PMI Best Management Practices for Indoor Residual Spraying in ...

PMI Best Management Practices for Indoor Residual Spraying in ...

PMI Best Management Practices for Indoor Residual Spraying in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

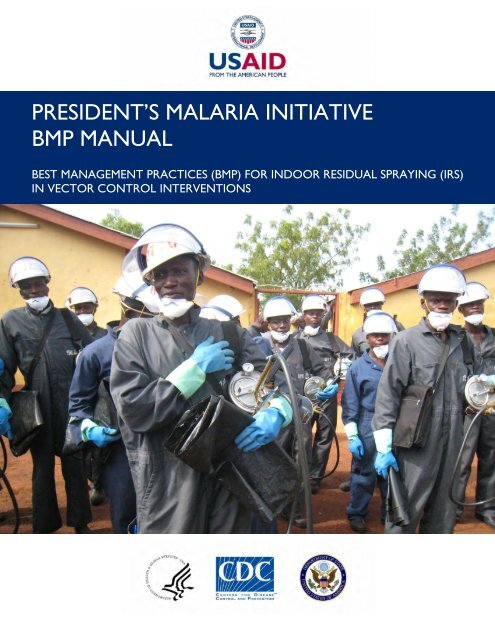

PRESIDENT’S MALARIA INITIATIVE<br />

BMP MANUAL<br />

BEST MANAGEMENT PRACTICES (BMP) FOR INDOOR RESIDUAL SPRAYING (IRS)<br />

IN VECTOR CONTROL INTERVENTIONS<br />

JUNE 2010

Updated July 2010<br />

Cover photograph: Spray Team ready <strong>for</strong> spray operation <strong>in</strong> Ghana.

ACRONYMS<br />

ACT Artem<strong>in</strong>s<strong>in</strong><strong>in</strong>-based Comb<strong>in</strong>ation Therapy<br />

BEO Bureau Environmental Officer<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

COP Chief of Party<br />

CDC U.S. Centers <strong>for</strong> Disease Control: Prevention<br />

COTR Contract<strong>in</strong>g Officer’s Technical Representative<br />

FAO U.N. Food and Agricultural Organization<br />

EIA Environmental Impact Assessment<br />

IPT Intermittent Preventive Therapy (<strong>for</strong> pregnant women)<br />

ITN Insecticide Treated Bed Net<br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

IVM Integrated Vector <strong>Management</strong><br />

MEO Mission Environmental Officer<br />

MOH M<strong>in</strong>istry of Health<br />

NMCP National Malaria Control Program<br />

OHS Occupational Health and Safety<br />

PEA Programmatic Environmental Assessment<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

SEA Supplemental Environmental Assessment<br />

USAID U.S. Agency <strong>for</strong> International Development<br />

WHO World Health Organization<br />

WHOPES World Health Organization Pesticide Evaluation Scheme<br />

3

TABLE OF CONTENTS<br />

Preface .....................................................................................................................................................................................................5<br />

Acknowledgements ..........................................................................................................................................................................6<br />

BMP 1: Environmental Assessment ..........................................................................................................................................7<br />

BMP 2: Worker and Resident Heath and Safety ........................................................................................................... 11<br />

BMP 3: Pesticide Storage, Stock Control and Inventory ........................................................................................... 21<br />

BMP 4: Pesticide Transport ....................................................................................................................................................... 29<br />

BMP 5: <strong>Spray<strong>in</strong>g</strong> Techniques ..................................................................................................................................................... 35<br />

BMP 6: Effluent Waste Disposal ............................................................................................................................................. 45<br />

BMP 7: Solid Waste Disposal ................................................................................................................................................... 57<br />

BMP 8: Spill Response .................................................................................................................................................................. 65<br />

BMP 9: DDT Special Considerations ................................................................................................................................... 73<br />

IRS Environmental Evaluation Checklist 1: Pre-Spray Activities - Storage and Transportation .................................... 81<br />

IRS Environmental Evaluation Checklist 2: <strong>Spray<strong>in</strong>g</strong> Activities ............................................................................................. 93<br />

IRS Environmental Evaluation Checklist 3: Post-<strong>Spray<strong>in</strong>g</strong> Activities - Wash up and Waste Disposal ................. 103<br />

4

PREFACE<br />

In June 2005, the United States Government announced a five-year, $1.2 billion President’s Malaria Initiative (<strong>PMI</strong>)<br />

to scale up malaria prevention and treatment <strong>in</strong>terventions <strong>in</strong> 15 priority countries <strong>in</strong> sub-Saharan Africa. The <strong>PMI</strong><br />

is a U.S. Agency <strong>for</strong> International Development (USAID)-led <strong>in</strong>itiative that is implemented <strong>in</strong> partnership with the<br />

U.S. Centers <strong>for</strong> Disease Control and Prevention (CDC). The program’s goal is to reduce malaria-related<br />

mortality by 50% after five years of accelerated implementation <strong>in</strong> each <strong>PMI</strong> country, with the aim of achiev<strong>in</strong>g 85%<br />

coverage of children less than five years of age and pregnant women with proven <strong>in</strong>terventions, <strong>in</strong>clud<strong>in</strong>g<br />

artemis<strong>in</strong><strong>in</strong>-based comb<strong>in</strong>ation therapy (ACT), <strong>in</strong>termittent preventive treatment (IPT) <strong>for</strong> malaria <strong>in</strong> pregnancy,<br />

<strong>in</strong>door residual spray<strong>in</strong>g (IRS), and <strong>in</strong>secticide-treated bed nets (ITNs). Start-up activities have been staggered <strong>in</strong><br />

three phases across the 15 <strong>PMI</strong> countries to allow <strong>for</strong> effective implementation and scale-up.<br />

IRS and ITN activities <strong>in</strong>volve the use of pesticides and hence are subject to USAID’s 22 CFR 216 regulations<br />

particularly the implementation of the monitor<strong>in</strong>g and mitigation requirements of the orig<strong>in</strong>al programmatic<br />

environmental assessment (PEA) of the Integrated Vector <strong>Management</strong> (IVM) Program and the development and<br />

application of standard procedures and best environmental management practices.<br />

This manual is comprised of the <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong> (BMPs) that cover the range of activities associated<br />

with pesticide use <strong>in</strong> IRS:<br />

1. Environmental Assessment<br />

2. Worker and Resident Health and Safety<br />

3. Pesticide Storage, Stock Control and Inventory<br />

4. Pesticide Transport<br />

5. <strong>Spray<strong>in</strong>g</strong> Techniques<br />

6. Effluent Waste Disposal<br />

7. Solid Waste Disposal<br />

8. Spill Response<br />

9. DDT Special Considerations<br />

To ensure that these best practices have been properly implemented, a series of BMP assessment checklists has<br />

been developed to be completed dur<strong>in</strong>g field <strong>in</strong>spections. The checklists are divided <strong>in</strong>to three chronological<br />

activities and <strong>in</strong>clude the follow<strong>in</strong>g:<br />

� Pre-spray activities - Storage and Transport<br />

� Spray Activities - <strong>Spray<strong>in</strong>g</strong><br />

� Post-spray Activities - Wash up and Waste Disposal<br />

The <strong>for</strong>ms are to be photocopied and completed at each region of operations that is visited. To fill out the <strong>for</strong>ms,<br />

first select the appropriate response, either yes or no, to each question and then <strong>in</strong>clude a comment to help<br />

expla<strong>in</strong> the response, or provide recommended actions and timel<strong>in</strong>es <strong>for</strong> these actions if the activity is not<br />

follow<strong>in</strong>g BMP guidel<strong>in</strong>es. These checklists will be used to prepare field reports that will be presented to <strong>PMI</strong> staff<br />

and will help guide <strong>for</strong>thcom<strong>in</strong>g IRS activities <strong>in</strong> environmental compliance.<br />

5

ACKNOWLEDGEMENTS<br />

International Resources Group (IRG) prepared this manual through an Environmental Policy and Institutional<br />

Strengthen<strong>in</strong>g (EPIQ) Indef<strong>in</strong>ite Quantities task order (Environmental Monitor<strong>in</strong>g and Capacity Build<strong>in</strong>g) with the<br />

US Agency <strong>for</strong> International Development, Bureau <strong>for</strong> Global Health (USAID/GH/HIDN) (Task Order No. 12).<br />

Susan Anderson and Jeanne Chabrier coord<strong>in</strong>ated the development of this manual and contributed technically to<br />

its contents. Special thanks to Kathy Alison, Maura Fulton and Jiwon Paik of Tra<strong>in</strong><strong>in</strong>g Resources Group, Inc. <strong>for</strong><br />

creat<strong>in</strong>g the f<strong>in</strong>al document.<br />

The BMP Manual was a collaborative ef<strong>for</strong>t with Research Triangle Institute (RTI) International. RTI provided<br />

<strong>in</strong>valuable experience based on IRS implementation s<strong>in</strong>ce 2004. Special thanks to the follow<strong>in</strong>g experts: Tito<br />

