Antifrogen SOL HT - Hubbard-Hall

Antifrogen SOL HT - Hubbard-Hall

Antifrogen SOL HT - Hubbard-Hall

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

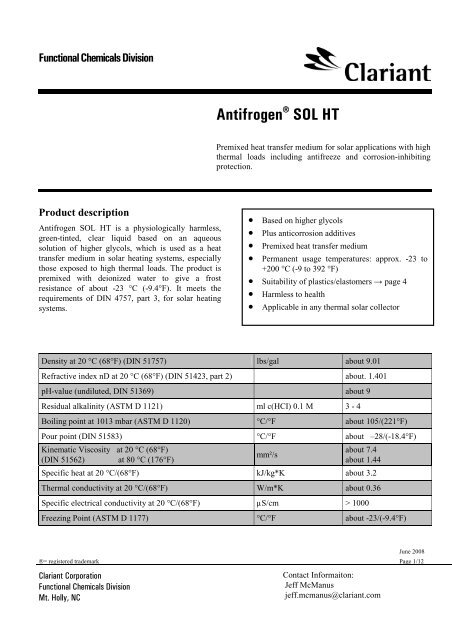

Functional Chemicals Division<br />

Product description<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is a physiologically harmless,<br />

green-tinted, clear liquid based on an aqueous<br />

solution of higher glycols, which is used as a heat<br />

transfer medium in solar heating systems, especially<br />

those exposed to high thermal loads. The product is<br />

premixed with deionized water to give a frost<br />

resistance of about -23 °C (-9.4°F). It meets the<br />

requirements of DIN 4757, part 3, for solar heating<br />

systems.<br />

June 2008<br />

®= registered trademark Page 1/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

Premixed heat transfer medium for solar applications with high<br />

thermal loads including antifreeze and corrosion-inhibiting<br />

protection.<br />

Density at 20 °C (68°F) (DIN 51757) lbs/gal about 9.01<br />

Refractive index nD at 20 °C (68°F) (DIN 51423, part 2) about. 1.401<br />

pH-value (undiluted, DIN 51369) about 9<br />

Residual alkalinity (ASTM D 1121) ml c(HCI) 0.1 M 3 - 4<br />

Boiling point at 1013 mbar (ASTM D 1120) °C/°F about 105/(221°F)<br />

Pour point (DIN 51583) °C/°F about –28/(-18.4°F)<br />

Kinematic Viscosity at 20 °C (68°F)<br />

(DIN 51562) at 80 °C (176°F)<br />

• Based on higher glycols<br />

• Plus anticorrosion additives<br />

• Premixed heat transfer medium<br />

• Permanent usage temperatures: approx. -23 to<br />

+200 °C (-9 to 392 °F)<br />

• Suitability of plastics/elastomers → page 4<br />

• Harmless to health<br />

• Applicable in any thermal solar collector<br />

mm²/s<br />

about 7.4<br />

about 1.44<br />

Specific heat at 20 °C/(68°F) kJ/kg*K about 3.2<br />

Thermal conductivity at 20 °C/(68°F) W/m*K about 0.36<br />

Specific electrical conductivity at 20 °C/(68°F) µS/cm > 1000<br />

Freezing Point (ASTM D 1177) °C/°F about -23/(-9.4°F)<br />

Contact Informaiton:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com

Functional Chemicals Division<br />

Notes on use<br />

Product properties<br />

The technical data below is used to describe the<br />

product and is taken from our own measurements or<br />

from literature. It does not constitute part of the<br />

delivery specification. The mandatory product<br />

specification will be found in the current technical<br />

data sheet.<br />

The certified quality system in accordance with DIN<br />

EN ISO 9001 is used in production and quality<br />

control. This ensures consistently high product<br />

quality.<br />

Application properties<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> was developed especially for use<br />

as a heat transfer medium in solar systems. The<br />

product is physiologically harmless.<br />

Phase separation of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>/water<br />

mixtures does not occur.<br />

Frost resistance of the mixture does not change even<br />

after many years’ use, provided the <strong>Antifrogen</strong> <strong>SOL</strong><br />

