Basyazıcıoglu Textile “Three ingredients of a successful company ...

Basyazıcıoglu Textile “Three ingredients of a successful company ...

Basyazıcıoglu Textile “Three ingredients of a successful company ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

NEWSLETTER PUBLISHED BY<br />

SAVIO MACCHINE TESSILI S.P.A.<br />

JULY, 2009 - N. 26<br />

SAVIONEWS<br />

SAVIONEWS<br />

26<br />

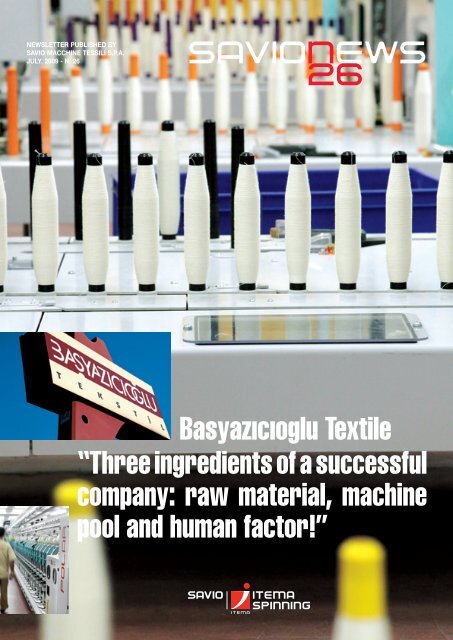

<strong>Basyazıcıoglu</strong> <strong>Textile</strong><br />

<strong>“Three</strong> <strong>ingredients</strong> <strong>of</strong> a <strong>successful</strong><br />

<strong>company</strong>: raw material, machine<br />

pool and human factor!”

2 SAVIONEWS<br />

3<br />

SAVIONEWS<br />

Turkish <strong>Textile</strong> Industry <strong>Basyazıcıoglu</strong> <strong>Textile</strong><br />

Turkish textile sector, mean at industry level, was born in the ‘20s,<br />

when, after the fall <strong>of</strong> the Ottoman Empire and the introduction <strong>of</strong><br />

a market economy thanks to Kernal Ataturk, rose the enormous<br />

value added potential coming from cotton that, until that moment,<br />

was mainly exported as raw material.<br />

In the ‘50s/’60s, the industrial nucleus took form, but the real<br />

industrialization turning point happened not before the ‘70s/’80s<br />

when started big investments in modern plants, and, at the same<br />

time, the presence <strong>of</strong> Turkish textile products begun to grow in the<br />

worldwide markets.<br />

The Turkish textile and clothing – that today gather a quarter <strong>of</strong> the<br />

total amount <strong>of</strong> bigger dimension companies – grow quicker and<br />

quicker. The textile industry in Turkey is mainly in private hands and<br />

it’s made in the 80% <strong>of</strong> medium dimension companies. The sector<br />

represents the 10,7% <strong>of</strong> the GDP and hires about 5.5 million<br />

people. Turkey is the fifth world manufacturer <strong>of</strong> cotton and is one<br />

<strong>of</strong> the first ten countries in clothing manufacture <strong>of</strong> wool, carpets,<br />

synthetic fibres and yarns <strong>of</strong> polyester and polyamide.<br />

With the abolition <strong>of</strong> sales restrictions with European Union, occurred<br />

after the customs agreements signed in 1996, Turkey has<br />

become the second clothing supplier <strong>of</strong> EU after China and the<br />

sixth <strong>of</strong> Italy.<br />

Turkey is an important customer <strong>of</strong> Italian textile machinery; quality<br />

fully corresponds to Turkish standards and, thanks to the geographical<br />

nearness to Italy, can be guaranteed an optimum service<br />

and quickness.<br />

Turkey is not only customer <strong>of</strong> textile machinery but also <strong>of</strong> innovative<br />

yarns and blends created in Italy. Are Italians also some<br />

services <strong>of</strong> technical consultation.<br />

Moreover, Turkey owns vertical structures going from the raw<br />

material (mainly cotton) to the finished product: formal, sportswear,<br />

children wear, but also leatherwear, rams cloth and sponge cloth.<br />

(from www.e-turchia.com/Economia.htm)<br />

History <strong>of</strong> <strong>Basyazıcıoglu</strong> <strong>Textile</strong><br />