Kodiaga, Autman Tembo, Gaspard Bikwemu, and John Chimumbwa.<br />

The guidance drew largely on decades of experience <strong>in</strong> pesticide management and vector control activities by the<br />

follow<strong>in</strong>g key organizations: World Health Organization (particularly the World Health Organization Pesticide<br />

Evaluation Scheme), United Nations Food and Agricultural Organization, and Crop Life.<br />

We appreciate the guidance of the USAID/GH Bureau, <strong>in</strong>clud<strong>in</strong>g Teresa Bernhard, Elissa Jensen, Brian Hirsch, Julie<br />

Wallace, and Michael Macdonald. We would also like to thank the staff and contractors of the USAID Missions <strong>in</strong><br />

the <strong>PMI</strong> countries - especially Regional and Mission Environmental Officers - <strong>for</strong> their cont<strong>in</strong>ued ef<strong>for</strong>ts to ensure<br />

the safe and judicious use of <strong>in</strong>secticides <strong>in</strong> vector control.<br />

6

BMP 1: ENVIRONMENTAL ASSESSMENT<br />

Purpose and Scope<br />

This <strong>Best</strong> <strong>Management</strong> Practice (BMP)<br />

establishes a uni<strong>for</strong>m approach <strong>for</strong> the<br />

environmental assessment of <strong>Indoor</strong> <strong>Residual</strong><br />

<strong>Spray<strong>in</strong>g</strong> activities <strong>in</strong>tended to ensure<br />

compliance with USAID and host country<br />

environmental regulations. It also describes<br />

the content requirements of the Supplemental<br />

Environmental Assessment (SEA).<br />

A Programmatic Environmental Assessment<br />

(PEA) <strong>for</strong> Integrated Vector <strong>Management</strong>,<br />

f<strong>in</strong>alized <strong>in</strong> January 2007, detailed the pathways<br />

of risk associated with IRS through various<br />

media (e.g., <strong>in</strong>halation, oral, etc) and activities<br />

(e.g., mix<strong>in</strong>g pesticides, spray<strong>in</strong>g, etc);<br />

evaluated human health risks associated with<br />

WHOPES-approved IRS pesticides; and<br />

conta<strong>in</strong>ed a section outl<strong>in</strong><strong>in</strong>g Environmental<br />

Assessment that <strong>in</strong>cluded a sample narrative<br />

<strong>for</strong> each section. The PEA outl<strong>in</strong>es a process<br />

by which <strong>in</strong>dividuals could then evaluate and<br />

document site specific impacts of IRS<br />

campaigns via a SEA.<br />

The BMP establishes requirements <strong>for</strong> the<br />

follow<strong>in</strong>g activities:<br />

• Responsibilities <strong>for</strong> Environmental<br />

Assessments<br />

• Contents of Supplementary<br />

Environmental Assessments (SEA)<br />

and Host-country Environmental<br />

Impact Assessments (EIA)<br />

• Determ<strong>in</strong><strong>in</strong>g scope of the project<br />

• Procedures <strong>for</strong> process<strong>in</strong>g<br />

Supplemental Environmental<br />

Assessment<br />

Acronyms & Def<strong>in</strong>itions<br />

BEO Bureau Environmental Officer<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

COTR Contract<strong>in</strong>g Officer’s Technical<br />

Representative<br />

EIA Environmental Impact Assessment<br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

MEO Mission Environmental Officer<br />

MOH M<strong>in</strong>istry of Health<br />

NMCP National Malaria Control Program<br />

OHS Occupational Health and Safety<br />

PEA Programmatic Environmental<br />

Assessment<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

REA Regional Environmental Advisor<br />

SEA Supplemental Environmental<br />

Assessment<br />

WHO World Health Organization<br />

WHOPES World Health Organization Pesticide<br />

Evaluation Scheme<br />

7

SUPPLEMENTARY ENVIRONMENTAL ASSESSMENT<br />

The general purpose of a Supplemental Environmental Assessment is to provide Agency and host country decision<br />

makers with full display of environmental effects to consider dur<strong>in</strong>g the decision mak<strong>in</strong>g process. There<strong>for</strong>e, a SEA<br />

is <strong>in</strong>itiated early, ideally six months prior to spray<strong>in</strong>g.<br />

The collection of basel<strong>in</strong>e data, analysis of impacts and consideration of alternatives should be done <strong>in</strong><br />

collaboration with the host nation to help build <strong>in</strong>stitutional capacity as well as ga<strong>in</strong> a solid understand<strong>in</strong>g of the<br />

local environmental conditions.<br />

Scop<strong>in</strong>g Environmental Impact<br />

Def<strong>in</strong><strong>in</strong>g the Purpose and Need (22 CFR 216.6 (C) (2))<br />

The assessor needs to def<strong>in</strong>e the exist<strong>in</strong>g conditions that are driv<strong>in</strong>g the need <strong>for</strong> vector control such<br />

as the malaria burden <strong>in</strong> country, low pesticide treated material use, and malaria morbidity. The<br />

assessor then describes the <strong>PMI</strong> team goals and objectives. This section becomes the basis <strong>for</strong> how<br />

decisions on alternatives will be made. Those alternatives which meet the goals will be considered.<br />

Def<strong>in</strong><strong>in</strong>g the Proposed Action and Alternatives (22 CFR 216.6 (C) (3))<br />

The assessor uses <strong>in</strong>teractions with the <strong>PMI</strong> team to understand the various alternatives that were<br />

considered when determ<strong>in</strong><strong>in</strong>g the preferred proposed action. These variations may be based on<br />

geography, pesticide choice etc. These various actions should be outl<strong>in</strong>ed <strong>in</strong> this section and their<br />

impacts also should be assessed along with the “no action alternative”. The “no action” alternative is<br />

def<strong>in</strong>ed as if the project were not to be implemented.<br />

Assess<strong>in</strong>g Impact<br />

Def<strong>in</strong><strong>in</strong>g the Affected Environment (22 CFR 216.6 (C) (4))<br />

Succ<strong>in</strong>ctly describe the potentially affected environments. A list of species of concern, such as local<br />

threatened and endangered species and local habitats of concern should be <strong>in</strong>cluded as well as a map of<br />

local special habitats and reserved lands as IRS will not be conducted <strong>in</strong> protected lands (such as parks,<br />

preserves, national <strong>for</strong>ests etc.). This section should <strong>in</strong>clude a brief description of soil types, prom<strong>in</strong>ent<br />

water bodies relevant to the project area, special habitats, fisheries, agricultural zones <strong>in</strong> IRS areas.<br />

Also describe the environmental impacts of the action and alternative actions, <strong>in</strong>clud<strong>in</strong>g the no action<br />

alternative. The level of detail should be commensurate to the potential effects on the environment.<br />

Assess<strong>in</strong>g the Environmental Consequences (22 CFR 216.6 (C) (5))<br />

This section describes the environmental and human health impact of the alternatives <strong>in</strong>clud<strong>in</strong>g the<br />

proposed action and any adverse effects that cannot be avoided, should the proposed action be<br />

implemented (22 CFR 216.6 (c)(5)). This section discusses the direct and <strong>in</strong>direct effects of the action,<br />

the cumulative effects, as well as any irreversible commitment of resources. Direct impacts <strong>in</strong>clude the<br />

impact that may occur to poultry that are not adequately isolated dur<strong>in</strong>g the spray<strong>in</strong>g or to workers<br />

that do not adequately use personal protection equipment dur<strong>in</strong>g spray operations. This section also<br />

describes the mitigation measures and conditions required to m<strong>in</strong>imize, avoid and offset environmental<br />

impacts. Conditions should <strong>in</strong>clude avoidance of spray<strong>in</strong>g with<strong>in</strong> 30 m of a water body or wetland, use<br />

of personal protective equipment by workers, and clear<strong>in</strong>g of houses of personal items prior to<br />

spray<strong>in</strong>g. The PEA has a list of other required conditions.<br />

8 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

Process<strong>in</strong>g the SEA<br />

Preparations of SEA/EIA reports should occur 4-6 months be<strong>for</strong>e the beg<strong>in</strong>n<strong>in</strong>g of spray operations by<br />

coord<strong>in</strong>ation with the <strong>PMI</strong> team host country experts, and a visit to the spray locations/sites. The draft<strong>in</strong>g of the<br />

SEA is the last step <strong>in</strong> the environmental plann<strong>in</strong>g and impact assessment process. It is at this step <strong>in</strong> the process<br />

that the data collection and analysis is completed to determ<strong>in</strong>e the preferred action, alternatives, conditions and<br />

mitigation measures.<br />

The SEA is reviewed by environmental officers (MEO, REA, BEO), the <strong>PMI</strong> advisors, the <strong>PMI</strong> COTR and the<br />