<strong>HT</strong> concentration remains constant.<br />

Since <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> has a higher viscosity and<br />

density than pure water, a higher pressure drop must<br />

be expected in pipelines etc; graphs of the relative<br />

heat transfer coefficient and relative pressure drop –<br />

in comparison with pure water – are particularly<br />

useful for calculation purposes. These graphs and<br />

other physical data can be found in the appendix.<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> contains corrosion inhibitors that<br />

protect the metals of the solar systems, even in<br />

combined systems, permanently against corrosion and<br />

prevent the formation of boiler scale.<br />

The effectiveness of the inhibitor combinations is<br />

checked constantly by the manufacturer by means of<br />

the well-known corrosion test method ASTM D 1384<br />

(American Society for Testing and Materials).<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 2/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Glycol/water mixtures without inhibitors cannot<br />

be used because they are more corrosive than pure<br />

water alone.<br />

The following table shows the relatively low<br />

corrosion of common metals caused by an <strong>Antifrogen</strong><br />

<strong>SOL</strong> <strong>HT</strong> compared with water and cooling brine.<br />

The values, determined by the above mentioned<br />

ASTM method, show the weight loss of metals in<br />

g/m² due to corrosion:<br />

Corrosion of metals in g/m², tested in accordance<br />

with ASTM D 1384 (336 h/88 °C/(190.4°F), 6 l<br />

air/h)<br />

Copper<br />

Soft solder<br />

(WL 30)<br />

Brass<br />

(MS 63)<br />

Steel<br />

(CK 22)<br />

Cast Iron<br />

(GG 25)<br />

Cast Aluminium<br />

(AlSi6Cu3)<br />

Stainless steel<br />

(1.4541)<br />

<strong>Antifrogen</strong> <strong>SOL</strong><br />

<strong>HT</strong> a<br />

Higher Glycols b<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

Propylene glycol c<br />

Tap water d<br />

-2.3 -15.3 -2.8 -1<br />

-3.7 -68.2 -136 -11<br />

-1.0 -64.4 -2.5 -1.0<br />

< 0.1 -148.5 -225 -76<br />

-0.4 -73.5 -92 -192<br />

-1.5 -6.7<br />

< -0.1 Not<br />

tested<br />

-68 -32<br />

Not<br />

tested<br />

-0.5<br />

a <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> (undiluted); b Higher glycols 1:1 water mixture<br />

without inhibitors; c Propylene glycol 1:2 water mixture without<br />

inhibitors, d Tap water (14° dH);

Functional Chemicals Division<br />

It is advisable, if at all possible, not to use the<br />

product in galvanized pipelines, since all<br />

glycol/water mixtures can dissolve zinc.<br />

The good corrosion-inhibiting properties of<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> decrease as expected with<br />

increasing water content. The water used to dilute<br />

<strong>Antifrogen</strong> N shall contain no more than 100 mg/kg<br />

(ppm) chlorides. A wide range of water hardness is<br />

acceptable (between 0 and 180 ppm). This means,<br />

that in addition to fully deionized water, ordinary<br />

tap water may be used.<br />

The frost resistance of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is<br />

adjusted to a pour point of -28 °C/(-18.4°F) (freezing<br />

point: -23 °C/(-9.4°F)). Trials have shown that under<br />

North American winter conditions this formulation<br />

will not cause bursts in metal system components<br />

because slush ice is formed when the product is<br />

cooled below the crystallization point. The frost<br />

resistance is of course reduced by mixing with water,<br />

as the curves in the appendix indicate.<br />

Special antifreeze testers are available for<br />

determining frost resistance.<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is premixed with deionized water<br />

and formulated to give the optimum frost and<br />

corrosion resistance. If traces of water still remain in<br />

the system after flushing or the user inadvertently<br />

dilutes the product, additions of water up to 10% can<br />

be tolerated without any adverse effect on corrosion<br />

resistance.<br />

Heat resistance<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> was developed because of the<br />

increased use of vacuum collectors, which have a<br />

high stagnation temperature of over +260<br />

°C/(+500°F). Typical ethylene and propylene glycol<br />

based heat transfer media tends to evaporate in such<br />

systems at high temperatures due to the low boiling<br />

point of these glycols. They leave partially insoluble,<br />

salt-like residues that can lead to operating problems<br />

if the collector is frequently idle and can result in<br />

failure of the system. <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> consists<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 3/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

predominantly of higher-boiling, physiologically<br />

harmless, higher-molecular-weight glycols with a<br />

boiling point of over +270 °C/(+518°F)at 1013 mbar.<br />

Use of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> ensures that the abovementioned<br />