In 1953, begun the entrepreneurial<br />

adventure <strong>of</strong> <strong>Basyazıcıoglu</strong> family, who<br />

started their activity in the textile sector<br />

with the third generation. The greatgrandfather<br />

Kilimci Hacı Sükrü Aga<br />

was a pioneer in the ‘30s, developing<br />

during the years several businesses,<br />

from foodstuffs, to cattle-breeding,<br />

to tourism, from building industry to<br />

shopping malls.<br />

In 2002, BAMEN YARNS has been<br />

taken over into the family businesses<br />

which today operates in the same<br />

sectors above mentioned.<br />

Raw material<br />

Production range Ne 16-100 Conventional<br />

and Compact yarns 100% Cotton,<br />

Carded and Combed, Bamboo,<br />

Modal, Viscose, Tencel and Blends.<br />

In requests: Cashmere, Wool, Jute<br />

fibers are also available.<br />

Founded by the brothers Mahmut e<br />

Murat <strong>Basyazıcıoglu</strong>, BAMEN YARNS<br />

with its quality standards, technological<br />

investments and motivated and creative<br />

team, aims to be a dynamic and long<br />

lasting leader in the textile industry.<br />

Today the <strong>company</strong> has 350 employees<br />

to whom are dedicated training<br />

courses, seminars and attendance to<br />

textile exhibitions.<br />

Through huge technological investments,<br />

the <strong>company</strong> has updated<br />

and increased the machine pool,<br />

increasing the production capacity day<br />

by day.<br />

In cotton production, PIMA and GIZA<br />

fibers can be used on requests.<br />

Control Union certificated organic<br />

cotton fiber can be used.<br />

On the other hand Bamen has a complete<br />

yarn dye house available to dye<br />

yarns, produced by all kind <strong>of</strong> materials.

4 SAVIONEWS<br />

5<br />

SAVIONEWS<br />

The choice <strong>of</strong> Polar/I-Direct Link System<br />

From left: Mahmut <strong>Basyazıcıoglu</strong> (Owner)<br />

and Selim Sarfati <strong>of</strong> Modiano (Savio's Agency in Turkey)<br />

Mahmut and Murat <strong>Basyazıcıoglu</strong> explain why they choose<br />

POLAR/I-DirectLinkSystem:<br />

“The investments on new machines and on new system represent<br />

in every <strong>company</strong> one <strong>of</strong> the most difficult decision to take<br />

and require convenient and accurate reflection. The machine<br />

pool together with the applied technologies sensitively modify the<br />

yarn features even in the slightest details. In this case, we had to<br />

choose how to optimize the link with the spinning frames. Polar/I<br />

represented the ideal choice. The solution <strong>of</strong> the link between the<br />

ring spinning frame and the automatic winder is becoming more<br />

popular in Turkey as a consequence <strong>of</strong> the difficulty to find workers<br />

for the mills.<br />

The automation brought by POLAR/I shows our way <strong>of</strong> integral<br />

thinking in terms <strong>of</strong> persistent quality and costs reduction.<br />

Have attracted our attention the systems and devices which allow<br />

us to minimize consumptions and increase efficiency: these systems<br />

allow to always maintain the maximum control on the yarn<br />

for what concerns quality <strong>of</strong> the final result and also quantity <strong>of</strong> the<br />

yarn produced. In fact, the request <strong>of</strong> yarns remaining reduction<br />

in the downstream process require the production <strong>of</strong> packages<br />

