Dental Asia May/June 2021

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

For more than two decades, Dental Asia is the premium journal in linking dental innovators and manufacturers to its rightful audience. We devote ourselves in showcasing the latest dental technology and share evidence-based clinical philosophies to serve as an educational platform to dental professionals. Our combined portfolio of print and digital media also allows us to reach a wider market and secure our position as the leading dental media in the Asia Pacific region while facilitating global interactions among our readers.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Behind the Scenes<br />

Based on the ideal situation already<br />

worked out, a new scan was performed<br />

(Figs. 1-3).<br />

After completing the scanning process,<br />

the frame was virtually adapted. The<br />

design of the bridge framework was<br />

started in the software.<br />

As this was to be manufactured from the<br />

millable Ceramill Sintron sintering metal,<br />

the corresponding material parameters<br />

had to be observed.<br />

Initially, we designed a reduced wax-up<br />

(Fig. 4). We reduced the tooth sections<br />

so that the shape resembled a prepared<br />

stump.<br />

The gingival portion was also defined.<br />

We had adopted the model, gingiva and<br />

abutment situation for the scan.<br />

Then, we screwed the matching<br />

scanbodies onto the model analogues.<br />

Due to the strong angulation of the<br />

implant at 26, a 20° angled Camlog<br />

titanium base had to be used.<br />

This made it possible to optimise the<br />

emergence of the occlusal screw<br />

connection in the occlusal surface<br />

(Fig. 5).<br />

PERFECT SYMBIOSIS OF<br />

STABILITY AND AESTHETICS<br />

For stability, Ceramill Sintron was used as<br />

material for the bridge framework.<br />

This is a so-called sintering metal, which<br />

in its raw state has a wax-like consistency<br />

and can be easily processed with desktop<br />

milling machines.<br />

As a result, the workflows have become<br />

more efficient with significant increase in<br />

the safety of the work process.<br />

Sintering the milled structure led to a<br />

biocompatible, stable, homogeneous<br />

and distortion-free cobalt and chromium<br />

(CoCr) frame (Figs. 6-7).<br />

Hence, the casting and labour-intensive<br />

finishing of CoCr is no longer necessary.<br />

After checking the fit, we polished the<br />

base to a high gloss and bonded the<br />

bonding bases to the frame. Now, the<br />

Sintron structure could be screwed onto<br />

the model (Figs. 8-9).<br />

This situation now formed the basis<br />

for the aesthetic finalisation of the<br />

superstructure.<br />

The model including the Sintron bridge<br />

was duplicated and another saw<br />

model was produced; allowing for the<br />

preparation margin of individual crowns<br />

to be better displayed and checked.<br />

This saw model was scanned and the<br />

data obtained “matched” with the CAD<br />

data of the temporary bridge enabling us<br />

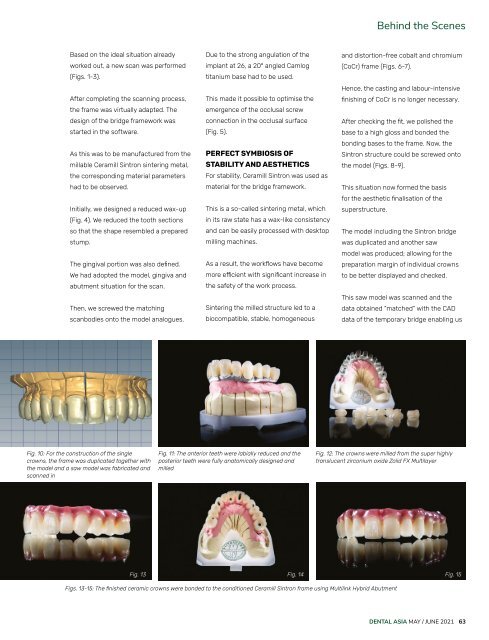

Fig. 10: For the construction of the single<br />

crowns, the frame was duplicated together with<br />

the model and a saw model was fabricated and<br />

scanned in<br />

Fig. 11: The anterior teeth were labially reduced and the<br />

posterior teeth were fully anatomically designed and<br />

milled<br />

Fig. 12: The crowns were milled from the super highly<br />

translucent zirconium oxide Zolid FX Multilayer<br />

Fig. 13 Fig. 14 Fig. 15<br />

Figs. 13-15: The finished ceramic crowns were bonded to the conditioned Ceramill Sintron frame using Multilink Hybrid Abutment<br />

DENTAL ASIA MAY / JUNE <strong>2021</strong> 63