Mission Director. Once the reviewer’s comments are <strong>in</strong>corporated <strong>in</strong>to the document the SEA is briefed to the<br />

mission director <strong>for</strong> his/her signature and then re-submitted to the Global Health and Africa Bureau Environmental<br />

Officers <strong>for</strong> signature.<br />

COUNTRY HOST EIA<br />

Most of the countries receiv<strong>in</strong>g support under the President’s Malaria Initiative have national laws that require<br />

environmental assessments <strong>for</strong> any public or private program with potential environmental and human health<br />

impacts. National regulations may require a separate Environmental Impact Assessment (EIA) that meets specific<br />

guidel<strong>in</strong>es <strong>for</strong> scope and contents, or it may be possible to satisfy national requirements simply by request<strong>in</strong>g that<br />

national officials review and approve the SEA prepared <strong>for</strong> USAID. Governments frequently require that the<br />

applicant pay a fee <strong>for</strong> the EIA or SEA review.<br />

Without fail, IRS activities, <strong>in</strong>clud<strong>in</strong>g procurement of pesticides and equipment cannot be <strong>in</strong>itiated until the SEA has<br />

been approved by USAID and the host country environmental protection agency where applicable.<br />

As a proof of USAID and host government approval of the reports, evidence of approval by way of signatures must<br />

be provided by:<br />

• EIA Approval Certificate from environmental authority<br />

• Provide certificate to Global Health BEO<br />

ENVIRONMENTAL ASSESSMENT 9

RESOURCES AND REFERENCES<br />

USAID<br />

10 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Integrated Vector <strong>Management</strong> Programs <strong>for</strong> Malaria Vector Control:<br />

Programmatic Environmental Assessment USAID (January 2007)<br />

USAID 22 CFR 216 USAID Environmental Procedures

BMP 2: WORKER AND RESIDENT<br />

HEALTH AND SAFETY<br />

Purpose and Scope<br />

This <strong>Best</strong> <strong>Management</strong> Practice (BMP) is<br />

<strong>in</strong>tended to provide acceptable safety standards<br />

and practices <strong>for</strong> the handl<strong>in</strong>g, storage,<br />

transportation and use of pesticides used <strong>in</strong><br />

<strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong> (IRS) of the <strong>PMI</strong><br />

program, to m<strong>in</strong>imize the risk <strong>for</strong> human<br />

exposure. It is drawn largely from guidel<strong>in</strong>es<br />

from the World Health Organization and<br />

(WHO) Food and Agricultural Organization<br />

(FAO).<br />

This BMP was developed <strong>for</strong> all spray personnel,<br />

(supervisors, storekeepers, drivers, washers, and<br />

spray operators) dur<strong>in</strong>g the handl<strong>in</strong>g, storage,<br />

transportation and spray operations, and the<br />

beneficiaries of the IRS program, and covers the<br />

follow<strong>in</strong>g areas:<br />

• Personal Protective Equipment<br />

(PPE)<br />

• Workers’ Safety Dur<strong>in</strong>g and After<br />

<strong>Spray<strong>in</strong>g</strong><br />

• Safety of Women Spray Personnel<br />

• Transportation of Spray Operators to<br />

and from the Field<br />

• Residents’ Safety<br />

• Pesticide Exposure and Treatment<br />

Acronyms & Def<strong>in</strong>itions<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

FAO Food and Agricultural Organization<br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

MOH M<strong>in</strong>istry of Health<br />

NMCP National Malaria Control Program<br />

OHS Occupational Health and Safety<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

WHO World Health Organization<br />

Exposure The condition of be<strong>in</strong>g unprotected<br />

from to the effects of pesticides<br />

Contam<strong>in</strong>ation To render impure by contact or<br />

mixture; pollute<br />

11

PERSONAL PROTECTIVE EQUIPMENT (PPE)<br />

Adapted from: Manual <strong>for</strong> IRS Application of <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong> <strong>for</strong> Vector Control, 5th edition.<br />

In accordance with WHO health and safety regulations, all persons work<strong>in</strong>g on IRS must be adequately protected<br />

aga<strong>in</strong>st potential harm due to exposure from pesticides. All persons with potential direct contact or exposure to<br />

pesticides dur<strong>in</strong>g handl<strong>in</strong>g, transportation, storage, use and clean<strong>in</strong>g of pesticides or pesticide contam<strong>in</strong>ated<br />

materials must wear appropriate personal protective cloth<strong>in</strong>g <strong>in</strong> accordance with the safety <strong>in</strong>structions on the<br />

product label or material safety data sheet (MSDS). The follow<strong>in</strong>g guidel<strong>in</strong>es should be followed:<br />

• Overalls should be made of cotton and of a<br />

weight and thickness appropriate <strong>for</strong> the<br />

climate.<br />

• Have a distribution of sizes <strong>for</strong> coveralls<br />

and boots that are appropriate <strong>for</strong> the<br />

specified work <strong>for</strong>ce (women’s sizes and<br />

men’s sizes). There must be extra gloves,<br />

boots, face shields, and helmets to<br />

mitigate <strong>for</strong> breakage and loss.<br />

• <strong>Spray<strong>in</strong>g</strong> staff must have two uni<strong>for</strong>ms<br />

m<strong>in</strong>imum to allow <strong>for</strong> frequent changes.<br />

• New filter masks must be replaced each<br />

day <strong>for</strong> spray operators. For the 8-hour<br />

filter mask, the masks can be changed<br />

once every two days.<br />

• Replace worn out gloves with new gloves<br />

immediately.<br />

• Gloves should be exam<strong>in</strong>ed carefully<br />

be<strong>for</strong>e use <strong>for</strong> any signs of wear or tear,<br />

particularly <strong>in</strong> the areas between the<br />

f<strong>in</strong>gers. If there is any doubt about their<br />

protectiveness, they should be replaced.<br />

At the end of each day’s use, gloves must<br />

be washed <strong>in</strong>side as well as outside<br />

be<strong>for</strong>e they are used aga<strong>in</strong>.<br />

• Overalls must be changed daily <strong>for</strong> spray<br />

operators us<strong>in</strong>g carbamates, pyrethroids,<br />

or organophosphates; every two days <strong>for</strong><br />

spray operators us<strong>in</strong>g DDT (to m<strong>in</strong>imize<br />

effluent waste).<br />

• Overalls must be changed immediately<br />

when a direct spill occurs onto the<br />

overalls.<br />

• Overalls should not be tucked <strong>in</strong>to boots.<br />

• Washers should wear their long gloves<br />

over sleeves.<br />

• The Supervisor shall ensure that all workers<br />

wear protective cloth<strong>in</strong>g.<br />

12 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Spray Operator wear<strong>in</strong>g full PPE

M<strong>in</strong>imum PPE Required <strong>for</strong> Workers<br />

Role M<strong>in</strong>imal PPE Required<br />

Store Manager & All<br />

Workers handl<strong>in</strong>g<br />

equipment and pesticides<br />

• Boots and overalls at all times<br />

• Gloves and filter mask when handl<strong>in</strong>g<br />

• Goggles when clean<strong>in</strong>g up dry or wet pesticide spills<br />

Washers • Overalls, pesticide apron, boots<br />

Site Managers/<br />

Supervisors<br />

• Filter mask<br />

• Nitrile rubber, neoprene, PVC or butyl rubber gloves long enough to<br />

cover <strong>for</strong>earm and very flexible to use <strong>in</strong> wash<strong>in</strong>gs, without <strong>in</strong>side l<strong>in</strong><strong>in</strong>g<br />

(l<strong>in</strong><strong>in</strong>g can reta<strong>in</strong> pesticide and <strong>in</strong>crease dermal exposure <strong>for</strong> staff rout<strong>in</strong>ely<br />

exposed to pesticide-contam<strong>in</strong>ated water); <strong>for</strong> more com<strong>for</strong>table<br />

protection, disposable polyethylene gloves can be used<br />

• Overalls, boots, gloves, and filter mask (when enter<strong>in</strong>g houses to supervise<br />

spray operations)<br />

Spray Operators • Filter masks (as identified <strong>in</strong> the MSDS <strong>for</strong> the pesticide be<strong>in</strong>g used),<br />

overalls, face shield, nitrile rubber, neoprene, PVC or butyl rubber gloves,<br />

broad-rimmed helmet (protects head, face and neck from spray droplets)<br />

• Face shield or goggles (face shield preferable -protects face and eyes<br />

aga<strong>in</strong>st spray fall-out)<br />

• 2 or 3 cotton long-sleeved overalls per spray operator (keep overalls<br />

outside of boots)<br />

• Rubber boots or heavy canvas boots that are unl<strong>in</strong>ed and can be easily<br />

r<strong>in</strong>sed<br />

• Helmet<br />

• Neck protection<br />

Drivers • Boots, gloves, filter mask (when wash<strong>in</strong>g vehicle after a spill)<br />

WORKER AND RESIDENT HEALTH AND SAFETY 13

Wash<strong>in</strong>g PPEs<br />

The follow<strong>in</strong>g are the steps taken when clean<strong>in</strong>g spray pump and PPEs at the end of the day:<br />