with extremely precise metering. The consequent cost saving is<br />

important for the yarns that we process, high value added yarns,<br />

such as innovative yarns”.<br />

PRODUCTION CAPACITY:<br />

Number <strong>of</strong> spindles: 52.512<br />

Total area: 46.000 sq.mt<br />

Covered Area: 33.000 sq.mt<br />

Productivity<br />

Ring compact & conventional:<br />

25 tons/day<br />

Dyeing: 7 tons/day<br />

In the dyeing dept. is possible to dye<br />

every type <strong>of</strong> fibre from a load <strong>of</strong> 3 kg<br />

up to a maximum <strong>of</strong> 600 kg.<br />

In the Ring Compact dept. are manufactured<br />

combed yarns between Ne30<br />

and Ne100.<br />

Export Markets<br />

Bulgaria, Syria, Egypt, Russia, Ukraine,<br />

Bosnia-Erzegovina, Macedonia,<br />

Lituania, Estonia, France, Iran, Great<br />

Britain, Tunisia, Algeria, Croatia, Serbia,<br />

Finland, Greece, Portugal, Holland,<br />

Slovakia, Germany, Belgium, Czech<br />

Republic, Romania, Denmark, Switzerland,<br />

Spain.<br />

Contact:<br />

BASYAZICIOGLU TEKSTIL SANAYI<br />

TICARET AS<br />

ORGANIZE SANAY BOLGESI 18<br />

CAD. N. 3<br />

38070 KAYSERI - TURKIYE<br />

Human factor<br />

The key factor for success is human<br />

factor. BAMEN YARNS organization<br />

and operative systems are based on an<br />

approach oriented to dynamism and<br />

team work. The <strong>company</strong> can count on<br />

350 employees who are responsible <strong>of</strong><br />

yarns development and manufacture,<br />

we can even say that every millimetre<br />

<strong>of</strong> every single yarn package in<br />

BAMEN YARNS has been subject <strong>of</strong> a<br />

tremendous amount <strong>of</strong> attention, work<br />

and devotion.<br />

To the human resources are dedicated<br />

training courses, seminars and attendance<br />

to textile exhibitions, in this way<br />

motivation and dynamism can grow<br />

more and more.<br />

BAMEN YARNS can count also on a<br />

Quality Control team formed by high<br />

level specialists who, with modern and<br />

sophisticated machinery, <strong>of</strong>fline test<br />

fibres, ribbons, slivers, packages and<br />

bobbins.<br />

MACHINE POOL<br />

Ring Compact Mill<br />

Blow-room (Blender-Carder) with Jossi<br />

Vision Shield MPX and MAGIC EYE<br />

Rieter<br />

D<strong>of</strong>fer<br />

Rieter C60<br />

Draw-frame<br />

Rieter SB D40-RSB-D40<br />

Wadding<br />

Rieter Omegalap E35<br />

Servolap D 25 -<br />

Comber<br />

Rieter D 76<br />

Cord<br />

Marzoli FTSDN -<br />

Ring<br />

Rieter K45<br />

Bobbin with Quantum<br />

Savio POLAR/I-DirectLinkSystem<br />

Yarn Fixing<br />

Welker Condibox Ecotherm<br />

Coolvap Automatic

6 SAVIONEWS<br />

7<br />

SAVIONEWS<br />

"Quality first"

8 SAVIONEWS<br />

9<br />

SAVIONEWS<br />

POLAR/I - Direct Link System<br />

In the winding segment, process development and innovations have been always dictated by the needs expressed by the<br />

world market. In order to provide an answer to the market requirements, Savio introduced the POLAR automatic winder,<br />

available in a number <strong>of</strong> versions: the M/L with manual bobbin feeding and manual/automatic package d<strong>of</strong>fing, and the E/I<br />

designed as a stand-alone machine or for direct linkage with spinning machine.<br />

The many configurations available make POLAR the ideal patner for the winding process.<br />

MAIN FEATURES<br />

The main features <strong>of</strong> the new model POLAR/I DLS (Direct Link<br />

System) include the uninterrupted movement <strong>of</strong> the bobbin from<br />

the ring spinning frame to the winder. The machine is equipped<br />

with a newly designed yarn-end finder station aimed to increase<br />

the machine efficiency.<br />

This device can be combined with additional second and third<br />

station in order to match the production <strong>of</strong> the longest ring frames.<br />

