You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

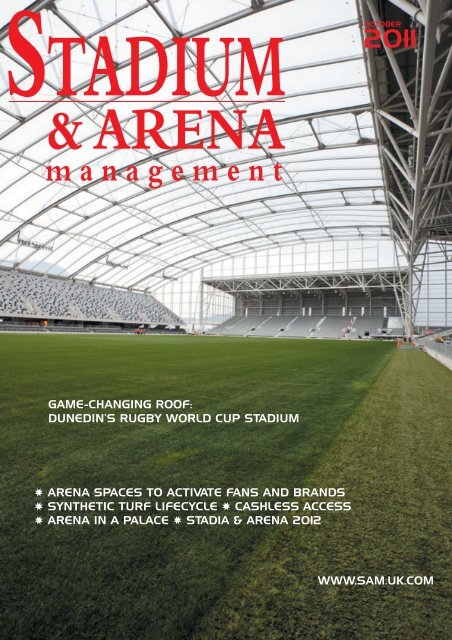

GAME-CHANGING ROOF:<br />

DUNEDIN’S RUGBY WORLD CUP STADIUM<br />

✸ ARENA SPACES TO ACTIVATE FANS AND BRANDS<br />

✸ SYNTHETIC TURF LIFECYCLE ✸ CASHLESS ACCESS<br />

✸ ARENA IN A PALACE ✸ STADIA & ARENA 2012<br />

OCTOBER<br />

2011<br />

WWW.SAM.UK.COM

Venue design and construction – roofs<br />

Roof revolution<br />

<strong>New</strong> architectural <strong>forms</strong> and new materials are leading to stadiums which better<br />

match the needs of owners and spectators, as cost goes down and comfort goes up.<br />

When it comes to customer<br />

comfort, what’s more important<br />

than the stadium roof? It keeps<br />

the rain, wind and sun off the<br />

seating areas so that spectators can enjoy the<br />

entertainment. It protects the rest of the<br />

stadium fabric and it can be an iconic structure<br />

for those walking up or watching an aerial shot<br />

on TV. First things first: the roof should be safe.<br />

Stadium roof collapses this year are a warning<br />

to the industry: at FC Twente’s De Grolsch Veste<br />

stadium (one death, 16 injured) and at<br />

Wollongong’s WIN Stadium, where (according<br />

to local newspaper reports) a recently installed<br />

roof buckled under gale-force winds.<br />

History suggests that where roofs are<br />

specified, they are enclosing more and more of<br />

the stadium. The ’dome arenas’ showed the<br />

way during the 1990s. Built by Mitsubishi<br />

Heavy Industries in Japan, domes housed<br />

ballparks (Tokyo and Fukuoka Domes) with<br />

retractable seating and pitching mounds to<br />

allow other events to take place, such as cycling<br />

and concerts. Mitsubishi’s technology included<br />

the bicycle racing banks, stage equipment and<br />

rigging machinery as well as the retractable<br />

roof drive equipment.<br />

When the Waldstadion in Frankfurt was<br />

finally redeveloped for the 2006 World Cup, its<br />

signature roof was constructed from a cablesuspended<br />

ring of fibreglass, similar to<br />

stadiums in Hamburg and Berlin, but this time<br />

around 80,000ft 2 of the inner roof was<br />

removable. An inner network of tensioned<br />

cables also suspended a cube with LED screens.<br />

BC Pavilion Corporation (PavCo) in<br />

Vancouver has specified a new roof as part of<br />

Right: Forsyth Barr Stadium, Dunedin. The<br />

roof and natural turf combination is the<br />

result of extensive research. Copyright<br />

reproduced courtesy of <strong>Vector</strong> <strong>Foiltec</strong>.<br />

32 STADIUM & ARENA MANAGEMENT www.sam.uk.com October 2011

the rejuvenation of the BC Place stadium that<br />

was previously covered by an air-supported<br />

structure. PavCo has quoted energy cost savings<br />

of $350,000 or 25% per year and maintenance<br />

cost savings of $100,000 per year. The roof is<br />

suspended from 36 masts, each 50 metres in<br />

length and weighing approximately 240<br />

tonnes. The retractable centre portion of the<br />

roof is made of flexible Tenara fabric. The outer<br />

permanently-fixed portion of the roof is made<br />

of PTFE coated fibreglass, and covers all of the<br />

seating in all weather conditions.<br />

Architects have employed materials such as<br />

fibreglass to design very different looking roofs.<br />

Stadiums in South Africa, for the FIFA World Cup,<br />

and in Poland for Euro 2012 are just some of<br />

the latest examples. Texlon, <strong>Vector</strong> <strong>Foiltec</strong>’s<br />