• Contam<strong>in</strong>ated protective cloth<strong>in</strong>g should be thoroughly washed us<strong>in</strong>g <strong>in</strong>dustrial grade detergent<br />

followed by several r<strong>in</strong>s<strong>in</strong>gs.<br />

• Wash overalls daily <strong>for</strong> spray operators us<strong>in</strong>g carbamates, pyrethroids, or organophosphates; every two<br />

days <strong>for</strong> spray operators us<strong>in</strong>g DDT (to m<strong>in</strong>imize effluent waste).<br />

• Protective cloth<strong>in</strong>g should only be washed <strong>in</strong> Wash Areas (see Effluent Waste Disposal BMP). Gloves<br />

should be worn when wash<strong>in</strong>g protective cloth<strong>in</strong>g.<br />

• Washed clothes should be hung to dry <strong>in</strong> the soak pit or evaporation tank wash area.<br />

• Where there is a large patch of fabric that has been contam<strong>in</strong>ated by toxic concentrates and<br />

replacement cloth<strong>in</strong>g is available, it is best to dispose of the cloth<strong>in</strong>g as per the Solid Waste Disposal<br />

BMP.<br />

Washer wear<strong>in</strong>g appropriate protection while wash<strong>in</strong>g PPE<br />

14 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

WORKERS’ SAFETY DURING AND AFTER SPRAYING<br />

Dur<strong>in</strong>g spray operations, scrupulous attention to personal hygiene is essential <strong>for</strong><br />

the safe use of pesticides. For spray staff, safety precautions will depend largely<br />

on personal hygiene, <strong>in</strong>clud<strong>in</strong>g wash<strong>in</strong>g and chang<strong>in</strong>g clothes. The follow<strong>in</strong>g<br />

guidel<strong>in</strong>es should be followed:<br />

• Eat<strong>in</strong>g, dr<strong>in</strong>k<strong>in</strong>g and smok<strong>in</strong>g while apply<strong>in</strong>g pesticides must be strictly<br />

<strong>for</strong>bidden. IRS operations can be physically demand<strong>in</strong>g under harsh<br />

environments and may tempt spray operators to break this rule. It is<br />

strongly advised to feed spray operators a large meal <strong>in</strong> the morn<strong>in</strong>g<br />

be<strong>for</strong>e they conduct spray operations.<br />

• Spray operators should be encouraged to hydrate frequently, and ideally,<br />

dr<strong>in</strong>k<strong>in</strong>g water will be provided. However, spray operations should take<br />

off gloves and wash hands with soap and water be<strong>for</strong>e dr<strong>in</strong>k<strong>in</strong>g any liquids<br />

• Spray operators must wash off immediately with soap and water if the sk<strong>in</strong><br />

is contam<strong>in</strong>ated with pesticide; if pesticide gets <strong>in</strong>to the eyes they should immediately flush<br />

with plenty of water. In case of <strong>in</strong>gestion, see pesticide poison<strong>in</strong>g BMP<br />

• In general, spray operators work only 5-6 hours a day.<br />

• Apply pesticide <strong>in</strong> the cooler hours of the day when it is more com<strong>for</strong>table to wear<br />

protective equipment.<br />

• Water breaks may be required if day extends beyond six hours. Wash<strong>in</strong>g of hand and face<br />

are required prior to dr<strong>in</strong>k<strong>in</strong>g. Wash face and hands after spray<strong>in</strong>g or handl<strong>in</strong>g pesticides<br />

and equipment.<br />

• After spray operation, spray personnel should wash their faces and hands at a m<strong>in</strong>imum. If<br />

showers are available/appropriate, then spray personnel should shower although this is<br />

often not feasible.<br />

SAFETY OF WOMEN SPRAY PERSONNEL<br />

Pregnant women should not<br />

conduct spray<strong>in</strong>g<br />

Staff should not eat <strong>in</strong> the<br />

pesticide storage area<br />

It is <strong>in</strong>advisable <strong>for</strong> pregnant women and nurs<strong>in</strong>g mothers to handle DDT<br />

pesticides. There<strong>for</strong>e, pregnant women and nurs<strong>in</strong>g mothers are<br />

prohibited from handl<strong>in</strong>g DDT pesticides. When recruit<strong>in</strong>g spray<br />

operators, pregnancy tests should be conducted dur<strong>in</strong>g a normal medical<br />

exam to ensure that pregnant women do not jo<strong>in</strong> the spray team as a<br />

spray operator or washer.<br />

• For spray campaigns last<strong>in</strong>g longer than 30 days, the pregnancy<br />

tests should be repeated once every month dur<strong>in</strong>g the campaign.<br />

As the literature regard<strong>in</strong>g DDT’s impact on fetal development is under<br />

review, it is advised, as an extra precaution, that countries us<strong>in</strong>g DDT<br />

exclude women as spray operators and <strong>in</strong>stead use women to mobilize<br />

communities. However, local labor regulations should be considered.<br />

WORKER AND RESIDENT HEALTH AND SAFETY 15

TRANSPORTATION OF SPRAY OPERATORS<br />

TO AND FROM THE FIELD<br />

The quality of the vehicle is an important requirement <strong>in</strong> assur<strong>in</strong>g the safety of the spray operators while en route<br />

to spray sites. Spray personnel are typically transported via pickup truck or m<strong>in</strong>i bus. Spray pumps should be<br />

placed between their legs to m<strong>in</strong>imize the risk of spillage. Ideally <strong>in</strong> the case of pickup truck transport where spray<br />

operators sit <strong>in</strong> the back compartment of the vehicle, it is recommended to retrofit this compartment with side<br />

hand bars on the periphery, and to <strong>in</strong>stall benches l<strong>in</strong><strong>in</strong>g the middle and the sides of the back (see photo below).<br />

While vehicle accident <strong>in</strong>surance is costly, if possible, it would be recommended to obta<strong>in</strong> this. In addition, it is also<br />

required to consult and abide by the health and safety worker regulations of the host country. For example, <strong>in</strong><br />

some countries it is required to offer the spray operators health <strong>in</strong>surance.<br />

Special Cases<br />

Truck retrofitted with side bars and<br />

benches both <strong>for</strong> SO safety and com<strong>for</strong>t<br />

In some countries, road access is very limited and/or poor. In many cases, these roads can only be accessed by<br />

foot or by smaller motorized vehicle such as a moped or even <strong>in</strong> certa<strong>in</strong> cases, donkeys and bicycles. It is advised<br />

that this <strong>for</strong>m of transport be used with caution and special care to avoid pesticide spills. This type of<br />

transportation should be authorized by the host country.<br />

16 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Spray Operator Transportation Vehicle overcrowded to an<br />

uncom<strong>for</strong>table and high-risk po<strong>in</strong>t; note woman spray<br />

operator not wear<strong>in</strong>g gloves while handl<strong>in</strong>g spray can

RESIDENTS’ SAFETY<br />

In<strong>for</strong>mational campaigns and mobilization are critical to ensure the safety of residents.<br />

The follow<strong>in</strong>g safety actions must be<br />

completed be<strong>for</strong>e spray<strong>in</strong>g can commence:<br />

• Clear homes of mats or rugs,<br />

furniture, cook<strong>in</strong>g implements and<br />

all foodstuffs prior to spray<strong>in</strong>g.<br />

• Move all furniture that cannot be<br />

moved from the home to the<br />

center of the room and cover it<br />

with a tarpaul<strong>in</strong>.<br />

• Advise occupants to stay outside<br />

the home dur<strong>in</strong>g spray<strong>in</strong>g and <strong>for</strong><br />

at least two hours after spray<strong>in</strong>g.<br />

• If persons are unable to be<br />

removed from the house, prohibit<br />

spray<strong>in</strong>g.<br />

• Move all animals outside the<br />

home and tether or cage away<br />

from the house dur<strong>in</strong>g spray<strong>in</strong>g,<br />

and <strong>for</strong> two hours after spray<strong>in</strong>g.<br />

Improper preparation of household<br />

be<strong>for</strong>e spray<strong>in</strong>g (all household items<br />

should be removed or covered)<br />

• Advise residents to keep children away from the house dur<strong>in</strong>g spray<strong>in</strong>g.<br />

• Advise residents not to prepare food <strong>in</strong> close proximity to the house dur<strong>in</strong>g spray<strong>in</strong>g.<br />