The winding path has been modified, as regards the position <strong>of</strong><br />

the bobbin which is vertical; n° two bobbins as spares are present<br />

in each position.<br />

Particular attention has also been paid to the suction system,<br />

which is the most energy consuming component <strong>of</strong> a winding<br />

machine.<br />

A special fan, featuring high aerodynamic performance blades and<br />

a direct drive motor, minimizes energy consumption.<br />

The motor is controlled by the machine’s PC via an inverter, which<br />

automatically adjusts its speed to the real process conditions and<br />

settings.<br />

All lints are picked up in a collector box with dedicated filter placed<br />

on the machine’s headstock.<br />

The same suction system discharges the dust from the travelling<br />

blower into another dust box with different filter.<br />

SAVIO QUALITY<br />

The CAT system (Computer Aided<br />

Tension) online controls the<br />

tension <strong>of</strong> the yarn. The winding<br />

tension is continuously measured<br />

by the piezoelectric Tensor device<br />

which interacts with the yarn tensioner<br />

via the machine’s PC and<br />

modifies the load on the yarn in<br />

order to keep the winding tension<br />

constant during the whole bobbin<br />

unwinding stage.<br />

This control does not require<br />

continuous contact between the<br />

yarn and the sensor.<br />

The Tensor device, located just<br />

before the package, measures<br />

the actual winding tension, acts<br />

as an anti-wrap system and is<br />

maintenance free.<br />

The package quality is ensured<br />

by electronic on-<strong>of</strong>f system antiribonning<br />

device which operates<br />

only at the critical diameters.<br />

Upon request, a new intelligent<br />

Savio Bobbin Identification<br />

System enables the detection<br />

<strong>of</strong> the ring frame spindle which<br />

produces faulty bobbins. As<br />

additional feature, this system<br />

can be equipped with a centralized<br />

station which will automatically<br />

remove the faulty yarn from<br />

the detected faulty bobbin. In<br />

addition, important features are<br />

available depending on yarn type<br />

and downstream process <strong>of</strong> the<br />

packages. For coarse cotton<br />

carded yarn count, each single<br />

winding position can also be<br />

equipped with a dust removal<br />

unit, located at the level <strong>of</strong> the<br />

balloon breaker, in order to catch<br />

all fibrils and dust generated during<br />

the bobbin unwinding stage.<br />

The necessary vacuum is created<br />

by an independent fan serving<br />

two sections. The dust is discharged<br />

in another collector box with<br />

separate filter.<br />

The CAP system (Computer<br />

Aided Package) controls the<br />

yarn deposit on the package,<br />

in order to eliminate patterning<br />

defects and optimise downstream<br />

processes, mainly used<br />

for wool and delicate yarns.<br />

The yarn layering is controlled<br />

through the variation <strong>of</strong> the<br />

drum-package speed ratio,<br />

every time a critical diameter is<br />

reached. A special step motor<br />

modifies the drum-package position<br />

in order to ensure that the<br />

relative distance <strong>of</strong> the wound<br />

coils is maintained.<br />

Finally, the CAM system<br />

(Computer Aided Metering)<br />

ensures accurately the yarn<br />

length on the package. The<br />

request for a reduction in yarn<br />

remnants in a downstream<br />

processes, requires that the<br />

packages produced contain an<br />

extremely precise yarn length.<br />

The resulting savings are<br />

particularly welcome in case<br />

<strong>of</strong> added value yarns, such as<br />

wool, cashmere and silk. The<br />

combination <strong>of</strong> the laser detector<br />

with the package and drum<br />

sensors is managed by the<br />

machine’s PC. This measuring<br />

system is totally independent <strong>of</strong><br />

the yarn structure, shape, evenness<br />

and hairiness.