residues remain liquid.<br />

Nevertheless, operating temperatures of more than<br />

+200 °C/(+392°F) should be avoided. At higher<br />

temperatures not only can the chemical basis of the<br />

heat transfer medium decompose, causing the liquid<br />

to darken, but some corrosion inhibitors can also be<br />

inactivated. Sporadic high temperature loads can<br />

cause a decoloration of the fluid, but decoloration<br />

alone has no effect on the properties of the product.<br />

Circulating pumps should be selected with special<br />

regard to their suitability for operation with antifreeze<br />

agents. Pump components made, for example, of<br />

materials based on phenolic resins do not meet this<br />

requirement. However, the circulating pumps<br />

normally used in heating installations have been<br />

found to be resistant.<br />

According to data published in the literature and the<br />

results of our own tests and trials, the following<br />

plastics and elastomers are suitable for the<br />

manufacture of components coming into contact with<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>. The maximum temperatures<br />

specified by the manufacturer should not be<br />

exceeded.<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com

Functional Chemicals Division<br />

Butyl rubber (IIR)<br />

Fluorcarbon elastomers, e.g. (FPM)<br />

®Viton (Du Pont)<br />

Natural rubber up to 80 °C (NR)<br />

Nitrile rubber, e.g.<br />

®Perbunan (Bayer)<br />

Olefin rubber, e.g. ®Buna AP<br />

(Bayer)<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 4/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

(NBR)<br />

(EPDM)<br />

Polychlorbutadiene<br />

(CR)<br />

elastomers, e.g. ® Neopren<br />

Silicon rubber, e.g. ®Elastosil (Si)<br />

(Wacker)<br />

Styrene butadiene rubber up (SBR)<br />

to 100 °C<br />

Polyacetal, e.g. ®Hostaform (POM)<br />

(Ticona)<br />

Polybutene, e.g. ®Rhiatherm (PB)<br />

(Simona)<br />

Polyester resins (UP)<br />

Polypropylene, e.g.<br />

®Hostalen PPH 2222<br />

(PP)<br />

Polyvinylidenedifluorid (PVDF)<br />

Polytetrafluoroethylene, e.g.<br />

®Hostaflon<br />

flex. Polyolefine<br />

e.g. ®Bauder Thermoplan T-<br />

SV (for flat roofs)<br />

(PTFE)<br />

(FPO)<br />

Phenol-formaldehyde resins, plasticized PVC and<br />

polyurethane elastomers are not resistant.<br />

Experience has shown that the well-known IT<br />

(rubber-asbestos) seals, as well as EPDM elastomer<br />

seals are suitable for these systems.<br />

For threaded pipe connections, in which hemp is used<br />

as a seal, coating with Fermit or Fermitol (Nissen und<br />

Volk) or Loctite 511 (Loctite Corp.) has proved<br />

successful.<br />

Tests have shown that the materials used for pressure<br />

surge compensators e.g. ® Flexon (Flamco) are not<br />

affected by <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>.<br />

Notes for use in solar heating systems<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is an ideal heat transfer medium<br />

for highly stressed solar heating systems, particularly<br />

those with vacuum collectors. The materials normally<br />

used in solar heating systems, such as copper,<br />

stainless steel and aluminum, are protected from<br />

corrosive attack for many years by special corrosion<br />

inhibitors. To ensure optimum protection, the<br />

following advice should be followed:<br />

1. The system should conform with the<br />

requirements of DIN 4757 and must be designed<br />

as closed circuits. The membrane pressure surge<br />

compensators must conform with DIN 4807.<br />

2. Before filling, the system should be flushed out<br />

with water. Pipe joints, valves and circulating<br />

pumps should be pressure-tested for leaks.<br />

3. Hard-soldered joints are preferable to softsoldered.<br />

Traces of flux (if possible chloride-<br />

free) must be removed by pumping through with<br />

hot water.<br />

4. If at all possible, galvanized components should<br />

not be used in the system. Zinc is not resistant to<br />

the <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> and tends to start<br />

dissolving, which can lead to formation of<br />

sludge. Dirt traps and filters can help here.<br />

5. After pressure testing, the system should be<br />

drained and then filled immediately with<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> to eliminate any air pockets.<br />