Upon completion of spray<strong>in</strong>g:<br />

After spray<strong>in</strong>g takes place, residual mosquitoes<br />

and other <strong>in</strong>sects should be swept and<br />

disposed of <strong>in</strong> a latr<strong>in</strong>e pit<br />

Immovable household furniture<br />

covered with a protective tarpaul<strong>in</strong><br />

be<strong>for</strong>e spray<strong>in</strong>g takes place<br />

• Residents must sweep floors free of residual pesticide and<br />

<strong>in</strong>sects killed from the spray<strong>in</strong>g and drop them <strong>in</strong> latr<strong>in</strong>e<br />

pits, or <strong>in</strong> lieu of a latr<strong>in</strong>e pit, dig a hole and bury the swept<br />

material. Do not allow children or animals <strong>in</strong>side until this<br />

has been completed.<br />

• Advise residents not to plaster or pa<strong>in</strong>t walls after walls<br />

have been sprayed.<br />

• If sk<strong>in</strong> itches after re-entrance <strong>in</strong>to the home, wash with<br />

soap and water; <strong>for</strong> eye irritation, flush eyes with water; <strong>for</strong><br />

respiratory irritation, leave the home <strong>for</strong> fresh air; if<br />

<strong>in</strong>gested, contact program staff or go to nearest health<br />

facility.<br />

• When spillage has occurred, restrict access and cover the<br />

spill with earth, sand, etc.; no attempt should be made to<br />

wash away the spill with water or other liquids. (See the<br />

Spill Response BMP).<br />

WORKER AND RESIDENT HEALTH AND SAFETY 17

PESTICIDE EXPOSURE AND TREATMENT<br />

All public health facilities near the spray sites should be stocked with the follow<strong>in</strong>g recommended medications <strong>for</strong><br />

use <strong>in</strong> case of accidental poison<strong>in</strong>g or dermal or eye exposure. The health officers, spray operators, supervisors,<br />

and drivers will also receive tra<strong>in</strong><strong>in</strong>g on treatment <strong>for</strong> emergency cases of critical exposure and poison<strong>in</strong>g be<strong>for</strong>e<br />

the spray<strong>in</strong>g occurs. In case of extreme exposure (such as direct spills on spray operators), remove contam<strong>in</strong>ated<br />

cloth<strong>in</strong>g and wash the affected sk<strong>in</strong> with clean water and soap, and flush the affected area with large quantities of<br />

clean water. Keep the patient calm and <strong>in</strong> quiet, shaded conditions and transfer to nearest health cl<strong>in</strong>ic.<br />

Basic List of Medic<strong>in</strong>es by Class of Pesticide<br />

To be adm<strong>in</strong>istered by a profession at the hospital:<br />

Organochlor<strong>in</strong>e (DDT):<br />

Activated Charcoal (priority)<br />

Diazepam or Lorazepam (<strong>for</strong> seizure)<br />

Phenobarbital<br />

Cholestryam<strong>in</strong>e res<strong>in</strong><br />

Organophosphates: Atrop<strong>in</strong>e sulfate or Glycopyrolate (priority treatment)<br />

Furosemide (less critical)<br />

Diazepam or Lorazepam (<strong>for</strong> seizure)<br />

Carbamates: Cholestryam<strong>in</strong>e Atrop<strong>in</strong>e (priority)<br />

Furosemide (less critical)<br />

Diazepam (<strong>for</strong> seizure)<br />

Pyrethroids: Name of Drug Active Ingredient(s)<br />

Promethaz<strong>in</strong>e Promethaz<strong>in</strong>e Hydrocloride<br />

Panadol Paracetamol<br />

Diazepam Benzodiazap<strong>in</strong>e/Diazapam<br />

Lorazepam Lorazepam<br />

Calam<strong>in</strong>e cream Calam<strong>in</strong>e, z<strong>in</strong>c oxide, glycerol, phenol, purified<br />

water, sodium citrate, betonite,<br />

Vit E Tocopherol, fragrance, m<strong>in</strong>eral oil, deionized<br />

water, sodium hydroxide, stearic acid<br />

Hydrocortisone cream 1% hydrocortisone<br />

Salbutamol Salbutamol 100 mcg, suspended <strong>in</strong>ert aerosol<br />

Salbutamol tablets Salbutamol sulphate 4 mg<br />

Activated Charcoal Activated Charcoal<br />

18 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

First Aid Kits<br />

The follow<strong>in</strong>g are m<strong>in</strong>imum requirements of a first aid kit:<br />

� Bandaids<br />

� Gauze<br />

� Anitbiotic Cream<br />

� Eye wash<br />

� Hydrocortisone Cream/Calam<strong>in</strong>e<br />

� Aspir<strong>in</strong><br />

Keep first aid kits at all storage facilities and <strong>in</strong> transport vehicles.<br />

Health Worker Tra<strong>in</strong><strong>in</strong>g<br />

Health workers should be tra<strong>in</strong>ed <strong>in</strong> recogniz<strong>in</strong>g and treat<strong>in</strong>g pesticide exposure symptoms. In some countries this<br />

is done dur<strong>in</strong>g the course of medical tra<strong>in</strong><strong>in</strong>g, <strong>in</strong> other countries, additional tra<strong>in</strong><strong>in</strong>g will be needed. Health<br />

<strong>in</strong>stitutions with<strong>in</strong> the country can provide this tra<strong>in</strong><strong>in</strong>g, or USAID can support such tra<strong>in</strong><strong>in</strong>g. All tra<strong>in</strong><strong>in</strong>g should be<br />

consistent with the exposure treatment guidel<strong>in</strong>es that are available through the M<strong>in</strong>istry of Health. If such<br />

guidel<strong>in</strong>es are not available or need supplementary material, exposure treatment guidel<strong>in</strong>es are <strong>in</strong>cluded <strong>in</strong> Annex I<br />

of USAID’s Integrated Vector <strong>Management</strong> <strong>for</strong> Malaria Vector Control: Programmatic Environmental Assessment (PEA).<br />

WORKER AND RESIDENT HEALTH AND SAFETY 19

RESOURCES AND REFERENCES<br />

RTI <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong> (IRS) <strong>for</strong> Malaria Control Indef<strong>in</strong>ite Quantity Contract (IQC)<br />

Task Order 1: IRS Tra<strong>in</strong><strong>in</strong>g Guide <strong>for</strong> Spray Operations – draft, RTI International.<br />

WHO Application of <strong>Residual</strong> Sprays <strong>for</strong> Vector Control, WHO Communicable Disease<br />

Control, Prevention and Eradication WHO Pesticide Evaluation Scheme, 2002<br />

USAID Integrated Vector <strong>Management</strong> Programs <strong>for</strong> Malaria Vector Control: Programmatic<br />

Environmental Assessment. USAID: January 2007<br />

FAO Guidel<strong>in</strong>es <strong>for</strong> Personal Protection When Work<strong>in</strong>g with Pesticides <strong>in</strong> Tropical<br />

Climates: March 1990<br />

Illustrations RTI, based on WHO , Manual <strong>for</strong> <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong>: Application of <strong>Residual</strong><br />

Sprays <strong>for</strong> Vector Control, 2003<br />

20 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

BMP 3: PESTICIDE STORAGE, STOCK<br />

CONTROL AND INVENTORY<br />

Purpose and Scope<br />

This <strong>Best</strong> <strong>Management</strong> Practice (BMP) provides<br />

guidance on the management of pesticide stocks<br />

from the po<strong>in</strong>t that they have been received <strong>in</strong><br />

country through the various storage options<br />

and eventually to the spray operators and their<br />

subsequent return as empty sachets. Close<br />

scrut<strong>in</strong>y is paid to storage and commodity<br />

cha<strong>in</strong>-of-custody as avoid<strong>in</strong>g the <strong>in</strong>advertent loss<br />

or leakage of pesticide stocks. It is critical to<br />

ensure that these pesticides will be used safely,<br />

thereby avoid<strong>in</strong>g adverse impacts on human<br />

health or environmental contam<strong>in</strong>ation. In<br />

addition, careful management of storage<br />

facilities, stock control and <strong>in</strong>ventory will<br />

m<strong>in</strong>imize the risk of leakage <strong>in</strong>to other sectors<br />

(e.g. agricultural sector) or the market. Extra<br />

care must be taken s<strong>in</strong>ce the pesticides are <strong>in</strong><br />

their concentrated <strong>for</strong>m.<br />

This BMP, drawn heavily from the FAO Storage<br />

and Stock Control Manual, is <strong>in</strong>tended to<br />

provide acceptable safety standards and<br />

practices <strong>for</strong> the follow<strong>in</strong>g:<br />

• Storage Facilities<br />

• Stock <strong>Management</strong><br />

Acronyms<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

FAO Food and Agriculture Organization<br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

MOH M<strong>in</strong>istry of Health<br />

MSDS Material Safety Data Sheet<br />

NMCP National Malaria Control Program<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