invention which employs ETFE (ethylene<br />

tetrafluoroethylene) for cladding, looked very<br />

interesting for some stadium design work that<br />

architect Populous was carrying out for rugby<br />

stadiums in <strong>New</strong> Zealand in preparation for the<br />

Rugby World Cup.<br />

Texlon allows natural light to penetrate and<br />

it therefore held out the hope of growing<br />

natural grass under a roof. The client’s team of<br />

experts wanted to know more. Angus Macleod,<br />

engineer at <strong>Vector</strong> <strong>Foiltec</strong>, explains: ”We<br />

designed and built a fully enclosed test rig with<br />

walls and a roof and tested various grasses.”<br />

Real rugby players and a mechanical scrum<br />

were used to see how the turf held up.<br />

Although the turf was lush and grew faster<br />

under the Texlon ETFE than outside, it was<br />

determined that the roots needed the help of a<br />

Desso Grassmaster system.<br />

The upshot of this early work is that<br />

Populous, in association with local firm Jasmax,<br />

designed the Forsyth Barr Stadium as the<br />

world’s first fully covered stadium with a natural<br />

grass pitch. It has 20,000 permanent seats, and<br />

11,000 temporary for the World Cup. The design<br />

and engineering of the roof allows optimal<br />

solar light transmission while natural ventilation<br />

is provided by raised facades. The supporting<br />

structure spans 105 meters with an internal<br />

roof clearance of 37 metres. Five trusses stretch<br />

from the north stand to a transfer truss above<br />

the metal deck roof of the south stand as the<br />

main support.<br />

The roof cladding is made up of inflated<br />

cushions of Texlon, which first found<br />

international acclaim when used on the 2001<br />

Eden Project, a series of gardens under domes<br />

in Cornwall, England. There are now 1,000<br />

projects worldwide using this technology,<br />

which was subsequently supplied by <strong>Vector</strong><br />

<strong>Foiltec</strong> for use in St Jacobs Stadium in Basel and<br />

the Olympic Aquatics Centre in Beijing.<br />

”In Carisbrook, spectators stood and froze,”<br />

says Macleod, referring to the previous<br />

incarnation of the stadium. ”It was lowering<br />

attendance at games. Stadium design is about<br />

winning people back from in front of their TVs<br />

October 2011 www.sam.uk.com STADIUM & ARENA MANAGEMENT 33

in their lounges, so we have to create a nice<br />

atmosphere and a comfortable experience.”<br />

Anyone who viewed games at the stadium in<br />

the recent Rugby World Cup will have noticed<br />

the fans jumping up and down in their<br />

shirtsleeves and drinking cold beer in what is<br />

the middle of winter in <strong>New</strong> Zealand.<br />

Texlon is about big numbers – 100,000m 2 on<br />

the water cube – and small – weighing one<br />

kilogram per square metre. Forsyth Barr<br />

Stadium has 20,500m 2 in the roof and Eden<br />

Park, Auckland, has used 10,000m 2 in the<br />

façade which is part of its new south stand.<br />

Macleod says the material’s lifespan is as yet<br />

unknown. After 20 years of maintenance,<br />

<strong>Vector</strong> <strong>Foiltec</strong> has detected no change in its<br />

