laminate can be inserted easily due to its slippery surface. Ideal for the<br />

production and repair of all types of winding machinery which need to<br />

reach high mechanical, dielectric and temperature standards.<br />

Polyester film covered on both sides with polyester fibres and then<br />

impregnated with a high temperature-resistant (200ºC) varnish. This<br />

laminate can be inserted easily due to its slippery surface. Ideal for the<br />

production and repair of all types of winding machinery which need to<br />

reach high mechanical, dielectric and temperature standards.<br />

Polyester film covered on both sides with polyamide fibres (Nomex). This<br />

laminate is used as Insulation for slots and interfaces in electric motors<br />

and transformer coils.<br />

Polyester film covered on both sides with polyamide Nomex 411 fibres.<br />

Used for interfaces and tape. High resin absorption.<br />

Polyester film covered on both sides with organic/inorganic fibres with<br />

high temperature resistance. High thermo-conductivity and low humidity<br />

absorption. Highly abrasion and break resistant. Ideal for the production<br />

and repair of all types of winding machinery which needs to reach high<br />

mechanical, dielectric and temperature standards (slots and interfaces).<br />

Standardised UL.<br />

Polyimide film covered on both sides with organic/inorganic fibres with<br />

high temperature resistance (200ºC), highly tear-resistant and good<br />

dielectric power. Used for machines which have to withstand the highest<br />

temperatures. Traction electric motors, electro-magnets etc.<br />

Polyimide film covered on both sides with polyamide fibres (Nomex).<br />

High temperature resistance and good dielectric power. Used for insulation<br />

of slots and interfaces in electric motors and transformer winders.<br />

Laminate made of fibreglass and Nomex 411. Very flexible and adaptable.<br />

Good varnish and impregnation resin absorption. Traction electric motors.<br />

Laminate made of polyimide film covered by one or two layers of fibreglass.<br />

High temperature resistance. Good flexibility and adaptability. Highly<br />

break and tear resistant. Used for machines that need to withstand high<br />

temperatures. Traction electric motors, electro-magnets etc.