This process also affords an opportunity to<br />

determine the capacity of the system from the<br />

amount of water used (water meter).XXXX<br />

XXXX XX XXXXXXXXxxxxxxxxxxxxXXXX<br />

XXXXXXXXX<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com

Functional Chemicals Division<br />

6. Long-term no-load operation of the system<br />

should be avoided because this can adversely<br />

affect the stability of the heat transfer medium<br />

and considerably reduce its service life.<br />

7. In the event of leaks, always top off with<br />

undiluted <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>. Avoid mixing it<br />

with other products. If, in exceptional cases,<br />

water is used to top off the system, the<br />

concentration (= frost resistance) of the heat<br />

transfer medium should be checked with a<br />

hydrometer. The frost resistance should be at<br />

least –20°C/(-4°F) to ensure adequate frost and<br />

corrosion resistance.<br />

Service and monitoring<br />

It has been found that <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> can be<br />

used in installations for many years. However, the<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> concentration (= frost resistance)<br />

should be checked annually. As required, the<br />

performance of the heat transfer medium and level of<br />

corrosion inhibition can also be checked by Clariant.<br />

If a 250 ml sample is provided, this service can be<br />

undertaken by Clariant Corporation, 625 East<br />

Catawba Ave, Mt. Holly, North Carolina, 28120.<br />

The data in our service report relate solely to the<br />

sample sent to us. Guidance on further use of the<br />

product tested assumes that the system is in proper<br />

condition and properly operated. We would expressly<br />

point out that, particularly where corrosion or scale is<br />

already present in the system, interactions with the<br />

product may occur with unpredictable consequences.<br />

We accept no liability whatsoever for any damage<br />

resulting from the improper condition or operation of<br />

the system.<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

Safety, Toxicology and Ecology<br />

June 2008<br />

®= registered trademark Page 5/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> has neither a flash point nor an<br />

ignition point. The product is based on non-toxic<br />

glycols (higher polyalkylene glycols). The corrosion<br />

inhibitor formulation is phosphate and nitrite-free and<br />

consists essentially of physiologically harmless<br />

additives.<br />

Flash point<br />

(DIN 51758)<br />

Ignition temperatur<br />

(DIN 51794)<br />

Temperature class<br />

(DIN/VDE 0165)<br />

°C<br />

°F<br />

°C<br />

°F<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

> 105 (not detectable)<br />

> 221<br />

> 420<br />

> 788<br />

T2<br />

More information can be found in the material<br />

safety data sheet (MSDS).<br />

The results of ecotoxicological studies confirm the<br />

good biodegradability and toxicological inertness of<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>. In concentrations up to 1000<br />

mg/l, <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> shows no acute harmful<br />

effects on fish and bacteria. <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is<br />

readily biodegradable.<br />

Spent <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> can be disposed of in a<br />

special waste incineration unit in accordance with<br />

local regulations. Further notes are contained in the<br />

latest material safety data sheet.

Functional Chemicals Division<br />

Transport and storage<br />

VbF (German regulations<br />

on flammable liquids)<br />

-<br />

GGVE/RID non-regulated<br />

GGVS/ADR non-regulated<br />

ADNR non-regulated<br />

IMDG-Code non-regulated<br />

DOT non-regluated<br />

IATA-DGR non-regulated<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> is supplied in road tankers, totes<br />

and drums. Since zinc is not resistant to <strong>Antifrogen</strong><br />

<strong>SOL</strong> <strong>HT</strong>, galvanized transport and storage containers<br />

should not be used. The product has a storage<br />

stability of two years.<br />

This information is based on our present state of<br />

knowledge and is intended to provide general notes<br />

on our products and their uses. It should not therefore<br />

be construed as guaranteeing specific properties of<br />

the products described or their suitability for a<br />

particular application. Any existing industrial<br />

property rights must be observed. The quality of our<br />

products is guaranteed under our General Conditions<br />

of Sale. We would like to specifically point out that<br />

any corrosion or deposits already present in the<br />

system may interact with the product with<br />

unpredictable consequences. We accept no liability<br />

for any damage due to the system being maintained in<br />

an improper condition or operated incorrectly.<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 6/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Appendix<br />