WHO World Health Organization<br />

21

STORAGE FACILITIES<br />

Suggested conditions <strong>for</strong> storage facilities differ by duration and quantity of stored pesticides. It is common <strong>for</strong> a<br />

given country to have multiple levels of storage facilities, <strong>in</strong>clud<strong>in</strong>g: annual, large-volume national/central facilities<br />

where pesticide are first delivered and then re-stored at end-of-campaign; regional facilities where pesticide are<br />

stored <strong>for</strong> up to four months; and district or operational base facilities where pesticides are received and<br />

distributed on a weekly or daily basis.<br />

Sit<strong>in</strong>g<br />

• Away from schools, animal feed depots, water courses<br />

and residential homes (generally 100 meters away)<br />

• M<strong>in</strong>imum of 50 meters away from health cl<strong>in</strong>ics, and<br />

generally away from pedestrian routes to the cl<strong>in</strong>ic<br />

• Out of potential flood zones, water zones, wells and<br />

other supplies of water <strong>for</strong> domestic or stock animal<br />

use<br />

• Away from areas where ground water is close to the<br />

surface<br />

• Easily accessible by transport and easy exit <strong>in</strong> case of<br />

an emergency<br />

Design and Structure of Build<strong>in</strong>g<br />

• Ventilated so that pesticide vapors as well as<br />

temperatures don’t reach dangerously high daytime<br />

temperatures (w<strong>in</strong>dow access usually provide proper<br />

ventilation)<br />

• Floors should be impermeable (e.g. concrete surface)<br />

to m<strong>in</strong>imize absorption <strong>in</strong> case of spills and facilitate<br />

clean up<br />

• Large enough to allow <strong>for</strong> proper accommodation of<br />

pesticides as well as stor<strong>in</strong>g empty conta<strong>in</strong>ers and<br />

pesticide waste<br />

Note: Due to access limitations and distances of some spray sites, small-scale storage facilities are often<br />

necessary. It is not always feasible to locate facilities away from hospital/cl<strong>in</strong>ic/markets. It is there<strong>for</strong>e<br />

important to be extra vigilant that access to unauthorized personnel is denied.<br />

22 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Pesticide storages should be kept away from sources of<br />

water and from flood zones.

Pesticide Shelv<strong>in</strong>g<br />

• Pesticides should always be shelved on wooden pallets and not directly on the floor to prevent them from<br />

gett<strong>in</strong>g wet.<br />

• Pesticide stack<strong>in</strong>g should not be unreasonably high, which poses two risks: 1)<br />

risks of tipp<strong>in</strong>g, and 2) risk of per<strong>for</strong>ation of boxes. A general rule is to not<br />

exceed a height of 2 m.<br />

• Do not store liquid materials above dry materials. This prevents any liquid<br />

leaks from com<strong>in</strong>gl<strong>in</strong>g with dry product.<br />

The follow<strong>in</strong>g four guidel<strong>in</strong>es apply to any pesticide storage facilities,<br />

regardless of size<br />

1. Storage facilities are expected to have double locks, and be guarded at all times<br />

2. Roofs should be well ma<strong>in</strong>ta<strong>in</strong>ed (e.g. no leakage)<br />

3. Post storage signage and warn<strong>in</strong>g notices<br />

� A notice should be prom<strong>in</strong>ently displayed on the outside of the store <strong>in</strong><br />

the local language(s) with a skull and crossbones sign say<strong>in</strong>g “Danger,<br />

Keep Out, Pesticide Storage” to convey that entry is prohibited to<br />

unauthorized persons.<br />

4. Pesticide Stack<strong>in</strong>g<br />

� Conta<strong>in</strong>ers should be arranged to m<strong>in</strong>imize handl<strong>in</strong>g and thus avoid<br />

mechanical damage giv<strong>in</strong>g rise to leaks.<br />

� Floor spaces should be uncluttered to permit easy <strong>in</strong>spection and allow<br />

free airflow. This also enables immediate clean up <strong>in</strong> the event of any<br />

leakage or spills.<br />

Pesticide boxes <strong>in</strong> this storage<br />

facility are stacked too high<br />

Boxes have been crushed, and<br />

pesticide is leak<strong>in</strong>g from them<br />

Example of a Danger Sign<br />

Danger sign <strong>in</strong> Amharic<br />

(Ethiopia)<br />

Floor <strong>in</strong> this storage facility is wet. This<br />

could <strong>in</strong>dicate a problem. Boxes<br />

should be stacked on pallets to<br />

protect the pesticide from contact<br />

with moisture.<br />

PESTICIDE STORAGE, STOCK CONTROL, AND INVENTORY 23

Essential Equipment with<strong>in</strong> a Pesticide Store<br />

Thick polyethylene sheet<strong>in</strong>g on floor (if surface is not concrete or otherwise impermeable)<br />

Wooden pallets<br />

Ramps at entrance to conta<strong>in</strong> leakage<br />

Entrance door with lock to prevent unauthorized entry<br />

Secured w<strong>in</strong>dows and ventilators to prevent unauthorized entry<br />

Spill response kit:<br />

� conta<strong>in</strong>er of absorbent sand, sawdust or dry soil<br />

� shovel<br />

� long-handled brush with stiff bristles, and<br />

� short-handled brush and pan<br />

� water supply, or conta<strong>in</strong>er of water, with soap<br />

� detergent solution<br />

Fire-fight<strong>in</strong>g equipment: fire ext<strong>in</strong>guisher and fireproof blanket<br />

Extra PPE (see Worker and Resident Health and Safety BMP)<br />

Empty pesticide conta<strong>in</strong>ers (preferably salvage drums that can conta<strong>in</strong> a whole 200-litre drum)<br />

Empty bags to repack heavily damaged or leak<strong>in</strong>g conta<strong>in</strong>ers<br />

Self-adhesive warn<strong>in</strong>g labels <strong>for</strong> mark<strong>in</strong>g conta<strong>in</strong>ers<br />

First aid kit<br />

Stock record sheets<br />

24 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

STOCK MANAGEMENT<br />

Storage facilities should have a proper system of stock plann<strong>in</strong>g and should ma<strong>in</strong>ta<strong>in</strong> a daily account<strong>in</strong>g of records<br />

of stocks received, held and issued. No more pesticide should be ordered than is required or than can be stored <strong>in</strong><br />

an appropriate way.<br />

The most effective safeguard is a direct and clear understand<strong>in</strong>g on the part of all staff <strong>in</strong>volved, <strong>in</strong>clud<strong>in</strong>g the spray<br />

operators, of their responsibilities <strong>for</strong> account<strong>in</strong>g <strong>for</strong> the pesticides entrusted to their care and the consequences<br />

<strong>for</strong> not do<strong>in</strong>g so. In addition, the follow<strong>in</strong>g best practices facilitate the control and accountability <strong>for</strong> pesticide<br />

stocks, <strong>in</strong>clud<strong>in</strong>g:<br />

• Careful plann<strong>in</strong>g of pesticides requirements is essential to avoid the accumulation of stocks.<br />

• Stock control beg<strong>in</strong>s with ensur<strong>in</strong>g that the correct pesticide has been procured and delivered and<br />

there<strong>for</strong>e all products should be appropriately and correctly labeled.<br />

• Material Safety Data Sheets (MSDS) should be readily available <strong>for</strong> dispatch with pesticides stocks leav<strong>in</strong>g the<br />

central storage facilities. Pesticide stock should be verified at each po<strong>in</strong>t of delivery. At all storage facilities<br />

the manager/storekeeper should be present when pesticide deliveries are be<strong>in</strong>g made and log receipt of<br />

boxes. Boxes are then randomly sampled <strong>for</strong> both quality and quantity controls. If, dur<strong>in</strong>g the visual<br />

<strong>in</strong>spection, they are damaged, the supplier should be notified and the pesticide should not be accepted.<br />

• Incom<strong>in</strong>g stock should be carefully recorded on <strong>in</strong>ventory stock cards. The follow<strong>in</strong>g is an example of a<br />

stock card:<br />

Estimated 25,000 sachets received on dd/mm/yyyy <strong>in</strong> central store<br />

o X sachets (from box #-box #) to district A on dd/mm/yyyy<br />

o X sachets (from box #-box #) to district B dd/mm/yyyy<br />

• Boxes should be numbered to track the distribution. In the event of <strong>in</strong>ventory loss, misplacement, or quality<br />

concerns, the boxes can be tracked back.<br />

• Pesticide stocks should be distributed on a “first-<strong>in</strong>/first-out” basis to avoid the risk of stocks becom<strong>in</strong>g<br />

obsolete (past their useable life dates).<br />

• Stock delivery records require dual signatures, of those dispatch<strong>in</strong>g or deliver<strong>in</strong>g the pesticide stocks and of<br />

those receiv<strong>in</strong>g them so that there is no confusion about the amounts utilized with<strong>in</strong> the program.<br />