10 SAVIONEWS<br />

11<br />

SAVIONEWS<br />

Steady Development<br />

When it was launched, POLAR set a new standard for the winding<br />

process. The new geometry <strong>of</strong> the cradle allows higher operating<br />

speeds especially with compact yarns, using at the same time<br />

take-up tubes <strong>of</strong> different shape and quality, and makes it possible<br />

to obtain compact and perfect packages even under strictest working<br />

conditions. Moreover, the machine is particularly reliable, as a<br />

result <strong>of</strong> minimizing maintenance downtimes. The natural evolution<br />

<strong>of</strong> this machine is represented by the POLAR/I Direct Link System,<br />

the ideal solution for linking winders with spinning frames.<br />

As a result, the solution <strong>of</strong> linking the ring spinning frame with the<br />

automatic winder is also becoming popular in low-wage countries.<br />

<strong>Basyazıcıoglu</strong> has a modern yarn dyeing plant where,<br />

thanks to the perfect winding obtained by universal drum<br />

and axial displacement <strong>of</strong> Savio Polar, perfect packages are<br />

<strong>successful</strong>ly dyed.<br />

Savio presence in Turkey<br />

Savio is represented in Turkey by Motex/Modiano which,<br />

since more than 40 years, operates in this country; it has<br />

always grown up to become today a point <strong>of</strong> reference in Turkey<br />

for the Italian textile machinery. Since several years, Motex/Modiano<br />

structure has been strenghtened by the creation<br />

<strong>of</strong> Modiano Teknik Hizmetler for providing the customers<br />

with a valid After-sales assistance.<br />

This society, thanks to its high qualified technical team in the<br />

mechanical and electronical field, carries the assembling and<br />

the technical assistance out, also providing the customers<br />

with spare parts on immediate delivery from the warehouses<br />

in Istanbul, Bursa and Gaziantep.<br />

From left: Mahmut <strong>Basyazıcıoglu</strong> (Owner), Selim Sarfati <strong>of</strong> Modiano<br />

(Savio's Agency in Turkey), Ali Güvendi (<strong>Basyazıcıoglu</strong> General Technical<br />

Director), Mustafa Boydak (<strong>Basyazıcıoglu</strong> Spinning Mill Technical Director),<br />

