Manufacturing Machinery World April 2021

Machinery World was launched in 1982 to serve the machinery & production engineering market. Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and as hard copy.

Machinery World was launched in 1982 to serve the machinery & production engineering market.

Editorially Machinery World is a news and information source that gives direct contact with the provider of innovative services and equipment. Editorial is available both online and as hard copy.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

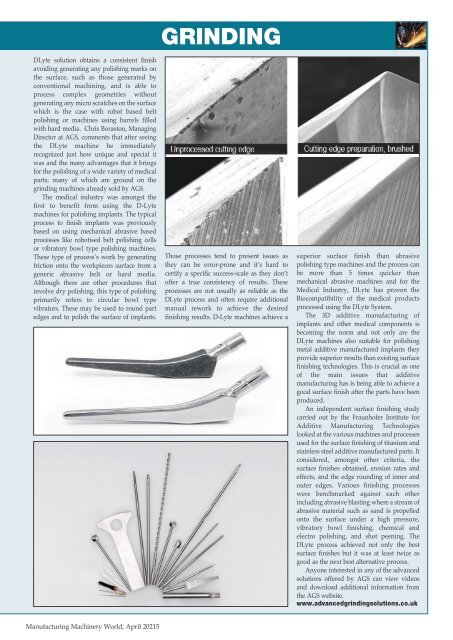

DLyte solution obtains a consistent finish<br />

avoiding generating any polishing marks on<br />

the surface, such as those generated by<br />

conventional machining, and is able to<br />

process complex geometries without<br />

generating any micro scratches on the surface<br />

which is the case with robot based belt<br />

polishing or machines using barrels filled<br />

with hard media. Chris Boraston, Managing<br />

Director at AGS, comments that after seeing<br />

the DLyte machine he immediately<br />

recognized just how unique and special it<br />

was and the many advantages that it brings<br />

for the polishing of a wide variety of medical<br />

parts; many of which are ground on the<br />

grinding machines already sold by AGS.<br />

The medical industry was amongst the<br />

first to benefit from using the D-Lyte<br />

machines for polishing implants. The typical<br />

process to finish implants was previously<br />

based on using mechanical abrasive based<br />

processes like robotised belt polishing cells<br />

or vibratory bowl type polishing machines.<br />

These type of process’s work by generating<br />

friction onto the workpieces surface from a<br />

generic abrasive belt or hard media.<br />

Although there are other procedures that<br />

involve dry polishing, this type of polishing<br />

primarily refers to circular bowl type<br />

vibrators. These may be used to round part<br />

edges and to polish the surface of implants.<br />

GRINDING<br />

Those processes tend to present issues as<br />

they can be error-prone and it’s hard to<br />

certify a specific success-scale as they don’t<br />

offer a true consistency of results. These<br />

processes are not usually as reliable as the<br />

DLyte process and often require additional<br />

manual rework to achieve the desired<br />

finishing results. D-Lyte machines achieve a<br />

superior surface finish than abrasive<br />

polishing type machines and the process can<br />

be more than 5 times quicker than<br />

mechanical abrasive machines and for the<br />

Medical Industry, DLyte has proven the<br />

Biocompatibility of the medical products<br />

processed using the DLyte System.<br />

The 3D additive manufacturing of<br />

implants and other medical components is<br />

becoming the norm and not only are the<br />

DLyte machines also suitable for polishing<br />

metal additive manufactured implants they<br />

provide superior results than existing surface<br />

finishing technologies. This is crucial as one<br />

of the main issues that additive<br />

manufacturing has is being able to achieve a<br />

good surface finish after the parts have been<br />

produced.<br />

An independent surface finishing study<br />

carried out by the Fraunhofer Institute for<br />

Additive <strong>Manufacturing</strong> Technologies<br />

looked at the various machines and processes<br />

used for the surface finishing of titanium and<br />

stainless steel additive manufactured parts. It<br />

considered, amongst other criteria, the<br />

surface finishes obtained, erosion rates and<br />

effects, and the edge rounding of inner and<br />

outer edges. Various finishing processes<br />

were benchmarked against each other<br />

including abrasive blasting where a stream of<br />

abrasive material such as sand is propelled<br />

onto the surface under a high pressure,<br />

vibratory bowl finishing, chemical and<br />

electro polishing, and shot peening. The<br />

DLyte process achieved not only the best<br />

surface finishes but it was at least twice as<br />

good as the next best alternative process.<br />

Anyone interested in any of the advanced<br />

solutions offered by AGS can view videos<br />

and download additional information from<br />

the AGS website.<br />

www.advancedgrindingsolutions.co.uk<br />

<strong>Manufacturing</strong> <strong>Machinery</strong> <strong>World</strong>, <strong>April</strong> <strong>2021</strong>5