• At the secondary level, a storekeeper must record and sign quantity of pesticide received and distributed. In<br />

order to m<strong>in</strong>imize theft, a double lock system should be utilized such that both the storekeeper and guard<br />

are needed to open the warehouse, and each will keep one key only.<br />

PESTICIDE STORAGE, STOCK CONTROL, AND INVENTORY 25

• For daily transactions, the team leader<br />

requests and signs <strong>for</strong> sachets from the<br />

store keeper. Normally, 6-7 sachets are<br />

distributed daily to each spray operator.<br />

The team leader there<strong>for</strong>e requests 24-42<br />

sachets of pesticide each day <strong>for</strong> his/her<br />

team of 4 to 6 spray operators. The store<br />

manager should track the name of the<br />

team leader and number of sachets with a<br />

pen. The team leader does the same,<br />

writes down the number of sachets given<br />

to each spray operators. Mark<strong>in</strong>g each of<br />

the sachets makes it easy to identify which<br />

team and eventually what spray operator<br />

had custody of any given sachet. Both the<br />

spray operators and the team leaders have<br />

their separate sachet <strong>in</strong>ventory cards.<br />

• It is highly recommended that a dedicated<br />

logistician periodically visit and verify the<br />

<strong>in</strong>ventory stock and storage at the storage<br />

facilities. He/She may also spot check the<br />

spray operators’ record sheets to ensure<br />

that their daily stock <strong>for</strong>ms are <strong>in</strong> order<br />

and be<strong>in</strong>g properly used, thus reiterat<strong>in</strong>g<br />

the pr<strong>in</strong>ciples of supervision and<br />

accountability.<br />

• Rout<strong>in</strong>e stock verification (physical<br />

count<strong>in</strong>g of exist<strong>in</strong>g stock <strong>in</strong> the store) is<br />

required at each operational site at least<br />

once every <strong>for</strong>tnight. This is done by the<br />

storekeeper.<br />

26 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Example of standardized stock card used by the <strong>PMI</strong> program

RESOURCES AND REFERENCES<br />

Crop Life International Guidel<strong>in</strong>es <strong>for</strong> the safe and effective use of crop protection products.<br />

Crop Life International, Brussels, May 2006, pp.- 62.<br />

USAID Environmental Guidel<strong>in</strong>es <strong>for</strong> Small-Scale Activities <strong>in</strong> Africa: Chapter 13-<br />

Pest <strong>Management</strong> II: Safer Pesticide Use. USAID/Africa Bureau,<br />

Wash<strong>in</strong>gton, March 2009, pp.- 13-1 to 13-61.<br />

UN FAO Pesticide and Stock Control Manual:<br />

www.fao.org/docrep/V8966E/V8966e00.HTM<br />

US EPA www.epa.gov/pesticides/regulat<strong>in</strong>g/storage.htm<br />

Illustrations Pesticide and Stock Control Manual:<br />

www.fao.org/docrep/V8966E/V8966e00.HTM<br />

PESTICIDE STORAGE, STOCK CONTROL, AND INVENTORY 27

28 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

BMP 4: PESTICIDE TRANSPORT<br />

Purpose and Scope<br />

This <strong>Best</strong> <strong>Management</strong> Practice (BMP) is <strong>in</strong>tended<br />

to cover transport activities <strong>in</strong>volv<strong>in</strong>g large<br />

quantities of pesticides (associated with spray<br />

activities) carried <strong>in</strong> motorized vehicles, typically<br />

trucks or pickup trucks. Frequently, because of<br />

the nature of the program, these pesticides are<br />

be<strong>in</strong>g transported to remote rural areas, over<br />

poor roads, and where supervision and assistance<br />

becomes more difficult <strong>in</strong> the event of an<br />

accident. These characteristics add to the hazards<br />

and the potential <strong>for</strong> adverse impacts and<br />

there<strong>for</strong>e underscore the need <strong>for</strong> extra care<br />

with the transport of the pesticides associated<br />

with IRS programs.<br />

The BMP is targeted at the prevention of<br />

accidents and also deals with the necessary<br />

responses should an accident occur and covers<br />

the follow<strong>in</strong>g areas:<br />

� Pesticide Load<strong>in</strong>g and Conta<strong>in</strong>ment<br />

� Pesticide Transportation Route Plann<strong>in</strong>g<br />

� Selection of Vehicles to be Used <strong>for</strong><br />

Transport<strong>in</strong>g Pesticides<br />

� Pesticide Driv<strong>in</strong>g Tra<strong>in</strong><strong>in</strong>g<br />

� Respond<strong>in</strong>g to an Accident<br />

� Vehicle Decontam<strong>in</strong>ation<br />

Acronyms & Def<strong>in</strong>itions<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

FAO Food and Agriculture Organization<br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

MOH M<strong>in</strong>istry of Health<br />

NMCP National Malaria Control Program<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

WHO World Health Organization<br />

29

TRANSPORT<br />

In this case, transport refers to motorized vehicles such as 10 ton trucks and pickup trucks. This BMP refers to the<br />

transport of pesticides or pesticides shipped <strong>in</strong> bulk with<strong>in</strong> the host country, from the port of entry, to the central<br />

storage facility, to the secondary district and operational site facilities. It does not address the transport of<br />

program personnel or spray operators (please see Worker and Resident Health and Safety BMP).<br />

The pr<strong>in</strong>cipal risk dur<strong>in</strong>g the transport of pesticides is that the packag<strong>in</strong>g might be damaged, as the result of be<strong>in</strong>g<br />

improperly stowed with<strong>in</strong> the vehicle and/or as the result of a road accident. Such an occurrence could lead to<br />

pesticide over-exposure of the driver, transport helper bystanders, or leakage <strong>in</strong>to the environment.<br />

AVOID ACCIDENT RELEASE<br />

The follow<strong>in</strong>g are measures to abide by to avoid accidental release dur<strong>in</strong>g transport.<br />

Pesticide Load<strong>in</strong>g and Conta<strong>in</strong>ment<br />

� Ideally, only IRS materials should be <strong>in</strong> the truck dur<strong>in</strong>g transportation. Open or leak<strong>in</strong>g conta<strong>in</strong>ers should<br />

never be transported. If co-transport is necessary, IRS materials should be compartmentalized.<br />

� Pesticide conta<strong>in</strong>ers should be loaded <strong>in</strong> such a way that they will not be damaged dur<strong>in</strong>g transport, that<br />

their labels will not be rubbed off and that they will not shift and fall off the truck on rough road surfaces<br />

(the load must be securely fixed).<br />

� The pesticide load should be checked at <strong>in</strong>tervals dur<strong>in</strong>g transportation and any leakage, spills or other<br />

contam<strong>in</strong>ation should be cleaned up immediately. If a leakage is noticed <strong>in</strong> transit, the vehicle should be<br />

brought to a halt immediately, the leak<br />

stopped and conta<strong>in</strong>ed, and the spill cleaned<br />

up.<br />

� The truck, <strong>in</strong>clud<strong>in</strong>g tarpaul<strong>in</strong>s and other<br />

goods, should be checked <strong>for</strong> evidence of<br />

spills or leaks after the pesticides have been<br />

unloaded, and then decontam<strong>in</strong>ated.<br />

� Newly arrived consignments should be<br />

checked <strong>for</strong> leaks and loose lids, and repacked<br />

immediately if necessary. Replace torn or<br />

unreadable labels.<br />

30 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Pesticide conta<strong>in</strong>ers should be loaded and unloaded carefully

Pesticide Transportation Route Plann<strong>in</strong>g<br />

� Plann<strong>in</strong>g is a key part of what must happen to avoid accidents and <strong>in</strong>cludes the follow<strong>in</strong>g:<br />

� plann<strong>in</strong>g <strong>for</strong> safe routes, with secure stopovers if necessary<br />

� verify<strong>in</strong>g that the driver has been tra<strong>in</strong>ed and fully briefed<br />

� provid<strong>in</strong>g the driver with a detailed <strong>in</strong>ventory of stock or bill of lad<strong>in</strong>g and material safety data<br />

sheet (MSDS)<br />

� Any risk that could be present dur<strong>in</strong>g the course of the route of transport should be considered when<br />

plann<strong>in</strong>g the transport route to its f<strong>in</strong>al dest<strong>in</strong>ation. These risks could <strong>in</strong>clude but are not limited to: poor<br />

quality of the road, driv<strong>in</strong>g at night, and/or pilferage/security threats. In certa<strong>in</strong> countries where security<br />

risks are high, it would be advisable to hire a security escort.<br />

� The project or organization do<strong>in</strong>g the transport should have a system of registration and a series of<br />

checklists <strong>for</strong> dispatchers, warehouse managers load<strong>in</strong>g or receiv<strong>in</strong>g cargos and drivers that have been<br />

prepared <strong>for</strong> the specific cargo and conditions.<br />

Selection of Vehicles to be used <strong>for</strong> Transport<strong>in</strong>g Pesticides<br />

� Vehicles should be <strong>in</strong> good condition (have a certification of road-worth<strong>in</strong>ess) and capable of the trip<br />

be<strong>in</strong>g planned. They should also be fully securable.<br />

� Vehicles should be equipped with a fire ext<strong>in</strong>guisher and first aid kit.<br />