and Sergio Muzzin (Savio's Technical Advisor).<br />

Alfredo Modiano<br />

ve Oğlu Koll.Şti<br />

Halit ZiyaTürkkan sok.Famas Plaza B.Blok K.3<br />

Okmeydanı/Şişli - Istanbul<br />

tel: +90 212 2105495 - fax:+90 212 2105499

12<br />

SAVIONEWS<br />

Important Turkish customers have<br />

chosen Savio for their mills:<br />

WINDING AKIN TEKSTIL - AKINAL - AKKON - AKKOZA - AKMERT IPLIK - AKREN - AKTEKS AKRILIK IPLIK<br />

SANAYI VE - AKYIL - ALTINYILDIZ - ALTINYILDIZ MENSUCAT VE KONFEKSIYON - AN TEKSTIL - ANTBIRLIK<br />

- ARSAN - ASKA - ASLAN - ATLANTIK - AYANOGLU - AYDIN M. - BAHARIYE MENS. - BAKIRKOY - BAKIRLAR -<br />

BASYAZICIOGLU - BERNI - BETAS - BIRLIK YUN - BITEKS - BOSSA - BOSSA 1 - BOSSA T.A.S. - BOYAR KIMYA<br />

- BOYNER SANAYI MENSUCAT FABRIK A.S. - BOZOGLU - BULUT - CANAN - CEMEN - DAMTEKS - DEMIR<br />

METAL - DIRI IPLIK - DORE MENSUCAT FABRIKASI A.S. - ELIT IPLIK - ELSAN ELYAF SANAYI VE TIC. A.S. - EL-<br />

YAF - EMBOY - EMBOY YUNTAS BIRLESIK A.S. - ERDEM - ESA TEKSTIL - ESRA - F.DEN-TEX - FIL MAN MADE<br />

- FILOTEKS - FISTAS - GAP INSAAT - GARANTI FIN - GARANTI IPLIK - GURAKRILIK - GURTEKS - GURTEKS<br />

TEKSTIL - HASKOY YUN IPLIK - FABRIKASI A.S. - IPLIKSAN - ISKO - ISPARTA M. - ISTANBUL IPLIK - ISTANBUL<br />

M - KADIFETEKS - KAPLAN - KARACA - KARTEKS - KAYNAK - KILIM MENSUCAT - KIPAS - KIPAS DENIM - KRI-<br />

STAL - KURTEKS - KUVETLER - M.MENSUCAT - M.PAMUKLU - MARMARA IPLIK - MARMARA P. - MARMARA<br />

PAMUKLU MENSUCAT SANAYI VE - MATESA - MENSA - MERINOS HALI - MIMATAS - MINK TEKSTIL - MURAT<br />

- ORAN - ORAN TEKSTIL - ORMO YUN IPLIK - OZSEVER TEKSTIL - PIRAMIT - REMTEKS - SAFTEKS - SANKO<br />

- SARAY HALI A.S. - SERFIL - SERTEN TRIKO VE CAMASIR SAN.VE TIC. - SIRECI - SIRIKCIOGLU - SONMEZ -<br />

SONMEZ PAMUKLU - SONMEZ PAMUKLU SANAYII A.S. - SUNERLER - T. MERSER. - TEKSKA - TOPKAPI TEK-<br />

STIL SAN.VE TIC. A.S. TUMTEKS - UGUR BALKUV - YAYLA - YENTUR - YUNSA - ZAFER<br />

TWISTING ADIL - AKCA - AKINAL - AKKON - AKSU IPLIK-DOKUMA FABR - AKTEKS - ANILSAN - ATLANTIK -<br />

AYDIN M. - BERDAN - BETAS - BILKONT - BOYAR - BOYAR KIMYA - BURTEKS - CANAN - CEMEN - DAMTEKS<br />

- DICLE - DIRI IPLIK - DOS TEKST. - DULGEROGL. - ELKOTEKS - EMBOY YUNTAS BIRLESIK A.S. - ERKENT<br />

MENSUCAT SANAYI - ESRA - FIL MAN MADE - FILOTEKS - GARANTI IPLIK - GULCAG - GUNOZ - GURAKRI-<br />

LIK - GURTEKS - GURTEKS TEKSTIL - ISTANBUL M - KADIFETEKS - KAPLANLAR - KARAN - KIPAS - KRISTAL<br />

- MARMARA P. - MELTEM - MERINOS HALI - MERT IPLIK - MIDAS - O.B.C. - OZDEMIR - OZSEVER TEKSTIL<br />

- SELCUK - SERFIL - SIRECI - SONMEZ - TANIS - TEKSKA - USTA - UZAY ORGU - YENTUR - YUKSEL - YUNSA<br />

CONTINUOUS SHRINKING & BULKING AK-AL TEKSTIL SANAYI A.S. - AKKON - AKMERT - AKREN - AKTEKS<br />

- AKTEKS AKRILIK IPLIK SANAYI VE - BETAS - BOYAR - BOYNER SANAYI MENSUCAT FABRIK A.S. - CANAN -<br />

CEMEN - DAMTEKS - EMBOY YUNTAS BIRLESIK A.S. - ESA - ESRA - GURAKRILIK - GURTEKS - KARAN - KRI-<br />

STAL - OZSEVER TEKSTIL - RITEKS - SAYYUN - SERYIL - SIRECI - TEKSKA - UZAY ORGU - ZAFER<br />

ASSEMBLING AK-AL TEKSTIL SANAYI A.S. - AKCA - ATLAS HALI - HALICILIK ISLETMELERI AS - ERKENT MEN-<br />

SUCAT SANAYI VE TICARET - KAYNAK - KILIM MENSUCAT SAN.VE. TIC. A.S. - MERINOS HALI - YUKSEL<br />

SPINNING AK-AL TEKSTIL SANAYI A.S. - KAYNAK<br />

NEWSLETTER PUBLISHED BY - SAVIO MACCHINE TESSILI S.P.A.<br />

33170 PORDENONE (ITALY) VIA UDINE, 105 - TEL. +39 0434 397422 - FAX +39 0434 397599<br />

WWW.SAVIOSPA.IT - ORDER@SAVIOSPA.IT<br />

CONTACT: BASYAZICIOGLU TEKSTIL SANAYI TICARET AS<br />

ORGANIZE SANAY BOLGESI 18 - CAD. N. 3<br />

38070 KAYSERI - TURKIYE