The following graphs provide information on the<br />

most important physical properties of <strong>Antifrogen</strong><br />

<strong>SOL</strong> <strong>HT</strong>.<br />

Due to calculations and the graphical illustration of<br />

the figures with an IT program, small variances of the<br />

physical data can occur.<br />

Clariant Corporation<br />

Functional Fluids Division<br />

Mt. Holly, North Carolina<br />

Tel. +1 704-822-2649, Fax +1 704-822-2193<br />

Clariant Vertrieb (Deutschland) GmbH & Co KG<br />

Division Functional Chemicals, Am Unisys Park 1<br />

D-65840 Sulzbach<br />

Tel. +49 6196/757-60, Fax: +49 6196/757-88 56<br />

Clariant Produkte (Deutschland) GmbH<br />

Werk Gendorf, Division Functional Chemicals<br />

Functional Fluids/R&D<br />

D-84504 Burgkirchen<br />

Tel. +49 8679/7-22 72, Fax: +49 8679/7-50 85<br />

Internet:<br />

http://www.clariant.com<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com

Functional Chemicals Division<br />

Kinematic Viscosity [mm²/s]<br />

1000<br />

100<br />

10<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 7/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

1<br />

Kinematic Viscosity<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

0<br />

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100<br />

Temperature [°C]<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

100 Vol.-%<br />

=<strong>Antifrogen</strong><br />

<strong>SOL</strong> <strong>HT</strong>

Functional Chemicals Division<br />

Density [g/cm³]<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 8/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Density<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

1.10<br />

1.09<br />

1.08<br />

1.07<br />

1.06<br />

1.05<br />

1.04<br />

1.03<br />

10/50 20/68 30/86 40/104<br />

50/122<br />

Temperature [°C/°F]<br />

60/140 70/158 80/176<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

100 Vol.-%<br />

= Antifroge<br />

SO L

Functional Chemicals Division<br />

Density [g/cm³]<br />

Spec. Heat [kJ/kgK]<br />

1.08<br />

1.08<br />

1.07<br />

1.07<br />

1.06<br />

1.06<br />

3.40<br />

3.35<br />

3.30<br />

3.25<br />

3.20<br />

3.15<br />

3.10<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 9/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Density<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> - water mixtures<br />

7 8 8 9 9 10<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> [Vol.-%]<br />

Specific Heat<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

40/104 50/122 60/140 70/158 80/176<br />

Temperature [°C/°F]<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

100 Vol.-%<br />

=<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong>

Functional Chemicals Division<br />

Thermal Conductivity [W/mK]<br />

0.40<br />

0.38<br />

0.35<br />

0.33<br />

0.30<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

Comment on Thermal Conductivity: Thermal conductivity has been analyzed by two independent external institutions. Multiple evaluations have<br />

revealed a slightly increased spread of the data points, especially at low temperatures. In the graph the averaged values are illustrated.<br />

June 2008<br />

®= registered trademark Page 10/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Thermal Conductivity<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

-20/-4 0/32 20/68 40/104 60/140 80/176 100/212<br />

Temperature [°C/°F]<br />

Vapor Pressure<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

40/104 60/140 80/176 100/212<br />

Temperature [°C/°F]<br />

0.<br />

0.<br />

0.<br />

0.<br />

0.<br />

0.<br />

0.<br />

0.<br />

0.<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

Pressure [bar]

Functional Chemicals Division<br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

June 2008<br />

®= registered trademark Page 11/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Coefficient of Cubic Expansion<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> VP 1981<br />

Coefficient of Cubic Expansion b [K -1 ]<br />

0.0009<br />

0.0008<br />

0.0007<br />

0.0006<br />

0.0005<br />

� = frost resistance<br />

0.0004<br />

-40/-40 -20/-4 0/32 20/68 40/104 60/140<br />

Temperature [°C/°F]<br />

80/176 100/212<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com<br />

100 Vol.-%<br />

=<strong>Antifrogen</strong> <strong>SOL</strong>

Functional Chemicals Division<br />

Refractive Index [nD20]<br />

1.4<br />

1.4<br />

1.3<br />

1.3<br />

Frost Resistance [°C]<br />

-10<br />

-15<br />

-20<br />

-25<br />

-30<br />

Refractive Index<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

<strong>Antifrogen</strong> ® <strong>SOL</strong> <strong>HT</strong><br />

7 8 8 9 9 10<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> [Vol.-%]<br />

June 2008<br />

®= registered trademark Page 12/12<br />

Clariant Corporation<br />

Functional Chemicals Division<br />

Mt. Holly, NC<br />

Frost Resistance<br />

of <strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong><br />

75 80 85 90 95 100<br />

<strong>Antifrogen</strong> <strong>SOL</strong> <strong>HT</strong> [Vol.-%]<br />

Contact Information:<br />

Jeff McManus<br />

jeff.mcmanus@clariant.com