Drivers Tra<strong>in</strong><strong>in</strong>g<br />

Prior to long-distance transport of pesticides from the customs warehouse/central storage facility to the secondary<br />

storage facility, drivers should be <strong>in</strong><strong>for</strong>med about pesticides and how to handle emergency situations (e.g. road<br />

accidents). Tra<strong>in</strong><strong>in</strong>g <strong>for</strong> long-distance transport should <strong>in</strong>clude:<br />

� Understand<strong>in</strong>g the toxicity of the pesticide and security issues and implications of the pesticide gett<strong>in</strong>g<br />

<strong>in</strong>to the public’s hands (such as contam<strong>in</strong>ation of environment and health hazards)<br />

� Handl<strong>in</strong>g an accident or emergency<br />

� The combustibility and combustion byproducts of pesticide<br />

� Handl<strong>in</strong>g vehicle contam<strong>in</strong>ation<br />

Vehicles and drivers should be carefully selected and suitably qualified and licensed <strong>for</strong> this k<strong>in</strong>d of transport tasks.<br />

Ensure that drivers are literate.<br />

PESTICIDE TRANSPORT 31

Appropriate Response<br />

Respond<strong>in</strong>g to an Accident<br />

Should an accident occur, the driver and helper should have been adequately tra<strong>in</strong>ed <strong>in</strong> the proper response under<br />

the circumstances, <strong>in</strong>clud<strong>in</strong>g:<br />

� Protective cloth<strong>in</strong>g should be donned prior to attempt<strong>in</strong>g to clean the spills.<br />

� It is imperative to avoid fire as a result of the accident and a fire ext<strong>in</strong>guisher should be deployed just <strong>in</strong><br />

case. The eng<strong>in</strong>e should be shut off and smok<strong>in</strong>g <strong>in</strong> the area strictly prohibited.<br />

� Onlookers and bystanders should be<br />

cautioned aga<strong>in</strong>st approach<strong>in</strong>g the<br />

accident site.<br />

� If the crew has come <strong>in</strong> contact with the<br />

pesticides, they should remove<br />

contam<strong>in</strong>ated cloth<strong>in</strong>g immediately and<br />

wash the pesticide off their sk<strong>in</strong>.<br />

� For major spills send <strong>for</strong> help<br />

immediately; drivers should have cell<br />

phones and an emergency number <strong>for</strong> use<br />

<strong>in</strong> such cases.<br />

� People should be kept away and the spill<br />

covered with earth, sand, etc.; no attempt<br />

should be made to wash away the spill<br />

with water or other substances.<br />

In case of accident refer to the Spill Response BMP.<br />

Pesticide transport vehicle <strong>in</strong> an accident, with spilled pesticide<br />

32 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING<br />

Bystanders should be at a safe distance away from the vehicular<br />

accident and spill

Vehicle Decontam<strong>in</strong>ation<br />

It is important to ensure that pesticide contam<strong>in</strong>ation <strong>in</strong> the vehicle does not have negative impacts when the<br />

vehicle is subsequently used <strong>for</strong> another purpose (e.g. food transport). Drivers are responsible <strong>for</strong> clean<strong>in</strong>g and<br />

decontam<strong>in</strong>at<strong>in</strong>g the <strong>in</strong>terior of the vehicle and exterior bed. The vehicle should be cleaned at the end of the spray<br />

day if the vehicle will then be used <strong>for</strong> other purposes. If it is used solely <strong>for</strong> transport<strong>in</strong>g pesticide <strong>for</strong> the duration<br />

of the spray season, clean<strong>in</strong>g once activities have concluded is sufficient. Drivers should be provided with gloves to<br />

wear <strong>for</strong> clean<strong>in</strong>g the vehicle. All cloths used <strong>in</strong> wip<strong>in</strong>g down the <strong>in</strong>terior and bed of the vehicle should be washed<br />

with spray operator overalls.<br />

PESTICIDE TRANSPORT 33

RESOURCES AND REFERENCES<br />

FAO FAO Storage and Stock Control Manual, 1996<br />

www.fao.org/ag/AGP/AGPP/Pesticid/.../103809_en_No_3___Storage.pdf<br />

Illustrations FAO Storage and Stock Control Manual, 1996<br />

www.fao.org/ag/AGP/AGPP/Pesticid/.../103809_en_No_3___Storage.pdf<br />

34 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

BMP 5: SPRAYING TECHNIQUES<br />

Purpose and Scope Acronyms & Def<strong>in</strong>itions<br />

This <strong>Best</strong> <strong>Management</strong> Practice (BMP) covers the spray<strong>in</strong>g<br />

techniques used <strong>for</strong> IRS. The effectiveness of residual<br />

spray<strong>in</strong>g depends on the tim<strong>in</strong>g of the spray<strong>in</strong>g relative to<br />

the peak of transmission, tak<strong>in</strong>g <strong>in</strong>to consideration the<br />

residual effect of the pesticide that is applied. Some<br />

pesticides stay effective longer than others and can<br />

determ<strong>in</strong>e how many times a year IRS should be<br />

conducted.<br />

Pesticides are applied to a household’s surface. Once<br />

sprayed on the wall the water evaporates leav<strong>in</strong>g a<br />

crystall<strong>in</strong>e “particle”. Upon contact with the sprayed<br />

surfaces (walls, eaves and roofs) the mosquitoes absorb a<br />

lethal dose of the pesticide.<br />

The effectiveness of <strong>in</strong>door residual spray<strong>in</strong>g depends on a<br />

host of factors, <strong>in</strong>clud<strong>in</strong>g:<br />

• The rest<strong>in</strong>g behavior of the particular mosquito<br />

• The toxicity and period of effectiveness of the<br />

pesticide aga<strong>in</strong>st the mosquito<br />

• The effect of the pesticide on the rest<strong>in</strong>g behavior<br />

of the mosquito<br />

• The type of structure and type of build<strong>in</strong>g material<br />

(mud, thatch, cement, t<strong>in</strong>, bamboo, etc.)<br />

This BMP is <strong>in</strong>tended to provide appropriate safety<br />

standards and practices <strong>for</strong> spray<strong>in</strong>g activities and covers<br />

best practices <strong>for</strong> the follow<strong>in</strong>g:<br />

• Appropriate equipment<br />

• Prepar<strong>in</strong>g pesticide mixture<br />

• <strong>Spray<strong>in</strong>g</strong> techniques<br />

• Clean<strong>in</strong>g spray pump and nozzles<br />

BMP <strong>Best</strong> <strong>Management</strong> <strong>Practices</strong><br />

IRS <strong>Indoor</strong> <strong>Residual</strong> <strong>Spray<strong>in</strong>g</strong><br />

MOH M<strong>in</strong>istry of Health<br />

NMCP National Malaria Control Program<br />

<strong>PMI</strong> President’s Malaria Initiative<br />

PPE Personal Protective Equipment<br />

WHO World Health Organization<br />

35

APPROPRIATE EQUIPMENT<br />

Spray Pumps (also referred to as sprayers)<br />

High quality, reliable spray pumps are essential <strong>for</strong> an effective spray<strong>in</strong>g program. <strong>Indoor</strong> residual spray<strong>in</strong>g of<br />

pesticides is normally done us<strong>in</strong>g hand-operated compression sprayers.<br />

Be<strong>for</strong>e start<strong>in</strong>g a spray operation, the equipment should be checked as faulty spray pumps may result <strong>in</strong> under or<br />

over application and/or leaks. Supervisors, team leaders, or dedicated ma<strong>in</strong>tenance technician should exam<strong>in</strong>e<br />

spray pumps visually to ensure that all parts are present, assembled correctly and <strong>in</strong> good condition.<br />

The Hudson X-Pert compression sprayers are commonly used <strong>in</strong> disease vector control programs.<br />

Sprayer<br />

36 BEST MANAGEMENT PRACTICES FOR INDOOR RESIDUAL SPRAYING

Nozzles<br />

Standardized nozzles should be used throughout the IRS program, although different types are necessary <strong>for</strong><br />

different pesticides and surfaces (absorbent and non-absorbent). Currently, there are two nozzles, both are fan<br />

type (TEEJET) and differ only <strong>in</strong> their throughput per m<strong>in</strong>ute at 40 psi (276 kPa). Specifications are as follows:<br />

HSS 8002 / 8001 or HSS 8002E / 8001E nozzle tips<br />

HSS = Hardened Sta<strong>in</strong>less Steel<br />

80 = 800 (angle of spray<strong>in</strong>g fan)<br />

02 = 0,2 US. gallons (757 ml) per m<strong>in</strong>ute, or<br />

01 = 0,1 US. gallons (378 ml) per m<strong>in</strong>ute<br />

E = Even (consistent uni<strong>for</strong>m coverage requir<strong>in</strong>g no overlapp<strong>in</strong>g of spray).<br />

The 8002 nozzle should typically be used <strong>for</strong>:<br />

• application of DDT<br />

• application of synthetic pyrethroids/carbamates on absorbent surfaces (e.g., mud<br />

and unpa<strong>in</strong>ted cement)<br />

The 8001 nozzle should typically be used <strong>for</strong>:<br />