optical or mechanical properties.<br />

The material is smooth and so dirt washes<br />

off easily and the cushions, which are five<br />

metres by 20 metres, won’t pop out of their<br />

framework in the event of an earthquake. If a<br />

cushion were to be damaged, the lightweight<br />

material would float to the ground. It has low<br />

embodied energy. Macleod assures that,<br />

although Texlon ETFE uses some fossil fuels in<br />

its production, it’s a byproduct of a mining<br />

process and doesn’t leave any harmful waste. It<br />

is also recyclable. If a building one day pulls<br />

down the Texlon ETFE – it hasn’t happened yet<br />

– the material can be taken back by <strong>Vector</strong><br />

<strong>Foiltec</strong>, melted down and re-used.<br />

”It’s very exciting,” sums up Macleod. ”You<br />

can grow natural turf pitches under a Texlon<br />

ETFE roof. Couple that with the material being<br />

lightweight and easy to adapt architecturally<br />

and you have to ask ’why not?’ It could be a<br />

revolution in stadium design and I’m told it’s the<br />

cheapest stadium in <strong>New</strong> Zealand judged by<br />

NZ$ per square foot.”<br />

”The permanent roof means Forsyth Barr is<br />

a true hybrid between a highly efficient, well<br />

functioning football/rugby stadium and an<br />

entertainment venue,” says Richard Breslin,<br />

Populous Senior Principal and Project Director of<br />

Forsyth Barr stadium. ”Research by many<br />

people has created this final concept of a<br />

natural grass pitch growing under a permanent<br />

roof structure. The fans are protected from the<br />

elements and the action goes on whatever the<br />

weather.” Breslin also thinks the rectangular<br />

design will change the way we view the live<br />

game: ”The angled seating pitch and enclosed<br />

roof will mean spectators are closer to the<br />

action than ever before and the atmosphere<br />

will be fantastic. I was there recently, and even<br />

though there was no game on, the sense of<br />

enclosure made the hairs stand up on the back<br />

of my neck.”<br />

Populous Associate Principal, Ron Van Sluijs,<br />

Project Architect of Forsyth Barr stadium during<br />

its design phase, says: ”The new roof means<br />

Top and middle: Forsyth Barr Stadium kicked off with games in the Rugby World Cup. It<br />

will prove its multi-purpose credentials in December with a first concert.<br />

Bottom: Eden Park, also a Rugby World Cup venue, has a new façade made from Texlon<br />

ETFE. Photos copyright reproduced courtesy of <strong>Vector</strong> <strong>Foiltec</strong>.<br />

34 STADIUM & ARENA MANAGEMENT www.sam.uk.com October 2011

Innovative<br />

Stadia Architecture<br />

<strong>Vector</strong> <strong>Foiltec</strong> is revolutionising sport and stadia<br />

design with the world’s first permanently covered<br />

natural turf pitch, the Forsyth Barr Stadium.<br />

International market leader and pioneer of Texlon ®<br />

ETFE, <strong>Vector</strong> <strong>Foiltec</strong> boasts 30 years of experience<br />

at the forefront of specialist design and ETFE<br />

technology. We offer our clients a complete service<br />

with unprecedented expertise.<br />

Our extensive portfolio includes The National<br />

Aquatic Centre, Beijing, The Khan Shatyr<br />

Entertainment Centre, Kazakhstan, Eden Park<br />

Stadium, <strong>New</strong> Zealand, and St. Jakob Stadium,<br />

Basel.<br />

www.vector-foiltec.com<br />

4<br />

1<br />

5<br />

1 National Swimming Center<br />

Beijing (CN), 2007<br />

2 Stadion St. Jakob-Park<br />

Basel (CH), 2009<br />

© Andreas Braun<br />

3 Eden Park Stadium<br />

Auckland (NZ), 2010<br />

© Julian Apse<br />

4 2022 Showcase Stadium<br />

Doha (QA), 2010<br />

5 Eden Park Stadium<br />

Auckland (NZ), 2010<br />

Forsyth Barr Stadium<br />

Dunedin (NZ), 2011<br />

2<br />

3

we can maintain a constant temperature and<br />

grow a stronger grass which will not become<br />

boggy because it will never rain, snow, or hail<br />

inside the stadium during a game at Forsyth<br />

Barr. This roof material allows for 90% of<br />

sunlight to still reach the pitch, along with UV<br />

light and fresh air.”<br />

Project Architect during the construction<br />

phase at Forsyth Barr, Populous Associate<br />

Jochem Veerman adds that the sectional profile<br />

of the stadium was carefully designed to<br />

maximise solar penetration onto the field as<br />

well as the natural ventilation:<br />

”The ETFE covers the roof and parts of the<br />

façades. The stands on the northern end are<br />

lower to allow maximum sunlight onto the<br />

pitch and the end facades are raised five<br />

metres so the stadium is open at these points,<br />

allowing natural ventilation of the grass, and to<br />

ensure spectators do not feel enclosed. There<br />

are also ventilation slots at a high level to<br />

ensure air circulates properly.”<br />

<strong>New</strong> <strong>forms</strong><br />

Thinking about the real needs of stadium<br />

spectators can result in interesting architectural<br />

<strong>forms</strong>, according to Mott Macdonald Divisional<br />

Director Leon Higgins.<br />

Roof design in hot countries, such as the<br />

Middle East, needs new thinking, he says: ”They<br />

don’t need an umbrella, they need a sun<br />

shade.” FIFA’s guidelines designate a roof to the<br />

edge of the seating but this isn’t always<br />

appropriate. Mott Macdonald Associate Paul<br />

Officer encourages architects to take a rational<br />

approach: ”It is sometimes more appropriate to<br />

relax the compliance with the guidelines and<br />

focus more on designing for<br />

the actual environmental conditions at the site.”<br />

Future-proofing customer comfort<br />

Mott Macdonald’s engineers consult on many<br />

stadium projects around the world. The company<br />

is currently working with Pattern Architects’<br />

Dipesh Patel, who has introduced a profile roof<br />

that provides complete shading at kick-off time in<br />

the afternoon in August for stadiums in the Middle<br />

East. This has resulted in a different, assymetrical<br />

form. Often this form is used to save money but<br />

Patel’s design is about achieving the right<br />

conditions for the environment.<br />

Patel explains that his design came about<br />

on a job which started out as a moving roof. ”To<br />

keep the aperture small enough to have a<br />

moving roof, you really struggle with getting<br />

enough daylight through.” The debate around<br />

the roof design included using artificial turf and<br />

the use of different roof materials.<br />

”It’s essentially a parasol – that’s the best<br />

way to describe it,” says Patel. ”It provides a<br />

balance of shading for spectators, but enough<br />

light during the rest of the day for the grass to<br />

grow. We’ve looked at several materials and<br />

settled on a polycarbonate and PVC sandwich,<br />

and that’s more about what it looks like. It’s<br />

effectively solid, which is good for the people<br />

underneath.”<br />

Officer points out that the moving roof on<br />

Wembley is principally about getting light to<br />

the pitch, a problem that hasn’t been<br />

completely solved by translucent materials. He<br />

suggests that Patel’s parasol is a less brutal<br />

approach to solving the shading versus grassgrowing<br />

conundrum. ”Moving roofs are big and<br />

heavy and expensive. You need a lot of<br />

steelwork to take the load which is<br />

concentrated on two lines where the rails are<br />

located. At Wembley we kept it down a bit by<br />

spreading the load around more panels.”<br />

Patel thinks that the ”firework roof<br />

structure” still has its place but that architects<br />

Holding things together: High Torque<br />

Jubilee Clips (made by L Robinson & Co) on<br />

the roof of the new Forsyth Barr Stadium,<br />

Dunedin, <strong>New</strong> Zealand. Auto Agencies<br />

(<strong>New</strong> Zealand distributor) supplied 208<br />

clips at short notice to the roof contractors.<br />

take a more holistic approach than a decade<br />

ago. ”A roof can still be iconic and striking, but<br />

through its overall form rather than the finery of<br />

the diagram.” For simple grandstand shapes,<br />

the cantilever is generally the most costeffective<br />

of the self-supporting structures. Patel<br />

agrees that these structures are cost-driven and<br />

that it’s difficult to scale down the <strong>forms</strong><br />

possible in larger stadiums, such as those he<br />

used to design City of Manchester Stadium, to<br />

smaller capacity venues.<br />

<strong>Vector</strong> <strong>Foiltec</strong> supplied Texlon to the showcase stadium built by the Qatar 2022 bid committee for the FIFA World Cup. The bid required<br />

looking into a future of comfortable and energy efficient stadiums hosting athletes and fans in summer. A combined team of architects,<br />

engineers and environmental services at Arup managed the project and Edwin Shirley Staging constructed the prototype. <strong>Vector</strong> <strong>Foiltec</strong><br />

worked with David Dexter Associates structural engineers to clad<br />

Photo: copyright reproduced courtesy of <strong>Vector</strong> <strong>Foiltec</strong>.<br />

the moving roof and two opening/closing façades.<br />

”The cladding is Texlon ETFE combined with tensile fabric shading<br />

and the design is all about controlling heat gain out and in,” says<br />

Stephen Jones, Design Director at <strong>Vector</strong> <strong>Foiltec</strong>.<br />

The principle is to open at night to cool the seating areas and base<br />

of the walls, closing in the day to keep out the heat. Jones explains<br />

that the Texlon ETFE is light and therefore doesn’t put big load or<br />

energy demands on the engineering needed to move the roof and<br />

façade structures.<br />

The stadium met Arup’s performance criteria and Qatar won the bid<br />

so the project succeeded in various ways.<br />

”We learned valuable lessons about value engineering our<br />

solution,” says Jones. ”I hope that Texlon ETFE is deemed applicable<br />

for this kind of stadium application.”<br />

36 STADIUM & ARENA MANAGEMENT www.sam.uk.com October 2011